Rig move training. Ruslan Gromovenko1. Lerus Group

advertisement

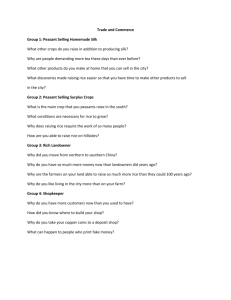

Rig Move Training Offshore Jack Up Middle East 2014 Ruslan Gromovenko, Lerus Group Our facility (KONGSBERG and MACGREGOR) allows Barge Master, Crane Operator us to conduct a training of the AHTS team and simultaneously in one We are approach able to virtual world. modulate to the MODU in “DP” that or AHTS can “Manual” modes. All instructors are Masters and DP unlimited, approved by the Nautical Institute UK. Crane operator Instructors are crane operators OPITO approved. stage 3 This course consists of two parts: 1. Theoretical Part. - QHSE Instructor; Ship’s Handling Instructor; ARAMCO approved instructor. 2. Practical Part. Three simulators: - Class “A” Barge Master is in command of the - Class “B” AHTS team is approaching to the MODU - Crane simulator Crane operator follows the Barge operation. Guide of the AHTS, two support tugs (optional: AHT or harbor tugs) and crane operator. as requested by the Barge Master; Master orders. QHSE and ARAMCO approved Instructors give training for: 1. Safety induction and procedures on the LERUS Training Centre, rules and regulations in our Centre. 2. Major points of the • pre-rig move meeting: PPE for all parts involved into operations; • All risks which could occur • Students’ attention is paid to the necessity of the proper risk assessment and contingency planning; • Requested inspections, checks and tests which are to be completed prior rig move. Critical points are Highlighted; • Degree of the responsibilities of all the involved; • Possibility of the Personnel transfer at sea. Listed below procedures are explained by: Ship’s Handling Instructor: • Offshore Rig • • • • • Move Planning and Preparation; Mobilization & Demobilization procedures; Operations in Offshore; Stability calculation and instruments; Equipment Stress-calculating; Weather limitations and other restrictions; Positioning Equipment (Veripos, Navipac…); • • Navigational Planning; • Tandem Operations planning; • Communications; • Record keeping; • Reporting and Rig move orders. Barge Master assesses: • Current environmental weather condition and a favorable forecast; •Predicted wind speed and swell/sea heights; • Wave types and period, long swell or short waves or a combination of both; •Nature and composition of seabed, hard or soft; • Proximity of other structures/flow lines from old and/or new rig location; •Required positional accuracy on new location, i.e., jacket or new drilling location; • Passage Plan and any restrictions around. (Using an ECDIS) Barge Master on the Semisub Bridge: •Guides by leading AHTS, Support tugboats (two AHT or harbor tugs), crane operator; •Carries out mooring analysis; •Decides when it is safe and practicable to commence operations within the limitations of the installations operating manual and Contingency Planning ; •Identifies specific risks associated with the operation and manage any changes; •Briefs Masters and notify points length of the working wire; •Calculates a catenary of connection and curves; • Controls barge and tugs position. Use a “Traffic Light” alert system. Leading Tug Master on the AHTS Bridge: •Assesses risk and contingency procedures; • Performs Tool box meeting; • Fills out all appropriate Check lists; • Approaches to the MODU on manual or DP mode as per Barge Master’s orders; • Connects to the installation; •Performs Barge Towing ; •Controls Vessel and barge position. VHF Communication between the MODU, vessels and involved personnel. The working language English. • • • • • • • • • Miscommunication; Lack of job and procedure knowledge; Sea height and Wind speed; Current changes direction, adverse impact operations; on Reduced Visibility - under one mile; Unexpected loads on AHTS or MODU; Problems with Mooring equipment; Mechanical problems aboard of AHTS or MODU; Navigation and survey equipment technical faults. On completion of a MODU move, the Instructors, Barge Master and vessel Masters conduct a post action review to evaluate what has gone well and to identify possible areas for improvement.