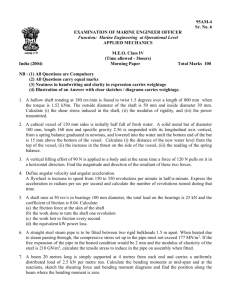

ME 343: Mechanical Design

advertisement

ME 343: Mechanical Design-3 Design of Shaft Aly Mousaad Aly, PhD Assistant Professor, Dept. of Mech. Eng. Faculty of Engineering, Alexandria University Outline • Practical information • Shaft design Lecture1: Design of Shaft 2 Instructor • Lecturer: Dr. Aly Mousaad Aly • Office: Last floor, Dept. of Mech. Eng., Faculty of Eng., Alexandria University • Office hours: Thursday 8:30 to 9:35 Thursday, Thursday, 11:00 to 12:05 Lecture 1: Introduction 3 Course Materials Slides: Available online. Available at the department copy center. Course website: www.engr.uconn.edu/~aly/ME343 References: • Shigley’s Mechanical Engineering Design, Eighth Edition, The McGraw−Hill Companies, Inc., 2006. Lecture 1: Introduction 4 Grading • • • • • Class participation Assignments Reports Midterm exam Final examination Lecture 1: Introduction 5 Policy • Attendance d to llectures and d exercises i iis compulsory. • We may check the attendance at the g g of lessons. beginning • Everybody should attend his scheduled classes according to his name and student number. number We will be VERY STRICT about this rule. • Come C t lessons to l about b t 5 min i b before f th the starting time. Lecture1: Design of Shaft 6 Outline • Practical information • Shaft design Lecture1: Design of Shaft 7 Definition of shaft? • It is i a rotating i member, b iin general,l h has a circular cross-section and is used to transmit power. • The shaft mayy be solid or hollow. It is supported on bearings and it rotates a set of ggears or pulleys p y for the purpose p p of p power transmission. • The shaft is generally acted upon by bending moments, torsion and axial forces. Lecture1: Design of Shaft 8 Shaft versus axle and spindle Axle is a non-rotating member used for pp g rotatingg wheels, etc., and do not supporting transmit any torque. Spindle is simply defined as a short shaft shaft. However However, design method remains the same for axle and spindle as that for a shaft. Lecture1: Design of Shaft 9 What does it mean “shaft shaft design”? design ? • • • • Material selection Geometric layout Stress and strength: static and fatigue Deflection and rigidity: bending defl., torsional g, slope p at bearings g and shafttwisting, supported elements, and shear deflection due to transverse loading on short shafts. shafts • Vibration: critical speed Lecture1: Design of Shaft 10 Material selection • M Many shafts h ft are made d ffrom low l carbon, b coldld drawn or hot-rolled steel. • Alloy steel: steel Nickel, Nickel chromium and vanadium are some of the common alloying materials. However alloy steel is expensive. However, expensive • Shafts usually don’t need to be surface hardened unless they serve as the actual journal of a bearing surface. • Hardening g off surface f ((wear resistant): ) case hardening and carburizing ; cyaniding and nitriding. Lecture1: Design of Shaft 11 Geometric layout Lecture1: Design of Shaft 12 Geometric layout • The geometry of shaft is generally that of stepped cylinder. li d • There is no magic formula to give the shaft geometry f any given for i d design i situation. it ti Lecture1: Design of Shaft 13 Geometric layout • The h b best approach h iis to llearn ffrom similar i il problems that have been solved and combining th b the bestt tto solve l your own problem. bl • A general layout to accommodate shaft elements, e.g. gears, bearings, and pulleys, must be specified early in the design process. • Shoulders are used for axially locating shaft elements and to carry any thrust loads. • Common Torque Transfer Elements: keys, set pins, p press or shrink fits, tapered p fits. screws, p Lecture1: Design of Shaft 14 Geometric layout • Small pinions are often machined onto shafts. • Sequence of assembly should be thought. • Use chamfers to ease assembly and avoid i interferences. f • Consider stress risers due to ggrooves and sharp steps in shafts. • What Wh t can ffailil and dh how will ill it h happen?? Lecture1: Design of Shaft 15 Shaft design based on strength Design i iis carried i d out so that h stress at any llocation i off the shaft should not exceed material yielding. Stress due to torsion: τ xy T × r 1 6T = = J π d o3 (1 − c τxy : Shear stress due to torsion T : Torque on the shaft Note: 4 ) 7024 × hp 9549 × kW T ≈ ≈ N (RPM ) N (RPM ) Lecture1: Design of Shaft 16 Shaft design based on strength Bending stress: σ b M × y 32M = = I π d o3 (1 − c ) M : Bending moment at the point of interest do : Outer diameter of the shaft c: di/do Lecture1: Design of Shaft 17 Shaft design based on strength Axial i l stress: σ a Fa 4α Fa = = A π d o2 (1 − c 2 ) Fa Fa Fa: Axial force (tensile or compressive) α: Column-action C l ti factor(= f t ( 1 1.0 0 for f tensile t il lload) d) α arises due to the phenomenon of buckling of l long slender l d members b which hi h are acted d upon b by axial compressive loads. Lecture1: Design of Shaft 18 Shaft design based on strength A i l stress Axial t ((continue): ti ) 1 α = , 1 − 0 .0 0 4 4 λ λ 2 s yc α = , 2 π nE (λ = L / r ) ≤ 1 1 5 λ > 115 n = 1.0 for hinged end; n = 2.25 for fixed end n = 1.6 for ends p partlyy restrained,, as in bearingg , L = shaft length p syc = yyield stress in compression Lecture1: Design of Shaft 19 Shaft design based on strength Maximum shear stress theory (ductile mat.): Failure occurs when the maximum shear stress at a point exceeds the maximum allowable shear stress for the material. material Therefore, Therefore 2 τ max = τ allowable τ allowable ⎛σx ⎞ 2 = ⎜ ⎟ + τ xy ⎝ 2 ⎠ 16 = 3 4 π d o (1 − c ) Lecture1: Design of Shaft ⎛ α Fa d o (1 + c ⎜M + ⎜ 8 ⎝ 2 ) ⎞⎟ ⎟ ⎠ 2 +T2 20 Shaft design based on strength Maximum normal stress theory (brittle mat.): σ max = σ allowable σ allowable σx 2 ⎛σx ⎞ = + ⎜ ⎟ + τ xy2 2 ⎝ 2 ⎠ 2 ⎡ ⎛ ⎞ + α F d 1 c ) 16 a o ( ⎢ ⎜M + ⎟ = 3 4 ⎟ 8 π d o (1 − c ) ⎢⎜⎝ ⎠ ⎣ ⎛ α Fa d o (1 + c + ⎜M + ⎜ 8 ⎝ Lecture1: Design of Shaft 2 ) ⎞⎟ ⎟ ⎠ 2 ⎤ ⎥ +T2 ⎥ ⎥⎦ 21 Shaft design based on strength Von Mises/ Distortion-Energy theory: σ max = σ allowable = σ x2 + 3τ xy2 σ allowable ll bl 16 = π d o3 (1 − c 4 ) Lecture1: Design of Shaft ⎛ α Fa d o (1 + c ⎜ 2M + ⎜ 4 ⎝ 2 ) ⎞⎟ ⎟ ⎠ 2 + 3×T 2 22 Shaft design based on strength ASME design code (ductile material): τ allowable 16 = π d o3 (1 − c 4 ) ⎛ α Fa d o (1 + c ⎜ km M + ⎜ 8 ⎝ 2 ) ⎞⎟ ⎟ ⎠ 2 + ( kt T ) 2 where, km and kt are bending and torsion factors where accounts for shock and fatigue. The values of th these ffactors t are given i iin ASME d design i code d ffor shaft. Lecture1: Design of Shaft 23 Shaft design based on strength ASME design code (brittle material): σ allowable 2 ⎡ ⎛ ⎞ α F d 1 c + ) 16 a o ( ⎢⎜ k m M + ⎟ = 3 4 ⎟ 8 π d o (1 − c ) ⎢⎜⎝ ⎠ ⎣ ⎛ α Fa d o (1 + c + ⎜ km M + ⎜ 8 ⎝ Lecture1: Design of Shaft 2 ) ⎞⎟ ⎟ ⎠ 2 ⎤ 2 ⎥ + ( kt T ) ⎥ ⎥⎦ 24 Shaft design based on strength ASME design code: Combined shock and fatigue factors Stationary shaft Rotating shaft Type of load Gradualyy applied pp load km kt km kt 1 1 1.5 1 Suddenly applied load, minor shock 1.5-2 1.5-2 1.5-2 1-1.5 Suddenly applied load load, heavy shock --- 23 2-3 Lecture1: Design of Shaft --- 153 1.5-3 25 Shaft design based on strength ASME design d i code: d Commercial steel shafting τallowable = 55 MPa for shaft without keyway τallowable = 40 MPa for shaft with keyway y y Steel under definite specifications τallowable = 30% of the yield strength but not over 18% of the ultimate strength in tension for shafts without keyways. These values are to be reduced by 25% for the presence of keyways. Lecture1: Design of Shaft 26 Standard sizes of shafts Typical sizes of solid shaft that are available in the market are: diameter up to 25 mm 25 to t 50 mm 50 to 100 mm 100 to 200 mm Lecture1: Design of Shaft increments 0.5 mm 1 0 mm 1.0 2.0 mm 5.0 mm 27 Example: problem A pulley ll d drive i iis ttransmitting itti power tto a pinion, i i which in turn is transmitting power to some other machine element. element Pulley and pinion diameters are 400 mm and 200 mm respectively. Shaft has to be designed g for minor to heavyy shock. A C B D . m Lecture1: Design of Shaft m m 28 Example: solution Torsion: TD = 6000 x (Dpinion/2) = 6000 x (200/2) = 6x10e5 N.mm OR TC = (4000 -1000) x (Dpulley/2) = 3000 x (400/2) = 6x10e5 N.mm Lecture1: Design of Shaft 29 Example: solution B di ((vertical Bending ti l plane): l ) A 200 mm C RAV 400 mm D 200 mm B RBV 1000 N 6000 N RBV= (1000x200- 6000x(400+200))/(200+400+200) = -4250 N MDV= -4250x200 4250x200 = -8 8.5e5 5e5 N.mm N mm MCV= 6000x400 - 4250x600 = -1.5e5 N.mm Lecture1: Design of Shaft 30 Example: solution B di (h Bending (horizontal i t l plane): l ) A 200 mm C 400 mm D 200 mm RAH 5000 N 2200 N B RBH RBH = (5000x200 + 2200x(400+200))/(200+400+200) = 2900 N MDH = 2900x200 2900 200 = 5.8e5 5 8 5 N.mm N MCH = 2900x600 - 2200x400 = 8.6e5 N.mm Lecture1: Design of Shaft 31 Example: solution Bending di ((resultant): l ) MD = Similarly Similarly, ( M DV ) + ( M DH ) 2 2 = 10.29 × 105 N .mm MC = (1.5 × 10 ) + (8.6 × 10 ) 5 2 5 2 = 8.73 × 105 N .mm Since TC = TD and MD > MC, section-D is critical. Lecture1: Design of Shaft 32 Example: solution ASME S code: d Under minor to heavy shock, let us consider km= 2 and kt = 1.5. Also let us assume the shaft will be fabricated from commercial steel, i.e. τallowable = 40 Mpa. 16 5 2 5 2 d = 2 × 10.29 × 10 ) + (1.5 × 6 × 10 ) ( 40 × π d o = 65.88 65 88 mm 3 o The value of standard shaft diameter is 66 mm. Lecture1: Design of Shaft 33