Appli cat i on N ote 2 0 6 3 9

Analysis of Benzophenone and

4-Hydroxybenzophenone in Breakfast

Cereal

Anila I Khan, Thermo Fisher Scientific, Runcorn, Cheshire, UK

Key Words

Benzophenones, food packaging, chemical migrant, QuEChERS

Abstract

The use of QuEChERS dispersive SPE as a simple, fast, and quantitative

sample preparation method for the GC-MS analysis of benzophenone

and 4-hydroxybenzophenone in breakfast cereal has been demonstrated.

Additionally, the suitability of the Thermo Scientific™ TraceGOLD™

TG-17MS GC column for benzophenones analyses has been shown.

The average recoveries for the spiked benzophenone and

4-hydroxybenzophenone in breakfast cereal at 0.6 mg/kg were 101.7% and

82.3%, with relative standard deviations of 2.3% and 4.6% respectively,

using the modified QuEChERS method described in EN15662.

Introduction

The Food Standard Agency (FSA) published a method for

analyzing benzophenone and 4-hydroxybenzophenone

from food[1]. Benzophenone is a chemical migrant,

associated with inks and coating in food packaging that

can migrate to the surface of the food. Directive 2002/72/

EC has a specific migration limit (SML) for benzophenone

at 0.6 mg/kg.

The FSA method uses a liquid-liquid extraction method

that involves shaking the homogenized food matrix

overnight with 1:1 acetonitrile/dichloromethane and then

extracting the samples with the same mixture of solvents

followed by centrifugation. The organic solvent is

removed and the solid is re-extracted with 1:1 acetonitrile/

dichloromethane. The combined organic extract is then

back extracted with hexane to remove any potential fat

from the matrix. Benzophenone is soluble in hexane and

this can give reduced extraction recoveries. This method is

highly laborious and can take up to 18 hours to perform

the analysis.

Alternatively, a novel approach can be used to extract

benzophenones from foods using a QuEChERS (Quick,

Easy, Cheap, Effective, Rugged and Safe) method.

QuEChERS is a dispersive solid phase extraction (SPE)

technique initially developed for extracting multi-residue

pesticides from fruits and vegetables. The extraction

method can be applied for removing matrix from

non-pesticide analytes such as benzophenones. The

advantages of this methodology are speed, ease of

execution, minimal solvent requirement, and cost.

The QuEChERS methodology was developed by

Anastassiades et al. [2] and has become widely used in

food safety analyses.

The method is:

• Quick – provides high sample throughput. Typically eight samples can be prepared in under 60 min.

• Easy – requires less handling of extracts than other techniques, i.e. fewer steps are required.

• Cheap – needs less sorbent material and less time to process samples compared to other techniques.

• Effective – gives high and accurate recovery levels for a range of different compound types.

• Rugged – detects a large number of compounds, including non-polar and polar compounds.

• Safe – does not require the use any chlorinated solvents, unlike other techniques. Extraction is typically carried out using acetonitrile, which is both GC and LC compatible.

2

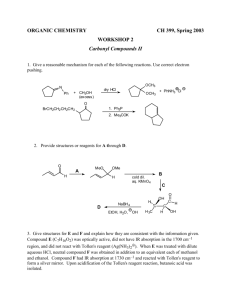

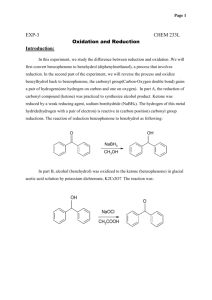

A modified sample preparation approach, described in the European EN15662 QuEChERS

procedure[3], was used for extracting benzophenones from breakfast cereal. This is a two-stage

process: sample extraction, followed by dispersive SPE (Figure 1).

In the sample extraction stage, the food sample is homogenized to increase the available surface

area of the sample to provide optimal extraction efficiency. The homogenized sample must be at

least 80% hydrated for the extraction to work. The food sample is placed in the extraction tube

with acetonitrile and a salt mix is then added comprising of magnesium sulfate, sodium chloride,

sodium citrate tribasic dihydrate, and sodium citrate dibasic sesquihydrate [P/N 60105-337].

Magnesium sulfate ensures that upon addition of acetonitrile, a phase separation is induced

between the water and organic solvent with the analytes of interest being extracted into the organic

phase. The tube is then capped, shaken vigorously, and centrifuged.

The second stage of the QuEChERS method uses dispersive SPE, which involves transferring a

portion of the acetonitrile extract to a clean-up tube containing a combination of sorbents for

removal of unwanted sample components. The sorbent combination of magnesium sulfate, PSA

(primary and secondary amines) silica, and C18 [P/N 60105-225] in the sample clean-up tube

removes fat from the matrix, reduces matrix effects, and therefore improves method robustness for

extraction recoveries.

This fast and simple approach was taken to analyze and extract benzophenone and

4-hydroxybenzophenone from breakfast cereal. The method typically takes approximately 2 hours

to complete, with reduced solvent usage compared to the liquid-liquid extraction method described

above in the official method[1]. Six extractions of 0.6 mg/kg spiked level were used for the recovery

experiments.

Dispersive SPE Clean up (dSPE)

Extraction Stage

(1)

Add 5 g of finely crushed cereal into a 50 mL empty centrifuge tube,

add 10 mL water.

(2)

Add Benzophenone standard

Sample spike: Add 3 µg of benzophenone to the sample

followed by 10 mL of acetonitrile (0.3 µg/mL benzophenones spike)

Blank: No standards added, 10 mL of acetonitrile added.

Mix thoroughly using a vortex and sonicate further for 30 minutes.

(5)

Transfer 5 mL of acetonitrile extract to the QuEChERS dSPE tube

P/N 60105-225.

(6)

Shake vigorously for 5 minutes and centrifuge for 10 minutes

at 3500 rpm.

(7)

Transfer 1 mL of sample extract to a GC vial.

(3)

Add the contents of the QuEChERS kit

(P/N 60105-337) to the centrifuge tube very slowly.

(8)

Add 10 µL of 10 µg/mL internal standard to 1 mL of sample extract.

(4)

Shake vigorously using a vortex for 5 minutes and centrifuge

for 10 minutes at 3500 rpm.

Figure 1: Sample preparation illustrating QuEChERS protocol

Experimental Details

Consumables

Part Number

Column:

TraceGOLD TG-17MS , 30 m x 0.25 mm x 0.25 μm

26089-1420

Septum:

BTO, 17 mm Liner:

Splitless FocusLiner for 50 mm needle, 5 x 8 x 105 mm

Column ferrules: 100% graphite ferrules for Thermo Scientific TRACETM29053488

injector 0.1-0.25 mm ID

Column ferrules: Graphite/Vespel® for transfer line 0.1–0.25 mm ID

Injection syringe:

10 μL fixed needle syringe for Thermo Scientific TriPlusTM365D0291

RSH Autosampler

Vials and closures:

9 mm Wide Opening Screw Thread Vial Convenience Kit, 60180-599

2 mL Clear Vial with Patch, Blue Polypropylene Closure

with Clear PTFE/Blue Silicone Septa

31303211

TM

453T2999

29033496

Consumables

Part Number

Fisher Scientific™ LC-MS Grade acetonitrile

A/0638/17

Fisher Scientific LC-MS Grade water

W/0112/17

Thermo Scientific HyperSep™ Dispersive SPE multipacks, 6000 mg magnesium sulfate,

1500 mg sodium chloride, 1500 mg sodium citrate dihydrate, 750 mg disodium citrate sesquihydrate.

Each pack contains 50 metalized pouches with 50 empty centrifuge tubes and plug seal caps

60105-337

Thermo Scientific HyperSep Dispersive SPE clean-up product:

15 mL tube containing 1200 mg magnesium sulfate, 400 mg PSA, 400 mg C18

60105-225

Preparation of Calibration Standards The calibration curve was constructed with benzophenone and 4-hydroxybenzophenone at the following concentrations:

50, 100, 300, 500, and 1000 µg/mL. To each 1 mL of calibration standard solution, 10 µL of 10 µg/mL

benzophenone-d10 and 4-fluoro-4’-hydroxybenzophenone (internal standards) were added.

Separation Conditions

Instrumentation: Thermo Scientific TRACE GC Ultra™

Carrier gas: Helium

Column flow: 1.2 mL/min, Constant flow

Oven temperature: 80 °C (1.0 min), 30 °C/min, 280 °C (5 min)

Injector type: Split/Splitless

Injector mode: Splitless (1 min), 50 mL/min split flow

Injector temperature: 250 °C

Detector type: Thermo Scientific ISQ™ Mass Spectrometer

Transfer line temperature: 280 °C

Source temperature: 250 °C

Ionization conditions: EI

Electron energy: 70 eV

Scan window

start time (min)

Compound name

Mass list (Quan ion),

Qual ions

Dwell time (sec)

4.00

Benzophenone

(182), 77, 105

0.05

4.00

Benzophenone-d10 (IS)

(192), 110

0.05

7.50

4-hydroxybenzophenone

(198), 77, 105

0.05

7.50

4-fluoro-4’-hydroxybenzophenone (IS)

(216), 121

0.05

Table 1: SIM scan Parameters

Injection Conditions

Instrumentation: Thermo Scientific TriPlus RSH Autosampler

Injection volume: 1 µL

Pre- and post-injection dwell time: 5 seconds

3

Results

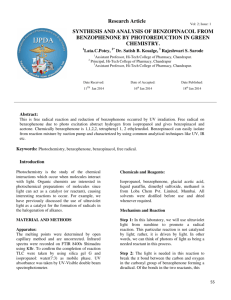

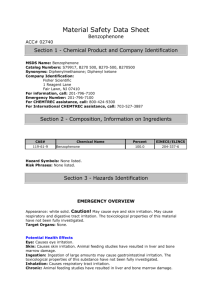

To assess the method linearity, a calibration curve was constructed for benzophenone and

4-hydroxybenzophenone in acetonitrile using benzophenone-d10 and 4-fluoro-4’-hydroxybenzophenone as the internal standards (IS). The coefficients of determination (R2) between the area

ratio of sample and internal standard for both compounds were >0.999 (Figure 2, Table 2),

demonstrating excellent method linearity using the Thermo Scientific TraceGOLD TG-17MS GC

column.

15

benzophenone

4-hydroxybenzophenone

12

10

10

8

Area Ratio

Area Ratio

4

6

5

4

2

200

400

600

ng/mL

800

1000

200

400

600

ng/mL

800

1000

Figure 2: Calibration curve for benzophenone and 4-hydroxybenzophenone

Peak

Compound

tR (min)

Linearity

% Recovery

%RSD (n=6)

1

Benzophenone-d10 (IS)

6.64

–

–

–

2

Benzophenone

6.67

0.9996

101.7

2.3

3

4-fluoro-4’-hydroxybenzophenone (IS)

8.13

–

–

–

4

4-hydroxybenzophenone

8.37

0.9996

82.3

4.6

a

Matrix impurities

6.79, 7.47

–

–

–

Table 2: Peak identification, linearity, and recovery data for benzophenone and 4-hydroxybenzophenone

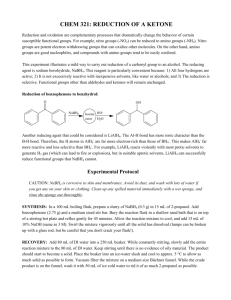

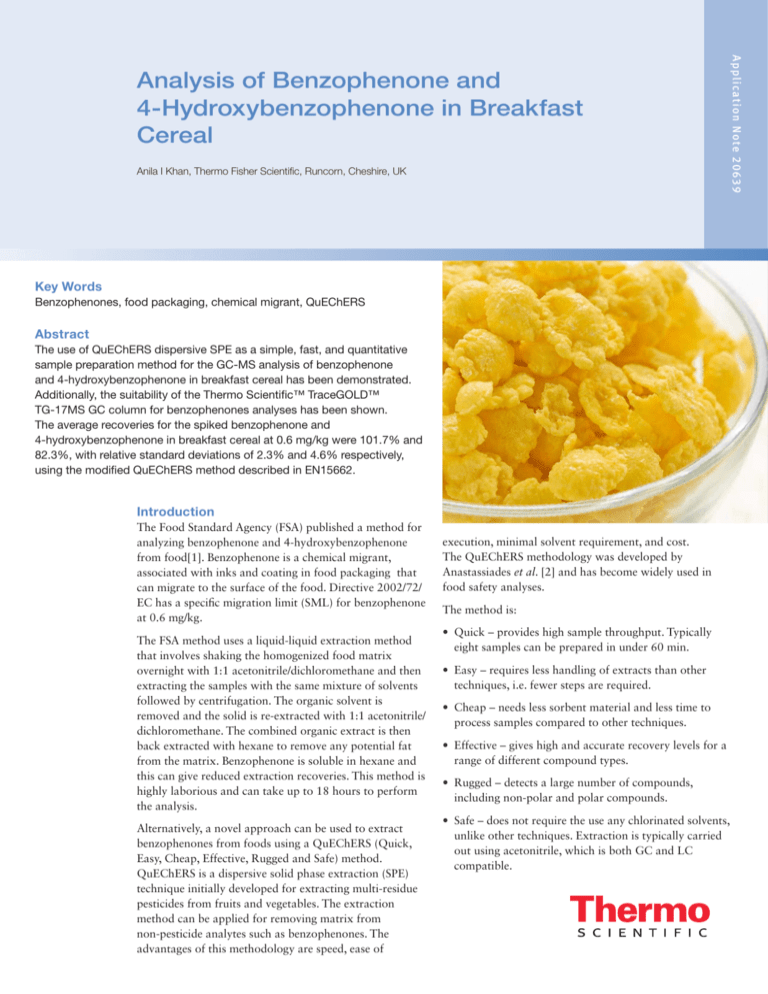

The analysis was performed in SIM mode. Figure 3 shows the SIM chromatogram of spiked

benzophenone and 4-hydroxybenzophenone in cereal matrix at 0.6 mg/kg. Six extractions of

spiked samples were carried out and recoveries measured. The recoveries for the spiked benzophenone and 4-hydroxybenzophenone were 101.7% and 82.3%, with an average relative standard

deviation (RSD) of 2.3% and 4.6%, respectively (Table 2).

90

90

80

80

70

70

Relative Abundance

Relative Abundance

100

2

60

50

40

30

20

60

50

3

40

30

1

a

20

a

10

0

4

6.5

10

7.0

7.5

Time (min)

8.0

0

8.5

6.5

7.0

7.5

Time (min)

8.0

8.5

Figure 3: SIM chromatogram for benzophenone and 4-hydroxybenzophenone spiked at 0.6 mg/kg in breakfast cereal

Conclusion

The QuEChERS sample preparation method provided

a fast and simple approach for extracting and analyzing

benzophenone and 4-hydroxybenzophenone in breakfast

cereal, achieving high recoveries and good reproducibility.

The QuEChERS – GC-MS method was found to be

linear in the concentration range of 50 to 1000 ng/mL.

The TraceGOLD TG-17MS GC column provided a good

chromatographic separation for all analytes studied.

References

1.Food Standards Agency: Survey of benzophenone and 4-hydroxybenzophenone migration from food packaging into foodstuffs. Number 18/06, November 2006. http://www.food.gov.uk/science/surveillance

2.M. Anastassiades, S.J. Lehotay, D. Stajnbaher and F.J. Schenck, J AOAC Int 86 (2003) 412.

3.Foods of plant origin - Determination of pesticide residues using GC-MS and/or LC-MS/MS following acetonitrile extraction/partitioning and clean-up by dispersive SPE–QuEChERS method. European Standard EN15662:2008

thermoscientific.com/crc

© 2012 Thermo Fisher Scientific Inc. All rights reserved. Vespel is a registered trademark of E. I. du Pont de Nemours and Company. FocusLiner is a trademark

of SGE Analytical Science Pty Ltd. All other trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. This information is presented as an

example of the capabilities of Thermo Fisher Scientific Inc. products. It is not intended to encourage use of these products in any manners that might infringe the

intellectual property rights of others. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your

local sales representative for details.

USA and Canada +1 800 332 3331

France +33 (0)1 60 92 48 34

Germany +49 (0) 2423 9431 20 or 21

United Kingdom +44 (0)1928 534110

Japan +81 3 5826 1615

AN20639_E 10/12S

China +86 21 68654588 +86 10 84193588

+86 20 83145199 800 810 5118

India +91 22 6742 9494 +91 27 1766 2352

Australia 1 300 735 292 (free call domestic)

New Zealand 0800 933 966 (free call domestic)

All Other Enquiries +44 (0) 1928 534 050

Technical Support

North America +1 800 332 3331

Outside North America +44 (0) 1928 534 440

Appli cat i on N ote 2 0 6 3 9

100