Schuler Pressen GmbH

advertisement

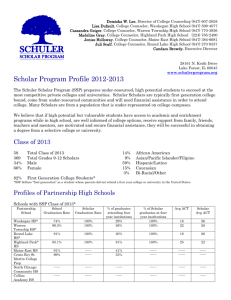

ASIA CAN TECH - BANGKOK SYSTEM SOLUTIONS FOR THE CAN MAKING INDUSTRY Marcel Schoumacker - Benny Liu 26- 28th October 2015 TRADITION IN INNOVATION SPECIALISTS IN THE METALFORMING INDUSTRY Founded in 1839 in Göppingen The more you know about the past, the better prepared you are for the future (Theodore Roosevelt) 11/4/2015 2 THE DNA OF SCHULER INNOVATION, QUALITY, PERFORMANCE, COST-EFFICIENCY, SERVICE/SUPPORT 11/4/2015 Servo Technology 3 SCHULER AT A GLANCE Facts and figures Schuler Group 2014 Technological and global market leader in the metal forming industry Sales € 1,178.5 million Founded 1839 in Göppingen, Germany New orders € 1,193.7 million Member of the ANDRITZ Group since 2012 Products: Cutting-edge presses, automation, dies, process know-how, and services for the entire metal forming industry, including the metal packaging industry Top-tier customers: Car manufacturers and their suppliers, packaging, household equipment, aerospace, minting EBITA EBITA margin € 104.1 million 8.8 % Group profit € 66.9 million Employees inc. apprentices1 5,423 Innovation by technology: Key to our success 11/4/2015 SCHULER CORPORATE PRESENTATION 1 as of Dec. 31, 2014 4 GLOBAL CUSTOMER BASE Automotive OEM Tier 0.5 Tier 1-3 Drives & Generators Minting 11/4/2015 Appliance PACKAGING Railway Aerospace Industrial Applications Large Pipes 5 SCHULER WORLDWIDE GLOBAL SOLUTION AND LOCAL SUPPORT USA Canton, MI Germany Great Britain Walsall USA Hastings, MI Spain Barcelona Poland Kędzierzyn-Koźle Slovakia Dubnica nad Váhom China Beijing, Jinan, Tianjin Thailand Bangkok China Shanghai, Dalian France Strasbourg Switzerland Gettnau Italy Turin Russia Moscow Mexico Puebla, Saltillo India Mumbai, Pune Brazil São Paulo Production & Service Service 11/4/2015 6 PRODUCTION- AND SERVICE LOCATION SCHULER DALIAN COUNTRY-SPECIFIC PRODUCTION AND PROXIMITY TO THE CUSTOMERS HIGHLIGHTS 2006 company Establishment as a 100% affiliated of Müller Weingarten AG 2007 Start of business activities, takeover of Müller Weingarten Dalian by Schuler AG 2012 Majority takeover by Andritz Group 2013 area Plant expansion of threefold workshop with 200t crane capacity 2014 Installation of a state-of-the-art boring machine for precision of manufacture Location Schuler Dalian 11/4/2015 CORPORATE PRESENTATION SCHULER DALIAN 7 DETAILS OF THE ASSEMBLY PROCESSES – PHASE 2 IN-HOUSE MANUFACTURE OF MAIN ASSEMBLY PARTS 11/4/2015 CORPORATE PRESENTATION SCHULER DALIAN 8 SCHULER CHINA – SERVICE ASSOCIATION HAND IN HAND FOR THE SATISFACTION OF OUR CUSTOMERS CURRENT SERVICE-SITUATION IN CHINA Changchun More than 1000 units since 1989 •More than 230 customers, located in 300 cities •Services in all technology fields •34 Service-Engineers in permanent use • Beijing Dalian Tianjin Jinan Chengdu PLANNED SERVICE EXPANSION Shanghai Chongqing Chengdu •Wuhan •Guangzhou •Changchun •Chongqing •additional 58 Service-Engineers CORPORATE PRESENTATION SCHULER DALIAN Wuhan • 11/4/2015 Guangzhou Service Service-Expansion Engineers / Consultants Manufacturing Shopfloor Spare part stock Hotline 9 Schuler AG, Konzernzentrale Göppingen SCHULER IN GERMANY Gräbener Pressensysteme, Netphen Schuler Pressen, Erfurt UmformCenter Erfurt, Erfurt Schuler Automation, Heßdorf Schuler SMG, Waghäusel Schuler Automation, Gemmingen Schuler Pressen, Göppingen Schuler Pressen, Weingarten W P O G N A B M S K Q A J J P K O L M Y W J E N E W U K M X C P D S G E S V H O T V F O R M I J R Y N G S B E C V B T E A M P A S D W M A C H I N E S X A S F H U X L Q A F J P 11 W P O G N A B M S K J Q A J P K O L M Y W J E N E W U K M X C P D S G V H O T J R Y V F O R M I N G S B E C V A S D M A C H I N E S X A J P W S F E B H S T U E X A L M Q P A F CUPFORMER @ 300spm – SERVO CUPFORMER - BODYFORMER – LIDS FORMER 12 WE HAVE ALSO INVESTED IN PEOPLE W P O N H A B M S K J Q A S R Z O L M Y W J E X P E R I E N C E D S G E S V H O T J R Y V L P A T F J C O B E C V B T E A M P A S D W D V G E I E P L X A S F H U X L Q A F J P Metal Forming EXPERTISE + Can Making `` SAVOIR FAIRE ´´ Guarantee of success for your project Savoir faire= know how – awareness – experience - background 13 14 KNOWLEDGE IS THE RAW MATERIAL FOR INNOVATION LEARN FROM THE PAST - LIVE IN THE PRESENT - PREPARE THE FUTURE competence Market needs Supplier Competition Science Knowledge Technology ideas Cu sto m corporate culture er innovation resources Best practice strategy Customer feedback 15 INNOVATION IS SCHULER DNA BETTER SOLUTION FOR THE CAN MAKERS IS OUR OBJECTIVE Lower life Cycle Cost competence innovation ideas High level of quality and performance Cu sto me r corporate culture strategy resources New Can Making Solutions We believe and teach people that each failure is a step along the road to success. 16 SCHULER SOLUTIONS FOR THE CANMAKING INDUSTRY CUP – FORMER: 300SPM – 4500 CPM Conversion press Shell press Good cups made Good cans 11/4/2015 17 CUP FORMER 4500 BELGRADE – TEHERAN – ROSSLYN – LUANDA – PUTIAN – ZIYANG – HESHAN – DA NANG – BEHAI…….. Best cost-effective solution in the market 11/4/2015 18 CUP FORMER 4500 FEATURES Dynamic Counter- Balance No Special foundations Spring Damper 11/4/2015 No vibrations 19 SCHULER DESIGN USED SINCE 15YEARS ON HIGH SPEED PRESSES UNIQUE DESIGN : PLAY-FREE, FIRM, RIGID PILLAR GUIDANCE No wear No maintenance No vibrations 11/4/2015 20 SUMMARY OF CUP FORMER 4500 BENEFITS PERFORMANCE – QUALITY AND REDUCED OWNERSHIP COST MAINTENANCE FREE main shaft and slides guidances + 30% TOOL LIFE & die sets guides pin 3examples CUPFORMER WITH SERVO TECHNOLOGY DWI BOTTLE CAN LINE OR MINI LINE UP TO 1200 CANS / MN • NO BRAKE – NO CLUTCHES • ENERGY-EFFICIENT • REVERSE DRAW DIE SET CAPABILITIES • PROGRAMMABLE: STROKE & PHASE SHIFT • DESIGNED FOR STD HALF COIL WIDTH PROVEN TECHNOLOGY 11/4/2015 22 SCHULER SOLUTIONS FOR THE CANMAKING INDUSTRY NEW MACHINES IN OUR PORTFOLIO Conversion press Shell press BODY FORMER 11/4/2015 23 SCHULER BODYFORMER HYPOCYCLOID TRANSMISSION UP TO 400 CANS PER MINUTE Proven technology: Under license of Universal Can, optimized by Schuler 11/4/2015 24 NEW SCHULER BODYFORMER QUALITY – RELIABILITY – ACCURACY - PERFORMANCE HYPOCYCLOID Transmission Dynamic balance: Less vibration Linear Transmission: less ram drop The invention concerns a mechanism operating Machine design: Low maintenance costs according to the principle which states that each point in a circle, running in a circle which is 2 times bigger, describes a rectilinear hypocycloid 11/4/2015 25 THE NEW SCHULER BODYFORMER - ECONOMICAL PRODUCTION BEVERAGE CANS, ALUMINUM BOTTLES, AND FOOD PACKAGING 11/4/2015 26 SCHULER Hypocycloid Body Former Best performance – Lower Lyfe Cycle Cost Ironing die life = 2.5 million cans Best performance on existing bodymakers 1 to 1.5 million cnas Seal pack : change every 6 month Best performance on existing bodymakers 2 to 3 month Tear off rate : average < 5ppm Best performance on existing bodymakers 10 to 15ppm Oil consumption 0,007l/1000 maintenance cost : 5000 $ / year Best performance on existing bodymakers oil : 0,014l / 1000 cans maitenance cost : 10 to 15000 $ / year SUMMARY OF SCHULER BODYMAKER RELIABILITY – ACCURACY – PERFORMANCE Maximum Production OUTPUT Low level of Tear offs + Superior Machine reliability High Quality level Precise and accurate body wall thickness Lower running costs Longer tool life – less oil consumption low maintenance costs 11/4/2015 28 SCHULER SOLUTIONS FOR THE CANMAKING INDUSTRY SCHULER NECKFORMER NeckFormer LidFormer ShellFormer Body F CupFormer or m e r Continuous NeckFormer 11/4/2015 29 SCHULER NECKFORMER NECKING AND FLANGING In preparation Under license of universal can 11/4/2015 30 SCHULER SOLUTIONS FOR THE CANMAKING INDUSTRY SHELLFORMER AND LIDFORMER 11/4/2015 31 TECHNICAL DATA SHELL PRESS AND CONVERSION PRESS SHELL PRESS The Smartline SA-S combines sustainability with improved quality at maximum output while offering excellent value for money. LIDFORMER 3400 FASTEST CONVERSION PRESS AVAILABLE - 850SPM 11/4/2015 shell and conversion presses 33 SPECIAL FEATURES for HIGH SPEED PRESSES Multi-piece cast frame and press frame braced with four tie rods for optimum stress distribution Oil chamber in table and uprights for even thermal expansion. Eccentric shaft running in anti-friction bearings. for increased damping of vibrations occuring during the blanking process. COMPARISON OF SLIDE GUIDING SYSTEMS SCHULER SLIDE GUIDING FOR HIGHEST PRECISION Schuler Slide Slideguiding guidingabove feed level above feed level Slide Slide guiding guidingatatfeed level feed level Slide guiding guiding above Slide above and and at at feed level level feed Comparison of slide guiding systems Horizontal vibration amplitude with different slide-guidings between slide and bed in BDC SCHULER SERVICE: TECHNICAL CUSTOMER SUPPORT OUR SERVICES FOR OUR CUSTOMERS –WORLDWIDE • Technical Customer Support • Machine inspections • Safety inspections • Preventive maintenance • Repair • Repair welding • Production support • Components and Accessories • Project Business • Special Services • Used Machinery Beispielbild – passendes Bild einfügen Technical Customer Support 37 SCHULER PRODUCT RANGE FOR THE BEVERAGE INDUSTRIE FORMING THE FUTURE WITH SCHULER CUPFORMER HIGH QUALITY CUP PRODUCTION NECKFORMER NECKING AND FLANGING BODYFORMER ECONOMICAL PRODUCTION OF CAN BODIES LINE INTEGRATION COMPLETE SYSTEMS SERVO CUPFORMER UP TO 1200 CPM SCHULER SERVICE SHELLFORMER AND LIDFORMER MANUFACTURING OF CAN ENDS BROADEST PORTFOLIO OF FORMING MACHINES WORLDWIDE 38 CONCLUSION YESTERDAY: THE PAST – TOMORROW: THE FUTURE BUT TODAY IS A GIFT THAT´S WHY IT IS CALLED THE PRESENT IT WAS A GIFT FOR US TO BE WITH YOU TODAY HOPE TO SEE YOU VERY SOON AND WORK TOGETHER IN FORMING THE FUTURE 11/4/2015 39 Thank you for your attention We welcome your questions MARCEL SCHOUMACKER Sales Director Beverage Packaging tel: 00 49 1520 1624 603 marcel.schoumacker@schulergroup.com •40