Networked PIP Series Reference Manual

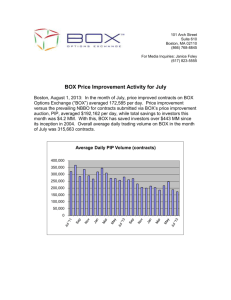

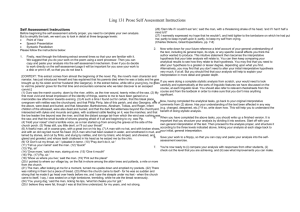

advertisement