SMTC Receives Product Quality Leadership Award from Frost

advertisement

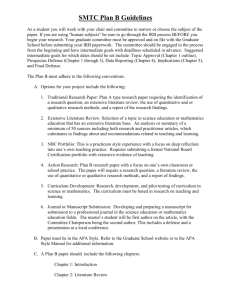

SMTC Receives Product Quality Leadership Award from Frost & Sullivan Decision Support Matrix for Product Quality Leadership Award SMTC Corporation leverages its product knowledge to anticipate and take proactive measures to meet new product development and manufacturing requirements. The company has also leveraged its new product introduction (NPI) capabilities to increase its market reputation and increase market share. Relative Weight (%) Product Reliability SMTC Corporation The company continuously monitors product quality and quality of service and it tracks feedback on finished/launched products between 90-180 days. There is also continuous focus on improving yield and rate of yield improvement. SMTC Corporation engages vendors and distributors, placing the same level of quality requirements on them. Regular audits are conducted to ensure certification and quality assurance. Every strategy and quality system initiated by SMTC Corporation measures defect rates, feedback, and corrective action For more information about SMTC visit our website. http://www.smtc.com Competitor 1 Competitor 2 Weighted Rating Measurement of 1 10 (1 = lowest; 10 = highest) Perceived Value Excellence in the basics of manufacturing execution has been the pivotal factor in SMTC Corporation’s success at ensuring high-quality products. Maintaining focus on ensuring high quality from sourcing, printed circuit board assemblies (PCBAs), system integration, and order fulfillment has enabled SMTC Corporation to meet and exceed its customers’ expectations. The company’s global footprint, strong supply chain network, and unified manufacturing sites have aided the company’s bid to achieve high levels of quality every time. Customers benefit from multiple options that are best suited to meet their time-tomarket and cost-competitive manufacturing needs while resting assured of high quality at every level of engagement. SMTC Corporation’s participation in high-reliability industries such as medical, aerospace, and defense has enabled it to carry over best practices into other verticals. Product Usability Product Performance Product Design For the Product Quality Leadership Award, the following criteria were used to benchmark SMTC Corporation’s performance against key competitors: GLOBAL ELECTRONIC MANUFACTURING SERVICES PRODUCT QUALITY LEADERSHIP AWARD Product Reliability Key Benchmarking Criteria for the Product Quality Leadership Award 2012 Product Performance SMTC has consistently delivered and exceeded customer expectations in product quality. Its achievements in maintaining quality in product design support, manufacturing, ensuring high visibility levels, and assuring quality of finished products is impressive and it sets the bar high for other market participants. Frost & Sullivan has honored SMTC with the 2012 Global Product Quality Leadership Award in the Electronics Manufacturing Service industry. 20% 20% 20% 20% 20% 100% 9 7 6 9 8 7 9 8 7 9 8.5 8.9 7 8.0 7.6 7 8.0 7.0 Best Practice Award Analysis for SMTC The Decision Support Matrix, shown in the Chart above, illustrates the relative importance of each criterion for the Product Quality Leadership Award and the ratings for each company under evaluation. To remain unbiased while also protecting the interests of the other organizations reviewed, we have chosen to refer to the other key players as Competitor 1 and Competitor 2. Frost & Sullivan - Best Practices Analyst Report Highlights through a supplier corrective action request (SCAR). The company also conducts quarterly business reviews with customers and obtains numerical feedback on partsper-million defect rates. Product Design To enhance quality further, SMTC Corporation fosters strong design for manufacturing support with customers and follows a “red, yellow, and green” test. This enables design support to ensure design manufacturability, parts availability, AVL expansion support, and alternative solutions for components reaching end-of-life and last time buys. SMTC Corporation provides customers ease of mind by assuring continuous supply and hastening qualification of alternate components and quality assurance. By offering component lifecycle support and bills of material (BOM) analysis at every stage, SMTC Corporation provides their customers with the benefits of reduced liabilities and faster lead times. Where innovation meets perfection Product Usability For SMTC Corporation, enabling ease of doing business and top-level customer service initiatives are vital to achieve delivered value and support. The company provides visibility and liability dashboards every month for customers. This helps customers identify inventory levels and opens collaboration throughout the engagement. This strategy has helped mitigate challenges with poor forecasting, it enables flexibility in the supply chain, and it offers the ability to make informed decisions in the event of a parts shortage. This system also gives customers foresight into levels of finished goods and semi-finished goods. Customers clearly benefit from time-to-market and speedier ramping up to volume manufacturing. SMTC Corporation actively strives to identify alternative supply chain solutions that offer customers, especially build-to-print customers, a better cost advantage. Customers benefit from the company’s expertise and ability to manage demand fluctuations and quick time to volume production. Perceived Value SMTC Corporation is reputed for its opulently reliable printed circuit board assemblies (PCBAs) and it has achieved this distinction through its masterful engineering and manufacturing teams. The company steadfastly believes that assurance of quality in front-end operations transfers seamlessly into design, manufacturing, and the final finished product. Best Practices Example: A customer required joint design partnership and new product introduction (NPI) support for a new product launch in the Telecom industry. The customer chose SMTC Corporation for its engineering and manufacturing skills that not only helped reduce costs but it also met manufacturability costs as well as crucial quality metrics. SMTC Corporation seamlessly transitioned the product into its manufacturing site and helped ramp up production. The resulting partnership enabled the customer to launch its product at competitive time-to-market and cost parameters while maintaining very high quality levels. SMTC Corporation has achieved a reputation for delivering cost effective solutions of best-in-class quality and with unrivaled support. This has helped create superior brand reputation and value for its loyal customer base. Conclusion SMTC Corporation has consistently delivered and exceeded customer expectations in product quality. Its dedicated focus has provided the company a brand value unrivaled by its peers. SMTC’s achievements in maintaining quality in product design support, manufacturing, ensuring high visibility levels, and assuring quality of finished products is impressive and it sets the bar high for other market participants. Based on Frost & Sullivan’s independent analysis of the Global Electronics Manufacturing Service market, SMTC Corporation is being recognized with the 2012 Product Quality Leadership Award. 2012 GLOBAL ELECTRONIC MANUFACTURING SERVICES PRODUCT QUALITY LEADERSHIP AWARD For more information about SMTC visit our website. http://www.smtc.com Frost & Sullivan - Best Practices Analyst Report Highlights