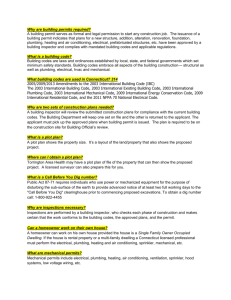

UNIFORM PLUMBING CODE UNIFORM PLUMBING CODE

advertisement