Lecture 1: Introduction Structure — An assemblage of materials

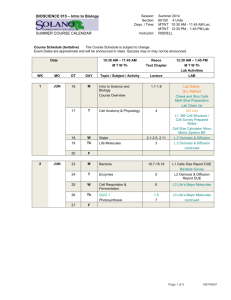

advertisement

Lecture 1: Introduction Structure — An assemblage of materials which is intended to sustain loads Functions to protect people and things Structures are so common and familiar to us, that when we are informed of their use and form we consider ourselves as knowledgeable 1 of 21 Airplane structures are complex AOE 2104 Intro. to Aero Engineering. Lec. 1: 2 of 21 Structural layout An aircraft is considered a system consisting of structural subsystem control subsystem propulsion subsystem cargo handling subsystem, etc. A structural subsystem has multiple components wing fuselage empennage Components consist of many subcomponents or structural members. AOE 2104 Intro. to Aero Engineering. Lec. 1: 3 of 21 Wing Fuselage Intersection AOE 2104 Intro. to Aero Engineering. Lec. 1: 4 of 21 AftFuselageStructure AOE 2104 Intro. to Aero Engineering. Lec. 1: 5 of 21 Typical structural subcomponents spar: main load-bearing members in the wing. wing skin: carries chordwise and spanwise pressure distribution to the ribs and spars. ribs: help the wing keep its airfoil shape, together with the skin and spars form wing-box that resist wing twist (torsion). stringers (stiffeners): keep the skin from bending. fuselage frames (bulkheads): maintain fuselage shape, provide support to internal structure. longerons: longitudinal fuselage beams. AOE 2104 Intro. to Aero Engineering. Lec. 1: 6 of 21 Typical (semimonococque) construction Longitudinal stringers Cover Skin Transverse frames (a) Cover skin Transverse rib Spar web Spar cap (b) AOE 2104 Intro. to Aero Engineering. Longitudinal stringers Lec. 1: 7 of 21 The structural functions of the skin 1.It transmits aerodynamic forces to the longitudinal and transverse supporting members. 2.It develops shearing stresses which react the applied torsional moments and shear forces. 3.It acts with the longitudinal members in resisting the applied bending and axial loads. 4.It acts with the longitudinals in resisting the axial load and with the transverse members in reacting the hoop, or circumferential, load when the structure is pressurized. AOE 2104 Intro. to Aero Engineering. Lec. 1: 8 of 21 The structural function of the longitudinals 1.They resist bending and axial loads along with the skin. 2.They divide the skin into small panels and thereby increase its buckling and failing stresses. 3.They act with the skin in resisting axial loads caused by pressurization. Longitudinal members are sometimes referred to as longitudinals, stringers, or stiffeners. If they have a large cross-sectional area they are called longerons. A strong underbody beam for heavy loads is called a keel beam AOE 2104 Intro. to Aero Engineering. Lec. 1: 9 of 21 The function of transverse members Frames, rings, bulkheads. 1.Maintain the cross-sectional shape. 2.Distribute concentrated loads into the structure and redistribute stresses around structural discontinuities. 3.Establish the column length and provide end restraint for the longitudinals to increase their column buckling stress. 4.Provide edge restraint for the skin panels and thereby increase the plate buckling stress of these elements. 5.Act with the skin in resisting the circumferential loads due to pressurization. AOE 2104 Intro. to Aero Engineering. Lec. 1: 10 of 21 Most vehicle structures are thin shells From the standpoint of structural weight, the most efficient location for the structural material is the outer surface. monococque fuselage — unstiffened shell: no keel, longerons, or stiffeners. It gets all of its bending and torsional stiffness from the tube/box formed by its skin and bulkheads. semimonococque — stiffened shell with some stringers and longerons AOE 2104 Intro. to Aero Engineering. Lec. 1: 11 of 21 Structures are made from materials The history of structures follows the development of materials and the development of tools to fabricate materials. Airframe Early aircraft were constructed of wire-braced frames with fabric covers. Stressed-skin construction Currently advanced composite materials are attractive for weight-sensitive structures. Material selection for structural efficiency: Strength-to-weight ratio Stiffness-to-weight ratio AOE 2104 Intro. to Aero Engineering. Lec. 1: 12 of 21 Evolution of wing structure AOE 2104 Intro. to Aero Engineering. Lec. 1: 13 of 21 Loads on structures The first step in preliminary design is to determine the external loads acting on the structure. Gravity forces, aerodynamic forces, and inertial forces act on maneuvering flight vehicles Landing loads Wind gust loads Loads on a vehicle maybe classified as Static or dynamic Deterministic or probabilistic (wind gusts) AOE 2104 Intro. to Aero Engineering. Lec. 1: 14 of 21 Loads (continued) AOE 2104 Intro. to Aero Engineering. Lec. 1: 15 of 21 Loads (concluded) In traditional design, these loads are not affected by the structural configuration or dimensions of the members. They are a function of the wing shape, say, and other nonstructural factors. Hence, determination of loads is essentially a separate task typically performed by the aerodynamicist. AOE 2104 Intro. to Aero Engineering. Lec. 1: 16 of 21 Lecture 2: How an Airplane is Built AOE 2104 Intro. to Aero Engineering. Lec. 1: 17 of 21 Lecture 2: Design Stages Conceptual Design: Weight and center of gravity analyses to ensure that the aircraft is light enough and will balance properly. Important criteria: producibilty, maintainability. Preliminary Design: Materials for major components are specified. Refined structure is analyzed to ensure strength without excess weight. Detailed physical and CAD/CAM drawings are created. Detail Design: Every component, fastener/ connector, linkage must be designed/specified in exact detail. Structural test prototypes are built and tested. AOE 2104 Intro. to Aero Engineering. Lec. 1: 18 of 21 Design guidelines Overall dimensions of an airplane are usually determined by more general requirements rather than for structural considerations. An important contribution to the overall vehicle performance is to minimize weight in the structural subsystem while maintaining integrity. more payload less fuel required greater range General guidelines: 1.Never attach anything to skin alone. 2.Structural members should not pass through air inlets, passenger cabins, cargo bays, etc. AOE 2104 Intro. to Aero Engineering. Lec. 1: 19 of 21 Design guidelines (continued) 3.Major load-carrying members should carry completely through a structural component. 4.Whenever possible, attach engines, equipment, landing gear, seats, pylons, etc., to existing structural members. Plan the position of major structural elements so that as many systems as possible can be attached to them. 5.Design redundancy into your structures to have multiple load paths. 6.Mount control surfaces and high-lift devices to a spar, not just the rear ends of ribs. 7.Innovate to come up with creative layouts....! AOE 2104 Intro. to Aero Engineering. Lec. 1: 20 of 21 Why do structures carry load? Crux of the issue in design of complex structures is know not only the use and form but why a structure carries load. By Newton’s law of action/reaction we know that isolated forces do not exist in nature. A force acting on an inanimate solid is reacted by a force produced by the solid. But how does the solid produce such a reaction force? Robert Hooke (1635 - 1702) “Ut tensio sic vis” (the subtitle of Chapter 7) Translation: as the stretch so the force AOE 2104 Intro. to Aero Engineering. Lec. 1: 21 of 21