pdf, 2 MiB - Infoscience

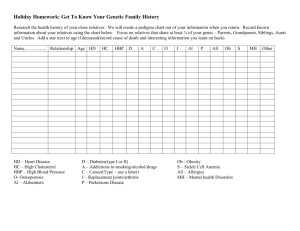

advertisement