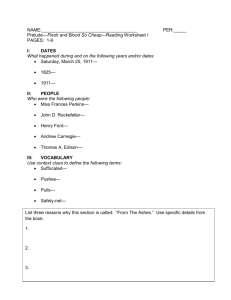

THE COMPLETE BOOK OF THE

advertisement

THE COMPLETE BOOK OF THE MODEL 1911 The Custom Edition ED BROWN Centennial WILSON COMBAT CONTEMPORARY CLASSIC Centennial From the Publishers of GUNS & AMMO ANNUAL USA/CANADA $8.99 Display until 11/07/2011 LES BAER CUSTOM CENTENNIAL Old New WHERE becomes Singer Mfg. Co. m1911a1 (mfg 1941) again Go inside the shop of Doug Turnbull to see how U.S. Model 1911s and M1911A1s are restored. Springfield armory 1911 (mfg. 1914) By Eric R. Poole // Photos by Tracy Halpin Remington Arms Co. umc 1911 (mfg 1918) Colt 1911 (mfg. 1913) Union switch & signal m1911a1 (mfg. 1943) Colt 1911 “black army” (Mfg. 1918) 6 BOOK of the 1911 gunsandammo.com WHERE Old New becomes again This was the official “before” picture taken of the author’s younger Model 1911 (MFG. 1918) submitted to Turnbull Mfg. for restoration. It had been subject to at least two arsenal rebuilds and was a host of mismatched parts. “I t can only be original once,” my dad would often say. As early examples of the U.S. Model 1911 start turning the century mark, those of us who possess a heavily used, refinished or obviously rebuilt 1911 struggle with the decision whether to preserve its weathered condition or restore it. “If it’s not documented to be historically significant,” says Keith VanOrman, president of Turnbull Manufacturing Company, “you should go ahead and let us restore it.” I sent serial number 340611 and 605521 to the expanding New York shop, and a few days later reality set in. There was nothing particularly special about my pair of 1918-manufactured Colt 1911s, something VanOrman’s team of researchers verified at the conclusion of the no-cost evaluation and work estimate. In terms of value, I had a high opinion of my older example since it retained better than 85 percent of its bluing and was found to be original except for one part. But, like so many collectors who want to believe that they possess a rare and unique treasure, I thought they would be valued for more than they’re actually worth. 8 BOOK of the 1911 SHOP HISTORY Doug Turnbull and two employees began restoring antique, American-manufactured firearms in the back room of Creekside Gun Shop near Bloomfield, New York. They were starting to build a name for themselves by accurately returning Parker, L.C. Smith and Fox shotguns as well as Winchester rifles made after 1873 Once the U.S. entered World War I, production of the 1911 increased dramatically. At about serial number 510,001 to the end of military production in 1945, the “United States Property” marking moved to the right side of the receiver, just behind the slidestop pin. to factory-new condition. The operations moved to a 4,000-square-foot facility in 1998 and expanded by 3,000 square feet in 2001 to accommodate the growing business driven by their reputation and word of mouth. As demand from inside the industry for Turnbull’s finishes increased, Turnbull Manufacturing Company was created and broke ground adjacent to the original building to create a 6,400-square-foot facility with a new showroom. Today there are currently 14 employees, including seven full-time gunsmiths and an in-house engraver. Turnbull Restoration obtained a federal license to become a manufacturer of firearms and started creating its own line of Colt-style single-action revolvers and Winchester-style rifles. Every gunsmith holds each piece to a strict hand-fitting and -polishing process before subjecting it to Turnbull’s highly respected, periodcorrect finishes. Much of its business is tied to the vault-kept bluing and color case-hardening formulas, coveted by other manufacturers and counterfeiters, used for specific serial-number ranges. With respect to the 1911 market, Turnbull has famously contributed the color case-hard- gunsandammo.com WHERE Old New becomes again ening, bone charcoal bluing and nitreblue finishes to the Kimber Centennial (see page 26 of last year’s 2010 edition of the Guns & Ammo Complete Book of the Model 1911), as well as the exacting bluing combination used on Bill Laughridge’s hand-crafted tribute from Cylinder and Slide to the original Model 1911 (see page 72 of this issue). Remington Arms, Colt, Smith and Wesson, U.S. Firearms and many gunsmiths around the world also look to Turnbull when the highest quality and historical accuracy are necessary for their most important projects. Since the business began in 1983, Doug Turnbull’s shop has restored or repaired more than 5,600 firearms and manufactured more than 200 new classics. SHOP VISIT Turnbull Manufacturing has restored in excess of 1,000 1911s in all makes and most variations. To fully understand what goes into the restoration of an important piece of history and experience one of my 1911s undergoing part of the process, I made a two-day road trip to Bloomfield, New York, from Illinois. I say “part of the restoration process” because as much as 40 hours of labor go into each pistol. Turnbull restores about 50 1911s each year, but with this year marking the 100th anniversary of the gun, the number of orders patiently waiting inside Turnbull’s bank vault (yes, it’s from an actual bank) has doubled. Clients are being told to expect a seven- to nine-month turnaround. Touring the shop section of the new Turnbull facility, I walked through the doors and was taken back to the memory of my years sitting at a bench with the warm smell of gun oil hovering in the air. The gunsmiths initially seemed unaware of my presence as they keenly focused on what they were doing within their own personally organized space. One was working on a side-by-side Fox shotgun, another on an old Winchester, and Mike Knowles up front was working on polishing the grip safety for one of my 1911s. In another room, a gunsmith/carpenter was working on restoring an old Hawkins shotgun recoil pad, but he was polite enough to take the time to discuss what goes into creating period-correct replacements for the different variations of 1911 stocks. The truncated diamond pattern cut into the walnut stocks of my 1918 pistols feature 14 diamonds per inch. Remington Arms-UMC stocks were cut with 13 to 13½ diamonds per inch, and Springfield stocks were cut with finer checkering and 10 BOOK of the 1911 15 diamonds per inch. Due to the large microscope positioned in the center of a sterile room, the next room visited within the shop appeared more like a laboratory. Behind the microscope was a thick-glassed engraver chiseling scrolls and flourishes into the slide of a commercial 1911 manufactured in 1921. He was working on his last project to illustrate his mastery of the four different types of engraving required to earn the highest rating from the Engraver’s Guild. He allowed me the opportunity to try my hand under the microscope, which only served to impress me with his ability to steady his hand with a fine degree of flawless perfection. It was an unexpected talent from a man who indicated that he wears his thick eyewear to correct his 20/600 vision. Moving deeper into the shop, parts bins towered along a wall, and I carefully noted the handwritten labels marking the discriminatory variations of several components. As such an example, there are nine types of front sights on 1911s and 1911A1s (military and commercial pistols), and within those types there are four variations of the Type 8. How does Turnbull still find so many period-correct parts? “We have sources,” VanOrman says. “If we disassemble the project and discover incorrect parts are on the gun, we work with the customer to make it more period correct. We also advise the customer as to what is correct and incorrect. Some replacement parts are original, while others are modern, but we use the correct stamps, polishing, checkering, roll dies and inspector marks to make it factory original. We do maintain a source for replacement parts, but I can’t mention from where.” Heading back to the older part of the facility, a room to the right revealed an enormous collection of wooden stock blanks—more exhibition-grade wood than I’ve ever seen in one room. Back and to the left was an antique lathe that worked like Thomas Jefferson’s original copy machine. An indicator on the left travels across the contours of an original stock, and a cutter on the right side mirrors its movement and forms the shape from a new blank. Little wood is wasted, and the gunsmiths at Turnbull are seasoned veterans in selecting and accessing the best art from the grain that each stock blank offers. The last room visited in the tour contained a roomful of lathes and milling machines, but my eyes were drawn to the wall of rollstamp dies as I realized that was one of the company’s secrets in obtaining correct markings. One of the easiest ways gunsandammo.com WHERE Old New becomes More than 130 unique roll stamps hang on a wall at Turnbull Manufacturing. From the scarce to the common, this unusual inventory is indicitive of the shop’s capability in addressing any restoration. again because the restoration would depreciate the pistol’s value. “The majority of our restorations are lower-condition, noncollectible 1911s,” says VanOrman. “These are typically $1,500 guns that bring the value to approximately $5,500 with $2,000 worth of restoration. It would be foolish to restore a high-quality gun.” When a 1911 comes in for a quote, it gets evaluated at no charge or obligation. A shop foreman takes a look at the gun, mechanically checks the condition (which does not involve a test fire) and creates to determine if a 1911 looks too good and has ever been refinished is to carefully inspect the markings. Gunsmiths will often polish the slabs on the slide and the frame to reduce the effects of rust pitting, but in doing so the stamps and proofmarks are smoothed over and the depth of the lettering becomes shallow by the time a 1911 is submerged in the bluing bath. In cases where a 1911 is pitted, a Turnbull gunsmith will completely remove any evidence of pitting, smooth out the slab and rollstamp the correct marking from one of the many dies the company has spent years collecting in order to produce an originalquality result. “We rarely see guns with too much pitting. They were built quite well,” says VanOrman. “We wouldn’t take on a project if [rust] pitting were too deep.” Heading to the new showroom, I noticed a locked door. “Is that where the bluing is done?” I asked. “Yes, but if I take you in there, I couldn’t let you out,” I was told. The formula and process to achieve the correct blue and color case-hardening is a Turnbull secret kept close to the chest. They won’t even explain how it’s done. “The one thing that I can share is that Colt used coal, and Turnbull Manufacturing Company uses propane for heating the ovens,” VanOrman indicated. “We know our bluing is correct based on comparing it to guns that are in 98 percent condition with a little bit of aging.” After nearly a century of service, serial number 605521 has been completely restored and appears exactly as it did the day it left Colt’s factory in late 1918. a detailed quote. At this stage, nothing about the gun has been disassembled. He considers what polishing or replacing of parts will likely need to occur before it’s even blued, then creates an estimate. After the client approves the work order, a gunsmith will disassemble the 1911 and examine the need for any internal parts replacement. The quote is amended with any unseen issues with the pistol, which are addressed with the client before a gunsmith continues. Each detail is broken down on a line-item quotation. The typical restoration costs about $2,500 and requires extensive research before beginning. The most common misunderstanding is when a client sends his Model 1911 to be blued after seeing a price of $250 listed on the Turnbull Web site. “What they don’t necessarily On several occasions Turnbull has rejected work on high-condition 1911s BOOK of the 1911 Turnbull’s shop with an average condition of 25 percent grade. Everything that leaves Turnbull’s shop is mechanically functional and ready to be fired. It doesn’t usually see a gun submitted for mechanical issues only; most gunsmiths are approached for that sort of work. Although Turnbull Manufacturing Company specializes in restorations, it will perform mechanical work while restoring a gun. Once a gunsmith completes restoration, it goes through the hands of quality control before it is returned to the client, but it’s never test fired. ARRIVAL TO RESTORE, OR NOT TO RESTORE? THAT IS THE QUESTION 12 think about is the work that has to be done to most projects before they can be blued,” says Tracy Haplin, marketing manager for Turnbull Manufacturing. “It usually has to be prepped and polished before any marks are added. Historically speaking, different parts got polished in different ways. There is more to what we do than simply bluing. Some people try to prep the pistol themselves, but most of the guns need an entire restoration. Occasionally, we do get one in from a gunsmith that has good prep work, and it can be simply blued for $250, but most gunsandammo.com gunsandammo.com end up needing additional work.” Sharing space inside the Turnbull vault are valuable materials including out-ofprint references, factory archival data and a library of pictures and notes gathered from encounters with other original samples known to be historically correct. No detail is too small, and only Turnbull’s restoration services have proven the ability to accurately reproduce every fine detail to exacting standards—proofmarks, inspector marks, the number of lines in checkering on different components, the sequence of tactile diamonds cut into a Colt stock slab in contrast to the lines of checkering on a Remington or Springfield. Even the direction and depth of the grain created from final polishing to every component gets critiqued. The most common restoration to a 1911 is applied to an early Colt M1911 U.S. Army, though the gunsmiths at Turnbull have completed a number of M1911A1 projects. For those who are of the opinion that allowing an original 1911 to be subject to restoration is sacrilege, consider the fact that most 1911 projects arrive to I purchased the pistols that I sent in for restoration for just $500 apiece. The younger of the two was in especially rough condition. A few short weeks after my visit, both of my 1918-vintage 1911s were signed for and unveiled in the office. It’s easy to understand why so many owners of the early .45s are looking to Turnbull Manufacturing Company for its restoration services. My vintage 1911s now appear as if they just came off the original assembly table. It is such an incredible feeling to think back upon their condition months ago, witness a day in their transformation and see what they have ultimately become. For a heavily worn or nonfunctioning, mismatched-parts gun without some type of documented provenance, Turnbull’s services can renew a 1911’s honor while creating an excellent investment. Occasionally, Turnbull Manufacturing Company offers similar restored pistols from its inventory or on customer consignment for a price usually falling between $4,500 and $5,500 (determined by a number of factors). At the time of this writing, there is a Remington UMC listed for $6,250 and a Colt Model 1911 Black Army priced at $4,750. As high as those prices might sound for a restored 1911, Turnbull has no problem selling them. This is the only shop I know where someone can send an honest antique to be restored without the risk of destroying its value. For more information, visit turnbullmfg.com. BOOK of the 1911 13 WHERE 14 Old New becomes BOOK of the 1911 again gunsandammo.com gunsandammo.com BOOK of the 1911 15