Molykote® Synthetic Fluids Offer up to

40% Better Cost/Performance Over

Conventional Mineral Oils

Smart Lubrication™

ECONOMIC MODEL

Plant Lubricants

Maintenance managers may achieve UP TO a 40 percent cost saving in air

compressor maintenance and better efficiency from gearboxes by replacing

conventional mineral lubricants with Molykote® brand synthetic lubricants

in high-volume applications. Here’s an analysis explaining how the benefits

are achieved.

Formulation saves money by

extending oil lifetime and lowering

labor workload.

Reduced Compressor Maintenance Cost

Lubricating rotary screw and reciprocating compressors with Molykote®

Synthetic Compressor Oils is a cost-effective way to extend maintenance

intervals and optimize compressor performance. Savings are possible

beacuse synthetic oils greatly extend changeout intervals and eliminate

varnish buildup inside compressors.

For example, a rotary screw compressor system requiring 30 gallons of

lubricant typically needs only one fill of Molykote Synthetic Compressor Oil,

compared with five fills of conventional mineral oil in the same time period.

This represents a saving in oil cost of about 13 percent. Add to this the

savings in labor, fluid disposal, less frequent demister changes, and the total

annual cost saving is 40 percent. Details are provided in the table below:

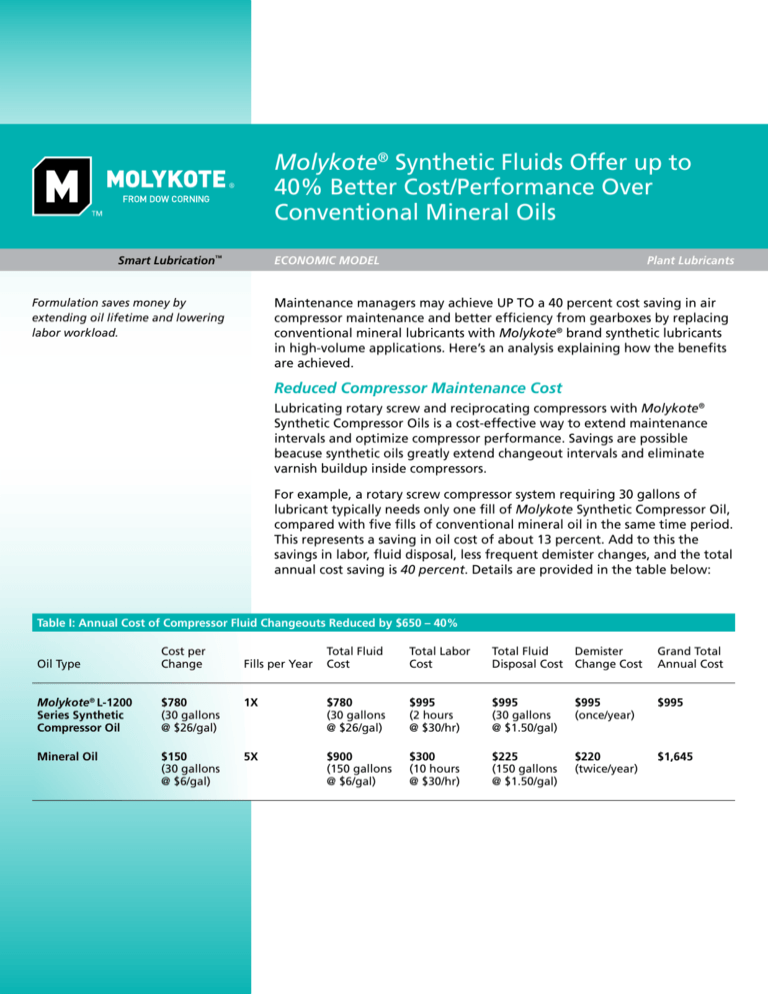

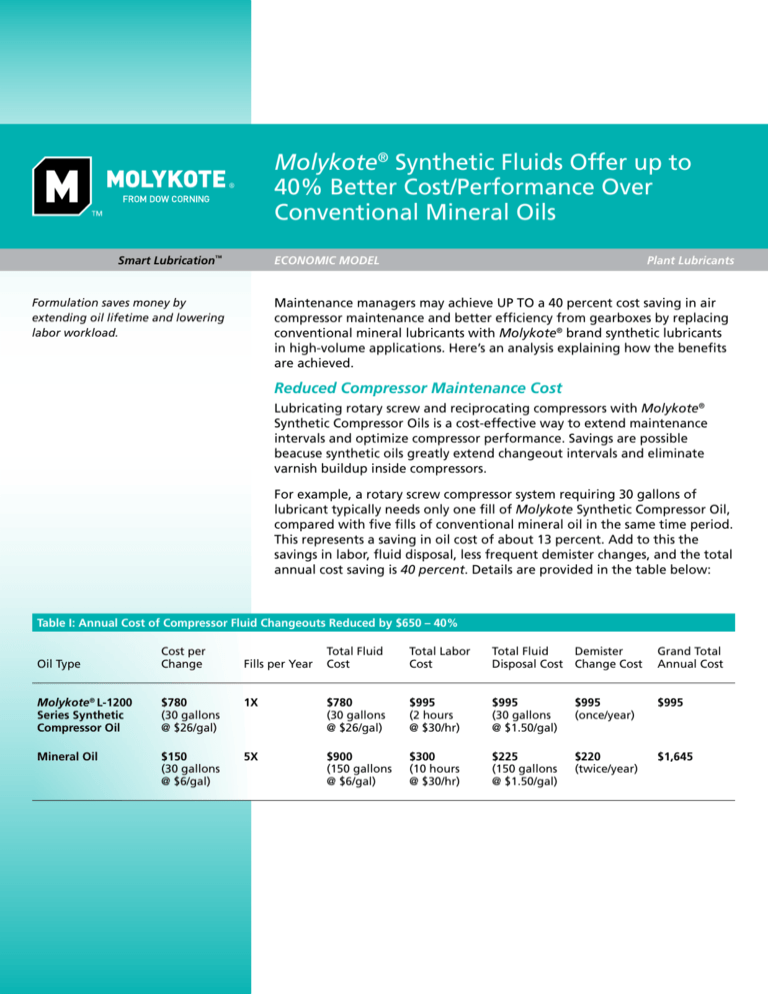

Table I: Annual Cost of Compressor Fluid Changeouts Reduced by $650 – 40%

Oil Type

Cost per

Change

Molykote® L-1200

Series Synthetic

Compressor Oil

$780

(30 gallons

@ $26/gal)

Mineral Oil

$150

(30 gallons

@ $6/gal)

Total Fluid

Cost

Total Labor

Cost

Total Fluid

Demister

Disposal Cost Change Cost

Grand Total

Annual Cost

1X

$780

(30 gallons

@ $26/gal)

$995

(2 hours

@ $30/hr)

$995

(30 gallons

@ $1.50/gal)

$995

(once/year)

$995

5X

$900

(150 gallons

@ $6/gal)

$300

(10 hours

@ $30/hr)

$225

(150 gallons

@ $1.50/gal)

$220

(twice/year)

$1,645

Fills per Year

Gearbox Efficiency Improvements

Using Molykote® Synthetic Gearbox Oils should also reduce costs associated

with maintaining and lubricating gearboxes throughout the plant. Because

the synthetic gearbox oils typically last about three times as long as conventional mineral oil products, the annual cost in each case is about the same.

This chart compares the costs:

Table II: Comparative Annual Cost of Gearbox Oils*

Oil Type

Cost per

Change

Fills per Year

Total Fluid

Cost

Total Labor

Cost

Total Fluid

Grand Total

Disposal Cost Annual Cost

Molykote®

Synthetic Gear Oils

$130

(5 gallons

@ $26/gal)

1X

$130

(5 gallons

@ $26/gal)

$15

(.5 hours

@ $30/hr)

$7.50

(5 gallons

@ $1.50/gal)

$152

Mineral Oil

$30

(5 gallons

@ $6/gal)

3X

$90

(15 gallons

@ $6/gal)

$45

(1.5 hours

@ $30/hr)

$22.50

(15 gallons

@ $1.50/gal)

$157

*5 gal. fill, mfr. rec. 2500-hr. service.

The Real Payoff Is in Performance

Because the synthetic gearbox oil lubricates more efficiently, it reduces the

amount of horsepower required to achieve a targeted level of torque. Unit

efficiencies are significantly improved by the use of synthetic lubricants,

so that the input horsepower consumption will be less for a given torque

capacity.

Table III: Comparative Input HP Needed to Achieve Output Torque Rating of Worm Gear Speed Reducers*

Gearbox Lubricant

Input RPM

Input HP

Output Torque

HP Savings

Molykote®

Synthetic Gear Oil

1750

0.35

557

16.6%, compared

to mineral oil

Conventional

Mineral Oil

1750

0.42

557

*Example is a 2-inch center distance, 60:1 ratio. Improvement in efficiency increases as ratio increases.

Improved lubricant performance and gearbox efficiencies associated with

synthetic lubricants offer several benefits. The energy that would have been

lost to friction is saved. Lower power consumption reduces cost. Less friction

means lower operating temperatures. Gearboxes with synthetic oils suffer

less wear during warmup from starting. Gearboxes filled with synthetic oils

run cooler, which means that the lubricant may last even longer than its

rated lifetime.

Keys to Performance

Both the cost/performance and efficiency improvements result from the

lubrication performance of synthetic Molykote products.

Because conventional mineral oils are produced in a conventional refining

process, they contain a significant amount of “impurities.” The high

percentage of impurities shortens the oil’s service lifetime by providing

many sites for oxidation to occur. Above the operating temperature range

of 140-160°F, the lifetime of a mineral-based lubricant is cut in half by every

20°F increase in temperature. As a mineral oil degrades, by-products of its

breakdown may cause a build-up of a hard, sticky “varnish” on the internal

metal surfaces. This build-up adversely affects performance.

By comparison, synthetic lubricants are made by chemically building complex

molecules from hydrocarbon “building blocks.” They feature identical,

strong molecular bonds in a saturated molecular structure. This provides

more resistance to oxygen attack at rated operating temperatures and less

heat-generating friction. Synthetic lubricants achieve full lubrication at

start-up more quickly and, therefore, reduce component wear. The synthetic

lubricant’s resistance to oxidation and other properties leads to longer

service lifetime, more efficient lubrication and less formation of undesirable

by-products in the lubricant.

Synthetic lubricants offer another benefit to food and beverage processors.

Many food plants have adopted a policy of using only food-grade synthetic

lubricant products for their MRO needs. All Molykote Synthetic Compressor

and Gearbox Oils are available in formulations that are approved for use in

food processes according to USDA standards. Price/cost benefits are detailed

in the tables. Standardizing on food-grade products eliminates the possibility

that plant workers will confuse food-grade and non-food-grade products.

Summary of Typical Benefits

• Fewer oil changes

• Lower waste lube disposal costs

• Fewer filters

• Lower labor costs

• Power and energy savings

• Lower operating temperatures

• Fewer replacement parts

• Fewer scheduled maintenance interruptions

• Fewer breakdowns/unscheduled interruptions

WARRANTY INFORMATION – PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However,

because conditions and methods of use of our products are beyond our control, this information

should not be used in substitution for customer’s tests to ensure that Dow Corning’s products are

safe, effective, and fully satisfactory for the intended end use. Dow Corning’s sole warranty is that

the product will meet the Dow Corning sales specifications in effect at the time of shipment. Your

exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement

of any product shown to be other than as warranted. Dow Corning specifically disclaims any other

express or implied warranty of fitness for a particular purpose or merchantability, unless Dow Corning

provides you with a specific, duly signed endorsement of fitness for use. Dow Corning disclaims

liability for any incidental or consequential damages. Suggestions of use should not be taken as

inducements to infringe any particular patent.

Dow Corning and Molykote are registered trademarks of Dow Corning Corporation.

We help you invent the future is a trademark of Dow Corning Corporation.

©2000 Dow Corning Corporation. All rights reserved.

Printed in USA

AGP12457

Form No. 10-1016A-01