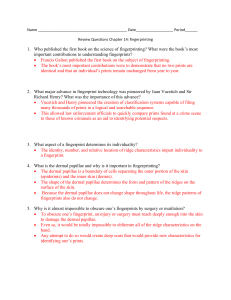

The Fingerprint Sourcebook - Crime Scene Investigator Network

advertisement