hurricane heating system - International Thermal Research

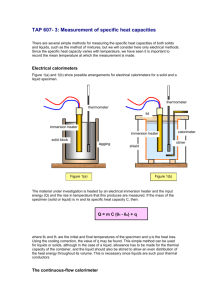

advertisement