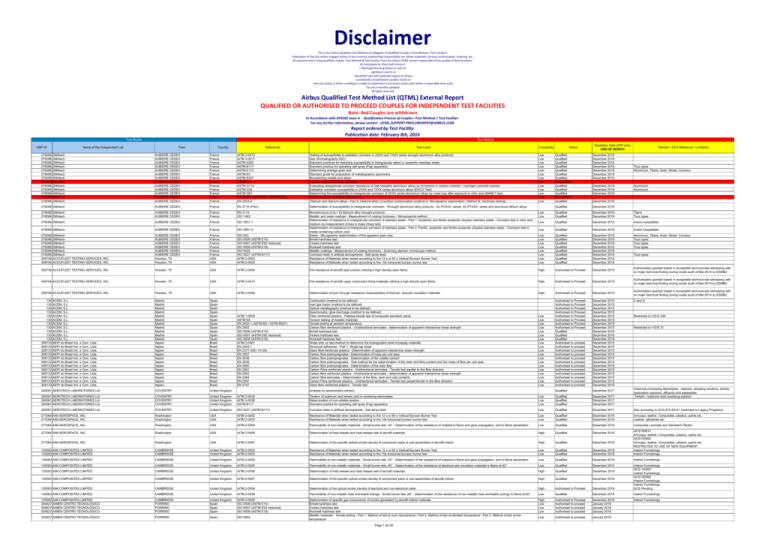

Disclaimer

This is the Airbus Qualified Test Method List (Register of Qualified Couples <Test Method / Test Facility>)

Publication of this list neither engages Airbus in any contract relationship/responsibility nor allows automatic contract authorization, ordering, etc.

All subcontractors using qualified couples 'Test Method & Test Facility' from the Airbus QTML remain responsible of the quality of their products.

As consequence, they shall conduct:

* Alerting/informing Airbus in case of:

- significant events or

- identified risks with potential impact on Airbus

- consistently unsatisfactory quality results or

- the test facility is either unwilling or unable to implement a corrective action plan within a reasonable time-scale

The list it monthly updated

All rights reserved

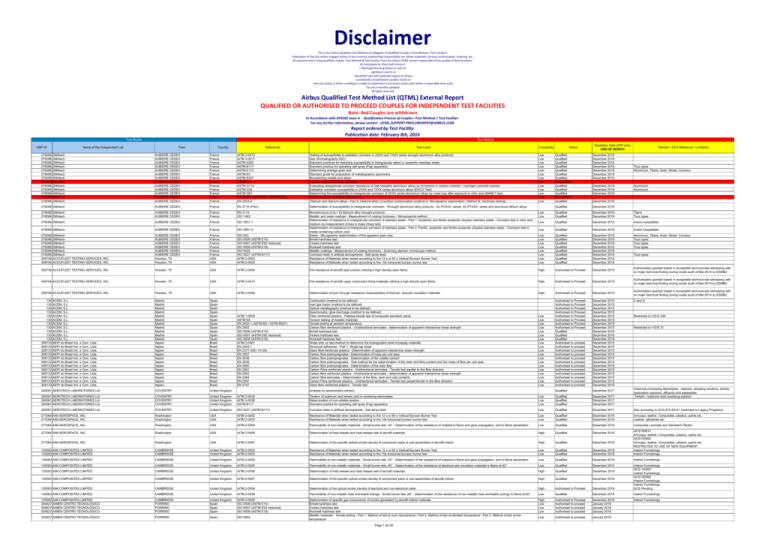

Airbus Qualified Test Method List (QTML) External Report

QUALIFIED OR AUTHORISED TO PROCEED COUPLES FOR INDEPENDENT TEST FACILITIES

Note: Red Couples are withdrawn

In Accordance with AP5262 Issue A - Qualification Process of Couples <Test Method / Test Facility>

For any further information, please contact : QTML.SUPPORT-PROCUREMENT@AIRBUS.COM

Report ordered by Test Facility

Publication date: February 8th, 2016

Test Facility

ARP-ID

276086

276086

276086

276086

276086

276086

276086

276086

276086

276086

276086

276086

276086

Test Method

Name of the Independent Lab

Town

Country

Referential

Test Label

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

France

France

France

France

France

France

France

France

France

France

France

France

France

AITM 3-0013

AITM 3-0017

ASTM A262

ASTM B117

ASTM E112

ASTM E3

ASTM E407

ASTM E8

ASTM G110

ASTM G34

ASTM G67

EN 2002-1 (ASTM E8 / ASTM B557)

EN 2003-9

Testing of susceptibility to exfolation corrosion in 2XXX and 7XXX series wrought aluminium alloy products

Gas chromatography (GC)

Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels

Standard practice for operating salt spray (Fog) apparatus

Determining average grain size

Standard guide for preparation of metallographic specimens

Microetching metals and alloys

Tension testing of metallic materials

Evaluating intergranular corrosion resistance of heat treatable aluminium alloys by immersion in sodium chloride + hydrogen peroxide solution

Exfoliation corrosion susceptibility in 2XXX and 7XXX series aluminum alloys (EXCO Test)

Determining the susceptibility to intergranular corrosion of 5XXX series aluminium alloys by mass loss after exposure to nitric acid (NAMLT test)

Tensile testing at ambient temperature

Titanium and titanium alloys - Part 9: Determination of surface contamination (method A: Micrographic examination / Method B: Hardness testing)

276086 2MAtech

AUBIERE CEDEX

France

EN 2716 (Pren)

Determination of susceptibility to intergranular corrosion - Wrought aluminium alloy products - AL-P2XXX- series, AL-P7XXX- series and aluminium-lithium alloys

276086 2MAtech

276086 2MAtech

AUBIERE CEDEX

AUBIERE CEDEX

France

France

EN 3114

ISO 1463

276086 2MAtech

AUBIERE CEDEX

France

ISO 3651-1

276086 2MAtech

AUBIERE CEDEX

France

ISO 3651-2

276086

276086

276086

276086

276086

276086

306756

306756

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

AUBIERE CEDEX

Houston, TX

Houston, TX

France

France

France

France

France

France

USA

USA

ISO 643

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

ISO 9220

ISO 9227 (ASTM B117)

AITM 2-0002

AITM 2-0003

Microstructure of (a + ß) titanium alloy wrought products

Metallic and oxide coatings - Measurement of coating thickness - Microscopical method

Determination of resistance to intergranular corrosion of stainless steels - Part 1: Austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in nitric acid

medium by measurement of loss in mass (Huey test)

Determination of resistance to intergranular corrosion of stainless steels - Part 2: Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in

media containing sulfuric acid

Steels - Micrographic determination of the apparent grain size

Brinell hardness test

Vickers hardness test

Rockwell hardness test

Metallic coatings - Measurement of coating thickness - Scanning electron microscope method

Corrosion tests in artificial atmospheres - Salt spray tests

Resistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner Test

Resistance of Materials when tested according to the 15s horizontal bunsen burner test

306756 ACCUFLEET TESTING SERVICES, INC.

Houston, TX

USA

AITM 2-0009

306756 ACCUFLEET TESTING SERVICES, INC.

Houston, TX

USA

306756 ACCUFLEET TESTING SERVICES, INC.

Houston, TX

USA

130

130

130

130

130

130

130

130

130

130

130

308133

308133

308133

308133

308133

308133

308133

308133

308133

308133

308133

308133

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Madrid

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Itapevi

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

Brasil

300081 AEROTECH LABORATORIES Ltd

COVENTRY

United Kingdom

300081 AEROTECH LABORATORIES Ltd

300081 AEROTECH LABORATORIES Ltd

300081 AEROTECH LABORATORIES Ltd

COVENTRY

COVENTRY

COVENTRY

United Kingdom

United Kingdom

United Kingdom

AITM 3-0030

AITM 3-0038

ASTM B117

Titration of sulphuric and tartaric acid in anodizing electrolytes

Determination of non-volatile-residue

Standard practice for operating salt spray (Fog) apparatus

300081 AEROTECH LABORATORIES Ltd

COVENTRY

United Kingdom

ISO 9227 (ASTM B117)

277064 AIM AEROSPACE, INC.

277064 AIM AEROSPACE, INC.

Washington

Washington

USA

USA

277064 AIM AEROSPACE, INC.

Washington

277064 AIM AEROSPACE, INC.

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

2MAtech

ACCUFLEET TESTING SERVICES, INC.

ACCUFLEET TESTING SERVICES, INC.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

ACEM, S.L.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

AEPI do Brasil Ind. e Com. Ltda.

Complexity

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Status

Expiration Date (ATP only)

END OF MONTH

Remark / QCS Reference / Limitation

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Disqualified

Qualified

Qualified

Qualified

Disqualified

Qualified

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

Qualified

December 2016

Low

Low

Qualified

Qualified

December 2016

December 2016

Titane

Tous types

Low

Qualified

December 2016

Aciers inoxydables

Low

Qualified

December 2016

Aciers inoxydables

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

Aluminium, Titane, Acier, Nickel, Cuivreux

Tous types

Tous types

Tous types

Fire resistance of aircraft seat cushion utilizing a high density open flame

High

Authorised to Proceed

December 2015

Authorisation granted based in acceptable technical test witnessing with

no major technical finding during onsite audit of Mar-2014 by ESMB2

AITM 2-0010

Fire resistance of aircraft cargo component lining materials utilizing a high density open flame

High

Authorised to Proceed

December 2015

Authorisation granted based in acceptable technical test witnessing with

no major technical finding during onsite audit of Mar-2014 by ESMB2

AITM 2-0056

Determination of burn through resistance characteristics of thermal / acoustic insulation materials

High

Authorised to Proceed

December 2015

Authorisation granted based in acceptable technical test witnessing with

no major technical finding during onsite audit of Mar-2014 by ESMB2

AITM 1-0025

ASTM E8

EN 2002-1 (ASTM E8 / ASTM B557)

EN 2563

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

AITM 2-0061

EN 2243-1

EN 2377 (ISO 14130)

EN 2557

EN 2558

EN 2559

EN 2560

EN 2561

EN 2563

EN 2564

EN 2597

EN 2747

Combustion (method to be defined)

Inert gas fusion (method to be defined)

Optical metallography (method to be defined)

Spectrometry: glow discharge (method to be defined)

Fiber reinforced plastics - Flatwise tensile test of composite sandwich panel

Tension testing of metallic materials

Tensile testing at ambient temperature

Carbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strength

Brinell hardness test

Vickers hardness test

Rockwell hardness test

Water pick up test-method to determine the impregnation level of prepeg materials

Structural adhesives - Part 1: Single lap shear

Glass fibre reinforced plastics - Determination of apparent interlaminar shear strength

Carbon fibre preimpregnates - Determination of mass per unit area

Carbon fibre preimpregnates - Determination of the volatile content

Carbon fibre preimpregnates - Test method for the determination of the resin and fibre content and the mass of fibre per unit area

Carbon fibre preimpregnates - Determination of the resin flow

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strength

Carbon fibre laminates - Determination of the fibre, resin and void contents

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test perpendicular to the fibre direction

Glass fibre reinforced plastics - Tensile test

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Qualified

Qualified

Qualified

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2016

December 2016

December 2016

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

December 2015

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

Aluminium

Aluminium

December 2016

Tous types

C and S

Restricted to I+D-E 246

Restricted to I+D-E 31

Chemical processing electrolytes, cleaners, stripping solutions, etches,

passivation solutions, effluents and wastewater.

Tartaric / sulphuric acid anodising solution

Qualified

December 2017

Low

Low

Low

Qualified

Qualified

Qualified

December 2017

December 2017

December 2017

Corrosion tests in artificial atmospheres - Salt spray tests

Low

Qualified

December 2017

Also according to QVA-Z10-59-01 (restricted to Legacy Programs)

AITM 2-0002

AITM 2-0003

Resistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner Test

Resistance of Materials when tested according to the 15s horizontal bunsen burner test

Low

Low

Qualified

Qualified

December 2016

December 2016

Armcaps, leather, Composites, plastics, paints etc.

Leather, adhesives etc

USA

AITM 2-0004

Flammability of non-metallic materials - Small burner test, 45° - Determination of the resistance of material to flame and glow propagation, and to flame penetration

Low

Qualified

December 2016

Composite Laminate and Sandwich Panels

Washington

USA

AITM 2-0006

Determination of heat release and heat release rate of aircraft materials

High

Qualified

December 2016

277064 AIM AEROSPACE, INC.

Washington

USA

AITM 2-0007

Determination of the specific optical smoke density of component parts or sub-assemblies of aircraft interior

High

Qualified

December 2016

135583 AIM COMPOSITES LIMITED

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

CAMBRIDGE

United Kingdom

United Kingdom

AITM 2-0002

AITM 2-0003

Resistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner Test

Resistance of Materials when tested according to the 15s horizontal bunsen burner test

Low

Low

Qualified

Qualified

December 2016

December 2016

QCS150910

Armcaps, leather, Composites, plastics, paints etc.

QCS150969

Armcaps, leather, Composites, plastics, paints etc.

RESTRICTED TO USE OF NEW EQUIPMENT

Interior Furnishings

Interior Furnishings

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0004

Flammability of non-metallic materials - Small burner test, 45° - Determination of the resistance of material to flame and glow propagation, and to flame penetration

Low

Qualified

December 2016

Interior Furnishings

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0005

Flammability of non-metallic materials - Small burner test, 60° - Determination of the resistance of electrical wire insulation materials to flame at 60°

Low

Qualified

December 2016

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0006

Determination of heat release and heat release rate of aircraft materials

High

Qualified

December 2016

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0007

Determination of the specific optical smoke density of component parts or sub-assemblies of aircraft interior

High

Qualified

December 2016

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0008

Determination of the optical smoke density of electrical and non-electrical cable

High

Authorised to Proceed

December 2016

Interior Furnishings

QCS 150891

Interior Furnishings

QCS150968

Interior Furnishings

Interior Furnishings

QCS Pending

135583 AIM COMPOSITES LIMITED

CAMBRIDGE

United Kingdom

AITM 2-0038

Flammability of non-metallic heat shrinkable tubings - Small burner test, 60° - Determination of the resistance of non-metallic heat shrinkable tubings to flame at 60°

Low

Qualified

December 2016

Interior Furnishings

135583

304627

304627

304627

CAMBRIDGE

PORRINO

PORRINO

PORRINO

United Kingdom

Spain

Spain

Spain

AITM 3-0005

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

High

Low

Low

Low

Authorised

Authorised

Authorised

Authorised

December 2016

January 2016

January 2016

January 2016

Interior Furnishings

PORRINO

Spain

ISO 6892

Determination of specific gas components of smoke generated by aircraft interior materials

Brinell hardness test

Vickers hardness test

Rockwell hardness test

Metallic materials - Tensile testing - Part 1: Method of test at room temperature / Part 2: Method of test at elevated temperature / Part 3: Method of test at low

temperature

Low

Authorised to proceed

AIM COMPOSITES LIMITED

AIMEN CENTRO TECNOLÓGICO

AIMEN CENTRO TECNOLÓGICO

AIMEN CENTRO TECNOLÓGICO

304627 AIMEN CENTRO TECNOLÓGICO

Analysis by spectrometry (others)

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

December 2016

December 2016

December 2016

Tous types

Aluminium, Titane, Acier, Nickel, Cuivreux

Page 1 de 28

to Proceed

to proceed

to proceed

to proceed

January 2016

Airbus Qualified Test Method List (QTML) External Report

QUALIFIED OR AUTHORISED TO PROCEED COUPLES FOR INDEPENDENT TEST FACILITIES

Note: Red Couples are withdrawn

In Accordance with AP5262 Issue A - Qualification Process of Couples <Test Method / Test Facility>

For any further information, please contact : QTML.SUPPORT-PROCUREMENT@AIRBUS.COM

Report ordered by Test Facility

Publication date: February 8th, 2016

Test Facility

ARP-ID

Test Method

Name of the Independent Lab

Town

Country

Referential

Test Label

Complexity

Status

Expiration Date (ATP only)

END OF MONTH

146561 AIRBUS MILITARY SL

146561 AIRBUS MILITARY SL

GETAFE

GETAFE

Spain

Spain

AITM 2-0002

AITM 2-0003

Resistance of Materials when tested according to the 12 s or 60 s Vertical Bunsen Burner Test

Resistance of Materials when tested according to the 15s horizontal bunsen burner test

Low

Low

Qualified

Qualified

December 2017

December 2017

146561 AIRBUS MILITARY SL

GETAFE

Spain

AITM 2-0004

Flammability of non-metallic materials - Small burner test, 45° - Determination of the resistance of material to flame and glow propagation, and to flame penetration

Low

Qualified

December 2017

146561 AIRBUS MILITARY SL

146561 AIRBUS MILITARY SL

GETAFE

GETAFE

Spain

Spain

AITM 2-0005

AITM 2-0010

Flammability of non-metallic materials - Small burner test, 60° - Determination of the resistance of electrical wire insulation materials to flame at 60°

Fire resistance of aircraft cargo component lining materials utilizing a high density open flame

Low

High

Qualified

Qualified

December 2017

December 2017

146561 AIRBUS MILITARY SL

GETAFE

Spain

AITM 2-0038

Flammability of non-metallic heat shrinkable tubings - Small burner test, 60° - Determination of the resistance of non-metallic heat shrinkable tubings to flame at 60°

Low

Qualified

December 2017

146561

304742

304742

304742

304742

304742

304742

304742

AIRBUS MILITARY SL

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

ALS CZECH REPUBLIC, S.R.O.

GETAFE

Ceská Lípa

Ceská Lípa

Ceská Lípa

Ceská Lípa

Ceská Lípa

Ceská Lípa

Ceská Lípa

Spain

Czech

Czech

Czech

Czech

Czech

Czech

Czech

ISO 2685

AITM 1-0024

AITM 3-0029

AITM 3-0032

AITM 3-0034

AITM 3-0035

AITM 3-0036

AITM 3-0038

Aircraft – Environmental test procedure for airborne equipment – Resistance to fire in designated fire zones

Determination of the completeness of cure of organic coatings

Determination of iron (III) as reactive compound in acidic surface treatment baths

Analysis of metals in galvanic bathes by ICP-spectroscopy

Combined determination of free hydroxide and aluminium in alkaline surface treatment baths

Determination of chloride contaminations in surface treatment baths

Determination of hydrogen ions in surface treatment baths

Determination of non-volatile-residue

High

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Authorised to Proceed

Qualified

Authorised to Proceed

Qualified

Qualified

December 2017

December 2017

December 2017

December 2016

December 2017

December 2016

December 2017

December 2017

304742 ALS CZECH REPUBLIC, S.R.O.

Ceská Lípa

Czech Republic

ISO 2143

Anodizing of aluminium and its alloys - Estimation of loss of absorptive power of anodic oxidation coatings after sealing - Dye-spot test with prior acid treatment

Low

Qualified

December 2017

303102 AMPP SERVICES LTD

Huntingdon

United Kingdom

Qualified

December 2016

303102

303102

303102

303102

303102

303102

303102

303102

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

Huntingdon

Huntingdon

Huntingdon

Huntingdon

Huntingdon

Huntingdon

Huntingdon

Huntingdon

United

United

United

United

United

United

United

United

303102 AMPP SERVICES LTD

Huntingdon

303102

303102

303102

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

298894

Republic

Republic

Republic

Republic

Republic

Republic

Republic

AITM 4-0002

ASTM A262

ASTM A604 (EN 2003-7)

ASTM E112

ASTM E3

ASTM E340

ASTM E407

EN 10247 (ISO 4967)

Microstructural characterization of welded aluminium structures

Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels

Macroetch testing of consumable electrode remelted steel bars and billets

Determining average grain size

Standard guide for preparation of metallographic specimens

Macroetching metals and alloys

Microetching metals and alloys

Micrographic examination of the non-metallic inclusion content of steels using standard pictures

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

United Kingdom

EN 2003-9

Titanium and titanium alloys - Part 9: Determination of surface contamination (method A: Micrographic examination / Method B: Hardness testing)

Low

Qualified

December 2016

Huntingdon

Huntingdon

Huntingdon

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

United Kingdom

United Kingdom

United Kingdom

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

USA

EN 3114

EN 3684

QVA-Z10-53-00

AITM 3-0029

AITM 3-0030

AITM 3-0032

AITM 3-0034

AITM 3-0035

AITM 3-0036

ASTM B117

ASTM D1125

ASTM D1876

ASTM D2240

ASTM D3359

ASTM E1135

ASTM E1447

ASTM E384

ASTM G85

ISO 1518

ISO 1519

ISO 2178

Microstructure of (a + ß) titanium alloy wrought products

Titanium alloy wrought products - Determination of ß transus temperature - Metallographic method

Metallographic test - Macroscopic examination - General information

Determination of iron (III) as reactive compound in acidic surface treatment baths

Titration of sulphuric and tartaric acid in anodizing electrolytes

Analysis of metals in galvanic bathes by ICP-spectroscopy

Combined determination of free hydroxide and aluminium in alkaline surface treatment baths

Determination of chloride contaminations in surface treatment baths

Determination of hydrogen ions in surface treatment baths

Standard practice for operating salt spray (Fog) apparatus

Standard Test Methods for Electrical Conductivity and Resistivity of Water

Peel resistance of adhesives (T-Peel test)

Rubber property - Durometer hardness

Measuring adhesion by tape test

Standard Test method for Comparing the Brightness of fluorescent Penetrants

Determination of hydrogen in titanium and titanium alloys by inert gas fusion thermal conductivity / infrared detection method

Microindentation hardness of materials

Modified salt spray (fog) testing

Paints and varnishes - Scratch test

Paints and varnishes - Bend test (cylindrical mandrel)

Non-magnetic coatings on magnetic substrates - Measurement of coating thickness - Magnetic method

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

298894 ANACHEM LABS

El Segundo

USA

ISO 2360

Non-conductive coatings on non-magnetic electrically conductive basis materials - Measurement of coating thickness - Amplitude-sensitive eddy current method

Low

Authorised to Proceed

December 2016

298894

298894

298894

298894

298894

298894

298894

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

El Segundo

USA

USA

USA

USA

USA

USA

USA

ISO 2409

ISO 2808

ISO 2812-1

ISO 2812-2

ISO 3696

ISO 4287

ISO 4288

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

December 2016

298894 ANACHEM LABS

El Segundo

USA

ISO 4628-2

Low

Qualified

December 2016

298894

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

124

ANACHEM LABS

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

El Segundo

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

PUDONG DISTRICT, SHANGHAI

USA

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

China

ISO 9227 (ASTM B117)

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

Authorised

December 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

March 2016

124 APPLUS (SHANGHAI) QUALITY INSPECTION CO., LTD

PUDONG DISTRICT, SHANGHAI

China

ISO 6892

Low

Authorised to proceed

March 2016

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

AITM 1-0002 (ISO 14129)

AITM 1-0007-A / B / C / D

AITM 1-0008-A3

AITM 1-0008-B / C / D

AITM 1-0009-1 / 2

AITM 1-0010 (EN 6038)

AITM 1-0018

AITM 1-0019

AITM 1-0025

AITM 1-0029

Paints and varnishes - Cross-cut test

Paints and varnishes - Determination of film thickness

Paints and varnishes - Determination of resistance to liquids - Part 1: Immersion in liquids other than water

Paints and varnishes - Determination of resistance to liquids - Part 2: Water immersion method

Water for analytical laboratory use - Specification and test methods

Geometrical product specifications (GPS) - Surface texture: Profile method - Terms, definitions and surface texture parameters

Geometrical product specifications (GPS) - Surface texture: Profile method - Rules and procedures for the assessment of surface texture

Paints and varnishes - Evaluation of degradation of coatings - Designation of quantity and size of defects, and of intensity of uniform changes in appearance - Part 2:

Assessment of degree of blistering

Corrosion tests in artificial atmospheres - Salt spray tests

Composite specimen machining / cutting / tabbing

Composite specimen production

Metallic specimen preparation (for mechanical testing) (method to be defined)

Fibre reinforced plastics - Determination of in-plane shear properties (±45° tensile test)

Determination of tensile lap shear strength of composite joints

Tensile properties of plastics

Flexural properties of unreinforced and reinforced plastics and electrical insulating materials

Determining average grain size

Tension testing of metallic materials

Tensile testing at ambient temperature

Structural adhesives - Part 1: Single lap shear

Glass fibre reinforced plastics - Determination of apparent interlaminar shear strength

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - Flexural test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strength

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test perpendicular to the fibre direction

Glass fibre reinforced plastics - Tensile test

Carbon fibre thermosetting resin unidirectional laminates - Compression test parallel to fibre direction - Method B

Brinell hardness test

Vickers hardness test

Rockwell hardness test

Metallic materials - Tensile testing - Part 1: Method of test at room temperature / Part 2: Method of test at elevated temperature / Part 3: Method of test at low

temperature

FPQ Mechanical Tests for Duqueine Window Frames on A350 XWB

Fibre reinforced plastics - Determination of in-plane shear properties (±45° tensile test)

Fibre reinforced plastics - Determination of plain, open hole and filled hole tensile strength

Fiber reinforced plastics - Determination of plain compression strength (loads < 500 kN)

Fiber reinforced plastics - Determination of open hole or filled hole compression strength

Fibre reinforced plastics - Determination of bearing strength by either pin or bolt bearing configuration

Fibre reinforced plastics - Determination of compression strength after impact

Fibre reinforced plastics - Sandwich flexural test - Four-point bending

Determination of tensile lap shear strength of composite joints

Fiber reinforced plastics - Flatwise tensile test of composite sandwich panel

Fibre reinforced plastics - Determination of tensile strength of a tapered or stepped joint

Low

Low

High

Low

High

High

Low

Low

Low

Low

Qualified

Qualified

Qualified

Authorised to Proceed

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

286347 APPLUS BARCELONA (LGAI)

BELLATERRA

Spain

AITM 1-0042 (ASTM E647)

Determination of fatigue crack growth rates for aluminium clad sheet and clad plate up to 12 mm in constant-load-amplitude tests - K-increasing method

High

Authorised to Proceed

December 2017

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

AITM 1-0047

AITM 1-0048

AITM 1-0049

AITM 1-0050-A / B

AITM 1-0058

AITM 1-0059

AITM 1-0064

AITM 1-0065

AITM 1-0066

AITM 1-0067

AITM 4-0002

AITM 4-0005

ASTM A604 (EN 2003-7)

ASTM B117

ASTM B769

Determination of apparent interlaminar shear strength of fibre metal laminates (Glare materials)

Compression test method of fibre metal laminates (Glare materials)

Tensile test method of fibre metal laminates (Glare materials)

Test method for the determination of blunt notch open and filled hole tensile strength of fibre metal laminates (Glare materials)

Mobile hardness testing

In-plane-shear test on fibre metal laminates (Glare material)

Butt welding of aluminium alloys - Bend test

Fiber reinforced plastics - Determination of joint strength of mechanically fastened joints

Fibre reinforced plastics – Determination of pull-out / pull-through strength on riveted joints

Determination of tension through the hole strength on fastened joints

Microstructural characterization of welded aluminium structures

Macroscopic and microscopic examination of fiber reinforced plastics

Macroetch testing of consumable electrode remelted steel bars and billets

Standard practice for operating salt spray (Fog) apparatus

Shear testing of aluminium alloys

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

AMPP SERVICES LTD

AMPP SERVICES LTD

AMPP SERVICES LTD

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

ANACHEM LABS

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

Kingdom

Kingdom

Kingdom

Kingdom

Kingdom

Kingdom

Kingdom

Kingdom

Optical metallography (method to be defined)

AITM 1-0002 (ISO 14129)

AITM 1-0019

ASTM D638

ASTM D790

ASTM E112

ASTM E8

EN 2002-1 (ASTM E8 / ASTM B557)

EN 2243-1

EN 2377 (ISO 14130)

EN 2561

EN 2562

EN 2563

EN 2597

EN 2747

EN 2850-B (Pren) (ISO 14126-2)

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

Page 2 de 28

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

to proceed

Remark / QCS Reference / Limitation

Waiting deviation form answer from engineering

All materials

Weld examinations as per ABP Specifications and BS ISO 24394

Aluminium welds

Austenitic stainless steel

Steel bars and billets

All

All

All

All

All

Titanium

Method A only

All

All

All

2016 AGS PTP mandatory

Pending QCS

QCS 141174

QCS 131074

only for CT specimens

Airbus Qualified Test Method List (QTML) External Report

QUALIFIED OR AUTHORISED TO PROCEED COUPLES FOR INDEPENDENT TEST FACILITIES

Note: Red Couples are withdrawn

In Accordance with AP5262 Issue A - Qualification Process of Couples <Test Method / Test Facility>

For any further information, please contact : QTML.SUPPORT-PROCUREMENT@AIRBUS.COM

Report ordered by Test Facility

Publication date: February 8th, 2016

Test Facility

ARP-ID

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

Test Method

Name of the Independent Lab

Town

Country

Referential

Test Label

Complexity

Status

Expiration Date (ATP only)

END OF MONTH

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

ASTM C273

ASTM C365

ASTM D1876

ASTM E111

ASTM E112

ASTM E340

ASTM E384

ASTM E399

ASTM E407

ASTM E407

ASTM E45

ASTM E647

ASTM E9

ASTM G110

ASTM G112

ASTM G34

ASTM G66

ASTM G67

ASTM G85

EN 2002-1 (ASTM E8 / ASTM B557)

EN 2002-2

EN 2002-6

EN 2003-9

EN 2243-1

EN 2243-2

EN 2243-3

EN 2243-4

EN 2377 (ISO 14130)

EN 2378

EN 2559

EN 2561

EN 2562

EN 2563

EN 2564

EN 2667-1 (PRen)

EN 2667-2 (PRen)

EN 2746

EN 2747

EN 2831

EN 2832 (ASTM F519)

EN 2850-B (Pren) (ISO 14126-2)

EN 3114

EN 3114

EN 3615

EN 3683

EN 3684

EN 6018

EN 6072 (ASTM E466)

Shear properties of sandwich core materials

Flatwise compressive properties of sandwich cores

Peel resistance of adhesives (T-Peel test)

Young’s modulus, tangent modulus, and chord modulus

Determining average grain size

Macroetching metals and alloys

Microindentation hardness of materials

Linear-elastic plane-strain fracture toughness KIc of metallic materials

Microetching metals and alloys

Microetching metals and alloys

Determining the inclusion content of steel

Measurement of fatigue crack growth rates (da/dn)

Compression testing of metallic materials at room temperature

Evaluating intergranular corrosion resistance of heat treatable aluminium alloys by immersion in sodium chloride + hydrogen peroxide solution

Standard guide for conducting exfoliation corrosion tests in aluminium alloys

Exfoliation corrosion susceptibility in 2XXX and 7XXX series aluminum alloys (EXCO Test)

Visual assessment of exfoliation corrosion susceptibility of 5XXX series aluminium alloys (ASSET test)

Determining the susceptibility to intergranular corrosion of 5XXX series aluminium alloys by mass loss after exposure to nitric acid (NAMLT test)

Modified salt spray (fog) testing

Tensile testing at ambient temperature

Tensile testing at elevated temperature

Metallic materials: Bend testing

Titanium and titanium alloys - Part 9: Determination of surface contamination (method A: Micrographic examination / Method B: Hardness testing)

Structural adhesives - Part 1: Single lap shear

Structural adhesives - Part 2: Peel metal-metal

Structural adhesives - Part 3: Peeling test metal-honeycomb core

Structural adhesives - Part 4: Metal-honeycomb core flatwise tensile test

Glass fibre reinforced plastics - Determination of apparent interlaminar shear strength

Fibre reinforced plastics - Determination of water absorption by immersion

Carbon fibre preimpregnates - Test method for the determination of the resin and fibre content and the mass of fibre per unit area

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - Flexural test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strength

Carbon fibre laminates - Determination of the fibre, resin and void contents

Foaming structural adhesives - Part 1: Tensile single-lap shear

Foaming structural adhesives - Part 2: Compressive tube shear

Glass fibre reinforced plastics - Flexural test - Three point bend method

Glass fibre reinforced plastics - Tensile test

Hydrogen embrittlement of steel - Test by slow bending

Hydrogen embrittlement of steel - Notched specimen test

Carbon fibre thermosetting resin unidirectional laminates - Compression test parallel to fibre direction - Method B

Microstructure of (a + ß) titanium alloy wrought products

Microstructure of (a + ß) titanium alloy wrought products

Fibre reinforced plastics - Determination of the conditions of exposure to humid atmosphere and of moisture absorption

Titanium alloy wrought products - Determination of primary a content - Point count method and line intercept method

Titanium alloy wrought products - Determination of ß transus temperature - Metallographic method

Determination of density according to displacement method

Constant amplitude fatigue testing (HCF)

Low

Low

Low

High

Low

Low

Low

High

Low

Low

Low

High

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

High

Qualified

Qualified

Qualified

Authorised

Authorised

Qualified

Qualified

Authorised

Qualified

Qualified

Qualified

Authorised

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Authorised

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Authorised

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Authorised

Authorised

Qualified

Authorised

Qualified

Qualified

Authorised

286347 APPLUS BARCELONA (LGAI)

BELLATERRA

Spain

ISO 1172

Textiles - Glass reinforced plastics - Prepregs, moulding compounds and laminates - Determination of the textile-glass and mineral-filler content - Calcination method

Low

Qualified

December 2017

286347

286347

286347

286347

286347

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

Spain

Spain

Spain

Spain

Spain

ISO 1463

ISO 148-1 (ASTM E23)

ISO 148-1 (ASTM E23)

ISO 1519

ISO 2178

Metallic and oxide coatings - Measurement of coating thickness - Microscopical method

Charpy pendulum impact test (ambient temperature)

Charpy pendulum impact test (low temperature)

Paints and varnishes - Bend test (cylindrical mandrel)

Non-magnetic coatings on magnetic substrates - Measurement of coating thickness - Magnetic method

Low

Low

Low

Low

Low

Qualified

Disqualified

Qualified

Qualified

Qualified

December 2017

286347 APPLUS BARCELONA (LGAI)

BELLATERRA

Spain

ISO 2360

Non-conductive coatings on non-magnetic electrically conductive basis materials - Measurement of coating thickness - Amplitude-sensitive eddy current method

Low

Qualified

December 2017

286347 APPLUS BARCELONA (LGAI)

BELLATERRA

Spain

ISO 3651-1

Low

Qualified

December 2017

286347 APPLUS BARCELONA (LGAI)

BELLATERRA

Spain

ISO 3651-2

Low

Qualified

December 2017

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

286347

306790

306790

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

BELLATERRA

ILLESCAS

ILLESCAS

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

ISO 3887

ISO 4516

ISO 4624

ISO 527-5

ISO 6270-1

ISO 643

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

ISO 9227 (ASTM B117)

NASM 1312-04

NASM 1312-05

NASM 1312-08

NASM 1312-09

NASM 1312-10

NASM 1312-13

NASM 1312-14

NASM 1312-17

NASM 1312-18

NASM 1312-20

NASM 1312-23

NASM 1312-26

NASM 1312-28

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Qualified

Qualified

Qualified

Qualified

Qualified

Authorised to Proceed

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

December 2017

December 2017

December 2017

December 2017

December 2017

December 2016

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS BARCELONA (LGAI)

APPLUS ILLESCAS

APPLUS ILLESCAS

Determination of resistance to intergranular corrosion of stainless steels - Part 1: Austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in nitric acid

medium by measurement of loss in mass (Huey test)

Determination of resistance to intergranular corrosion of stainless steels - Part 2: Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels - Corrosion test in

media containing sulfuric acid

Steels - Determination of depth of decarburization

Metallic and other inorganic coatings - Vickers and Knoop microhardness tests

Paints and varnishes - Pull-off test for adhesion

Determination of tensile properties - Part 5: Test conditions for unidirectional fibre-reinforced plastic composites

Paints and varnishes - Determination of resistance to humidity - Part 1: Continuous condensation

Steels - Micrographic determination of the apparent grain size

Brinell hardness test

Vickers hardness test

Rockwell hardness test

Corrosion tests in artificial atmospheres - Salt spray tests

Fastener test methods - Method 4: Lap joint shear

Fastener test methods - Method 5: Stress durability

Fastener test methods - Method 8: Tensile strength

Fastener test methods - Method 9: Stress corrosion

Fastener test methods - Method 10: Stress rupture

Fastener test methods - Method 13: Double shear test

Fastener test methods - Method 14: Stress durability (internally threaded fasteners)

Fastener test methods - Method 17: Stress relaxation

Fastener test methods - Method 18: Elevated temperature tensile strength

Fastener test methods - Method 20: Single shear

Fastener test methods - Method 23: Tensile strength of panel fasteners

Fastener test methods - Method 26: Structural panel fastener lap joint shear

Fastener test methods - Method 28: Elevated temperature double shear

Composite specimen machining / cutting / tabbing

Composite specimen production

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

to Proceed

December 2017

December 2017

December 2017

December 2017

December 2016

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2016

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2016

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2017

December 2016

December 2016

December 2017

December 2016

December 2017

December 2017

December 2017

ILLESCAS

Spain

AIPS/AIPI 03-02-019

Manufacture of monolithic parts with thermoset prepreg materials

High

Authorised to Proceed

December 2016

306790 APPLUS ILLESCAS

ILLESCAS

Spain

AIPS/AIPI 06-01-004

Mechanical surface preparation of non-structural adherend prior to adhesive bonding

Low

Authorised to Proceed

December 2016

306790 APPLUS ILLESCAS

ILLESCAS

Spain

AIPS/AIPI 06-02-002

Non-structural adhesive bonding

Low

Authorised to Proceed

December 2016

306790 APPLUS ILLESCAS

306790 APPLUS ILLESCAS

306790 APPLUS ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

Spain

Spain

Spain

AITM 1-0003

AITM 1-0005 (EN 6033)

AITM 1-0007-A / B / C / D

Determination of the glass transition temperatures (DMA)

Fibre reinforced plastics - Determination of interlaminar fracture toughness energy - Mode I - G1c

Fibre reinforced plastics - Determination of plain, open hole and filled hole tensile strength

High

High

Low

Qualified

Qualified

Qualified

December 2017

December 2017

December 2017

306790 APPLUS ILLESCAS

ILLESCAS

Spain

AITM 1-0008-A1 (<200kN) / A2

Fiber reinforced plastics - Determination of plain compression strength

High

Qualified

December 2017

306790

306790

306790

306790

306790

306790

306790

306790

306790

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

AITM 1-0008-B / C / D

AITM 1-0019

AITM 1-0025

AITM 1-0053

AITM 2-0061

AITM 3-0002

AITM 3-0008 (EN 6064)

AITM 3-0027

EN 2243-1

Fiber reinforced plastics - Determination of open hole or filled hole compression strength

Determination of tensile lap shear strength of composite joints

Fiber reinforced plastics - Flatwise tensile test of composite sandwich panel

Carbon fibre reinforced plastics - Determination of fracture toughness energy of bonded joints - Mode I - G1c

Water pick up test-method to determine the impregnation level of prepeg materials

Analysis of non metallic material (uncured) by differential scanning calorimetry (DSC)

Determination of the extent of cure by differential scanning calorimetry (DSC)

Determination of the melting behaviour and the extent of cristallinity of semi-cristalline materials by differential scanning calorimetry (DSC)

Structural adhesives - Part 1: Single lap shear

Low

Low

Low

High

Low

High

High

High

Low

Qualified

Qualified

Authorised

Qualified

Qualified

Authorised

Authorised

Authorised

Qualified

December 2017

December 2017

December 2016

December 2017

December 2017

December 2016

December 2016

December 2016

December 2017

Page 3 de 28

to Proceed

to Proceed

to Proceed

to Proceed

Pending QCS

Pending QCS

Also according to Legacy standard I+D-E-352

QCS Pending

December 2017

December 2017

December 2017

306790 APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

Remark / QCS Reference / Limitation

LIMITED TO TEST SPECIMEN MANUFACTURING.

Authorisation to proceed based on technical assessment.

ME1325431 granted by Nicolas LARROSE.

Pending participation in qualification campaign.

LIMITED TO TEST SPECIMEN MANUFACTURING.

Authorisation to proceed based on technical assessment.

M1325431 granted by Nicolas LARROSE.

Pending participation in qualification campaign.

LIMITED TO TEST SPECIMEN MANUFACTURING.

Authorisation to proceed based on technical assessment.

M1325431 granted by Nicolas LARROSE.

Pending participation in qualification campaign.

QCS 131027

QCS 120305

QCS126574 (A1) and QCS126563 (A2), for use of HCCF ONLY. /

QCS151573 (A) restricted to i. Determination of plain modulus ONLY and

ii. Use of hydraulic grips. Determination of plain strength is not allowed.

QCS 120321 / Polymers, plastics

QCS Pending

QCS Pending

QCS Pending

Airbus Qualified Test Method List (QTML) External Report

QUALIFIED OR AUTHORISED TO PROCEED COUPLES FOR INDEPENDENT TEST FACILITIES

Note: Red Couples are withdrawn

In Accordance with AP5262 Issue A - Qualification Process of Couples <Test Method / Test Facility>

For any further information, please contact : QTML.SUPPORT-PROCUREMENT@AIRBUS.COM

Report ordered by Test Facility

Publication date: February 8th, 2016

Test Facility

ARP-ID

306790

306790

306790

306790

306790

306790

306790

306790

306790

306790

306790

306790

306790

143041

143041

143041

143041

143041

143041

Test Method

Name of the Independent Lab

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS ILLESCAS

APPLUS+ BKWerkstofftechnik GMBH

APPLUS+ BKWerkstofftechnik GMBH

APPLUS+ BKWerkstofftechnik GMBH

APPLUS+ BKWerkstofftechnik GMBH

APPLUS+ BKWerkstofftechnik GMBH

APPLUS+ BKWerkstofftechnik GMBH

Town

Country

Referential

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

ILLESCAS

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Spain

Germany

Germany

Germany

Germany

Germany

Germany

EN 2243-3

EN 2377 (ISO 14130)

EN 2557

EN 2558

EN 2559

EN 2560

EN 2561

EN 2562

EN 2563

EN 2564

EN 2597

EN 2747

EN 2850-B (Pren) (ISO 14126-2)

143041 APPLUS+ BKWerkstofftechnik GMBH

BREMEN

143041 APPLUS+ BKWerkstofftechnik GMBH

143041 APPLUS+ BKWerkstofftechnik GMBH

Test Label

Complexity

Status

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

Low

AITM 1-0001

AITM 1-0002 (ISO 14129)

AITM 1-0003

Structural adhesives - Part 3: Peeling test metal-honeycomb core

Glass fibre reinforced plastics - Determination of apparent interlaminar shear strength

Carbon fibre preimpregnates - Determination of mass per unit area

Carbon fibre preimpregnates - Determination of the volatile content

Carbon fibre preimpregnates - Test method for the determination of the resin and fibre content and the mass of fibre per unit area

Carbon fibre preimpregnates - Determination of the resin flow

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - Flexural test parallel to the fibre direction

Carbon fibre reinforced plastics - Unidirectional laminates - determination of apparent interlaminar shear strength

Carbon fibre laminates - Determination of the fibre, resin and void contents

Carbon Fibre reinforced plastics - Unidirectional laminates - Tensile test perpendicular to the fibre direction

Glass fibre reinforced plastics - Tensile test

Carbon fibre thermosetting resin unidirectional laminates - Compression test parallel to fibre direction - Method B

Metallic specimen preparation (for mechanical testing) (method to be defined)

Optical metallography (method to be defined)

Spectrometry: optical emission (OES) (method to be defined)

Fiber reinforced plastics - Determination of mechanical degradation due to chemical paint strippers

Fibre reinforced plastics - Determination of in-plane shear properties (±45° tensile test)

Determination of the glass transition temperatures (DMA)

Low

Low

High

Authorised

Qualified

Qualified

Qualified

Qualified

Qualified

Qualified

Authorised

Qualified

Qualified

Qualified

Qualified

Authorised

Qualified

Qualified

Authorised

Qualified

Qualified

Authorised

Germany

AITM 1-0005 (EN 6033)

Fibre reinforced plastics - Determination of interlaminar fracture toughness energy - Mode I - G1c

High

Qualified

December 2017

BREMEN

BREMEN

Germany

Germany

AITM 1-0006 (EN 6034)

AITM 1-0007-A / B / C / D

Fibre reinforced plastics - Determination of interlaminar fracture toughness energy - Mode II - GIIc

Fibre reinforced plastics - Determination of plain, open hole and filled hole tensile strength

High

Low

Qualified

Qualified

December 2017

December 2017

143041 APPLUS+ BKWerkstofftechnik GMBH

BREMEN

Germany

AITM 1-0008-A1 (<200kN) / A2

Fiber reinforced plastics - Determination of plain compression strength

High

Qualified

December 2017

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

143041

265473

265473

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

BREMEN

ALBANY

ALBANY

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

Germany

USA

USA

AITM 1-0008-B / C / D

AITM 1-0009-1 / 2

AITM 1-0010 (EN 6038)

AITM 1-0018

AITM 1-0019

AITM 1-0029

AITM 1-0048

AITM 1-0049

AITM 1-0050-A / B

AITM 1-0051

AITM 1-0053

AITM 1-0060

AITM 1-0065

AITM 1-0066

AITM 1-0067

AITM 1-0069 (thick specimens)

AITM 1-0069 (thin specimens)

AITM 2-0061

AITM 3-0008 (EN 6064)

AITM 3-0027

AITM 4-0002

AITM 4-0003

AITM 4-0005

ASTM A604 (EN 2003-7)

ASTM E112

ASTM E238

ASTM E3

ASTM E340

ASTM E384

ASTM E407

ASTM E9

ASTM G110

ASTM G34

EN 2002-1 (ASTM E8 / ASTM B557)

EN 2002-2

EN 2243-1

EN 2243-2

EN 2377 (ISO 14130)

EN 2561

EN 2562

EN 2563

EN 2564

EN 2597

EN 2746

EN 2747

EN 2823 (prEN)

EN 2850-A (Pren) (ISO 14126-1)

EN 2850-B (Pren) (ISO 14126-2)

EN 3683

EN 3684

EN 6072 (ASTM E466)

ISO 148-1 (ASTM E23)

ISO 148-1 (ASTM E23)

ISO 178

ISO 527-4

ISO 604

ISO 643

ISO 6506 (ASTM E10)

ISO 6507 (ASTM E92 historical)

ISO 6508 (ASTM E18)

NASM 1312-04

NASM 1312-06

NASM 1312-08

NASM 1312-13

NASM 1312-18

AITM 3-0032

ASTM E1409

Fiber reinforced plastics - Determination of open hole or filled hole compression strength

Fibre reinforced plastics - Determination of bearing strength by either pin or bolt bearing configuration

Fibre reinforced plastics - Determination of compression strength after impact

Fibre reinforced plastics - Sandwich flexural test - Four-point bending

Determination of tensile lap shear strength of composite joints