Expert Report - MDL 2179 Trial Docs

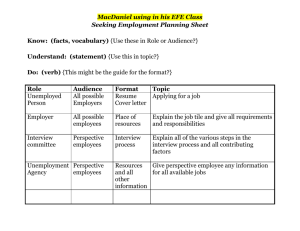

advertisement