Attachment - El Paso Water Utilities

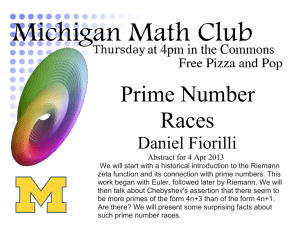

advertisement