IQ-PIP-SLM Reference Manual

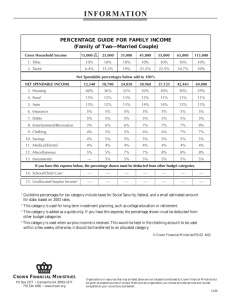

advertisement