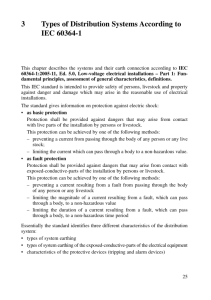

5 Protective Measures for Persons and Installations

advertisement