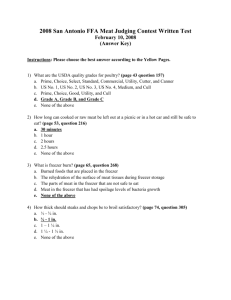

Guidance Notes - Food Standards Agency

advertisement