High efficiency MW PEM electrolyzers

advertisement

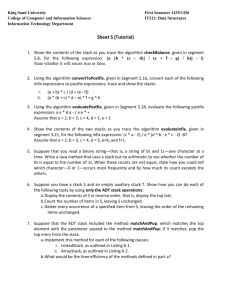

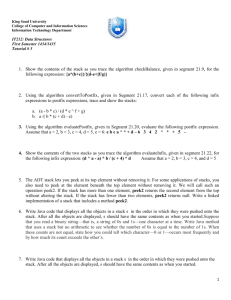

High Efficiency Large PEM Electrolyzers Timothy Norman VP of Engineering Giner, Inc. 89 Rumford Ave, Newton, Ma. 02466 Hall 27, C 40 Outline Giner, Inc. Overview Advancements in Efficiency New Membranes Performance & Efficiency Lifetime Durability Cost Reduction Innovative Stack Designs High Pressure Electrolysis Performance & Validation Large Scale PEM Electrolyzer Wrap-Up 2 GINER, Inc. Giner, Inc. Founded in 1973 Specializing in research & development of PEM based electrochemical technology and systems Since 2005 Giner has accelerated growth Key driver has been the manufacturing of PEM electrolyzers to OEMs Global leader in Polymer Electrolyte Membrane (PEM)-based electrolyzers Highest efficiency technology for commercial applications Core Mission: Provide Innovative PEM Technologies with the Highest Efficiencies at the Lowest Costs to Developing Hydrogen Markets Staff: 65 people Facility 25,000 sq ft + Synergy of Giner, Inc. Technologies 3 Giner Electrolyzers Electrolyzer Stacks Electrolyzer Systems Vehicle Applications Differential Pressure Balanced Pressure Anode Feed Cathode Feed Vapor Feed On-Site H2 Generators Laboratory Hydrogen Static Feed Regenerative (Combined Fuel-Cell & Electrolyzer) Electrochemical H2-Compressors Life Support Oxygen Concentrators 4 Giner, Inc. Overview Advancements in Efficiency New Membranes Performance & Efficiency Lifetime Durability Cost Reduction Innovative Stack Designs High Pressure Electrolysis Performance & Validation Large Scale PEM Electrolyzer Wrap-Up 5 Membrane Development Giner Dimensionally Stable Membranes (DSMTM): High-strength, High-efficiency membranes PFSA ionomer incorporated in an engineering plastic support (2D & 3D) Superior Mechanical Properties No x-y dimensional changes upon wet/dry or freeze-thaw cycling Stronger Resistance to tear propagation Superior to PTFE based supports, 10x stronger base properties Membranes optimized for ionomer EW and thickness Enabling technology for high pressure applications Role to role process underway Commercial viability in 2015/16 Laser-Drilled 3D Substrates Chemically Etched Cast Membrane Supports R&D funded U.S. Department of Energy 6 Membrane Efficiency Demonstrated high efficiency DSM membranes in single-cell and large multi-cell stacks Cell voltage efficiency up to 90%(HHV), 44.0 to 47 kWhe/kg-H2 @ 1500 mA/cm² MEAs utilize low-loaded catalyst loadings (reduced by 90%) Nafion is a registered trademark of E.I. du Pont Nemours and Company 7 Membrane Lifetime Scaled-up Membrane Performance Demonstrated 5,000+ hrs lifetime of scaled-up DSM membrane at 80C DSM MEA from 5-cell short stack re-assembled into a single-cell stack, total testing time = 5,430 hours Efficiency: up to 88% (HHV) @ 1500 mA/cm² Scaled-up testing includes low-cost stack components Membrane Degradation (Estimated Lifetime) F ion Release Rate: 3.7 µg/hr (<10 ppb) DSM -1100EW (Stabilized Ionomer): ~55,000 hours 8 Membrane Durability Membrane Degradation (Estimated Lifetime) Performance Under Aggressive Conditions Demonstrated high current density (5,000 mA/cm²) Advanced DSM: Improved membrane stability at and high pressure (5,000 psig) operation high operating current density Operated 4-Cell stack at 5,000 mA/cm² for 1,000 Low degradation enables longer operation at hours DSM operated at 10,000 mA/cm² (in continuous 24 higher temperatures hour test) Advanced DSM with proprietary additive mitigates degradation and improves life at high operating current densities 9 Stack Efficiency Vs. Cost of H2 Production Hydrogen production cost dominated by feedstock Feedstock is largest $ contributor Efficiency is key to cost competitiveness! Larger benefit for MW Scale Feedstock H2 Forecourt Station H2 Production Cost Component Breakdown 10 Giner, Inc. Overview Advancements in Efficiency New Membranes Performance & Efficiency Lifetime Durability Cost Reduction Innovative Stack Designs High Pressure Electrolysis Performance & Validation Large Scale PEM Electrolyzer Wrap-Up 11 Stack Advancements & Cost Reductions Stack Improvements Repeating Cell Unit Fluid End Plate Negative Terminal 30 to 90 Nm3/hr Cell Separator Anode Support Mat’l Cell Frame (O2) MEA Cathode Support Mat’l Cell Frame (H2) Positive Terminal End Plate The repeating cell unit comprises 90% of electrolyzer stack cost Part Count Required to Generate 1500 kgH2/day >60% Stack Cost Reduction Increased active area (2x) Reduced catalyst loadings by 90% Implemented new manufacturing techniques Molded Thermoplastic Components Improved Cell-Separators: Lifetime > 60,000 hours Material requirements reduced by 30% Reduced Cathode & Anode Support Mat’l Alternative low cost materials utilized Reduced non-repeater costs >50% Reduced Part Count from 41 to 10 Parts/Cell-50% labor reduction Commercialized Electrolyzer 1st to market with 47 kWh/kg stack @ 1700 mA/cm² Rapid market penetration Product sold in 7 Countries Product exclusively used in renewable energy applications Compliant 12 Improving Pressure Capabilities of PEM Electrolyzers Advantages of High Pressure PEM Electrolysis Eliminates one or more stages of mechanical compression Reduces system complexity Hydrogen at 5,000 psig (350 Bar), Ambient O2 Generated directly in PEM Electrolyzer Lower drying requirements Low maintenance No moving parts No contaminants Cross-cutting technology, applicable to Electrochemical Hydrogen Compressors Permits hydrogen generation at user endsite DSMTM Enabling Technology 13 High Pressure Electrolyzer Systems Increasing electrolyzer pressure leads to system simplification, but remaining challenges exist: Higher cost BOP components Innovative system component development required Extended durability testing/validation Hydrogen dryers Gas-phase separators Level sensing Full optimization studies Increased back diffusion R&D program initiated to develop new ionomers with reduced gas permeation FCV Home Refueling 14 Validation at National Renewable Energy Laboratory System Validated at NREL in June 2012 Nominal operating conditions: 390 psig (27 bar), 1500 -1900 mA/cm² High stack voltage efficiency: >87% HHV; Energy efficiency;46.6 kWhe/kg-H2 Stack Efficiencies in line with DOE 2012 Targets Development of low-cost high-efficiency components Hydrogen drying losses: ~3% (Industry: 10%) Giner Stack Efficiency ~87.5% @ 1500 mA/cm² NREL Report: Milestone 3.7.6 (CPS 52066) 15 Electrolyzer Stack Validation Third Party Validation Giner commercial electrolyzer stack in-use at Areva Site Operating at multiple sites Customer confirms 2,000 hours at 47 kWhe/kg 1,700 mA/cm² AREVA’s energy storage platform ‘GREENERGY BOX’ in Corsica, France Utilizing GES Low-Cost Electrolyzer Stack Modular RFC systems with energy storage from 0.2 to 2MWh 16 Giner, Inc. Overview Advancements in Efficiency New Membranes Performance & Efficiency Lifetime Durability Cost Reduction Innovative Stack Designs High Pressure Electrolysis Performance & Validation Large Scale PEM Electrolyzer Wrap-Up 17 Large Scale Electrolysis Led by Market Demand Market Drivers U.S. National Defense Authorization Act of FY2007/FY2010: DoD must produce 25% of total energy from renewable energy sources by 2025 European Commission1 2020 Strategy: 20% share of renewable energy in EU energy consumption, with a 10% share in transport 2050 Roadmap calls for a 55 - 75% share of RES in gross final energy consumption, 80% reduction in green house emissions Next step: >220 Nm3/hr (MW Scale) 1http://ec.europa.eu/energy/energy2020/roadmap/doc/com_2011_8852_en.pdf Target markets require larger electrolyzer stacks and systems Intermittent Renewable Energy Source (RES) integration Backup power for grid outages and load shedding Mobility Power to Gas 30-90 Nm3/hr 2-3 Nm3/hr 0.05 Nm3/hr 18 MW Scale PEM Electrolysis Increased system output requires larger stacks to be competitive In-house program initiated to develop MW Scale electrolyzer Large scale stacks previously designed and manufactured MW stack design leverages work developed on earlier stacks Reliability, Efficiency, Cost,… 220 Nm3/hr MW Electrolyzer 19 Giner, Inc. Overview Advancements in Efficiency New Membranes Coming to Market Performance & Efficiency Lifetime Durability Cost Reduction Innovative Stack Designs High Pressure Electrolysis Performance & Validation Large Scale PEM Electrolyzer Wrap-Up 20 Summary Giner’s capabilities continue to grow to meet new market demands Increase efficiency High pressure electrolysis stacks & systems New membrane development Mobility and storage Increased hydrogen output MW scale PEM electrolyzer Efficiency is Key to Competitiveness Giner commercial PEM Electrolyzers exceed market performance High stack efficiencies and improved durability reduce overall operating costs Reduction in Capital Cost achieved by implementing innovate stack designs PEM Electrolysis is a mature technology that is highly cost competitive 21 Thank You! VP of Engineering Timothy Norman mhamdan@ginerinc.com +1 781 529 0526 Business Development Hector Maza hmaza@ginerinc.com +1 781 529 0589 www.ginerinc.com Hall 27, B66 22