BIODIESEL

advertisement

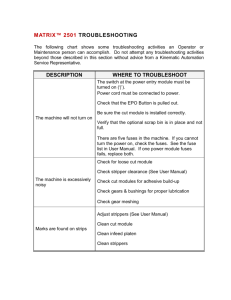

GREEN!! What is the green term for all of that grease in the exhaust systems? BIODIESEL Fire, heat and light result from the rapid combination of oxygen with other materials (namely excessive grease buildup in a kitchen grease exhaust system in the case of restaurant kitchens). The conditions necessary for the existence of fire are the presence of a combustible substance or fuel, a temperature high enough to cause combustion (called the ignition temperature) and the presence of enough oxygen (usually provided by the air) to enable rapid combustion to continue. Fire fighting and prevention consists of removing one or more of the three elements essential to combustion-fuel, heat, and oxygen-or of interrupting the combustion chain reaction. The elimination of oxygen is not currently feasible in kitchen exhaust systems as proven by the failure of the fire damper systems installed in the 1960!s and early 70!s. With the high temperature (over 1750 Degrees) of a grease fire, it is very important to eliminate or reduce the amount of fuel (grease) in the exhaust systems. A proper housekeeping program consisting of proper hood and filter cleaning on a daily to weekly basis depending on the buildup, a regular professional complete system cleaning and inspection is also required per NFPA 96 recommendations. (Per the National Fire Protection Association), and a regular service program for the exhaust fan belts and bearings. Following is a detail description and pictures from actual jobs detailing what is needed, what you should expect, and why you must be very careful on whom you trust with the safety of your restaurant. Here is another way to think of your grease exhaust maintenance. If there is too much grease in your exhaust vent system, Mother Nature!s method of cleaning your system is a damaging and possibly fire fatal . This is her way of telling you your system is not cleaned often enough or you are using a service company that does not clean the system thoroughly or completely. Both of these conditions are far more common than you may think. There are several things to think of when determining a proper company. Most companies have many reasons they will tell you for not cleaning the systems thoroughly or completely. They also have other underlying unspoken reasons for short cutting the cleanings. A quality company will clean the system completely down to the metal. Let us look at the results and compare improper and proper cleanings. What is quality pertaining to Kitchen Exhaust cleaning (KEC)? • Thorough and complete cleanings!! • ALL grease and carbon removed from ALL air flow areas in the system. • Proper documentation, records, and notifications both on file, to customers and to AHJ. • Proper timely scheduling • Proper setups and cleanups of the job • NO INACCESSIBLE AREAS!!!!!! NFPA 96 Standards (National Fire Protection Association) Current is 2011 Edition 2001 changes and update in NFPA96 will be highlighted in the tan shaded boxes 1 True or False Automatic Cooking Line Fire Suppression can typically be relied upon for the total extinguishment of a cooking surface fire. True or False Automatic Cooking Line Fire Suppression can typically be relied upon for the total extinguishment of a cooking surface fire. FALSE Proper maintenance and cleaning of Grease Exhaust Systems prevents Grease Exhaust System fires. Proper maintenance and cleaning of Grease Exhaust Systems prevents Grease Exhaust System fires. FALSE NFPA 96 provides the minimum fire safety requirements related to the design, installation, operation, inspection, and maintenance of all public and private commercial cooking operations. 4.1 General 4.1.5 The responsibility for inspection, maintenance, and cleanliness of the ventilation control and fire protection of the commercial cooking operations shall be the ultimate responsibility of the owner of the system provided that this responsibility has not been transferred in written form to a management company or other party. 4.1.7 Multi-tenant applications shall require the concerted effort of design, installation, operation, and maintenance responsibilities by tenants and by the building owner. NFPA 96 (continued) 11.4 Inspection for Grease Buildup. The entire exhaust system shall be inspected for grease buildup by a properly trained, qualified, and certified company or person(s) acceptable to the authority having jurisdiction in accordance with table 11.3. 11.6 Cleaning of Exhaust Systems 11.6.1 Upon inspection, if found to be contaminated with deposits from grease-laden vapors, the contaminated portions of the exhaust system shall be cleaned by a properly trained, qualified, and certified company or person(s) acceptable to the authority having jurisdiction. 11.6.13 When an exhaust cleaning service is used, a certificate showing the name of the servicing company, the name of the person performing the work, and the date of inspection or cleaning shall be maintained on the premises. IKECA International Kitchen Exhaust Cleaning Association • Certification of cleaning companies. • Inspection and Fire safety Training programs including on line library • Currently working on and writing new ANSI standards for exhaust system cleanings. What Happens when systems are not cleaned to proper quality Standards? 2 Kansas Turnpike Fire 4/12/02 7:06-7:07PM Kansas Turnpike Fire 4/12/02 7:08-7:09PM Kansas Turnpike Fire 4/12/02 7:09PM-7:11PM At Least there was no loss of life at the Kansas Fire But, August of 2007 in Boston, that was a different story Fire site had code violations Built-up grease fueled fatal restaurant blaze two firefighters died Wednesday in a blaze fueled by built-up grease in the ceiling Those were just free standing restaurants. Now imagine investigating the following kitchen fire scenarios!! and ductwork above the hood. The system had been cleaned every 3 months according to the cleaning company records. However, the ductwork hidden above the hood had no access and there was no record of this section getting cleaned. Fire officials believe the mix of flames and toxic gases trapped in the ceiling intensified when a massive air conditioner fell through the roof and into the ceiling, providing fresh oxygen for the flames. At the same time, firefighters may have poked at the ceiling from below to ventilate the fire, fire officials said. A fire ball erupted, engulfing Payne. Cahill died in the smoke and heat. The cleaning company has refused additional interviews • Mixed-use, multi story structures with residential, offices, restaurants, etc • Downtown area high rise structures • Shopping malls • Hospitals • Nursing homes • Assisted living facilities • Schools Boston Globe|! August 31, 2007 The West Roxbury restaurant where 3 By Bill TurqueWashington Post Staff Writer Sunday, October 5, 2008; Page C08A smoky two-alarm fire damaged four Dupont Circle buildings early yesterday afternoon, routing lunchtime diners from two popular restaurants but injuring no one, authorities said.Fire officials said the blaze in the 1200 block of 19th St. NW appears to have started in the kitchen of Penang, a Malaysian restaurant at 19th and M streets. It most likely spread through a vent above the stove and into portions of three adjacent five-story rowhouse-style buildings that include offices, a Starbucks and Porter's, a bar and restaurant at 1207 19th St. NW.The official cause of the fire is under investigation, "but it looks to be accidental," said D.C. Fire and Emergency Services spokesman Alan Etter. Kevin Moran, owner of Integral, a consulting firm at 1203 19th St. NW, said he was having lunch with a colleague down the block when he noticed smoke pouring from the roof above his fifth-floor office."It was unbelievable," he said. "Black, black smoke." Damage to his office and most of the upper floors was primarily from smoke and water, officials said.At the height of the blaze, 110 firefighters responded to the two alarms, Etter said.Officials said Penang appeared to be the most seriously damaged business. Fire Capt. K.R. Moore said that firefighters were forced to cut a hole through the secondfloor ceiling of the restaurant and that the joists between the second and third floors had been weakened by the blaze. Sunday, February 23, 2003 750 Restaurant Fire Statistics • In 2002*, an estimated 7,100 reported restaurant structure fires in US were responsible for: – 108 cililian injuries and $116 million in property loss – 64% of fires involved cooking. Grease and cooking oil were involved in 68% of cooking fires – Automatic systems extinguished (only) 6% of restaurants fires in NFDC database! *References: FEMA - U.S. Fire Administration - National Fire Data Center - “Restaurant Fires” dated October 2004 flee Westin fire Guests in PJ's forced out in the cold By Susan Vela The Cincinnati Enquirer Fans of the rock band Phish and hundreds of other Westin Hotel guests fought off visions of the Rhode Island nightclub disaster when they woke Saturday morning to pounding on doors and the smell of smoke. Westin guards successfully alerted them to a four-alarm fire that started in a second-floor kitchen before igniting grease built up along the lengthy second- and fourth-floor ventilation ducts shortly before 8 a.m. While the flames remained confined within the ducts, smoke crept to every one of the hotel's 17 floors, scaring the 750 occupants. All were safely evacuated via smoky hallways and stairwells. "I was terrified. My heart was pounding. I was expecting there to be a big blaze at the end of the stairs," said Elizabeth Ray, 24, a Phish fan from Lexington. She grabbed her bags after someone banged on her door about 8:15 a.m. She could see and smell smoke. Ray and other guests spilled out of the Fifth Street hotel as 85 Cincinnati firefighters took command. Firefighters kept the hotel empty for three hours. The guests, including some of the 32,000 Phish fans that had tickets to the band's Friday and Saturday shows at the U.S. Bank Arena, huddled on Fountain Square. Some still sporting their pajamas, they watched the firefighters work in drizzling rain. Others peered from Starbuck's, Bruegger's bagel shop and other restaurants. Michael Altvater, 22, of Dayton, Ohio, thought of Rhode Island - where 96 died in a nightclub fire - as he and his friends rushed from their 13th-floor hotel room. They stayed awake hours after the Phish concert but moved quickly after they learned of the hotel fire. "It was a bit unnerving considering everything going on," he said. Alarm also struck District Chief Steve Kluesener. Because the fire was in the ventilation ducts, the flames were not easily accessible. "It was a very serious fire," he said. "It was just very difficult chasing down the fire. We had no idea where it was headed." According to the chief, cooks for The Albee, the hotel's restaurant, had started making morning meals when flames broke out on one of the gas stovetops. While the kitchen's extinguishing system doused the visible flames, the fire already had spread to the grease spots in the ventilation ducts. The fire, which caused an estimated $250,000 in damage, shot up a third-floor shaft and then attacked the fourth-floor ventilation ducts. They traveled laterally to the fourth-floor's west side, causing firefighters to shut down a stairwell because of the heavy smoke. Laura Wainer, Andy Siegel and Alex Herring traveled from Atlanta to see Friday night's Phish show at U.S. Bank Arena. Afterward, the friends and selfpronounced Phish Heads returned to the Westin and stayed up until 6 a.m. Two hours later, they were rushing through the hotel, hurriedly layering themselves in wool hats and sweaters. "When you see the band run out of the hotel, you run, too," Wainer said. A typical setup for a kitchen hood cleaning Usually cleaning starts at the fan (cleaning the intake and than clean down the vertical) 4 PROPER HOOD AND GREASE DUCT CLEANING • Ductwork before cleaning But no matter how thick and old the buildup, cleaning to the highest standards mean a responsibility to remove ALL of the grease buildup This is way beyond a fire danger, but all of it can be removed. A PROPER CLEANING SHOULD TURN THIS FIRE HAZZARD BELOW • TO THIS Impressive, isn’t it!! Same ductwork after cleanings 5 Looking up a properly cleaned vertical stack for a fast food restaurant 6 NFPA96 - Chapter 11 Procedures for the use and Maintenance of Equipment Weather permitting of course!! • 11.6.10 When an access panel is removed, a service company label or tag preprinted with the name of the company and giving the date of the inspection or cleaning shall be affixed near the affected access panels • 11.6.13 When an exhaust cleaning service is used, a certificate showing the name of the service company, the name of the person performing the work, and the date of the inspection The hood should have a performance sticker clearly showing the last cleaning date and the next scheduled cleaning date This complete kitchen hoods and grease exhaust vent system has been professionally cleaned by ABC HOOD CLEANING 12345 Metcalf Overland Park, KS 1-800-123-4567 Cleaning conforms to NFPA 96 standards As certification stickers that are written on can be and often are easily erased (and even changed by customers in some cases), we highly recommend allowing only the punch out style hood stickers.(Be careful of hanging chads!) Last cleaning date________________________ Next Scheduled cleaning date_______________ Cleaning reports should contain the following with copies mandated to be sent to the AJH • Non-compliant issues found • Access issues found • Areas not cleaned detailed where and why – NOTE: We do not believe in inaccessible areas as they should not exist with proper bidding procedures along with proper AJH procedures. If inaccessible areas do exist, the entire system(s) needs to be made compliant (accessible) before any cleanings are done!! 7 Inspections NFPA 96 Standards (National Fire Protection Association) help in setting up an efficient and thorough inspection program for grease exhaust systems. NFPA 96, 8-3 Lets see what you can miss if you fail to properly inspect a cleaning. Following are systems with pictures taken the day after a professional company charged them for cleaning (all pictures were taken before the restaurant opened and all are different companies). Companies should be licensed by the city or county and should required to carry the following insurance to to protect their customers and the local communities. Many cities have tied proper insurance to their licensing requirements. Last, but not least, the cleaning companies must be certified Liability insurance, full workman!s compensation coverage on all employees (with special policy!s covering even the owners), completed operations insurance, and a bond. *NFPA96, 8-3 CLEANING ! 8-3.1 Hoods, grease removal devices, fans, ducts, and other appurtenances shall be cleaned to bare metal at frequent intervals prior to surfaces becoming heavily contaminated with grease or oily sludge. After the exhaust system is cleaned to bare metal, it shall not be coated with powder or other substance. The entire exhaust system shall be inspected by a properly trained, qualified, and certified company or person(s) acceptable to the authority having jurisdiction in accordance with Table 8-3.1. A cleaning permit system is useful for the following 1) Revenue to pay for the program and for the inspectors time. 2) Track the cleanings to make sure they are done on time. 3) 4) Allows proper notifications of the cleanings Allows enforcement of codes during and after cleanings Table 8-3.1 Type of Volume of Cooking Frequency Systems serving solid fuel cooking operations Monthly Systems serving high volume cooking operations such as 24 hour cooking, charbroiling, or wok cooking- Quarterly Systems serving moderate-volume cooking operations Semiannually Systems serving low-volume cooking operations, such as Churches, day camps, seasonal businesses, or senior centers- Annually 8 A modern fire prevention program needs complete inspections for the grease exhaust vent systems. Also, inspectors need to assist commercial cooking facilities in new and remodel designs for systems. 8-3.1.1 Upon inspection, if found to be contaminated with deposits from grease-laden vapors, the entire exhaust system shall be cleaned by a properly trained, qualified, and certified company or person(s) acceptable to the authority having jurisdiction in accordance with Section 8-3 A.11.6.2 After removing the shroud from this fan- we see why it failed. It was just cleaned 3 hours before this picture was taken. The company only had standard pressure washer wands and not the specialized equipment needed to clean this fan properly. Note the heavy buildup on the blades. Inspecting up at vertical Looking at the back of the fan blades The method of measurement is a depth gauge comb, shown in Figure A.11.6.2, which is scraped along the duct surface. For example, a measure depth of 2000um(0.078”) indicates the need to remove the deposition risk. The system would also include a point measurement in critical areas. For example, 3175um (.0125”) in a fan housing requires cleaning. 9 If you look up the stack and do not see the fan, look above the hood for horizontal ductwork and access plates Looking up a vertical stack make sure you can see the fan or you need to look for access Also check above the hood for leaks If grease reaches this electrical, watch out! Next check above the ceiling for access plates(and open them up!) CHECK OUT BOTH DIRECTIONS IN THE ACCESS PLATES Check for leakage through the insulation! 10 Side wall style fan INSPECT THE ROOF AND OUTSIDE OF THE FAN CONDITION CHECK THE BACK OF THE FAN BLADES CHECK INSIDE OF THE FAN BOWL 1 After checking the fan, check down the vertical from the roof Please note the fan hinge Cables are too long and the fan tips in the wrong direction If you cannot see the blades, feel behind them from the inside Looking down the Vertical stack from the roof AND IF THE ENTIRE JOB LOOKS LIKE THIS, YOU ARE DONE Ethnic restaurant system- 4 years old. Just cleaned previous to following pictures(1st cleaning) Looking up from a hood, there was no access above the hood 2 Looking in horizontal looking from above the hood Looking in horizontal looking from above the hood And looking at same system after re-cleaning 3 Just looking down from the roof and your would think this system was in pretty good shape But then we look on the roof and into the system • First we see the roof area where all the grease runoff goes into the storm sewer system • Then we look up the stack from the hood where there are clear areas where the cleaning stopped. 4 Grease Age and Buildup You can tell how old by several factors • Color of grease • Hardness of grease(cooking style may factor into this a bit. • Thickness of buildup • Texture of grease (Dry, wet, Sloppy, etc) This was just cleaned??!!!! Fan Need access here Painted over access plates Vertical down to 1st floor Top view on roof above apartments Access plate above hood Hardened glazed grease from years of neglect. This had to be chiseled out. Looking up at the hood Need access here Vertical up to roof Top view 1st floor Drawings of the next system we will inspect A just cleaned fast food Mexican style restaurant Next, lets look up the vertical from the hood 5 Now, we look above the hood to show an extreme fire danger Looking straight into the access plate that was just installed for this cleaning NEED ACCESS HERE Access plate Painted on shut Access plate for Top of vertical on Next slide Lets now go to the ductwork on the roof Note, painted screws Looking at the access plate screws, we don’t have to look further to know if this was done properly At least something was cleaned on this system 6 Why the program now? Minneapolis Inspection Program Effective 1/1/10 • Permit system • Digital pictures of inside of all systems for every cleaning Below and following are actual pictures taken the day after competed jobs inspected by Mpls that were cleaned by licensed companies before the new program • Verified scheduling to NFPA96 • Licensing • Systems are all cleaned to bare metal NATIONAL INSPECTION PROGRAM • What is it? • How does it work? • How should it affect all certified companies in the future? National Inspection program This program insures all cleanings are done to exacting Enviromatic and NFPA96 standards with complete picture verifications of each completed job. It also includes verification of system compliance with Enviromatic and NFPA96 standards with detailed reports and recommendations to make sure the system can be properly cleaned and maintained. • Enviromatic does not accept the idea of inaccessible areas. We require all areas of the system to be made accessible and company have the proper equipment to reach the complete system and properly clean it. • We do not allow program/partial cleanings unless prior authorization is granted in writing. • We do not allow "Catching up" and "Getting a little more each time" for grease exhaust cleanings as those statements have always been the biggest lie in the industry in the past. • Initial cleanings will be done to the same standards as the normally scheduled (repeat) cleanings. 7 FOLLOWING IS A EXAMPLE OF A PICTURE INSPECTION REPORT FROM A COMPANY (A CERTIFIED IKECA MEMBER) 8 Simply receiving pictures does not insure the job is clean. You must always be careful and diligent to make sure you are looking at the complete and correct system and that you have complete verification all areas are clean. The following is an example of what you may encounter from companies attempting to pass inspections that are less than NFPA96 standards. Following are pictures received by use to pass inspection. Looking down the stack you can tell there is a horizontal or a jog. Everything looks good in these pictures so far…… BUT………Notice there were no pictures looking up the stacks nor any of the horizontal or jog. An inspector was sent to the location and here are the pictures of the stack and horizontal. We found there was no access into the horizontal. 9 Newer digital cameras are small and waterproof. They allow you to use the camera to verify places where you could not see before. Here are pictures inside a Gaylord hood that was cleaned 7 days before this store closed its doors. Do you think this is 7 days buildup? 10 What more is there to say!!!!!! Next, we look at a chain concept that was just cleaned in MN this past month. This store is new(less than a year old) so the buildup that the current cleaning company is not cleaning and had left behind is not bad yet. However, at the end, we will also see inside the duct at another one of their locations that is over 10 years old with the same areas being skipped over the entire time. You can see where the cleanings stop above the hood stack here You can see where the cleanings stop up the stack here You can see where the cleanings stop up the other hood stack 1 Same concept after 10 years of the same neglect, they were getting cleaned quarterly! At first look looking up from hood it looks fairly clean, when we look further up however…….. Inside the horizontal run above the hood and ceiling with years of buildup How important are inspection programs? Here are pictures from a location in MN that had a full grease exhaust inspection program with permits several years ago and every single duct was cleaned to NFPA96 standards including this one. That program has been scaled back and following is how the duct now looks that permits and inspections are not longer required and no one is looking past the hood area. This had just been cleaned a few weeks prior and you can clearly see where the cleanings stopped Hood sticker showing job was just completed Clear scrape mark lines where the cleaning(s) stopped Just taking pictures means very little if you do not follow up with proper filing and verifications!!! As you noticed by the previous pictures, somebody highly qualified AND experienced must look over and verify the pictures!! 2 Ability to look at pictures easily and quickly is critical. First you have to have a way to file them so you can easily access them. We use a numerical system based on our work order numbers. This also allows us to find any group of pictures so they can be easily emailed to the customer and also linked to a secure web site for customers to view. I suggest checking pictures that are downloaded in case one of your crews likes to have a little fun at your expense. Here is what the raw data looks like. Next you need a way to look at pictures in a variety of ways. We link them to both the work orders and the invoices with ties to the crews time sheets. This way we can simply look at a customers work order and view the pictures with a click of the mouse. 3 You also can pull groups of job pictures up by date, customer, areas, states, trucks, shops, or individual crewpersons. You can check one crew supervisor’s jobs for the entire month in less than 10 minutes, easily verifying the quality of both the pictures and the jobs. This next group was pulled up by date. Ability to track you crews also means a way to easily view the follow up calls and the ability to look up ALL complaints and ALL attaboys both by crew and all the other criteria. Here is an easy report that shows tracking for crews and job report. We also do more sophisticated reports for job costing, crew reports, payroll, etc. 4 Also, problems with leakage and just left over above the hood are critical- this is the same thing that fed the Boston fire! There is often no fire suppression and there is open electrical(top of lights, etc) in these areas outside of the grease exhaust ductwork!! A typical leaky duct(we will visit this picture later on the inspection part Grease saturated insulation above a permanent ceiling 5 And they can also show if the access plates are missing screws or leaking. Even with a picture program, an inspector must be diligent and MUST have baseline pictures to compare to. The following job has complete sets of pictures on a web site file by the national contractor doing the work. The pictures show the system was clean. When the baseline inspection pictures were taken, here is what it really looked like… At first you see the system was just cleaned recently. RED ROBIN FIRE-LESS THAN 72 HOURS AFTER CLEANING!!??? 6 Guess who the company was that supposedly cleaned this hood less than 72 house prior to the fire?! Two items were the major factors in this fire,1.!! The grease ducts were not cleaned2.!! The hood fire suppression system did not discharge, secondary to the nitrogen pressure cartridge not being installed. ! If god forbid, we have a fire here and someone is injured or killed (Firefighter or Civilian) given that I can prove it was cause by a hood cleaning company, the next stop will be felony criminal charges with a grand jury indictment.!If a firefighter is killed in the line of duty, because of the Public Safety Officer Death Benefit Act,Alcohol Tobacco & Firearms and FBI will be more than happy to assist in convicting the responsible individuals(property owners, cleaning company, persons doing the actual cleaning)!I hear that the federal prison in Leavenworth is nice in the summer. !! Grease Exhaust Systems Part 2 Design, Layout, Construction, and Technologies FRANK J. HERRICK - CITY!OF LEAWOOD FIRE DEPARTMENT ! OFFICE OF THE FIRE MARSHAL 14801 MISSION ROADLEAWOOD, KS. 66224-9560 OFFICE:! !!!!! 913.681.6788 x 26 FAX:!913.681.2399 Fire Sprinklers Save Lives, Property, the Environment, and Water -! Protect what you value most!! 2 type of systems depending on use Type 1 systems Used to exhaust most grease producing equipment Ex: Grills, Fryers, Broilers, Woks, Most Stoves, Salamanders,etc. 7 Water Leak Testing of New Grease exhaust vent systems. Summary: The purpose of this leak test is to verify that all welds pertaining to the commercial kitchen grease exhaust system are liquid tight as specified in the NFPA 96 Standard. All welds are to be sprayed directly with a high pressure tip or with a high pressure multi-nozzle spin-jet that can be passed through the duct system. All water used in the test must be collected in some fashion for discharge to the sanitary sewer system. During this process the testing contractor will also: Check for safe and adequate access to the grease duct access doors and other problems that can be repaired during the construction phase. Verify that fire rated grease duct access doors that comply with the NFPA96 and UL listings, have been installed in accordance to the manufactures specifications. Verify that the fire wrap or enclosure has not been jeopardized with the installation of the access doors. Verify that a liquid duct sealant or liquid weld of any kind has not been applied to the joints. (NO JB WELD, FIRE CAULK, OR SIMILAR) Verify that a Viroguard roof protection unit has been properly installed (when applicable) as specified by the manufacturer. Verify that the up-blast fan or other fans have been properly installed on the Viroguard. (when applicable) or other roof curb setups with proper hinging. PLUS that the electrical wiring to the fan is long enough to allow the fan to hinge back for cleaning, allowing the drain on the fan to be down. 1. Enviromatic Corporation to receive construction reports with approximate dates for construction from either the owner or the testing contractor. 2. A Purchase Order should be issued which will include the water testing plus any other products or services being purchased from Enviromatic. The Water leak testing total will be an add on after billing is complete as all testing is to be done on a per hour basis only. 3. Enviromatic to notify the proper approved Testing Contractor two weeks after construction start date for each required location that testing will be needed and give them the contact information for the Job Superintendent. 4. The water testing job (process) is to be scheduled for after the welded grease exhaust system, with the hood, Viroguard (when applicable), exhaust fan and all access plates are have been installed.. **Arraignments will be made by the job superintendent with the Testing Contractor at least two-weeks prior to the desired test date. 5. All testing is to be done before any fire-wrap is installed. 6. Testing Contractor will: Verify water availability, building access, electrical availability, amount of high pressure hose needed to reach all areas of system, and any needed roof access with Job Superintendent when scheduling job. Make a job reminder phone call to the Job Superintendent the working day before the job is scheduled. 7. A water source where a hose can be connected will be needed. If not available, a portable or separate self contained water source will be brought with. Total amount of water needed depends on length of system and retesting needed, to be calculated and allowed for by the Testing Contractor. 8. A high pressure; pressure washer is needed with minimum capabilities of 1000PSI @ 3GPM. (Gas powered where 220 volt electrical is not available) 9. Plenty of high pressure hose along with a 6” or 12” spinjet (or multi nozzle Roto-nozzle) required to be provided by the testing company. 10. The system is to be tested beginning at the hood duct collar joint and work toward the discharge portion of the system (or at the electrostatic precipitator where applicable) When a spin-jet or Roto-nozzle is used, the nozzle should be worked through the system at a rate of approximately one foot every five seconds. 11. With the hood in place, the Testing Company will have to collect 100% the water similar to a routine cleaning with the hood taped and clamped up with at least two mil clear poly (Plastic) funneling into a large watertight brute (or similar) bucket. Testing contractor is also to protect all other areas with poly that may be damaged by leaking water or overspray. 12. A water vacuum will be used to make sure all excess water is removed from hood and duct when done. 13. The general contractor's welder with welding equipment, a bright portable light, and a torch will be on-site with access to all parts of the system so he can spot any leaks and do any repairs where needed. 14. The welder will need the torch to dry off any moisture in the welds prior to rewelding any leaks. 15. If the duct leaks, the leaks shall be repaired and the test is to be redone after allowing adequate time for the welds to cool. 16. All leaks are to be repaired and re-tested until no leaks exist. Attempts shall be made to allow the testing and repairs can be completed in one day. 17. The Testing Company is to dry out the duct, remove the plastic and return system to same condition as found (with leaks repaired). 18. The Testing Company will take pictures of the system and the leak test work order, and then e-mail them to Enviromatic to verify the job is done correctly. 19. Invoicing sent to General Contractor from Enviromatic along with the signed and completed leaktesting form shall be verification that system is liquid tight as specified by NFPA96 guidelines. 21. The testing company shall fax the completed water leak testing within 48 hours of job completion to 877-325-8476 or 612-861-5576. Spinjet setup This is a typical setup where the duct terminates at roof instead of at the top of the curb Standard spinjet that is raised up into the duct at about 1" per 5 seconds to test ductwork for leakage( Always start at the hood 8 We have found mechanical companies to use any temporary means to try to pass the leak tests and hide the attempts to bypass the NFPA96 standard of welded leak proof seams. The next pictures were taken this fall after a contractor failed the leaktest, requested the testing team to come back in a couple days and used this to attempt to repair it and pass the leak test. Anything other than proper welding WILL FAIL in time!! Improperly installed Class 1 system (9/6/08) Note: screws and sealant used instead of welding Grease pouring out of non compliant access plate and bolted flanged ductwork Leaking ductwork at welded joint allow grease to flow past where there is proper fire protection Flanged-Boltedgasketed ductwork not conforming to NFPA96 9 Type 2 systems Used to exhaust heat producing equipment that does not produce grease Ex: Pizza ovens, some bakery ovens, convection ovens Recommendation: THESE SHOULD NEVER BE INSTALLED!! INSIDE BAXTER OVEN STACK Access plate locations for a “T” or manifold style system LET US LOOK AT SOME RECOMMENDED EQUIPMENT AND DESIGN GUIDELINES FOR GREASE EXHAUST VENT SYSTEMS #1 Recommendation-Keep it simple #2-Make sure it does not leak #3- Make is accessible to clean Location depends on access to areas above hood, (make up air may be in way). Plates to reach top of verticals may be at ends, on top or on back of stacks also. T O F A N Horizontal plenum Access Plates Hood 10 To side wall fa n Be sure there is proper access both on top of vertical just before the fan to properly reach the fan intake without having to completely remove the side wall style fan. Hood Another way to access the ductwork on a sidewall fan easier than an access plate above the ceiling is with a proper hinge setup. It must also contain a locking mechanism as the ductwork can also be used to enter the building. NFPA96 Chapter 7 Exhaust Duct Systems • 7.4.1.3 Openings on horizontal grease duct systems shall be provided with safe access and a work platform when not accessible from a 3m (10ft.) stepladder • 7.6.4 All ducts shall be protected on the exterior by paint or other suitable weatherprotective coating 24” x 24” clearance needed for cleaning staff and inspectors to reach access plate from a maximum of a 10’ ladder with no permanent obstructions To side wall fa n Ceiling Hood Floor 24” virtual box 1 EXAMPLES OF DUCTMATE F1 and F2 ACCESS: DO NOT USE THESE STYLE ACCESS PLATES ON GREASE DUCTS, THE GASKETS ON THESE DO NOT KEEP THE GREASE FROM LEAKING-USE THE UL LISTED DUCTMATE ULTIMATE PLATE ONLY Locate access every 12 feet on long horizontals Even closer on solid fuel and “Wok” style systems Make sure plates are not flush with bottom of duct. Top of duct installation is permitted. Try to make sure horizontals run back toward the hood if possible. You made need additional access plates to remove grease and water from low areas. NEVER allow bottom access plates unless you have no choice Ductmate Ultimate Access plate. UL listed for grease duct. Flamegard Access Plates. UL listed for grease duct. Make sure any access through rated Enclosures are large enough To reach the access plate behind it!! Middle point This access plate extends 12” to the right of the opening! ! 7.4.2.3 If not easily accessible from the floor or a 3m (10ft) stepladder, openings on vertical grease ducts shall be provided with safe access or a work platform. ! 7.4.4 (Protection of Openings) ! 7.4.4.2 Enclosure openings required to reach access panels in the ductwork shall be large enough for the removal of the access panel through the enclosure opening. NPFA96 - Chapter 5 Hoods • 5.1.13 Wall mounted exhaust hood assemblies shall be tight fitting against the back wall so as to not permit passage of grease vapor behind the hood or between the back wall and the hood assembly • 5.5 Listed Ultraviolet Hoods, listed ultraviolet hoods shall be installed and maintained in accordance with the terms of their listing and the manufacturer’s instructions • 5.6 Listed Ventilated Ceiling Technology, listed ventilated ceiling technology shall be installed and maintained in accordance with the terms of their listing and the manufacturer’s instructions 2 ! 10.2.8.7.1 Where the automatic fire extinguishing system in accordance with NFPA 17A provides protection for the hood and duct in a fixed baffle hood containing a water wash system, the water wash system shall be made inoperable or delayed for a minimum of 60 seconds upon operation of the automatic fire-extinguishing system. NFPA96 states UL listed water wash hood assemblies must be in operation condition to manufacturers specifications. We have found Most if not all of these systems in the MN area are failing to be properly maintained. You can easily check this out with the test switch on Gaylord water wash hood Chemical pumps. Also check to make sure FRESH chemical is in the soap tank. All of these items are in the hood control cabinet. 3 The connections between the walls under the hoods are a huge problem and only get worse over time. As little as 1/32” gap can allow the grease vapor to bypass the hood and saturate the areas above the ceiling areas. Following is a typical gap we see in many installations. A simple removable stainless steel iron angle piece with sealant can repair this. The wall canopy hood is used when the cooking equipment is placed against a wall. Hoods that are used against a wall have a tendency to capture and contain the effluent using less airflow than in an island type application. Make-up air from the kitchen enters the area below the hood replacing the air being exhausted.The wall located on the backside of the hood will cause the make-up air to enter at the front and sides of thehood creating a front-to-rear airflow pattern. The plume will rise from the appliance and will be attracted to any surface parallel and near the cooking equipment, in this case, the wall. This phenomena is known as the Coanda Effect. The plume is then directed into the hood, enhancing capture and containment.Cross drafts still threaten spillage, but to a lesser degree than island style hoods. National Fire Protection Association (NFPA 96)and International Mechanical Code (IMC) should always be consulted when using a wall canopy hood. Wall canopy hoods may or may not be mounted directly against the wall depending on the type of wall. NFPA 96 defines three types of walls; noncombustible,limited combustible, and combustible. Most commercial kitchen applications have limited combustible walls which require a 3inch air space between the back of the hood and the wall. Most hood manufacturers provide a 3-inch space with the hood enabling it to be placed against the wall. Side walls and side panels on hoods have found as much as a 20% increase in efficiency in testing. Even partially enclosing the side of the hoods with end skirts keep side drafts from interfering with the proper exhaust flow. Hoods need to be designed as close to a Chimney as possible for maximum efficiency. ASHRAE 1202-RP and ASTM 1704-05 1 One of the new technologies is the UV hood system.The following pictures are a Halten Hood system with UV that had failed due to lack of proper maintenance. Regular cleaning of the bulbs is critical in the units functioning properly. (At least every 600-1200 hours of run time) Once the bulbs are heavily coated with the white residue, they fail to properly remove the grease from the air stream and become coated with grease and have to be replaced. The bulb replacements are VERY EXPENSIVE!! Grease filters at hood Mesh Pre-filters at hood Current manufacturers are Halten/Ventmaster (same company now) and Gaylord Close-up of UL bulbs The fans are also a fire danger. This is due to the proximity of Electrical wire, bearings, rotating metal, the roof material, and of course - the grease! Proper setup for the wiring, a hinge system, and UL listed Grease containment system go a long ways to prevent fan damage and possible fires UV Hood system Hood showing UL bulbs NFPA96 Chapter 8 Air Movement • 8.1.5.3.2 Upblast fans shall be supplied with an access opening of a minimum of 76mm x 127 mm(3in. x 5in.) or a circular diameter of 101mm (4in.) on the curvature of the outer fan housing to allow for cleaning and inspection of the fan blades. • 8.1.5.3.2 On existing upblast fans where sufficient access in not available to allow for the removal grease contamination, an approved hinge mechanism or access panel shall be installed. UTILITY SET FAN SOME DIFFERENT STYLES OF FANS 2 NOTE, LACK OF PROPER SUPPORT LEADS TO FAILURE How fans are cleaned with proper hinges installed ALSO- BE CAREFULL THAT THE EQUIPMENT REQUESTED IS OF PROPER DESIGN Access to back of fan blades A FULL FRAME HINGE ON FAN WITH WEAK BASE SOLVES POTENTIAL PROBLEMS Here is an example of wooden support system for fan maintenance on a metal pitched roof. These are very dangerous with some sort of support or permanent ladder 3 *NFPA96, 4-8.2.1 Rooftop terminations shall be arranged with or provided with the following: c.) The ability to drain grease out of any traps or low points formed in the fan or duct near the termination of the system into a collection container that is noncombustible, closed to the elements, rainproof, structurally sound for the service to which it is applied, and will not sustain combustion. A grease collection device that is applied to exhaust systems shall not inhibit the performance of any fan. Exception: Grease containers that are evaluated for equivalency with the preceding requirements and listed as such. ROOFTOP CLEANUP AND CONTAINMENT SYSTEMS: Another large problem is the grease leaking from your fan onto the roofing membrane. Not addressing this grease can be very expensive roof repairs. Grease is acidic and will eat into most roof systems in time. It actually voids most roofing warranties. The four school of thought are what follows. 1) Leave the grease go and have the cleaning company deal with it during the cleaning process. PRO: No costs for a system, CONS: Roof ends up getting eaten up by grease, the grease is hard if not impossible to completely remove once it sits on the roof, and it is illegal in most states to discharge greasy water into the environment that can result during rainstorms and cleanings, grease on roof in hot sun is huge fire danger, grease eating up electrical is huge danger. 2) Remove the grease before it gets to the fan by a high tech filtration system. PRO: very little grease gets to the fan so cleaning is not required as often. CONS: Very very expensive to install and upkeep. (EX: UV and Smog hog style systems). They often (Actually almost always) fail in time. ! 9.3.1.2 Equipment listed for reduced clearances shall be listed in accordance with ANSI/UL 1978. ! 9.3.1.3 Equipment shall have space provided to all access panels or doors for the safe removal and servicing of control devices, such as filters, electrostatic precipitator cells, and odor control media beds, and for cleaning of the equipment housing. ! 9.3.6 Equipment commissioning report(s) shall be provided for other equipment installed. 4 3) Contain the grease leaking between the cleanings with devises that contain absorbent materials (IE: Polypropylene pads and/or socks, kitty litter, sand, lava rock material, and other materials that can soak up the grease) and replace the absorption material at regular intervals. PROS: Less expensive for initial cost that a full blown containment system, pads and other material can be simply thrown away at any time between cleanings, works well in low and medium grease leakage situations, and they are fairly easy to maintain if kept on track. Some of the pad systems also work with almost all fan types. They are also fairly easy to install with little tools. CONS: Almost no containment during cleaning process or requirements to cover the pads and run cleaning solutions with the grease onto the roof to collect there, expensive to change some of the more exotic materials, very few choices in UL listed products, track record of not working well in high grease discharge situations. Some products lay on the roof and hide leaking grease that could be under the devise. Some products do not seal to the curb properly and grease leaks between the material and the curb. Some materials(Polypropylene) freeze in winter and cannot be removed or changed during cold weather. Improper trained technicians might not properly install or lay out the pads on pad systems so they work properly. Polyprop ylene/pol yolefin pad system Sandbox system 1 4) Contain the grease with a devise that holds the grease off the roof without pads until the grease exhaust system cleaning company performs its regular service. PROS: Complete containment of all the grease and all the cleaning solution during and between the cleaning process. No pads to change. No ongoing replacement pad expenses. Can be cleaning during the normal cleaning cycle. Generally located off the roof so you can see under the unit to verify it is working. Works in cold and warm weather conditions. CONS: Limited selection of UL listed products. Generally more expensive that pad systems. Discharge valves can be left open or vandalized defeating the purpose of the system. Some cleaning companies do not properly drain the system during the cleaning and it may overflow if not services at regular intervals. Needs some technical expertise to measure and install. Changes to the American National Standard 2 ! 5.1. Insulation materials other than electrical insulation shall have a flame spread index of 25 or less when tested in accordance with ASTM 84 or ANSI /UL 723. ! 5.1.12 Devices that require penetration of the hood, such as pipe and conduit penetration fittings and fasteners shall be listed in accordance with ANSI/UL 1978. In existing systems, when changes in the cooking media, positioning, replacement of cooking equipment occur, the fire-extinguishing system shall be made to comply with 10.2.3. ! 4.1.5 The responsibility for inspection, testing, maintenance, and cleanliness of the ventilation control and fire protection of the commercial cooking operations shall be that of the owner of the system, provided that this responsibility has not been transferred in written form to a management company, tenant, or other party. ! 10.2.3.1 ! 11.2.5 The year of the manufacture and the date of installation of the fusible links shall be marked on the system inspection tag. The tag shall be signed or initialed by the installer ! 11.2.5.2 The fusible links shall be destroyed when removed. ! 11.2.6 Detection devices that are bulb-type automatic sprinklers and fusible links other than the metal alloy type shall be examined and cleaned or replaced annually. ! 11.2.5.1 ! 11.1.6 Cooking equipment shall not be operated while its fire-extinguishing system or exhaust system is nonoperational or impaired. ! 11.6.1 Where the fire-extinguishing system or exhaust system is nonoperational or impaired, the systems shall be tagged as non-compliant, and the owner or owner’s representative shall be notified in writing of the impairment. ! 14.9.3.6.1 Ash, cinders, and other fire debris shall be removed from the firebox at regular intervals to prevent interference with the draft to the fire and to minimize the length of time the access door is open. ! 14.9.3.6.3 The ash shall be sprayed with water before removal to extinguish any hot ash or cinders and to control the dust when the ash is moved. 1 ! 14.9.3.7.4 For either application, the nozzle shall be fitted with a manual shutoff device and shall be of the type to provide a fine to medium spray capable of reaching all areas of the combustion and cooking chambers. Make sure you are informed and help keep it safe for all • • • • No inaccessible areas Keep it simple Make sure it does not leak Documentation of all areas of the system every time!! • Out of sight must NOT be out of mind • ALL GREASE REMOVED EVERY TIME!! – WRITTEN REPORTS INCLUDING DRAWINGS – PICTURES, PICTURE, PICTURES 2