Capillary Column Selectivity and Inertness for Sulfur Gas Analysis in

advertisement

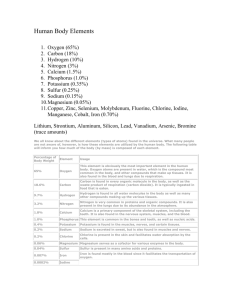

Gulf Coast Conference 2000, Poster #75 Capillary Column Selectivity and Inertness for Sulfur Gas Analysis in Light Hydrocarbon Streams by Gas Chromatography Allen K. Vickers, Jason Ellis and Cameron George 91 Blue Ravine Road, Folsom, CA, 95630-4714 Abstract: Detector quenching and poor detection limits are problems frequently encountered in applications involving the analysis of sulfur compounds in light hydrocarbon streams. Both of these problems present obstacles to the analyst hoping to accurately determine the concentration of reactive sulfur compounds in a hydrocarbon sample. This paper will examine four different columns commonly used in volatile sulfur compound analysis. These columns will be evaluated with respect to elution order profile of light hydrocarbons and sulfur compounds, as well as inertness toward reactive sulfur compounds such as hydrogen sulfide, sulfur dioxide and the mercaptans. Introduction: Unrefined C1 to C5 hydrocarbon streams typically contain significant to trace amounts of volatile sulfur compounds as impurities. Analysis of these sulfur compounds is critical to final product purity as well as avoidance of costly catalyst poisoning in the processing stream. Sulfur gas analysis is important not only in the petrochemical industry but also in environmental (EPA, CARB, etc.), industrial hygiene (NIOSH, OSHA) and food products applications (e.g. sulfur compounds in beer or wine). While low detection limits are certainly important in petrochemical test methods, often times lower detection limits are required for the other industries listed above due to very low odor threshold levels and Permissible Exposure Limits of sulfur-containing compounds. It is not uncommon to require quantitation of sulfur gases such as hydrogen sulfide or methyl mercaptan down to low part-per-billion levels. Sulfur selective detectors are typically employed for these applications because of their high selectivity and sensitivity for sulfur species. Most commonly used are the Flame Photometric Detector (FPD), Pulsed Flame Photometric Detector (PFPD) and Sulfur Chemiluminescence Detector (SCD). More general selective detectors may also be employed, such as the Atomic Emission Detector (AED) and Mass Spectrometer (MSD). Regardless of the detector selected for the application, possible quenching of response for low-level sulfur compounds may occur if they elute underneath large hydrocarbon peaks. Quenching makes accurate quantitation difficult due to detector response reduction and may also cause difficulties in compound identification. Thus, column selectivity is critical in these applications if accurate results are to be obtained. B-0332 Technical Support 800-552-0413 2 Due to the high vapor pressure of target analytes, columns used for these applications must possess a high degree of retention if the analysis is to be performed without using cryogenic oven temperatures. Thickfilm wall-coated open tubular (WCOT) columns and porous-layer open tubular (PLOT) columns can provide high enough retention to separate these volatile species at above ambient starting oven temperatures. While WCOT columns can exhibit high enough retention, phase selectivity is often not ideal. PLOT columns possess higher retention and selectivity for these compounds, however many PLOT phases available that exhibit acceptable elution patterns for sulfur and hydrocarbon compounds also exhibit unwanted stationary phase surface activity. This activity can dramatically affect the sensitivity of the system for reactive sulfur compounds such as mercaptans and hydrogen sulfide, producing higher detection limits. Hence, column inertness is just as critical as stationary phase selectivity in column selection for these applications. This paper examines four different phases commonly used in volatile sulfur compound analysis. PLOT columns examined include a silicabased, a carbon molecular sieve and a divinylbenzene porous polymer. These PLOT columns are compared to a thick-film 100% dimethylpolysiloxane WCOT column. Elution orders of common C1 to C5 hydrocarbons will be given as well as six sulfur gases: hydrogen sulfide, carbonyl sulfide, sulfur dioxide, methyl mercaptan, ethyl mercaptan and carbon disulfide. Column inertness will be evaluated by examining peak shape and response for hydrogen sulfide. Experimental: A Hewlett-Packard 5890 GC (Avondale, PA) equipped with a Flame Ionization Detector (FID; Hewlett-Packard, Avondale, PA) and a PulsedFlame Photometric Detector (PFPD; OI Analytical, College Station, TX) was used to generate the chromatograms in this study. Injection volume for each standard was held constant at 1.0 mL. Data acquisition was performed via Hewlett-Packard Chemstation software. Split injection was used in this study to reduce residence time in the inlet and thus reduce potential peak tailing associated with inlet-related activity. B-0332 Technical Support 800-552-0413 3 J&W Scientific (Folsom, CA) manufactured all columns evaluated. The columns used in this study were: DB-1, 30 m x 0.32 mm I.D., 5.0 µm GS-CarbonPLOT, 30 m x 0.32 mm I.D., 3.0 µm GS-Q, 30 m x 0.32 mm I.D. GS-GasPro, 30 m x 0.32 mm I.D. A variety of hydrocarbon blend standards were used to generate retention times on each column. These standards were obtained from Scott Specialty Gases (Plumsteadville, PA) and Hewlett-Packard and were used for qualitative results only. The balance gas in each hydrocarbon standard is nitrogen. Three different sulfur gas standards were used in this study: n Sulfur dioxide standards were generated using a permeation tube device obtained from GC Industries (Fremont, CA). n A mixture of five sulfur compounds was obtained from Scott Specialty Gases at 1.0% each component, balance gas nitrogen. The compounds represented in this standard were hydrogen sulfide, carbonyl sulfide, carbon disulfide, methyl mercaptan and ethyl mercaptan. This standard was used for qualitative results only. Due to the age of the standard (over two years old) it was noted that reactive compounds were no longer at their stated concentrations. This standard was diluted to a working level by transferring an aliquot to a Tedlar bag containing a known volume of nitrogen. n Quantitative detection limit studies were performed with a hydrogen sulfide standard obtained from Scott Specialty Gases. The hydrogen sulfide concentration in this standard was 100 ppmV, balance gas nitrogen. The sulfur compounds were not combined with the hydrocarbons to produce one analytical standard. This allowed for investigation of true retention times and peak shape without the influence of quenching on the PFPD. Each column was first installed into the PFPD and detector conditions were optimized for sulfur response. Retention time data was then obtained for each of the sulfur compounds on the column. The column was then uninstalled from the PFPD, installed into the FID and B-0332 Technical Support 800-552-0413 4 retention time data was obtained for the hydrocarbons. Column headpressure was held constant during this procedure so as to not affect carrier gas linear velocity. This allowed for generation of retention times using both detectors without introduction of possible activity associated with a glass Y-splitter or deactivated fused silica tubing. Results and Discussion: Figure 1 and Table 1 illustrate selectivity for hydrocarbons and sulfur compounds on DB-1, a 100% dimethylpolysiloxane stationary phase. DB-1 was the only wall-coated open tubular (WCOT) column evaluated in this study. WCOT columns do not exhibit high retention at ambient operating temperatures for gaseous compounds such as ethane and propane. The column used for this study possessed a very low phase ratio (ß=16). This allowed for adequate retention at 40°C to resolve hydrogen sulfide (H2S) from carbonyl sulfide (COS), however we can note from the chromatograms that these sulfur gases are eluted amidst the C2 and C3 hydrocarbons. Additionally, methyl mercaptan (MeSH) is eluting in the C4 range. This elution pattern can create problems with detector quenching by large amounts of hydrocarbons potentially present in a sample. For example, if testing propylene streams for trace sulfur gases, difficulty quantitating hydrogen sulfide, carbonyl sulfide and sulfur dioxide due to their close elution to the propylene peak would result. Figure 1 also shows that carbonyl sulfide and sulfur dioxide (SO2) coelute on this phase under these analysis conditions. The peak shape for hydrogen sulfide and methyl mercaptan are both excellent on DB-1, indicating little-to-no surface adsorption problems with these reactive compounds in this column. Figure 2 and Table 2 illustrate selectivity on GS-CarbonPLOT, a carbon-layer PLOT stationary phase. This column exhibits much higher retention than the DB-1 - the chromatograms in Figure 2 were generated using a temperature program from 100° to 310°C. This higher retention of GS-CarbonPLOT helps to resolve light hydrocarbons much better than DB-1. On GS-CarbonPLOT, H2S and COS do not coelute with the C3 hydrocarbons, however H2S does coelute with ethane and COS coelutes with SO2 (Figure 2). Excessive peak tailing is noted on the H2S peak on GS-CarbonPLOT (Figure 2). Additionally, methyl mercaptan and ethyl mercaptan were B-0332 Technical Support 800-552-0413 5 not detected on GS-CarbonPLOT, even at very high concentrations. This behavior indicates adsorption of active sulfur compounds on this phase. The elution profile on GS-Q (a divinylbenzene porous polymer PLOT phase) is shown in Figure 3 and Table 3. GS-Q shows a favorable elution profile of sulfur compounds relative to light hydrocarbons. Here we see H2S, COS and the mercaptans pulled away from potential hydrocarbon interferences. This elution profile works well for analysis of sulfur gases in propylene, LPG or LNG for example. Peak tailing is noted on the H2S peak on GS-Q (Figure 3), indicating some surface adsorption. Sulfur dioxide was analyzed on the GS-Q however is not shown in Figure 3 due to very poor peak shape. Sulfur dioxide exhibited Gaussian peak shape, but was approximately 2 minutes wide with an apex at about 9.1 minutes. Obviously, this would not be an ideal column for quantitation and identification of sulfur dioxide in a sample due to the extreme broadness of the peak. Figure 4 and Table 4 illustrate selectivity of GS-GasPro (a silica-based PLOT phase) for these compounds of interest. GS-GasPro exhibits a favorable elution profile without the tailing hydrogen sulfide problem observed on GS-Q. This elution profile would also work well for analysis of sulfur gases in propylene, LPG or LNG. GS-GasPro resolves carbonyl sulfide and sulfur dioxide (Figure 4), making it the only column observed in this study to be useful for analysis of these two compounds. Peak shape exhibited by GS-GasPro for hydrogen sulfide and methyl mercaptan is symmetrical, while only slight peak tailing is noted on the sulfur dioxide peak shown in Figure 4. This indicates little-to-no surface adsorption is occurring for these reactive compounds. Figure 5 shows a comparison of approximate detection limits for hydrogen sulfide obtained on each column using this system setup. "Oncolumn equivalent" denotes the approximate concentration delivered to the column after standard dilution and split ratio were accounted for. Clearly, DB-1 and GS-GasPro exhibit the best inertness characteristics for reactive sulfur compounds in this application, making them the best choices for trace-level sulfur determination. Tailing peak shape observed on GS-Q and GS-CarbonPLOT for hydrogen sulfide indicates presence of surface activity. While there are obvious differences in signal-to-noise present in the chromatograms shown in Figure 5, response was erratic at B-0332 Technical Support 800-552-0413 6 concentrations much lower than those shown on GS-Q and GSCarbonPLOT. These two columns exhibited an apparent quenching phenomenon, whereby response improved for hydrogen sulfide after several injections of high-level standards. This quenching effect can make accurate quantitation difficult, as the effect is not long lasting. The chromatograms shown in Figure 5 are meant to show relative differences in inertness between the four columns studied, and are not meant to be definitive examples of detection limits obtainable. Ultimately, detection limits obtained on a given analytical system are extremely system dependent - lower detection limits may be obtained, however the entire system must be finely "tuned" for trace-level analysis of reactive compounds. Figures 6 and 7 show chromatograms from a system that has been optimized for trace-level analysis of volatile sulfur compounds in ambient air samples. Figure 6 shows the chromatogram of an injection of 1.0 mL of a 6.0 ppbV standard of volatile sulfur compounds on a 5 meter GS-GasPro. The detection limit obtained by this analytical laboratory is 4.0 ppbV for each compound shown in the chromatogram, the same detection limit obtained on the previously used WCOT column. Figure 7 shows a chromatogram on the same system of a 100 ppbV sulfur dioxide standard. These chromatograms show the type of detection limits obtainable on an optimized system. The analytical laboratory that generated the chromatograms shown in Figures 6 and 7 (Air Toxics Ltd., Folsom, CA) was seeking a column that could resolve sulfur dioxide from carbonyl sulfide, allow trace-level quantitation and provide a relatively short analysis time. This laboratory was able to obtain this by using a short (5-meter) GS-GasPro column in their system, replacing a 30-meter thick-film 100% dimethylpolysiloxane column. This column allowed for an analysis time of only 15 minutes, compared with approximately 35 minutes on the previous column. A subambient starting oven temperature (0°C) was required due to the time required to transfer the large sample loop to the 0.32 mm I.D. GS-GasPro column (approximately 20 seconds). Without a subambient starting temperature, peak shape suffered for both carbonyl sulfide and hydrogen sulfide due to their chromatographic movement during the sample transfer time. Sulfur dioxide and carbon disulfide switch elution order in Figure 4 and Figure 7. This elution order change can be attributed to differences in column length and analysis conditions. B-0332 Technical Support 800-552-0413 7 Conclusion: Detector quenching can be a significant problem when quantitating volatile sulfur compounds in hydrocarbon streams such as bulk propylene, bulk ethylene or LPG. Column selectivity is important in these applications to allow for elution of sulfur compounds away from large hydrocarbon peaks in the sample matrix. As shown in this paper, the GS-Q and GS-GasPro appear to have the best selectivity for these applications. Quantitation of low-level sulfur compounds requires inertness in the entire analytical system, including the capillary column. For truly tracelevel sulfur analysis this paper showed evidence that DB-1 and GSGasPro provided the most inert stationary phase surfaces for reactive sulfur compounds such as hydrogen sulfide and the mercaptans. Of all four columns evaluated, the GS-GasPro was the only column that resolved sulfur dioxide from carbonyl sulfide. Sulfur dioxide was eluted from the GS-GasPro with very good peak shape and response. When elution pattern and inertness are both evaluated, it can be seen that the GS-GasPro appears to be an excellent column choice for tracelevel quantitation of sulfur compounds in hydrocarbon streams. Acknowledgements: The authors would like to thank Wade Bontempo and Sandia Kao of Air Toxics, Ltd. in Folsom, California for providing chromatograms on the 5-meter GS-GasPro. B-0332 Technical Support 800-552-0413 8 Figure 1. DB-1 CS2 H 2S COS/SO2 MeSH EtSH PFPD 1 3 2 Time (min) 4 FID 5 iC5 6 7 C5 C2B MA iC4 C4 t2B C1 C3/C3= C4= /13BD C2 C2= /acetylene Table 1. DB-1 Column: Injector: Carrier: Oven: RT 1.61 1.72 1.78 1.97 2.13 2.17 2.20 2.75 3.10 3.25 DB-1 30 m x 0.32 mm I.D., 5.0 µm 200°C, 1:20 split Helium, 10 psig, 2.0 mL / min @ 40°C 40°C for 5 min, 5°/min to 75°C and hold Compound methane acetylene / ethylene ethane H2S propylene propane COS / SO2 iso-butane butene-1 n-butane RT 3.42 3.47 3.71 5.05 5.77 5.96 7.32 10.56 Compound trans-2-butene methyl mercaptan cis-2-butene iso-pentane ethyl mercaptan n-pentane CS2 n-hexane B-0332 Technical Support 800-552-0413 9 Figure 2. GS-CarbonPLOT CS2 COS/SO2 H2S PFPD 2 4 Time (min) 6 8 10 FID C3= C2= MA C4 C3 iC4 C4= C1 acetylene C2 Table 2. GS-CarbonPLOT Column: Injector: Carrier: Oven: RT 1.95 2.46 2.75 3.21 3.22 5.03 6.28 6.71 GS-CarbonPLOT 30 m x 0.32 mm I.D., 3.0 µm 200°C, 1:20 split Helium, 10 psig, 1.7 mL / min @ 100°C 100°C for 2 min, 20°/min to 310°C and hold Compound methane acetylene ethylene ethane H2S COS / SO2 propylene propane RT 9.57 9.85 10.08 11.06 12.50 12.75 15.44 Compound iso-butane butene-1 n-butane CS2 iso-pentane n-pentane n-hexane Mercaptans not detected B-0332 Technical Support 800-552-0413 10 Figure 3. GS-Q CS2 COS MeSH EtSH H2S PFPD 1 2 4 Time (min) 3 FID 5 6 7 8 iC5 iC4 C5 C3= T2B MA C1 C3 C4/C2B 13BD C2 C4= C2= /acetylene Table 3. GS-Q Column: Injector: Carrier: Oven: RT 2.07 2.38 2.47 2.83 3.21 3.60 3.75 5.31 5.48 ** SO 2 GS-Q 30 m x 0.32 mm I.D. 200°C, 1:20 split Helium, 10 psig, 1.7 mL / min @ 100°C 100°C for 2 min, 20°/min to 250°C and hold Compound methane ethylene / acetylene ethane H2S COS propylene propane methyl mercaptan iso-butane RT 5.75 5.98 6.02 6.16 7.42 7.67 7.69 8.00 9.06 9.62 Compound butene-1 n-butane cis-2-butene trans-2-butene ethyl mercaptan CS2 iso-pentane n-pentane SO2 ** (not shown) n-hexane peak is 2 minutes wide B-0332 Technical Support 800-552-0413 11 Figure 4. GS-GasPro COS H2S SO2 CS2 MeSH EtSH PFPD 4 2 Time (min) 6 8 10 FID C2= iC5 C5 C3= C1 C2B iC4 C4 13BD t2B C3 C2 MA/C4= acetylene Table 4. GS-GasPro Column: Injector: Carrier: Oven: RT 1.82 2.35 2.62 3.34 3.39 3.63 4.01 5.34 6.14 6.35 6.45 GS-GasPro 30 m x 0.32 mm I.D. 200°C, 1:20 split Helium, 10 psig, 2.0 mL / min @ 60°C 60°C for 2 min, 20°/min to 260°C and hold Compound methane ethane ethylene COS acetylene H2S propane propylene iso-butane SO2 n-butane RT 6.61 7.60 7.92 8.13 8.35 8.38 8.56 10.29 10.30 Compound CS2 butene-1 trans-2-butene cis-2-butene iso-pentane methyl mercaptan n-pentane ethyl mercaptan n-hexane B-0332 Technical Support 800-552-0413 12 Figure 5. H2S Detection Limit and Peak Shape GS-GasPro GS-Q DB-1 ≈ 25-50 ppbV H2S on-column equivalent GS-CarbonPLOT ≈ 2500-5000 ppbV H2S on-column equivalent Figure 6. Trace Level Sulfur Determination GS-GasPro 5 m x 0.32 mm I.D. Gas sample valve, 1.0 mL fixed sample loop Sievers SCD, reaction tube 800°C Helium, 39 cm/sec at 0°C (determined by TR of COS) 0°C for 1 min, 30° / min to 160°C, hold at 160°C for 4 min, 50° / min to 260°C, hold at 260°C for 5 min Column: Injector: Detector: Carrier: Oven: Pk # 1 2 3 4 5 6 7 8 9 Compopund COS H2S CS2 Methyl mercaptan Ethyl mercaptan Thiophene Dimethyl sulfide & Isopropyl mercaptan n-Propyl mercaptan t-Butyl mercaptan 3 Pk # 10 11 12 13 14 15 16 17 18 19 Compopund Isobutyl mercaptan 3-Methylthiophene n-Butyl mercaptan Ethyl methyl sulfide Dimethyl disulfide Diethyl sulfide 2-Ethylthiophene 2,5-Dimethylthiophene Tetrahydrothiophene Diethyl disulfide 19 6.0 ppbV each component 15-18 7 11-14 4 5 6 8 2 9 10 1 2 3 4 5 6 7 8 Time (min) 9 10 11 12 13 B-0332 Technical Support 800-552-0413 13 Figure 7. Sulfur Dioxide Determination Column: GS-GasPro 5 m x 0.32 mm I.D. Injector: Gas sample valve, 1.0 mL fixed sample loop Detector: Sievers SCD, reaction tube 800°C Carrier: Helium, 39 cm/sec at 0°C (determined by TR of COS) Oven: 0°C for 1 min, 30° / min to 160°C, hold at 160°C for 4 min, 50° / min to 260°C, hold at 260°C for 5 min CS2 MeSH H2S EtSH SO2 others = 100 ppbV = 89 ppbV SO2 COS 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 B-0332 Technical Support 800-552-0413 14