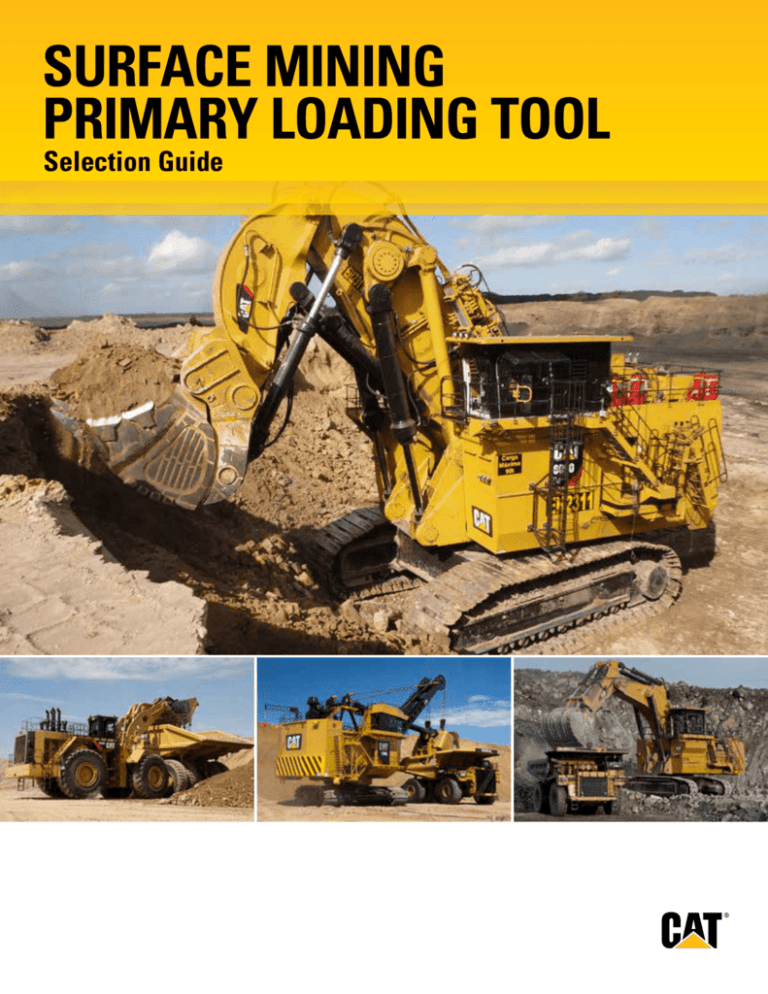

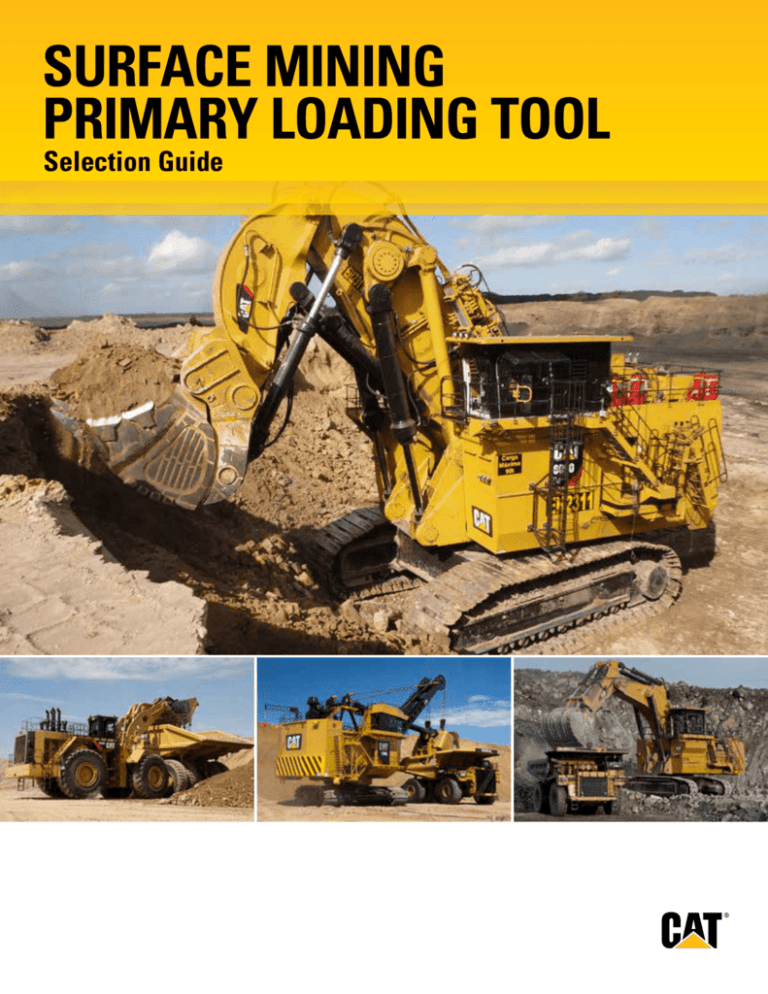

Surface Mining

Primary Loading Tool

Selection Guide

Wherever there’s loading, we’re there.

Loading applications vary between mine sites, so it’s important to have appropriate loading tools.

Caterpillar is the only mining equipment manufacturer to offer every type of loading tool for surface

mining – electric rope shovels, hydraulic front shovels, hydraulic backhoes, and wheel loaders.

This guide presents an overview of these tools and describes how to use each type most effectively.

Together, you and your customer can use this information to make highly informed decisions for

every mine plan.

Contents

Selection Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Descriptions. . . . . . . . . . . . . . . . . . . . . . . . .5-7

Site Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Mining Methods/Techniques. . . . . . . . . . . . . . . . 13-19

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-21

Buckets and Dippers. . . . . . . . . . . . . . . . . . . . . . . 22-23

Selection Process

Surface mining-specific needs and working face attributes are primary selection considerations. The overall goal is to maximize profit

with a loading system that meets targeted hourly production at the lowest cost-per-unit of material moved.

Mine Site Considerations

Equipment Considerations

• Electrical infrastructure

•Life of the surface mining operation

• Longevity of the operation

•Electric power availability

• Annual production target

•Primary loading

• Face material

•Multiple loading faces

• Material fragmentation

•Secondary functions such as stockpiling, loading rail cars,

feeding the primary crusher, cleanup, and maintaining a

surge pile

• Penetration characteristics

• Material angle of repose

• Face height and angle

• Bench width

• Maneuvering space

• Multiple loading faces

• Floor conditions

• Job set-up

• Load area support equipment needs

• Blasting restrictions

4

The electric rope shovel, hydraulic front shovel, hydraulic

backhoe, and wheel loader fit into primary loading functions in

surface mining applications. The equipment that is best for the

job depends on the characteristics of the job site.

Product Descriptions

Electric Rope Shovels

Electric rope shovels offer the lowest cost-per-ton loading

solution for long-life mines. Although they have traditionally

required electrical infrastructure, Caterpillar is developing an

off-grid power solution to allow non-electrified mines to consider

this loading tool option.

They are most efficient when the work face is between 12 and 18

meters (39 and 59 feet) high. Line of sight is high above the truck

being loaded, giving the rope shovel operator excellent visibility

of the truck bed.

Due to the large size of the machine, it is possible to use a

double-side loading method for added efficiency. This method

allows the rope shovel to load one truck while another truck gets

into position on the other side, for continuous loading. Trucks are

positioned up to 7 meters (20 feet) away from the rope shovel’s

crawlers throughout the loading cycle, helping to reduce or

eliminate collisions during truck spotting.

An electrically powered machine, the rope shovel’s immense

payload capability, low maintenance requirements, and

high reliability make it the lowest total cost-per-unit loading

tool available.

Favorable Conditions

• Working a single face of the correct height

• Solid, level floor

• Wide benches to facilitate truck maneuverability

• Well-shot material

• Cleanup and ground support

• Good trail cable management

Unfavorable Conditions

• Poor underfoot

• Low faces

• Poorly shot or unshot material

• Multiple face location

• Selective digging

5

Product Descriptions

Hydraulic Front Shovels and Hydraulic Backhoes

Hydraulic shovels combine the benefits

of high digging forces with large capacity

buckets. They can selectively dig deposits

anywhere in the face, giving operators

added flexibility. Hydraulic front shovels

are usually used in tight material (12 m/

40 ft plus) to penetrate tough material.

benches may be narrow. Truck positioning

and proper truck match are critical. The

operator’s eye level is also sufficient

for same level loading if the truck is not

extremely oversized.

Hydraulic shovels are also available as

AC version with electric drive, which

offers lower cost-per-ton for electrified

mine sites, similar to electric rope

shovels.

Hydraulic backhoes work best when

positioned on an upper bench with

haulers at a lower level for high

productivity and best operator view into

the truck bed. They are also capable of

same-level loading if required. Bench

height should correspond to stick

length for adequate reach in loading

and dumping.

Hydraulic Front Shovels

Hydraulic Backhoes

Free-flowing faces with low angles of

repose favor the front shovel due to the

limited reach of the backhoe.

Hydraulic shovels work well in poor

underfoot conditions (soft or jagged

floors) and in tight quarters, where

6

Favorable Conditions

• Selective digging

• Multiple face heights

• Single face loading

• Multiple targets

• Tight load area

• Tough digging

• Can work in poor floor conditions

• Define dig pattern and maintain

Unfavorable Conditions

• Excessive tramming

• Low benches

• No cleanup support

• Multiple faces

Favorable Conditions

• Low to moderate bench heights

• Truck spotted either on top of bench

or on the floor below the backhoe

• Tight load area

• Short swing – 60°

• Well-shot material

Unfavorable Conditions

• High benches

• Excessive tramming

• Multiple benches

• Unstable benches

• Low angle of repose material

• No cleanup support

Surface Mining Primary Loading Tool Selection Guide

Wheel Loaders

Large wheel loaders have grown in size over time to match

increasing off-highway and mining truck payload capacities.

They increase productivity with consistent high bucket fill

factors and are used effectively as primary loading tools where

mobility is paramount. In conditions common to crushed-stone

applications, wheel loaders keep loading floors clean, work

between multiple faces, and transport oversize material away

from loading area. Productivity remains high even when the

machines encounter face conditions such as free-flowing

material or material with low angles of repose.

These reasons, plus traditionally low owning and operating

costs, have made wheel loaders very popular in mines

worldwide.

Although wheel loaders articulate at a full 40 degrees, they still

need ample maneuvering room. Caution should be noted with

wheel loaders in tight box cuts. Due to the lack of room, the

loader may grind tires and decrease their life. This occurs by

not keeping the loader moving fore and aft while making tight

maneuvers and chewing the rubber from the tread.

Favorable Conditions

• Level, dry, smooth, firm floors

• Sufficient crossfall and drainage in wet areas to minimize

tire damage

• Well-fragmented materials that minimize crowding time,

particularly in the toe-area of the cut

• Lower face profile

• Multiple faces and frequent traming

Unfavorable Conditions

• Poor underfoot conditions – wet, soft, jagged

• Tight load areas

• Poorly shot material

7

Site Conditions

INFRASTRUCTURE

ESTIMATED LIFE-OF-MINE

Mine sites equipped with an electrical infrastructure have the

option to choose electric rope shovels and/or electric powered

hydraulic shovels for their loading tool needs. Using electric

machines lowers the operation’s overall cost and reduces

emissions. They do require trail cables connected to substations, which limits their mobility.

The expected longevity of the mine site also plays a role in

loading tool selection. Electric rope shovels are designed to have

an operating life of 120,000 hours, making them a viable option

for mines with estimated lives that meet or exceed a timeframe

of 20 years.

For non-electrified mine sites, diesel-powered hydraulic shovels

and wheel loaders remain the primary loading tool options.

Diesel-powered machines offer a distinct advantage in mobility

and flexibility, despite a higher operating cost. However, with the

introduction of our off-grid power solution, non-electrified mines

now have the option to use electric rope shovels. Greenfield

mines in the planning process must weigh the long-term cost

implications between investing in an electrical infrastructure

for electric-powered loading tools and using diesel-powered

equipment only.

8

For mine sites with shorter estimated lives, hydraulic shovels

and wheel loaders may be more viable options. Hydraulic

shovels and wheel loaders are designed to have an operating

life of approximately 50,000 to 60,000 hours without exchange of

major steel structures, dependent upon application and proper

maintenance.

Surface Mining Primary Loading Tool Selection Guide

Loading Conditions

There is no single loading tool that will do all things on all jobs; each has a definite application range in which it is regularly used and is

suitable economically. This chart shows generally accepted guidelines for matching equipment to loading conditions.

Factor

Condition

Load Area

Single open bench

Wheel

Loader

Hydraulic

Front Shovel

Hydraulic

Backhoe

Electric

Rope Shovel

Double-sided loading

Multiple benches

Confined area

Poor truck positioning

Material Condition

Good fragmentation

Tight material

Oversize material

Selective digging

Bench Height

Angle of Repose

High

*

Low

*

Steep

Shallow

Floor – Shape

Level and firm

Uneven or undulating

Floor – Surface

Dry, good traction

Wet, good traction

Wet, low traction

Wet and jagged

Bucket/Dipper Performance

Achieve rated capacity

Match multiple targets (truck size)

Dig above grade

Dig below grade

Cleanup

Blast cleanup

Scaling face

Load area cleanup

Digging out toe

Travel

Multiple loading sites

Mobility for blasting

Load and carry

Secondary Tasks

Blending

Dark Yellow – Ideal

*Bench height needs to be optimized for hydraulic backhoe.

Medium Yellow – Recommended

Light Yellow – Capable

Grey – Not recommended

9

Site Conditions

Blasting and Fragmentation

Good blasting and fragmentation techniques play an important

role in the productivity and life expectancy of your loading tools,

whether you’re using an electric rope shovel, hydraulic shovel, or

wheel loader. Benefits include:

•Improved bucket fill and reduced bucket load time result in

better loader productivity, longer loading tool life, and reduced

cost per ton of material loaded

•Improved primary loading tool productivity, as less time is

spent digging out and placing oversized pieces of material for

secondary breakage

•Reduction of oversized pieces of material and associated

secondary breakage costs

•Reduced congestion in the loading area caused by a shortage

of oversized pieces of material rocks, leading to improved

truck exchange time

•More consistent truck payloads

•Less tipping impact at hoppers and crushers

•Reduced crushing costs and improved crusher throughput,

lowering crushing cost-per-ton

10

Improved fragmentation through blasting can have downsides

as well:

•Higher cost of drilling

•Increased cost of explosives

•More fines produced

Typically, the improvements in loading tool productivity more than

offsets the higher costs associated with drilling and blasting.

Surface Mining Primary Loading Tool Selection Guide

Floor Conditions

Solid, flat floors are ideal for all loading systems, but changing floor conditions require a careful choice of track shoes for hydraulic

shovels and electric rope shovels, and tires for wheel loaders, that are the best fit for the operation.

Tracks

In most surface mining applications, the narrowest single

grouser shoes are generally the most durable choice. In soft,

spongy conditions, a wider shoe provides better flotation. On

jagged or rolling ground, hydraulic shovels and electric rope

shovels will often “pad” a floor by adding fines to form a stable

loading platform. This can prevent the shovel from rocking

on the undercarriage during the loading cycle, as rocking

significantly reduces undercarriage life and operator efficiency.

Wheel loaders, which do not experience these undercarriage

constraints, also do an excellent job of adding fines and

filling in low areas to construct a better working surface.

Soft/Spongy

Jagged/Rolling

Electric rope shovels and the larger hydraulic shovels rely on

support equipment, like track-type tractors or wheel dozers, to

adequately prepare ground conditions.

Most loading systems can work on pitched slopes, or pitched

seams, but wheel loaders typically are less effective than

hydraulic shovels on steeper grades. Electric rope shovels are

also not well suited to work on highly pitched slopes or seams. If

floor conditions are severe (wet) or change cannot be controlled,

wheel loader production may decrease. Tracked machines are

better suited for such conditions.

Pitched

Wet

11

Site Conditions

ground pressure

Nominal ground pressure and gross machine weight are

indicators of machine flotation in poor underfoot conditions.

Hydraulic shovels exert approximately one-third of the ground

pressure compared to similar-sized wheel loaders.

Ground Pressures

Tire or Track

Electric Rope Shovels*

7295-7495

220-374 kPa (32-54.1 psi)

Hydraulic Shovels

6015/6015 FS-6090 FS

167-251 kPa (24-37.4 psi)

Wheel Loaders

988-993

Changing floor conditions, such as rainwater or the freeze/thaw

cycle, must also be taken into account. Good mobility, traction,

and flotation must be considered during the entire range of

conditions. The operator has the ability to adapt the face and

floor conditions for the loading tool to ensure

continued productivity:

•Face height

•Floor padding (adding rock fines to the floor)

345-551 kPa (50-80 psi)

* The 7495 HF includes a high-floatation undercarriage specifically

designed for soft ground conditions, similar to what is found in the

Canadian oil sands. The ground pressure for the 7495 HF is 216 kPa

(31.4 psi).

12

In general, ground pressures increase as machine size

increases. Very large machines, like electric rope shovels and

larger scale hydraulic shovels, must have a solid sub-base to

operate effectively. Also, wider tracks or tires will reduce

ground pressure.

•Additional support units

Surface Mining Primary Loading Tool Selection Guide

Mining Methods/Techniques

the loading process

In many ways, loading is the central part of any earthmoving process. The entire system’s productivity is governed by the loading

tool’s productivity. There are strong links to the muckpile condition upstream and the truck fleet downstream of the loading tool.

If the loading process is productive and cost-effective, the entire material moving process will be as well.

$

Blasting

Loading

Cost

Rock strength

Crowd/rimpull

Repairs

Laminations

Breakout

Tires and U/C

Drill pattern and angle

Bucket shape

Bucket/GET

Hole size

Penetration

Labor

Explosives

Fill factor

Powder factor

Productivity

Productivity

A good indicator of material ability is the average time it takes

to fill the bucket/dipper. A proper loading tool productivity study

measures the four-part loading cycle:

1. Dump

2. Travel empty or swing empty

3. Dig

4. Travel loaded or swing loaded

The total cycle time is the sum of segments 1 through 4.

•Loading time should take less than 16 seconds, regardless of

the loading tool.

•Loading times longer than 10-16 seconds may be an indication

that the material/muckpile is not properly conditioned for the

loading tool. It could also be an indication of the operator’s

skill level.

Note: Load times are averaged and will vary cycle to cycle as the

loading face changes. Handling oversize pieces of material or

digging the toe of a highwall will increase individual dig times.

Typical cycle times (in seconds):

Electric Rope Shovels

28-44 sec (avg 37)

Hydraulic Front Shovels

21-32 sec (avg 26.5)

Hydraulic Backhoes

21-31 sec (26)

Wheel Loaders

28-42 (avg 35)

13

Mining Methods/Techniques

digging ranges

Electric Rope Shovel

Hydraulic Backhoe

14

Surface Mining Primary Loading Tool Selection Guide

Hydraulic Front Shovel

Wheel loaders, hydraulic front shovels,

and electric rope shovels are positioned

in front of the working face. All three are

able to dig from the bottom to the top

of the face in one fluid motion, but only

the hydraulic front shovel has selective

digging capability. Selective digging

refers a machine’s ability to penetrate

the face at any height. Hydraulic

backhoes are generally positioned at

the top of the face, allowing the machine

to dig below grade via a digging motion

that moves toward the machine, enabling

selective digging capability.

Wheel Loader

15

Mining Methods/Techniques

SINGLE-SIDE LOADING

DOUBLE-SIDE LOADING

•Truck is on left-hand side, so that truck driver and shovel

operator have direct eye contact

•Minimized truck spotting time for higher short-term productivity

•Shovel can follow a straight working face without major

repositioning effort

•Well-trained operators required

•Good floor conditions are easy to maintain

•Support equipment can clean the excavated area behind

the shovel without interfering the loading action

•Always mine the face from right to left, then travel back

and continue

•Tracks 45° towards face, travel motors to rear

Hydraulic Backhoe Top loading –

Truck on upper level

•Applied for drop cuts and difficult-to-access or wet areas at

the pit bottom

•Increased lifting effort and larger swing angle requires longer

cycle time

•Approximately 15% to 20% lower productivity

16

•Higher risk of collisions

•While loading to the right side, both shovel operator and truck

driver are on the blind side

•Shovel cannot follow straight working face and has higher

repositioning effort

•Permanent clean-up support required

•Tracks 90° towards face, travel motors to rear

Surface Mining Primary Loading Tool Selection Guide

Typical Hydraulic Backhoe application –

Truck on lower level

•Lowest risk for collision with proper bench height due to clear

separation of loading and hauling equipment

•Excellent operator view into the truck body

•Potential for short swing angles

Drive-by loading

•Truck spotting time eliminated for highest productivity, because

the next truck does not need to reverse for positioning

•90° swing angle

•Loading through the gate is more difficult due to limited space

for dumping

•Shortest attachment lifting distance possible

•Various options for truck positioning with loading through the

body gate or over the side wall

17

Mining Methods/Techniques

PASS MATCH

Caterpillar offers a world-class range of wheel loaders, hydraulic shovels, and electric rope shovels, as well as a full line of offhighway and mining trucks designed to work together for maximum productivity. The loading tool must be matched to the truck, with

the correct bucket/dipper size, to optimize loading cycles.

Rope Shovel Pass Match Guide

Truck

Rope Shovel

7495

4

797F

MT6300 AC

Passes

795F

MT5500 AC

Passes

MT5300 AC

3

3

7495 HF

7495 HD

7395

7295

4

–

–

–

3

–

–

–

4

–

–

4

–

4

–

Passes

Passes

3

Passes

Passes

793F, 793D

MT4400D AC

–

–

789D

MT3700 AC

–

–

785D, 785C

MT3300 AC

–

–

18

Passes

3

Passes

3

Passes

Passes

Passes

–

–

3

Passes

Surface Mining Primary Loading Tool Selection Guide

Hydraulic Shovel Pass Match Guide

Truck

Hydraulic Shovel

6090 FS

4

797F

MT6300 AC

Passes

795F AC

MT5500 AC

Passes

MT5300D AC

793F, 793D

MT4400D AC

3-4

3

Passes

3

Passes

6060

6060 FS

6

Passes

5-6

5

4

–

777G

777D

–

–

6015

6015 FS

7-8

–

–

–

–

6-7

–

–

–

–

6

–

–

–

–

6

–

–

–

6

–

–

7-8

–

5

Passes

3-4

–

6018

6018 FS

Passes

Passes

785D, 785C

MT3300 AC

6030

6030 FS

Passes

Passes

–

6040

6040 FS

Passes

Passes

789D

MT3700 AC

6050

6050 FS

Passes

4

Passes

5

Passes

Passes

3

Passes

4

Passes

Passes

–

–

4-5

Passes

Passes

3-4

5

Passes

Passes

8

Passes

Wheel Loader Pass Match Guide

Truck

Wheel Loader

Extended High Lift

High Lift

994H

994H

7

–

994H

793F, 793D

MT4400D AC

Passes

6

789D

MT3700 AC

–

785D, 785C

MT3300 AC

–

–

777G

777D

–

–

Passes

993H

993H

–

–

5

Passes

4

992H

992H

–

–

–

–

–

–

–

–

–

6

–

7

–

–

High Lift

Passes

Passes

–

–

3-4

Passes

High Lift

Passes

4-5

Passes

4

Passes

990H

High Lift

5-6

Passes

19

Applications

Working the Face

Excavating and loading operations account for a significant

portion of total material movement costs, so it is prudent to

search for the most cost-effective approach.

There are several types of excavating faces:

•

Well Fragmented – The ideal conditions for all loading tools.

•

Selective Digging – Both hydraulic front shovels and hydraulic

backhoes are able to selectively dig. The narrow bucket and

ability to load anywhere in the face makes it a good selective

loading tool for extracting specific material without disturbing

or handling unwanted material.

•

Consolidated/Poorly Shot – Hydraulic shovels may work in this

situation. Other site needs may drive the selection process. In

some cases hydraulic shovels can even work in free digging

rock applications, such as limestone. Pre-condition is a

certain grade of natural fractures in the deposit, such as layer

boundaries or fissures.

•

Free Flowing – Favors the wheel loader, but a hydraulic

backhoe could be placed on top of the pile for high production

applications with proper support equipment. This type of

material produces high fill factors and fast cycle times,

resulting in high productivity.

All the loading tools can work these types of faces, but each

one has its best fit. For instance, a loading tool with high digging

forces applied at an easy loading face would be a waste of

capability, raising the cost-per-unit. Or a wheel loader digging in

consolidated excavation might result in low productivity and high

component wear (GET), driving up unit cost.

Breakout forces and digging range play a part in each machine’s

digging ability.

•

Electric Rope Shovels provide breakout forces that can

facilitate digging of the toughest materials. However, digging

well-blasted material is preferred, as it reduces wear and tear,

limits downtime for maintenance, extends operating life, and

provides high rates of productivity.

•

Hydraulic Shovels have the ability to dig tougher materials,

partly due to the higher breakout force per length of cutting

edge. The bucket can penetrate at the weakest spot of the

working face, which is typically the border area of individual

layers, and can follow the direction of the layers. These higher

cutting forces provide better loading, particularly for material

that is fragmented and keyed together, or material that does

not flow well into a bucket.

•

Wheel Loaders have adequate breakout force for all but the

toughest materials.

Free Flowing

Consolidated

Selective Digging

Tight Shot Face

20

Well Fragmented

Surface Mining Primary Loading Tool Selection Guide

Mobility and Multiple Uses

Electric Rope Shovels

Hydraulic Shovels

Wheel Loader

Electric rope shovels have limited mobility.

The sheer size of the electric rope shovel

places stress on the crawler links during

tramming, increasing maintenance costs

as a result of excessive movement. In

addition, electric rope shovels require a

trail-cable that is connected to a nearby

sub-station, limiting the rope shovel’s

ability to move great distances quickly

and frequently.

Due to slower travel speeds compared

to wheel loaders, the hydraulic shovel’s

mobility tends to be limited. In most

mining applications the hydraulic

shovel is a primary loading tool, and

is therefore used primarily for the

loading of overburden and ore in the

mine. However, hydraulic backhoes

can also be used for auxiliary jobs

(e.g., drop cuts and preparation of

ramps). Moreover, diesel-powered

hydraulic shovels offer more mobility

than electric rope shovels (and electricpowered hydraulic shovels), because

they are not tethered to a trail cable.

With their ability to quickly move from

face to face, wheel loaders have a

mobility advantage over hydraulic shovels

and electric rope shovels. This provides

a degree of flexibility not available with

track machines. Tires provide wheel

loaders the flexibility to save time:

Similar to hydraulic shovels, electric

rope shovels are considered primary

loading tools in a mining application.

They are primarily used for the loading

of overburden, and in some cases ore,

in the mine.

•Moving out for a blast

•Moving to a new face

•Moving to a stockpile for a blending

operation

•Hopper and crusher loading

•Moving back to the service shop for

maintenance

Mobility is a key attribute that allows

the wheel loader to do multiple tasks

throughout a mine site.

Support Equipment and Bench PREPARATION

With any loading system, “good housekeeping” habits are

necessary in the load area to avoid unnecessary undercarriage

maintenance and tire failures due to running over loose rocks on

the floor. A wheel dozer or wheel loader can be used as cleanup

support by pushing loose material back into the face, most often

in the loading area where the trucks are staging, but in some

cases for the electric rope shovel and hydraulic shovel working

areas. The wheel loader is very mobile and has a wide sweeping

bucket. It is therefore well suited to handle its own cleanup

chores. To a certain extent, the hydraulic shovel is also able to

clean up the loading area; however, in most cases the use of

support equipment is more economical.

maximum travel speeds (forward)

Electric Rope Shovel

1.3 km/hr (.82 mph)

Hydraulic Shovel

6015/6015 FS-6090 FS

Large Wheel Loader

21.7-38.6 km/hr (13.5-24 mph)

21

Buckets and Dippers

Bucket and Dipper Options

Caterpillar offers a wide range of purpose-built, high

performance buckets and dippers, each designed to function

as an integral part of the wheel loader, hydraulic shovel, and

electric rope shovel. The combination of the correct bucket or

dipper with the correct machine will provide the best possible

performance in a particular application.

Electric Rope Shovel Dipper

Electric rope shovels do not have buckets, they have dippers.

22

Choosing the correct bucket or dipper can:

•Reduce cycle and loading times

• Lower operating costs by 10 to 20 percent or more

•Eliminate unnecessary stress and fatigue for the machine,

bucket, and operator

Hydraulic Front Shovel Bucket

Surface Mining Primary Loading Tool Selection Guide

Hydraulic Backhoe Bucket

Wheel Loader Bucket

23

Caterpillar Loading Solutions

The success of your operation has a lot to do with selecting the

proper loading machine. The goal is to achieve the best results

at the lowest cost. First-hand knowledge and experience in

analyzing field data and site conditions can greatly increase

efficiency and improve production.

Deciding on one machine over another is a complicated process.

Cat wheel loaders, hydraulic shovels, and electric rope shovels

offer an established reputation in the industry for quality, with

exceptionally low owning and operating costs.

For more information, visit https://mining.cat.com.

CAT, CATERPILLAR, their respective logos, “Caterpillar

Yellow” and the “Power Edge” trade dress, as well as

corporate and product identity used herein, are trademarks

of Caterpillar and may not be used without permission.

AEXQ0956

©2013 Caterpillar

All rights reserved.