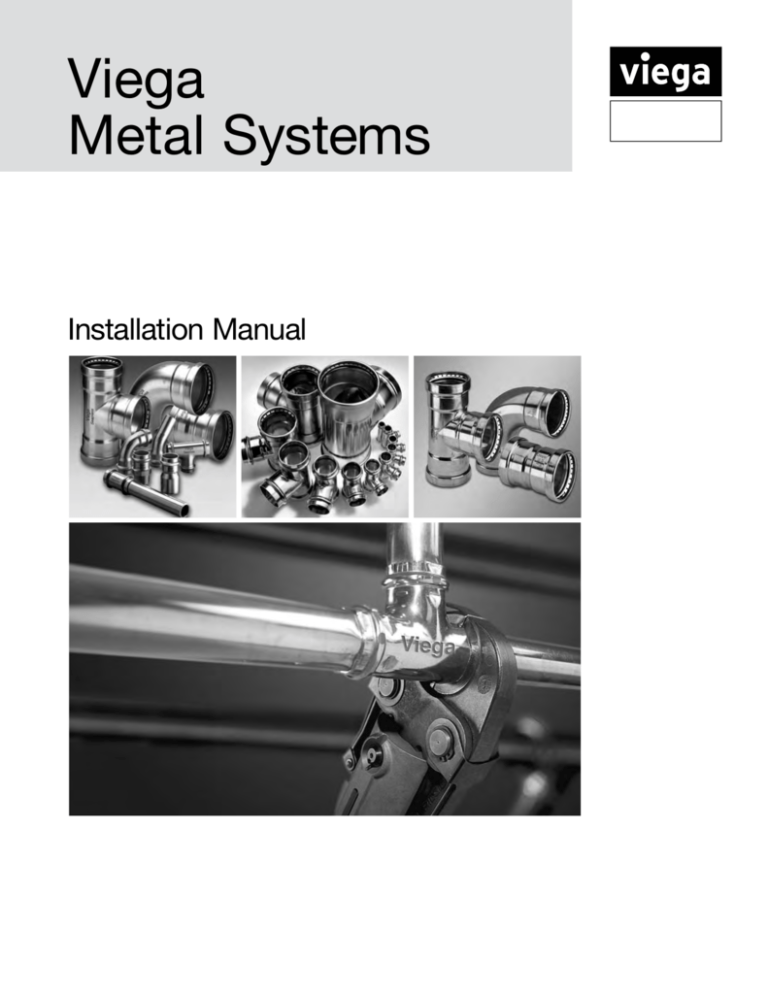

Viega Metal Systems Installation Manual

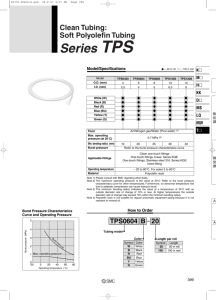

advertisement