Industrial Automation - National University of Ireland, Galway

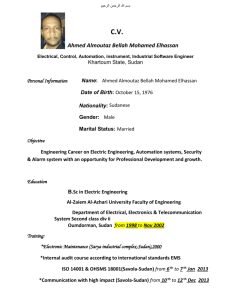

advertisement