Porter, Jason M. (2009). - The Hanson Group

advertisement

LASER-BASED DIAGNOSTICS FOR

HYDROCARBON FUELS IN THE LIQUID AND VAPOR PHASES

A DISSERTATION

SUBMITTED TO THE DEPARTMENT OF MECHANICAL

ENGINEERING

AND THE COMMITTEE ON GRADUATE STUDIES

OF STANFORD UNIVERSITY

IN PARTIAL FULFILLMENT OF THE REQUIREMENTS

FOR THE DEGREE OF

DOCTOR OF PHILOSOPHY

Jason Morgan Porter

November 2009

iv

Abstract

Infrared laser-absorption diagnostics are widely used in combustion research for fast,

sensitive, and non-intrusive measurements of species concentration, temperature, and

pressure. A large number of species important to combustion have been successfully

measured including: H2 O, CO2 , CO, NO2 , NO, and vapor-phase hydrocarbon fuels

and fuel blends. These measurements help designers, operators, and researchers of

engines and burners to reduce pollution, increase efficiency, and study combustion

chemistry.

Laser-absorption measurements of fuel concentration are often made at mid-infrared

wavelengths near 3.4 µm, which overlap with the strong C-H stretch vibrational transitions of hydrocarbons, ensuring sensitive detection even for short measurement path

lengths. Recent advances in laser technology have produced tunable mid-infrared

laser sources near 3.4 µm, using difference-frequency-generation (DFG). Previous researchers in this laboratory have used DFG lasers operating at two wavelengths in

shock tube studies to simultaneously measure temperature and species concentration

for several gaseous fuels and fuel blends.

This thesis presents new applications of DFG lasers for multiphase (vapor and

liquid) measurements of hydrocarbon fuels in harsh environments. Quantitative measurements of the real and imaginary refractive index spectra of several liquid hydrocarbons are used to develop two novel multi-phase diagnostics: a three-wavelength

diagnostic for fuel-vapor mole fraction and temperature in evaporating aerosols, and a

two-wavelength diagnostic for fuel-vapor mole fraction and liquid fuel film thickness.

Quantitative absorption spectra for several hydrocarbon fuels in the liquid phase

at 25 ◦ C are presented. Measurements of toluene, n-dodecane, n-decane, and three

v

samples of gasoline were made over the spectral region 2700 − 3200 cm−1 to support

development of mid-infrared laser-absorption diagnostics for measurements of fuel

vapor in the presence of liquid films and aerosols. A procedure for quantitative FTIR

absorption measurements of strongly absorbing liquids is described and the resulting

absorption spectra are compared with previously measured absorption spectra in the

vapor phase. The measured absorption spectra for liquid gasoline are shown to scale

with the volume percent of olefin, alkane, and aromatic hydrocarbons in each sample.

Finally, the observed frequency shift of ∼8 cm−1 in the spectra of vapor and liquid

hydrocarbons near 3.4µm is discussed, which is important for liquid film thickness

measurements.

The development of a 3-wavelength mid-infrared laser-based absorption/extinction diagnostic for simultaneous measurement of temperature and vapor-phase mole

fraction in an evaporating hydrocarbon fuel aerosol (vapor and liquid droplets) is described. The measurement technique was demonstrated for an n-decane aerosol with

D50 ∼ 3 µm in steady and shock-heated flows with a measurement bandwidth of 125

kHz. Laser wavelengths were selected from FTIR measurements of the C-H stretching

band of vapor and liquid n-decane near 3.4 µm (3000 cm−1 ), and from modeled light

scattering from droplets. Measurements were made for vapor mole fractions below 2.7

percent with errors less than 4 percent, and simultaneous temperature measurements

over the range 300 K < T < 900 K were made with errors less than 3 percent. The

measurement technique is designed to provide accurate values of temperature and

vapor mole fraction in evaporating polydispersed aerosols with small mean diameters

(D50 < 10 µm), where near-infrared laser-based scattering corrections are prone to

error.

Finally, a 2-wavelength mid-infrared laser-based absorption diagnostic for simultaneous measurements of vapor-phase fuel mole fraction and liquid fuel film thickness

is presented. The measurement technique was demonstrated for transient n-dodecane

liquid films in the absence and presence of n-decane vapor. Laser wavelengths were

selected from FTIR measurements of the C-H stretching band of vapor n-decane and

liquid n-dodecane near 3.4 µm (3000 cm−1 ). n-Dodecane film thicknesses < 20 µm

were accurately measured in the absence of vapor, and simultaneous measurements

vi

of n-dodecane liquid film thickness and n-decane vapor mole fraction (300 ppm) were

measured with < 10 % uncertainty for film thicknesses < 10 µm. A potential application of the measurement technique is to provide accurate values of fuel-vapor

mole fraction in combustion environments where strong absorption by liquid fuel or

oil films on windows make conventional direct absorption measurements unfeasable.

vii

Acknowledgments

This thesis represents the culmination of over 11 years of study. In that time, I have

attended two community colleges: Butte College in Oroville, CA, and Utah Valley

State College in Orem, UT, and three universities: Brigham Young University in

Provo, UT, the University of Texas at Austin, and Stanford University in Palo Alto,

CA. In that time, I also married my wife Marilyn and we have had three children:

Dallin (7) while at BYU; Sarah (5) while an intern at Sandia National Laboratories

in Albuquerque, NM; and Ashley (2) while at Stanford. This has been a long journey,

with many advances and setbacks, but overall I have loved my time as a student.

Academically, I have been fortunate to study under some fantastic mentors of

which I name a few. Larisa Call (from my hometown near Corning, CA) tutored

me in math as a teenager and gave me a love for math and the confidence to learn

independently. Paul Mills and Gary Carlson at UVSC (now UVU) taught me to love

physics and calculus, respectively. Matt Jones at BYU taught me thermodynamics

and let me assist him with consulting in energy. Brent Adams at BYU was the first

to encourage me to pursue a PhD. Jack Howell, at UT Austin, advised my masters

work, taught me radiation heat transfer, provided me with a valuable internship at

Sandia, Albuquerque, and helped me obtain the NDSEG fellowship, which funded

much of my PhD work. His guidance and help were invaluable. The many “Hanson students” I have worked with over the past four years have taught me so much

and have made working a joy. Jay Jeffries at Stanford provided invaluable guidance

and countless hours reviewing papers and presentations. Dave Davidson at Stanford

helped with all things experimental and gave me needed encouragement. My thesis

advisor at Stanford, Ron Hanson, taught me how to perform quality research and

viii

produce professional presentations and papers. I am especially grateful for his understanding of my unique work-life balance issues. He always pushed me to do my

best, but never pushed too hard. Ultimately, he made studying at Stanford possible,

fulfilling a childhood dream.

I save the most important thank you’s for last: my family. I would like to thank

my entire extended family for their encouragement; they always thought of me as

their “smart” brother, son-in-law, etc. at Stanford, even when I felt inadequate.

My parents provided ample opportunities for me to work and learn, and instilled

self confidence. My older brother, Mike, kept me grounded through weekly phone

conversations. My children, Dallin, Sarah, and Ashley, gave me their enthusiasm and

love. Most importantly, I want to thank my wife Marilyn for her perfect devotion

and patience. Neither she nor I knew at the start how long this educational journey

would be, but through it all she has been an outstanding companion and friend.

Above anyone else, she has made this possible.

ix

Contents

Abstract

v

Acknowledgments

viii

1 Introduction

1

1.1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1.2

Laser-absorption spectroscopy . . . . . . . . . . . . . . . . . . . . . .

4

1.2.1

Beer’s Law . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

1.2.2

The absorption cross-section . . . . . . . . . . . . . . . . . . .

6

1.2.3

Measuring temperature . . . . . . . . . . . . . . . . . . . . . .

10

1.2.4

Modifications to Beer’s law . . . . . . . . . . . . . . . . . . . .

12

1.3

1.4

The refractive index

. . . . . . . . . . . . . . . . . . . . . . . . . . .

12

1.3.1

Beer’s Law from Maxwell’s equations . . . . . . . . . . . . . .

12

1.3.2

Dispersion relation . . . . . . . . . . . . . . . . . . . . . . . .

15

1.3.3

Kramers-Kronig relation . . . . . . . . . . . . . . . . . . . . .

18

Light scattering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

1.4.1

Mie theory

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

1.4.2

Droplet distributions . . . . . . . . . . . . . . . . . . . . . . .

23

2 Measurements of Absorption Spectra in Liquid Fuels

2.1

2.2

25

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

2.1.1

Motivation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

Absorption measurements in liquids . . . . . . . . . . . . . . . . . . .

27

2.2.1

27

Experimental setup . . . . . . . . . . . . . . . . . . . . . . . .

x

2.3

2.4

2.2.2

Measurement procedure . . . . . . . . . . . . . . . . . . . . .

27

2.2.3

Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34

Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

2.3.1

Hydrocarbons measured . . . . . . . . . . . . . . . . . . . . .

35

2.3.2

Plots of absorption spectra for liquid and vapor . . . . . . . .

36

Discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

2.4.1

Band strength . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

2.4.2

Spectral shift . . . . . . . . . . . . . . . . . . . . . . . . . . .

42

2.4.3

Gasoline composition . . . . . . . . . . . . . . . . . . . . . . .

42

3 Evaporating Fuel Aerosols

45

3.1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45

3.2

Laser diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

3.2.1

Laser absorption in gases . . . . . . . . . . . . . . . . . . . . .

46

3.2.2

Laser extinction in absorbing aerosols . . . . . . . . . . . . . .

47

3.2.3

Droplet extinction model . . . . . . . . . . . . . . . . . . . . .

48

3.2.4

Liquid optical constants . . . . . . . . . . . . . . . . . . . . .

50

3.2.5

Droplet extinction calculation . . . . . . . . . . . . . . . . . .

50

3.2.6

Wavelength selection . . . . . . . . . . . . . . . . . . . . . . .

53

3.2.7

Uncertainty analysis . . . . . . . . . . . . . . . . . . . . . . .

56

Validation experiments . . . . . . . . . . . . . . . . . . . . . . . . . .

58

3.3.1

Optical arrangement . . . . . . . . . . . . . . . . . . . . . . .

58

3.3.2

Aerosol flow-cell experiment . . . . . . . . . . . . . . . . . . .

60

3.3.3

Flow cell results . . . . . . . . . . . . . . . . . . . . . . . . . .

62

3.3.4

Shock tube experiment . . . . . . . . . . . . . . . . . . . . . .

63

3.3.5

Shock tube results . . . . . . . . . . . . . . . . . . . . . . . .

64

3.3

4 Liquid Fuel Films

4.1

4.2

67

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67

4.1.1

Fuel films and measurement techniques . . . . . . . . . . . . .

67

Two-phase laser-absorption measurements . . . . . . . . . . . . . . .

69

4.2.1

69

Beer’s law: vapor and liquid . . . . . . . . . . . . . . . . . . .

xi

4.2.2

4.3

4.4

Laser wavelength selection . . . . . . . . . . . . . . . . . . . .

72

Refractive index matching . . . . . . . . . . . . . . . . . . . . . . . .

74

4.3.1

Measuring I0 . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

4.3.2

Modeling I0 in the presence of a film . . . . . . . . . . . . . .

76

4.3.3

FTIR measurements of n-dodecane films . . . . . . . . . . . .

78

Demonstration experiments . . . . . . . . . . . . . . . . . . . . . . .

81

4.4.1

Experimental setup . . . . . . . . . . . . . . . . . . . . . . . .

81

4.4.2

Demonstration of liquid film measurement . . . . . . . . . . .

83

4.4.3

Demonstration of fuel vapor and liquid film measurement . . .

85

4.4.4

Films and vapor composed of same fuel . . . . . . . . . . . . .

87

5 Summary and future work

5.1

5.2

89

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

89

5.1.1

Absorption spectra of liquid fuels . . . . . . . . . . . . . . . .

89

5.1.2

Evaporating fuel aerosols . . . . . . . . . . . . . . . . . . . . .

90

5.1.3

Fuel films . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91

Future work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91

5.2.1

Extension of film technique for vapor and film temperature . .

91

5.2.2

FTIR spectroscopy . . . . . . . . . . . . . . . . . . . . . . . .

93

A Derivation of X and T in an aerosol

94

B C++ code for Mie scattering calculations

96

C Transmittance and reflectance for absorbing media

108

Bibliography

111

xii

List of Tables

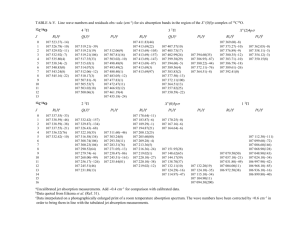

2.1

Integrated band intensities of liquid (Al ) and vapor (Av ) absorption

spectra. The integration limits were from 2600cm−1 to 3400cm−1 .

Temperatures are listed in the plotted spectra. . . . . . . . . . . . . .

2.2

Fractional composition of alkanes, aromatics, and olefins for the three

gasoline blends analyzed. . . . . . . . . . . . . . . . . . . . . . . . . .

3.1

42

Dependency of calculated extinction ratios (R21 = 1.08 and R31 = 1.14)

on initial droplet size distribution (log-normal, see equation 3.7). . . .

4.1

41

56

Refractive indices of common infrared window materials near 3.4 µm [1]. 76

xiii

List of Figures

1.1

Schematic of monochromatic light passing through a thin slab of absorbing material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2

Schematic of laser light passing through a gas cell filled with an absorbing gas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3

6

Infrared absorption spectrum of n-decane (Top figure from Sharpe et.

al. [2]).

1.4

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Schematic of n-decane molecule showing fundamental C-H stretch vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9

1.5

Temperature dependent absorption of n-decane. . . . . . . . . . . . .

11

1.6

Electromagnetic plane wave propagating in the z-direction. . . . . . .

13

1.7

Measured complex refractive index of liquid n-decane in the infrared.

17

1.8

Schematic of light being scattered and absorbed by a liquid droplet. .

20

1.9

Calculated extinction efficiency for liquid toluene droplets. . . . . . .

23

2.1

Optical cell used in liquid absorption measurements. Teflon spacers

with thicknesses between 0.5 mm and 15 µm were used. . . . . . . . .

2.2

30

Measured extinctance of liquid toluene for three path lengths. Two

anchor points were selected near the absorption band (2681 and 3290

cm−1 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3

31

Extrapolation of measured refractive index data [3] at visible wavelengths to 8000 cm−1 . The extrapolated refractive indices at 8000

cm−1 for liquid toluene, n-decane and n-dodecane are 1.477, 1.404,

and 1.413, respectively. . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv

33

2.4

Flow chart showing the data analysis in converting the measured extinction spectra to real and imaginary refractive index spectra. The

computer codes used [4] are shown in brackets (All computer codes

assume log base ten extinctance.). The initial n spectrum needed for

the ANCHORPT program was calculated, without anchor point correction, from the shortest path length extinction spectrum. . . . . . .

2.5

Measured absorption cross-sections for liquid toluene near 3000 cm−1

are compared with published data. The residual is defined as σporter −

σbertie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6

2.7

2.8

34

35

Measured real refractive index for liquid toluene near 3000 cm−1 are

compared with published data. The residual is defined as nporter − nbertie . 36

Measured real refractive index for liquid n-decane and n-dodecane

(2000 − 4000 cm−1 ). . . . . . . . . . . . . . . . . . . . . . . . . . . .

37

Measured absorption cross-section for liquid and vapor toluene. . . .

38

Measured absorption cross-section for liquid and vapor n-decane. . . .

38

2.10 Measured absorption cross-section for liquid and vapor n-dodecane. .

39

2.9

2.11 Measured absorption cross-section for liquid and vapor gasoline sample1. 39

2.12 Measured absorption cross-section for liquid and vapor gasoline sample2. 40

2.13 Measured absorption cross-section for liquid and vapor gasoline sample3. 40

2.14 Comparison of measured absorption near 3000 cm−1 for three liquid

gasoline samples. Absorption is proportional to alkane, aromatic and

olefin content of gasoline in the identified spectral regions. . . . . . .

3.1

43

Calculated evolution of an initially log-normal droplet size distribution

(D50 = 3.3 µm, q = 1.3 µm) in an evaporating n-decane aerosol. The

median diameter, D50 , was calculated for each distribution. . . . . . .

49

3.2

Measured complex refractive index of liquid n-decane in the infrared.

51

3.3

Liquid n-decane droplet extinctance (no vapor absorption) calculated

from modeled droplet size distribution and measured optical constants. 51

3.4

Normalized extinction curves (at 2938 cm−1 ) showing wavelengths with

constant extinction ratios during evaporation. . . . . . . . . . . . . .

xv

52

3.5

FTIR measurements (corrected to ensure a constant integrated cross

section for this band) of temperature-dependent n-decane vapor absorption. Wavelengths ν̄1 and ν̄3 were chosen to maximize temperature

sensitivity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6

Temperature dependence of vapor-phase n-decane absorption crosssections at chosen wavelengths. . . . . . . . . . . . . . . . . . . . . .

3.7

55

Calculated extinction ratios during evaporation for two initial droplet

size distributions. Ratios are largely constant during evaporation. . .

3.8

54

57

Sensitivity analysis of measured mole fraction and temperature using

a 2 percent uncertainty. The ratio of droplet extinction to vapor absorption at ν̄1 , γ, was varied to show sensitivity to droplet loading (a

and b). The magnitude of extinction at 2938 cm−1 was also varied to

show sensitivity to extinctance (c). . . . . . . . . . . . . . . . . . . .

3.9

58

Time-division multiplexing used with two DFG lasers to generate three

mid-infrared wavelengths. . . . . . . . . . . . . . . . . . . . . . . . .

59

3.10 Schematic showing the optical setup with common mode rejection (reference detector) and the combination of four laser beams with bandpass

optical filters.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

59

3.11 Flow-cell experiment (viewed from above). Ambient air flows through

the aerosol sweeping it into the laser path. . . . . . . . . . . . . . . .

61

3.12 Schematic of the aerosol shock-tube. The shock-tube is filled with ndecane aerosol through the endwall. Endwall valves are closed and

a shock wave travels down the tube shock-heating the aerosol and

starting evaporation. . . . . . . . . . . . . . . . . . . . . . . . . . . .

63

3.13 Measured vapor mole-fraction and temperature behind the incident

shock in the aerosol shock-tube. The measured mole fraction increases

as the liquid-phase n-decane evaporates. Measured temperature decreases as the aerosol evaporates. . . . . . . . . . . . . . . . . . . . .

xvi

64

3.14 Comparison between predicted and measured n-decane mole fraction

and temperature for 16 different shocks. Mole fraction measurements

showed agreement within 4 percent. Temperature measurements showed

agreement within 3 percent. . . . . . . . . . . . . . . . . . . . . . . .

4.1

Schematic of laser light passing through a window, a fuel film of thickness δ, and fuel vapor. . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2

69

Measured absorption cross-section of n-decane liquid and vapor at 25

◦

C. A wavelength shift of ∼8 cm−1 is observed in the absorption spectra

of vapor and liquid phases. . . . . . . . . . . . . . . . . . . . . . . . .

4.3

66

70

a: Comparison of the infrared absorption spectra of liquid n-decane

and liquid n-dodecane. b: Comparison of the absorption cross-section

of n-dodecane liquid and n-decane vapor at 25 ◦ C , with ∼8 cm−1

wavelength shift evident [5]. . . . . . . . . . . . . . . . . . . . . . . .

4.4

71

a: Calculated reciprocal condition number of matrix A for all wavelength pairs (ν̄1 , ν̄2 ) between 2800 − 3000cm−1 . Darker regions show

wavelength pairs yielding well-conditioned matrices. a & b: Three

wavelength pairs are highlighted: the selected wavelength pair (ν̄1 =

2854.7cm−1 and ν̄2 = 2864.7cm−1 ) within the DFG phase matching

range, and two optimal wavelength pairs (I & II) not attainable with

the current DFG system.

4.5

. . . . . . . . . . . . . . . . . . . . . . . .

73

Schematic of light transmission through a window without a liquid

film (a) and a window with a non-absorbing liquid film (b). When the

refractive index of a film lies between that of the window and the gas

(i.e. nwindow > nf ilm > ngas ), then Io,f ilm > Io . . . . . . . . . . . . . .

4.6

Measured refractive index of n-dodecane (right) and calculated baseline

offset for liquid n-dodecane films on several window materials (left). .

4.7

75

77

FTIR measurements of liquid n-dodecane films injected onto the windows listed in Table 4.1. . . . . . . . . . . . . . . . . . . . . . . . . .

xvii

78

4.8

a: Measured absorbance of free-standing liquid n-dodecane for several film thicknesses, where the measured transmission, I, is equal to

Io,f ilm − absorption, and Io is the same as in Fig. 4.5a. b: Comparison of inferred cross-sections from free-standing film measurements to

previously measured cross-section.

4.9

. . . . . . . . . . . . . . . . . . .

80

Schematic of DFG system. Two near-IR signal lasers are modulated

at 1 kHz to provide time-multiplexed mid-IR light at two wavelengths.

81

4.10 Optical setup for demonstrating the diagnostic. Two mid-IR and onenear-IR beams used; mid-IR to measure absorption, near-IR to monitor

beam steering and other losses. . . . . . . . . . . . . . . . . . . . . .

82

4.11 A liquid n-dodecane film is injected onto a CaF2 window and subsequently removed by air flow.

. . . . . . . . . . . . . . . . . . . . . .

83

4.12 n-Dodecane film measurement. a: Measured n-dodecane absorbance

at both wavelengths. b: Measured liquid film thickness. . . . . . . . .

84

4.13 A vapor cell with CaF2 windows containing 300 ppm n-decane vapor

in air at 1 atm and 24 ◦ C. n-Dodecane films were injected onto and

removed from the CaF2 window.

. . . . . . . . . . . . . . . . . . . .

85

4.14 n-Dodecane film and n-decane vapor measurement. a: Combined absorbance from n-dodecane liquid and n-decane vapor at both wavelengths. b: Measured liquid n-dodecane film thickness and vapor ndecane mole fraction. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1

86

Potential laser frequencies for sensitive detection of vapor temperature,

vapor mole fraction, and liquid film thickness. . . . . . . . . . . . . .

C.1 Reflection and transmission of normally incident light.

xviii

92

. . . . . . . . 109

Chapter 1

Introduction

1.1

Overview

The advent of the laser (light amplification by stimulated emission of radiation) in

1960 ushered in an era of laser-based research that has contributed to nearly all

branches of science and engineering, with applications from nuclear fusion to digital

communication [6]. Lasers can provide a powerful light source with a narrow spectral

bandwidth (i.e. light at only one color) that is spatially coherent (easily collimated).

These attributes of lasers make them an excellent spectroscopic tool, as the narrow

bandwidth allows probing of individual absorption transitions in atoms and molecules,

and the spatial coherence allows for large light intensities over long path-lengths with

good spatial resolution ( < 1 mm) [7]. In addition, the time response of continuouswave laser-based sensors is often only limited by the detection electronics, resulting in

measurement bandwidths that can exceed 10 MHz. This high bandwidth allows for

near instantaneous measurements in transient environments (e.g. flames, high-speed

flows, and combustors).

Infrared laser-absorption diagnostics are widely used in combustion research for

fast, sensitive, and non-intrusive measurements of species concentration [8] and temperature [9]. A large number of species important to combustion have been successfully measured including: H2 O [10], CO2 [11, 12], CO [13], NO2 [14], NO [8],

and vapor-phase hydrocarbon fuels and fuel blends [15, 16]. Fuel measurements are

1

2

CHAPTER 1. INTRODUCTION

often made using a helium-neon (HeNe) laser, as its fixed wavelength at 3.39 µm

overlaps with the strong C-H stretch vibrational transitions of hydrocarbons near 3.4

µm, ensuring sensitive detection even for short measurement path lengths. For many

fuels, absorption at the HeNe wavelength is largely independent of temperature and

pressure, allowing for accurate measurements over a large range of temperatures and

pressures [17]. Some examples of fuels and fuel blends successfully measured using

HeNe laser-based diagnostics include: methane [18], n-dodecane [19], diesel [20], and

iso-octane and gasoline in IC engines [16, 21, 22, 23].

Recent advances in laser technology have produced tunable mid-infrared laser

sources near 3.4 µm, using difference frequency generation (DFG) [24, 25]. These

tunable laser sources provide two key advantages over HeNe lasers: first, the laser

can be tuned to wavelengths for which the absorption by the vapor has the desired

temperature dependence and total absorption needed for the application. Second,

multiple wavelengths are possible, allowing for measurements of multiple species or

temperature. Previous researchers in this laboratory have used DFG lasers operating

at two wavelengths in shock tube studies to simultaneously measure temperature and

species concentration for several fuels and fuel blends, including: n-heptane [26], ndodecane [27], JP-10 (jet fuel) [28], and iso-octane and gasoline [29]. n-Dodecane

concentration has also been measured in the presence of interfering species and liquid

droplets [30].

This thesis will focus on the application of lasers as fuel sensors, as motivated

by combustion diagnostic measurements. In particular, applications of tunable midinfrared lasers for multiphase (vapor and liquid) laser-absorption measurements of

hydrocarbon fuels will be presented. This work is divided into three main parts:

1. Measurements of the real and imaginary refractive index spectra of liquid hydrocarbons in the mid-IR region of the C-H stretching vibrations

2. Development of a diagnostic for vapor-phase fuel mole fraction and temperature

in evaporating aerosols

3. Development of a diagnostic for vapor-phase fuel mole fraction and liquid fuel

film thickness

1.1. OVERVIEW

3

The order of the above topics is important; before developing laser-absorption diagnostics for multiphase environments, the wavelength-dependent refractive indices,

often referred to as the optical constants, must be measured quantitatively. There is

very little quantitative optical constant spectra for liquid hydrocarbons in the literature. Thus, it was necessary to make these measurements in the laboratory. As will be

shown in Chapter 2, these measurements are not straightforward, and a significant

portion of this thesis is dedicated to methods for accurate measurements of liquid

hydrocarbons and characterization of the measured spectra. This characterization

revealed a fortuitous wavelength shift in the liquid phase spectra relative to vapor

phase spectra that made the liquid film diagnostic (discussed in Chapter 4) possible.

In Chapter 3, the influence of optical scattering by liquid fuel aerosols on laserabsorption measurements will be presented. This work was motivated by combustion

applications where liquid fuel is directly injected into the combustion chamber (e.g.

direct gasoline injection engines, diesel engines, and gas turbines). Making measurements of vapor in the presence of droplets has been a topic studied by many

researchers. This work builds upon previous work to provide measurements of temperature and vapor mole fraction by simultaneously measuring the absorption at

multiple mid-infrared wavelengths. This technique also allows for droplet scattering

corrections for mean droplet sizes < 10 µm, including applications in evaporating

aerosols, both of which are not possible with other techniques. This work relies heavily on the optical constants measured in Chapter 2.

Finally, a method for measuring fuel vapor in the presence of absorbing liquid

films is presented. This work makes extensive use of the measured optical constants in

Chapter 2, and the multiple wavelength strategies developed in Chapter 3. Similarly,

this method was motivated by liquid fuel injection in combustion systems, this time

focusing on fuel and oil films that are known to exist within the combustion chamber.

This diagnostic not only makes it possible to measure the fuel vapor in the presence

of films, but also allows direct and simultaneous measurement of the film thickness.

Before presenting these three research topics, the fundamentals of light absorption

and scattering, including a derivation of Beer’s law and a discussion of its importance

to quantitative absorption measurements will be presented. The origin of the real

4

CHAPTER 1. INTRODUCTION

and imaginary refractive indices will then be explained, including dispersion and

the Kramers-Kronig relations. Finally, the Mie theory of light scattering by small

particles will be summarized along with applications to hydrocarbon liquid aerosols.

1.2

1.2.1

Laser-absorption spectroscopy

Beer’s Law

The fundamental physical principle behind laser absorption is the absorption of light

by atoms and molecules. Laser absorption can be converted to material properties of

interest (e.g. concentration and temperature) using Beer’s law, which is a mathematical statement of an experimental observation: the attenuation of light through certain

material samples is dependent on the sample’s thickness and concentration. The dependence on sample thickness was first reported by Pierre Bouguer (1698-1758) in

1729. Johann Lambert (1728-1777) independently discovered the same phenomenon

in 1760 and for the first time expressed his observation in mathematical form. August

Beer’s (1825-1863) contribution was the addition of the concentration dependence in

1852. Because of multiple contributors, this relation is sometimes referred to as BeerLambert-Bouguer’s law or Beer-Lambert’s law, but it will be referred to as Beer’s law

in this thesis [31, 32].

Iv

Iv + dIv

dz

Figure 1.1: Schematic of monochromatic light passing through a thin slab of absorbing

material.

The derivation of Beer’s law can be found in many texts (see for example [33, 34]),

and is repeated here for convenience. Imagine light of optical frequency ν̄, where ν̄

1.2. LASER-ABSORPTION SPECTROSCOPY

5

represents the optical frequency in wavenumbers1 , with intensity, I, incident on a

slab of absorbing material with thickness dz. It was experimentally shown, that the

attenuation of light, dI, was proportional to the local intensity, I, and the path length,

dz, according to the relation:

dI = −αIdz

(1.1)

where α is a coefficient of proportionality called the absorption coefficient and has

units of inverse length. Integrating Eq. 1.1 from z = 0 to z = L, where L (called the

path length) is the distance light has traversed through the material, assumed here

to be uniform, yields Beer’s law:

− ln

I

Io

= αL = Xnσ(ν̄, T )L

(1.2)

ν̄

In Eq. 1.2, the term on the left is called the absorbance, if light attenuation is only

due to absorption, where I and Io are the light intensities with and without absorption.

Expressing the absorption coefficient in terms of the mole fraction of the absorbing

species, X, the total molar concentration, n [mole/cm3 ], and the absorption crosssection, σ [cm2 /mole], where T is the material temperature, gives a direct relation

between the concentration of the absorbing species in the medium and the absorbance.

Intuitively, one can think of the absorption cross-section as the effective size of an

absorbing molecule if it simply blocked light from passing through a volume. Imagine

molecules being replaced by opaque spheres of cross sectional area Am , where Am is

not the molecules actual size, but rather a measure of how much light it absorbs. The

absorption cross-section then expresses the sum over all molecular cross-sections, Am ,

per mole of molecules. The product nσL is dimensionless and is referred to as the

optical thickness or opacity of a path length through a given material, where large

optical thicknesses correspond to significant radiation attenuation.

The basic arrangement for quantitative measurements of gases is shown schematically in Fig. 1.2. Light passes through the optical ports (windows) of a gas cell of

1

In this thesis frequencies and wavelengths are used interchangeably as they are inversely related:

1

.

ν̄[cm−1 ] = λ[cm]

6

CHAPTER 1. INTRODUCTION

Thermocouple

Pressure

Gas cell

Laser light (v )

Io

X, Tg , P

L

I

Windows

Figure 1.2: Schematic of laser light passing through a gas cell filled with an absorbing

gas.

length, L, and the incident light, I0 , and transmitted light, I, are measured with a

photo detector. The amount of light attenuation at a laser optical frequency ν̄ can be

related to the mole fraction, X, of the absorbing species in the medium using Beer’s

law (Eq.1.2) if the pressure and temperature are measured separately (e.g. with a

thermocouple and pressure gage). There are, however, several restrictions on the

applicability of Beer’s law:

• The light source must be monochromatic and spectrally narrow compared to

the probed absorption transition.

• The medium must be homogeneous in concentration and temperature along the

path length (or line of sight).

• Light attenuation not due to absorption (e.g. reflections, window fouling, and

scattering) must be included in I0 .

Each of these items will be addressed later in the thesis, but it is important to note

that ignoring these restrictions can lead to significant measurement errors.

1.2.2

The absorption cross-section

For quantitative measurements, the absorption cross-section must be known or measured directly. The absorption cross-section of the species of interest is typically a

7

1.2. LASER-ABSORPTION SPECTROSCOPY

function of temperature, pressure, and wavelength, and can be measured in the laboratory. The absorption cross-section at a single wavelength can be measured by

passing a laser beam at that wavelength through a gas cell as in Fig. 1.2, where the

exact path length, species mole fraction, temperature, and pressure are known. The

cross-section is then found directly from the measured absorbance at that wavelength.

150

n-decane vapor

T = 300 K

P = 1 atm

50

0

2000

2

( , T ) [m /mole]

100

150

6000

T = 325 K

T = 500 K

T = 625 K

T = 725 K

100

50

4000 -1

Frequency [cm ]

P = 1 atm

0

2700

2800

2900

3000

-1

Frequency [cm ]

3100

Figure 1.3: Infrared absorption spectrum of n-decane (Top figure from Sharpe et. al.

[2]).

If the absorption cross-section spectrum is desired, a Fourier transform infrared

spectrometer can be used. The FTIR uses a broadband light source (in this case, a

black body which emits light from 600−10, 000 cm−1 ) which is intensity modulated by

a Michelson interferometer and passed through the gas cell. The transmitted light is

then detected and the Fourier transform is taken to recover the frequency-dependent

absorption spectrum. Commercial FTIRs are now available with internal software

8

CHAPTER 1. INTRODUCTION

that performs the post-processing of the data automatically, and provides the desired

absorbance spectrum of a particular gas sample directly2 .

For hydrocarbons, which are the molecules of interest in this thesis, the strongest

absorption in the infrared is near 3.4 µm (3000 cm−1 ) corresponding to C-H stretching

vibrations within the molecule. Weaker absorption occurs near 1470 cm−1 and 1390

cm−1 due to bending vibrations [35]. Thus, the most sensitive diagnostics use lasers

near this wavelength, as the strong absorption will increase the minimum detectable

species concentration. FTIR measurements of the absorption spectrum of n-decane,

which is representative of most hydrocarbon fuels, is shown in Fig. 1.3 along with

the temperature dependent cross-section near 3.4 µm.

The strong absorption seen in Fig. 1.3 is due to fundamental C-H stretch vibrational transitions near 3.4 µm. The terminology used in spectroscopy comes from the

classical mechanics notion of the harmonic oscillator, often represented by a mass on

a spring. When the mass is displaced from equilibrium and released, it will begin

to oscillate at a frequency which depends on the spring constant and the mass. A

harmonic oscillator may also be driven at some oscillation frequency by an external

force. When the driving frequency approaches the resonant frequency of the system,

the oscillation grows in magnitude. This situation is similar to what a hydrocarbon

molecule experiences when exposed to infrared light (see the schematic of an n-decane

molecule in Fig. 1.4). The individual atoms vibrate about an equilibrium inter-atomic

separation dictated by the charges of the electron cloud and nuclei. Collisions with

neighboring molecules cause these vibrations to increase or decrease and also cause

changes in rotation about the molecule’s center of mass. Unlike the mass-spring

system, a molecule’s vibrational and rotational energies are quantized, as stipulated

by quantum mechanics. Deriving the quantum mechanics solution for hydrocarbon

molecules is well beyond the scope of this thesis, but the basic principles are outlined

below.

In discussing the quantum mechanical solutions for molecular absorption, it is

more convenient to use the photon description of light instead of the electromagnetic

2

In this research, a Nicolet 6700 FTIR was used, with a minimum resolution of 0.09 cm−1

(FWHM).

9

1.2. LASER-ABSORPTION SPECTROSCOPY

n-decane molecule (C10H22)

ω

C

H

Figure 1.4: Schematic of n-decane molecule showing fundamental C-H stretch vibration.

wave description. For photons of light incident on a molecule, when the photon

energy corresponds to one of the quantum mechanically allowed energy transitions

of the molecule, a photon is absorbed. Absorption is thus the conversion of the

photon’s energy to internal molecular energy (e.g. vibrations, rotations, or excitation

of electrons). In a vacuum, the molecule would subsequently re-emit a photon of the

same energy in a random direction and return to its previous energy state. In a gas

at moderate pressures, however, the excited molecule may loose the absorbed energy

by a collision with a neighboring molecule before re-emission of a photon can occur.

Thus, in a laser-absorption measurement, a large number of photons are absorbed

and subsequently converted to thermal energy within the gas. However, since the

powers of the lasers used in this research is small (< 1 mW), this thermal energy

increase is negligible.

When a hydrocarbon molecule absorbs an infrared photon, it undergoes a transition from its current vibrational energy level and a particular rotational level to

the next available vibrational level and a different rotational level; the difference in

energy being equal to that of the absorbed photon. Only certain frequencies of light

are absorbed, as only quantized energy levels are allowed according to quantum mechanical selection rules. These transitions show up as discrete absorption lines in the

10

CHAPTER 1. INTRODUCTION

absorption spectra of small molecules (e.g. H2 O, CO2 , and CO). For larger hydrocarbon molecules like n-decane, there are so many vibrational transitions available (e.g.

many C-H bonds) that the transitions are close together and no individual transitions

are visible in the spectrum (see Fig. 1.3). This overlapping of the transition lines

results in the spectra being largely independent of pressure, which reduces the complexity of laser-absorption measurements for hydrocarbons. Only the temperature

dependence of the absorption spectrum in needed, and the pressure dependence does

not need to be characterized.

A number of broad peaks are observed in the absorption spectra of n-decane in Fig.

1.3. These peaks are all due to the C-H stretching vibrational mode of the molecule.

However, the number of hydrogen atoms bonded to each carbon atom affects the C-H

stretching transition wavelengths. For the alkanes studied in this thesis, two atomic

groupings dominate the absorption spectrum: the CH2 group and the CH3 group.

These groups are illustrated in Fig. 1.4 where the CH2 group corresponds to internal

carbon atoms each bonded to two hydrogen atoms, and the CH3 group, also referred to

as the methyl group, corresponds to the two carbon atoms at each end of the molecule

each bonded to three hydrogen atoms. The CH3 group absorbs at frequencies near

2960 cm−1 and 2870 cm−1 , while the CH2 group absorbs at frequencies near 2925 cm−1

and 2855 cm−1 [35]. Different vibrational modes and spectral shapes are present in

other hydrocarbon molecules such as alkenes (double-bonded carbon molecules, also

referred to as olefins) and aromatics (carbon-ringed molecules).

1.2.3

Measuring temperature

The temperature dependence seen in the absorption feature shown in Fig. 1.3 is

largely due to the probability distribution of the rotational energy states. For a gas

at moderate pressure and temperature, there is a broad distribution of rotational

energy levels. As the temperature changes, this distribution changes, resulting in a

broadening effect on the spectra (i.e. lower peak cross-sections and a wider absorption

band).

Due to the temperature dependence of the absorption spectra, it is possible to

11

1.2. LASER-ABSORPTION SPECTROSCOPY

measure the temperature of a gas from the ratio of the measured absorbance at two

wavelengths. The ratio of absorbance is only a function of temperature as the mole

fraction, concentration, and path length all cancel in the ratio:

− ln

2

( , T ) [m /mole]

− ln

I

Io

ν̄1 =

I

Io

σ(ν̄1 , T )

= f (T )

σ(ν̄2 , T )

n-decane

T = 325 K

T = 500 K

T = 625 K

T = 725 K

v2

100

50

(1.3)

ν̄2

v 1

150

P = 1 atm

0

2700

200

2800

2900

3000

-1

Frequency [cm ]

3100

= 2938 cm

-1

2 = 2952 cm

-1

3

)/ (

)

2

1

2

(

1

2

100

1

0

300

400

500

600

700

800

Temperature [K ]

0

900

Absorption ratio

( T ) [m /mole]

Figure 1.5: Temperature dependent absorption of n-decane.

By careful selection of wavelengths it is possible to obtain a strong temperature

dependence in the absorption ratio, as demonstrated in Fig. 1.5 for n-decane. The

first laser wavelength, ν̄1 , has been chosen near peak absorption, where the absorption

decreases rapidly with increasing temperature, and the second laser wavelength, ν̄2 ,

is chosen where the absorption is less sensitive to temperature. The resulting ratio

is temperature dependent, with decreasing temperature sensitivity as temperature

increases. Using two wavelengths, the gas temperature and the concentration of the

12

CHAPTER 1. INTRODUCTION

absorbing species can be determined simultaneously. This is important for applications where the temperature is needed either for the application, or to determine the

appropriate value of the temperature-dependent absorption cross-section.

1.2.4

Modifications to Beer’s law

The form of Beer’s law stated in Eq. 1.2 only accounts for changes in transmitted light

intensity due to absorption. Other common factors that can change the transmitted

light intensity include: light emission from heated gases, light scattering from small

particles, and changes in the real refractive index due to phase change (gas to liquid),

non-uniformity along the path length (e.g. due to temperature change), or density

changes (boundary layer effects). Interference from light emission is often corrected for

by momentarily interrupting the light beam and collecting the emitted radiation to be

subtracted in real time from the collected light signal. Alternatively, the laser intensity

can be modulated at some frequency and passed through a lock-in amplifier, effectively

rejecting the slowly varying emission signal. The effects of transverse gradients in

density, which steer the beam away from the normal path, can be minimized by

careful alignment of the laser beams and collection optics. The other two effects:

multi-phase absorption and light scattering, are more involved and will be addressed

next.

1.3

1.3.1

The refractive index

Beer’s Law from Maxwell’s equations

The derivation of Beer’s law presented previously was based on experimental observation of the attenuation of light as it passed through certain materials. It is also

possible to derive Beer’s law from Maxwell’s equations, and as this reveals the definition of the refractive index in an intuitive way, this derivation is summarized here.

For laser light, which is highly collimated, it is common to represent the electromagnetic radiation as plane waves. The plane wave approximation is characterized by a

traveling electromagnetic wave with harmonic oscillations in its electric and magnetic

13

1.3. THE REFRACTIVE INDEX

fields. If an infinite plane is placed orthogonal to the direction of propagation, the

electric field (and accompanying magnetic field) is in-phase at all points on this plane

(e.g. the magnitude of the electric field and magnetic field are zero everywhere on

the plane in Fig. 1.6).

B

x

E

z

y

Figure 1.6: Electromagnetic plane wave propagating in the z-direction.

Using phaser notation, the electric field and magnetic field of an electromagnetic

plane wave traveling in the z-direction can be represented mathematically as:

~c = E

~ 0 exp(iκz − i2πc0 ν̄t)k̂;

E

~c =B

~ 0 exp(iκz − i2πc0 ν̄t)k̂

B

(1.4)

~ 0 and B

~ 0 are constant vectors equal to the magnitude of the waves, κ is the

where E

propagation number3 , ν̄ is the optical frequency of the wave, t is time, k̂ is the unit

vector in the positive z-direction, and i denotes imaginary numbers. The propagation

number, κ can be complex, in which case κ = κ′ + iκ′′ . It can be shown that the

plane waves in Eq. 1.4 satisfy the Maxwell equations if the following relation is met:

√

κ = κ′ + iκ′′ = 2πν̄co ǫµ ≡ 2πν̄(n + ik)

(1.5)

where co is the speed of light in vacuum, ǫ is the complex permittivity, µ is the permeability, and m = n + ik is introduced as the complex refractive index. This holds

for a medium that is linear (independent of the field strength), homogeneous (independent of the position), and isotropic (independent of the direction). Substituting

3

Wavenumber is also used, but this would create confusion with frequency units.

14

CHAPTER 1. INTRODUCTION

the complex refractive index into Eq. 1.4 results in a plane wave of the form:

~c = E

~ 0 exp(−2πν̄kz)exp(i2πν̄nz − i2πc0 ν̄t)

E

(1.6)

This equation represents a plane wave propagating in the z-direction, but with an

exponential decay that is a function of the imaginary refractive index. Thus, the

imaginary refractive index determines the attenuation of the light as it propagates.

The real refractive index is a measure of the relative wave speed in the material:

n = c/co , where c is the speed of light in the material and co is the speed of light in

vacuum. For anisotropic media, n is a function of position, causing the light beam to

bend or even reflect.

Equation 1.6 can be related to the light intensity using the time-averaged Poynting

vector, ~S, which is the rate of transfer of electromagnetic energy at all points in space

and is found by taking the cross product of the electric and magnetic field vectors:

o

n

~S = 1 Re E

~c ×B

~∗

c

2

(1.7)

where the complex conjugate of the magnetic field vector has been taken. Performing

the calculus one then obtains:

~S = 1 Re

2

r ǫ ~ 2

E0 exp(−4πν̄kz)k̂

µ

(1.8)

The magnitude of ~S is the irradiance

or intensity

of the light, which is given the

q

~ 2

ǫ

symbol I [W/m2 ]. Defining I0 ≡ 21 Re

E0 , results in Beer’s law derived from

µ

Maxwell’s equations:

I = I0 exp(−αz)

(1.9)

where z is the distance and the absorption coefficient α is defined as:

α ≡ 4πν̄k

(1.10)

1.3. THE REFRACTIVE INDEX

15

Thus, the imaginary refractive index is directly proportional to the absorption coefficient derived from observation, and is a measure of the attenuation of electromagnetic

energy propagating through an absorbing medium. Equation 1.10 also shows that

measuring the absorption coefficient gives a direct measure of the imaginary component of the refractive index. Before discussing experimental methods for measuring

the complex refractive index in Chapter 2, it is useful to first develop a deeper physical intuition for the real and imaginary refractive indices, including how they can be

derived from each other using dispersion relations.

1.3.2

Dispersion relation

The wavelength dependence of the refractive index (or alternatively, ǫ or µ) is referred

to as dispersion, dispersion relations being expressions of this wavelength dependence.

As just stated, the real index of refraction is the ratio of the speed of light in a medium

divided by the speed of light in vacuum: n = c/co . While this is true, it does not

describe the physical processes leading to the change in the speed of light. For a more

fundamental understanding, it is helpful to start at the atomic level and individual

photons4 .

Atoms, either isolated or bound in molecules, are composed of nuclei surrounded

by an electron cloud. Electromagnetic radiation can perturb this electron cloud relative to the nucleus causing an oscillating dipole moment (i.e. positive and negative

charge separation). Once perturbed, this oscillating dipole then emits radiation at

the same wavelength as the incident photon, with the direction of the emitted photon

dependent on the polarization of the incident light. Dispersion arises from the fact

that the excitation of the electron cloud is not instantaneous, but depends on the

particular molecule and on the wavelength of the light. The resulting delay results in

a phase shift of the emitted light relative to the incident light, and a corresponding

reduction in the phase velocity of the light. Thus the real refractive index is a measure of this phase shift, or equivalently, a measure of the speed of light in the medium

relative to vacuum.

4

This discussion follows that of Hecht [36].

16

CHAPTER 1. INTRODUCTION

Some further physical understanding can be achieved by modeling the nucleus

electron-cloud dipole as a forced harmonic oscillator with damping. The oscillating

electromagnetic wave acts as the forcing function driving the electron cloud of the

atom. The damping force is due mainly to photon emission, but also to collisions

with other molecules, which reduce the energy of the oscillation. The details of this

are not presented here, but can be found in many optics texts [36, 37]. The governing

equation is Newton’s Second Law:

qe E(t) − me ω02 r − me γ

dr

d2 r

= me 2

dt

dt

(1.11)

where r is the displacement of the oscillator, qe is the electron charge, me is the

electron mass, ω0 is the resonant frequency of the oscillator in radians per second, the

electric field, E(t), is harmonic (i.e. E(t) = E0 cosωt), and the three force terms on

the left are due to the driving force, restoring force, and a damping force proportional

to the speed of the oscillation, respectively.

For N electrons per unit volume, the electric polarization is given by P = qe rN .

Substituting the solution of Eq. 1.11 into the polarization and combining this with

the relations: P (t) = E(t)(ǫ − ǫ0 ) and m2 = ǫ/ǫ0 , results in the dispersion equation:

m2 (ω) = 1 +

N qe 2 X

fj

2

2πǫ0 me j 2π(ω0j − ω 2 ) + iγj ω

(1.12)

where m is the complex refractive index (m = n + ik) and the solution has been

expanded to include multiple characteristic frequencies j, at which the molecule can

absorb or emit light. This relation holds for gases, where inter-molecular forces are

neglected, but can be applied to liquids by adding a factor of 1/3 to the summaP

tion [36]. The weighting factor, fj , where

fj = 1, corresponds to the number of

molecules per unit volume with natural frequencies ω0,j . This same relation can be

arrived at from the quantum mechanical approach, but with ω0,j being the quantum

mechanically allowed transitions and fj being the oscillator strength or transition

probability, which determines the likelihood of a transition occurring (i.e. absorption

or emission of a photon).

17

1.3. THE REFRACTIVE INDEX

0.3

n

k

1.4

1.3

1.2

2000

0.2

T = 300 K

P = 1 atm

2500

3000

3500

-1

Frequency [cm ]

0.1

Refractive Index, k

Refractive Index, n

1.5

0.0

4000

Figure 1.7: Measured complex refractive index of liquid n-decane in the infrared.

The dispersion relation provides some valuable information about the relationship

between absorption and the refractive index. First, in order to calculate m(ω) at any

one frequency, a sum over all absorption transitions for that medium is required.

Thus, the full absorption spectrum is required for an accurate calculation of m at

2

any one wavelength. Second, at frequencies away from absorption transitions, (ω0j

−

ω 2 ) >> iγj ω, and iγj ω may be neglected. Thus, in the absence of damping, which is

largely due to absorption, the complex term in Eq. 1.12 vanishes and the refractive

index is real (k → 0 and m = n). At frequencies just below absorption transition

frequencies, as ω increases toward ω0 , the summation in Eq. 1.12 is positive and n(ω)

increases above 1, corresponding to c < c0 . At absorption transition frequencies, k

is non-zero, dn/dω is negative5 , and n decreases with increasing wavelength and can

actually reach values where n < 1 (c > c0 ). At frequencies just above absorption

transition frequencies, ω increases away from ω0 , and n(ω) increases with increasing

frequency. These trends are easily seen in Fig. 1.7, which shows the measured complex

5

Spectral regions with dn/dω < 0, are referred to as exhibiting anomalous dispersion.

18

CHAPTER 1. INTRODUCTION

refractive index for n-decane liquid as a function of frequency, ν̄.6 Away from the

absorption feature, the real index increases with frequency as expected, increasing

more rapidly with frequency as it approaches the absorption feature, then rapidly

decreasing through each absorption peak. As expected, k is zero at non-absorbing

wavelengths, but scales with the absorption cross-section at absorbing wavelengths.

Hydrocarbons have few absorption transitions through the visible to near-IR, allowing a simplified dispersion equation to be used that relates the real refractive index

to the optical frequency [37]:

n(ν̄)2 = A1 + A2 ν̄ 2 + A3 ν̄ 4

(1.13)

where A1 , A2 , and A3 are constant functions of the oscillator strengths and fundamental frequencies of individual transitions in the ultra-violet, which are dominant

transitions for all atoms and molecules. The utility of Eq. 1.13 is for extrapolating

refractive index data measured at visible wavelengths to the infrared, as will be required for the refractive index measurements of liquid hydrocarbons discussed in the

next chapter.

1.3.3

Kramers-Kronig relation

We have shown from classical mechanical arguments that the real and imaginary refractive indices are dependent upon each other. A similar but more useful relation can

be deduced mathematically. It can be shown that the real and imaginary refractive

indices belong to a family of functions for which the real and imaginary components

are related through integral equations. The derivation of this relationship is not covered here as it has little physical intuition, but the result is the Kramers-Kronig or

dispersion relations [34]:

2

n(ν̄i ) − n(∞) = P

π

Z∞

0

6

ν̄k(ν̄)

dν̄

ν̄ 2 − ν̄i2

The angular frequency is converted to wavenumbers by

ω

c0

= 2πν̄.

(1.14)

19

1.4. LIGHT SCATTERING

−2ν̄i

P

k(ν̄i ) =

π

Z∞

0

n(ν̄)

dν̄

− ν̄i2

ν̄ 2

(1.15)

where n(∞) is the real refractive index at the highest frequency analyzed, and the P

indicates that the principal value of the improper integral must be taken because of

the singularity at ν̄ = ν̄i .

The Kramers-Kronig relations state that the value of the real or imaginary component of the complex refractive index is dependent upon the value of the other

component at all wavelengths. Using the convolution theorem, it can be shown that

the finite response time of molecules to electromagnetic radiation leads to this result.

In practice, the Kramers-Kronig relations can be used to calculate the real refractive

index spectrum by integrating over the measured imaginary refractive index spectrum, and visa-versa. This relation will later prove very useful when measuring the

optical constants of liquid fuels.

Thus far, the fundamental processes of light absorption and the origins of the

refractive index have been presented. With this fundamental background established,

the first application of these principles can be presented: light scattering by small

particles.

1.4

Light scattering

Light scattering by small particles can be divided roughly into two domains: particles

with diameters much smaller than the wavelength of light (i.e. D << λ), referred to

here as Rayleigh scattering, and particles with diameters on the order of the wavelength of light. This latter form of scattering is referred to as Mie scattering when

the particles can be approximated as spheres. Rayleigh found that the scattering of

light intensity by particles much smaller than the wavelength of light was inversely

proportional to λ4 . As this work is performed in the infrared (long wavelengths), this

effect is small and not addressed here. However, many liquid aerosols used in combustion have particle sizes on the order of microns, which leads to larger scattering

of laser light. Methods for correcting for this effect will be addressed at length in

20

CHAPTER 1. INTRODUCTION

Chapter 3, but first a brief introduction to Mie scattering is needed.

1.4.1

Mie theory

Es , Bs

Eint ,Bint

Ei , Bi

D

m2

Et , Bt

m1

Figure 1.8: Schematic of light being scattered and absorbed by a liquid droplet.

Mie scattering has been extensively studied and analytical expressions for scattering efficiencies and directions can be found in many texts (Bohren and Huffman’s

book [34] is recommended). Mie theory considers light scattering by spherical particles, which is typical of liquid droplets in the absence of strong pressure fluctuations.

A schematic showing light scattering by a sphere of diameter D is shown in Fig. 1.8.

The refractive index of the sphere, m1 , and the surrounding gas, m2 , are sufficiently

different to cause reflections at the boundaries of the two media. For liquid fuel

droplets, m1 is complex in the mid-infrared due to light absorption by the liquid.

When an incident electromagnetic field interacts with the droplet, an internal field, a

scattered field, and a transmitted field are generated. Solving the Maxwell equations

for the incident, internal, and scattered fields results in the scattered intensity as a

function of wavelength and scattering direction.

For line-of-sight measurements, only the transmitted light is measured, corresponding to the total extinction of light in the forward direction. Extinction of light

in the forward direction is due to the interaction of the incident light field and the

forward scattered light field. Alternatively, the transmitted field can be related to the

21

1.4. LIGHT SCATTERING

absorption within the droplet and the scattering in all directions other than forward,

by conservation of energy:

Wt (ν̄) = Wi (ν̄) − Ws (ν̄) − Wa (ν̄)

(1.16)

where Wt is the power of the transmitted light in the forward direction, Wi = Ii A

is the incident light power, Ws is the light power lost to scattering in directions

other than forward, and Wa is the power absorbed within the particle. Thus, a

detector placed in the path of the incident beam, with a sufficiently small solid angle

of detection, would measure the extinction of light due to absorption and scattering.

A small solid angle of detection is required to minimize detection of scattered light at

small angles to the incident direction, as these rays are not included in the extinction

calculation. In the scattering measurements presented in Chapter 3, the solid angle is

reduced by placing the detector far from the measurement location, and by passing the

transmitted beam through an optical iris. The measured extinction can be related

to an extinction cross section per particle, Cext [cm2 ], which is analogous to the

absorption cross section in Beer’s law. Gustav Mie (1869-1957) developed analytical

expressions for the scattering and extinction cross sections by solving the plane wave

version of Maxwell’s equations for spherical particles. A derivation of Mie’s solutions

would be beyond the scope of this thesis, but the basic solution proceeds as follows.

Maxwell’s equations for plane electromagnetic waves can be manipulated to yield

the scalar wave equation:

∇2 ψ + κ2 ψ = 0

(1.17)

where ψ is a scalar function corresponding to the amplitude of the wave. The wave

equation can be converted to spherical polar coordinates and solved by separation of

variables (i.e. ψ(r, θ, φ) = R(r)Θ(θ)Φ(φ)) yielding two infinite series solutions: ψomn

and ψomn (caution: do not confuse the integers n and m in these solutions with the

refractive index m and real refractive index n). These solutions, also called generating

functions, are complete, meaning they can be expanded to generate any function that

satisfies the scalar wave equation in spherical polar coordinates. Although not shown

here, these solutions to the scalar wave equations can also be used to generate another

22

CHAPTER 1. INTRODUCTION

~ = ∇ × (~rψ)).

set of complete vector functions: the vector spherical harmonics (i.e. M

The vector spherical harmonics are in turn used to generate solutions to the vector

~ + κ2 E

~ = 0). After applying the appropriate boundary

wave equations (i.e. ∇2 E

conditions, these solutions can be combined to determine rates of energy loss due to

scattering and absorption, which by conservation of energy, equals the total extinction

(Ws + Wa = Wext ). The ratio of the rate of energy loss to the incident light intensity

has units of area and is given by:

Cext

∞

Wext

2π X

=

(2n + 1)Re {an + bn }

= 2

Ii

κ n=1

[cm2 ]

(1.18)

which is the desired extinction cross section . The terms an and bn are coefficients in

the series solutions to the vector wave equations and are functions of two variables,

x and m̄:

x=

πm2 D

λ

m̄ =

m1

m2

(1.19)

where D is the particle diameter, λ is the wavelength of the incident light, and m1 and

m2 are the refractive indices of the particle and the surrounding medium, respectively.

For the simulations and experiments in this work, the medium surrounding the droplet

is a gas with m2 ∼ 1, therefore m̄ = m1 = m. The extinction cross section is

often reported as an extinction efficiency, Qext , which is the extinction cross section

normalized by the cross sectional area of the particle (Qext = 4Cext /πD2 ). The term

efficiency can be misleading however, as Qext > 1 is common due to edge diffraction

effects that remove more light than given by the particle’s cross sectional area.

It is informative to plot the extinction efficiency versus optical frequency, which

is done in Fig. 1.9 for three liquid toluene droplet sizes [38] (toluene is used here

because its optical constants were known over the large spectral range needed to

generate this plot). For λ >> D (i.e. low frequency), Rayleigh scattering dominates

and Qext varies as 1/λ4 (or as ν̄ 4 ). This is observed as the near-monotonic increase

in Qext at low frequencies. In the Rayleigh scattering region, extinction is dominated

by bulk absorption within the droplet, which can be observed as two large spikes in

Qext below 0.1 µm−1 . These spikes correspond to large absorption features in the

23

1.4. LIGHT SCATTERING

6

5

Qext

4

Liquid toluene droplet

D = 6 µm

T = 25°C

P = 1atm

D = 1 µm

D = 3 µm

3

2

1

0

0.5

1.0

1.5

-1

Inverse wavelength [µm ]

2.0

2.5

Figure 1.9: Calculated extinction efficiency for liquid toluene droplets.

absorption spectrum of liquid toluene. This analysis only considers droplets down to

tens of nanometers. At the nanometer scale the bulk absorption may be influenced by

inter-molecular surface effects, which are not addressed here. The large oscillations in

Qext are referred to as interference structure and are caused by interference between

the incident and forward scattered light. The finer oscillations are referred to as ripple

structure and will not be discussed here. As measurements were only made in aerosols

with many thousands of droplets with different sizes, this ripple structure was always

averaged out. For λ << D (i.e. high frequency), Qext asymptotes to a value of 2.

Thus, for large particles relative to the wavelength, Qext may be considered constant

at 2 and the scattering calculations are greatly simplified.

1.4.2

Droplet distributions

The extinction cross section calculated from Mie theory can be thought of as the area

of the detector surface that is blocked by one particle. In practice, many particles

of many different sizes are present along the optical path of the laser. Adding up

over many particles, it is possible to define an extinction coefficient similar to the

24

CHAPTER 1. INTRODUCTION

absorption coefficient presented earlier (Eq. 1.1):

τ=

X

Nj Cext,j

(1.20)

j

where τ [cm−1 ] is the extinction coefficient, and Nj [cm−3 ] is the number of particles

per unit volume of type j. For example, if there were ten particles per unit volume

with four of diameter D1 , four of diameter D2 , and two of diameter D3 , Eq. 1.20

would yield: τ = 4Cext,1 + 4Cext,2 + 2Cext,3 . The number of particles of each diameter

is referred to as the droplet distribution. This droplet distribution can be discrete,

as in the above example, or it can be continuous (i.e. f (D)), in which case Eq. 1.20

takes an integral form:

τν̄ =

Z

Dmax

Dmin

N · f (D)

πD2

Qext,ν̄ (D, m)dD

4

(1.21)

where the limits of integration are from the smallest diameter to the largest. In Eq.

1.21, N [cm−3 ] is the total number of droplets of all sizes per volume, also called the

droplet loading, and f (D) [cm−1 ] is the size distribution function, or the number of

particles per differential diameter dD.

Calculating the series solution to Cext (Eq. 1.18) is best done using a computer,

as an and bn require solving recursive relations for Bessel functions. Many computer

codes have been written to perform these calculations, and the SCATMECH C++

class library developed at NIST [39] was used for this work as it provided the most

flexible open source computer code. As a C++ library, SCATMECH provided Mie

scattering functions (e.g. for calculating Qext ) which could be called in the C++ routines developed for this research. The combined computer code is listed in Appendix

B, and calculates the extinction cross section, τν̄ , for user defined refractive index

spectra and droplet size distributions.

Chapter 2

Measurements of Absorption

Spectra in Liquid Fuels

2.1

2.1.1

Introduction

Motivation

In practical combustion environments, fuels are often injected as a liquid spray which

quickly evaporates at elevated temperatures. Direct measurement of vapor-phase

properties (e.g. vapor-phase mole fraction and temperature) in the presence of liquid

fuels is valuable for studying combustion in gas turbine engines and direct-injection

gasoline and diesel engines [23, 40, 21, 41]. Laser-absorption measurements at these

conditions are difficult, however, because light scattering by liquid droplets and strong

absorption by liquid films interfere with measurements of the vapor. Liquid films are

also common in liquid fuel injection combustion systems, with film thicknesses up to

5 µm having been observed in direct injection IC engines [42]. Moreover, liquid films

present a challenge for optical measurements as strongly absorbing liquid films on

optical access ports interfere with vapor-phase measurements. Tunable mid-infrared

lasers are promising for direct measurements of liquid hydrocarbon films, as strong

liquid absorption in this spectral region allows for sensitive film thickness measurements down to sub-micron thicknesses. However, in order to develop diagnostics

25

26CHAPTER 2. MEASUREMENTS OF ABSORPTION SPECTRA IN LIQUID FUELS

for liquid hydrocarbon films and aerosols, quantitative absorption spectra of liquid

hydrocarbon fuels in the mid-infrared spectral region are required.

The absorption spectra of liquid hydrocarbon fuels are used for many engineering

modeling and diagnostic applications, including radiative heat-transfer modeling in internal combustion engines [43, 44, 45, 46, 47] and pool fires [48], and laser light scattering corrections for optical diagnostics in absorbing liquid aerosols [49, 50, 51, 40, 23].

Many different techniques for measuring absorption in liquids have been reported in

the literature using both reflection techniques [52, 44, 45, 53] and transmission techniques [47, 54, 55, 56]. For a summary of available methods see the review by Bertie

[57]. Despite this body of previous work, there remains little quantitative absorption

data for liquid hydrocarbons with the spectral resolution needed for optical diagnostic

development. Further, there is virtually no quantitative data available for fuels in the

spectral region of the fundamental C-H stretch vibrational transition, where strong

liquid absorption requires short transmission measurement path-lengths (< 15µm).

In this chapter a Fourier Transform Infrared (FTIR) spectrometer transmission measurement technique for absorbing liquid hydrocarbons, originally developed within

the chemistry community [58], is described. More specifically, details of this method

as applied to quantitative absorption measurements over the fundamental C-H stretch

absorption band are presented.

Mid-infrared FTIR transmission measurements of the absorption spectra of three

liquid hydrocarbons (toluene, n-dodecane, and n-decane) and three hydrocarbon fuel

blends (gasoline) were made at 27 ◦ C in the spectral region 2700 − 3200 cm−1 . These

are the only known quantitative absorption measurements of n-decane, n-dodecane,

and gasoline in this important spectral region. The toluene measurements were made

for comparison with the published data of Bertie et. al. [38]. The influence of

gasoline composition on the liquid absorption spectrum is presented. The measured