petroleum terminal's operation processes on vessel turnaround time

advertisement

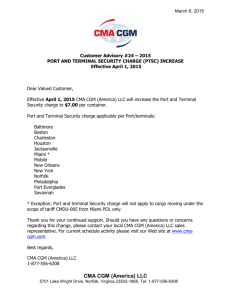

EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. PETROLEUM TERMINAL’S OPERATION PROCESSES ON VESSEL TURNAROUND TIME Ng Siew Ming1 and Muhammad Zaly Shah2 ABSTRACT Vessel turnaround time is the duration of vessel’s stay afloat alongside berth and also viewed as port’s operational indicator for its optimum performance in term of the capability, efficiency, and productivity of operation processes of petroleum terminal in handling inbound and outbound cargoes via public liquid-bulk jetties. Main reasons of this study arise from rapid development in petroleum storage industry and the high expectation on the terminal performance as demanded by multinational oil companies and oil traders in facing the issues of volatility and contango oil market. Furthermore, information and literatures on the port performance in term of vessel turnaround times related to variable operations processes of the liquid-bulk terminal are not easily available or limited. The purpose of this study is to identify the operation processes by a petroleum terminal that are controllable and have significant influence over port performance of five (5) liquidbulk jetties in Port Klang. At the same time, data of the actual operation processes over the six months period from January 1 to June 30, 2008 are used to develop a regression model that enable terminal to determine optimum usage of facilities in their operation processes in improving the vessel turnaround time. Keywords: Vessel turnaround time, terminal operation processes, optimum allocation, multiple linear regression. 1 2 Corresponding author. Post-graduate, Dept. of Urban and Regional Planning, Faculty of Built Environment, Universiti Teknologi Malaysia, 81310 Skudai, Johor. Email: siewming@kic.com.my Senior Lecturer. Dept. of Urban and Regional Planning, Faculty of Built Environment, Universiti Teknologi Malaysia, 81310 Skudai, Johor. 1 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. 1 INTRODUCTION In the past, the petroleum storage facilities in Malaysia are often commonly known as Petroleum Depots, mostly if not all owned by oil majors and oil producers which primarily engaged in the merchant wholesale, distribution of petroleum products to retails stations. The stocks held generally follow a seasonal pattern with levels varying from one geographic region to another. Over the past few years, the global logistics and oil market is transforming rapidly and its complexity compounded by the following factors particularly the volatility and contango markets of petroleum product pricing due to the effect of crude oil price globally (Figure 1); the growing demands for petroleum products particularly in Asia Pacific region; new products of different specifications due to environmental regulations on Prevention of Air Pollution from Ships (MARPOL Annex VI); on double hull and double bottom requirements for oil tankers delivered before 6 July 1996 (Regulation 20, MARPOL Annex I); on Prevention of oil pollution from oil tankers carrying heavy grade oil as cargo (Regulation 21 MARPOL Annex I); the International Ship and Port Security Code (UNCTAD-ISPS, 2007) officially implemented on July 1, 2004 by International Maritime Organization (IMO), and shortages of strategic storage capacity in this region. Such volatile and contango crude oil market have driven the traders and even oil majors/producers to use storage facilities for futures trading and consolidation of crude oil and refined petroleum products (Traver, S. R., 2007). Thus, the emerging practices in the deployment of converted vessels as floating terminals at strategic location along the routes of international oil trade took place in order to meet the sudden increase in demand for storage space. At the same time, many more larger independent-operated petroleum terminals of excellent pipeline transfer capability and better facilities were constructed or in the final stage of construction in this region having their own dedicated marine jetties which support importation; storage; value-added blending; break bulking; transhipment; re-export and export, shipment activities; and also the multimodal transportation from land to sea or vice-versa. In addition, the pioneering project of rock cavern underground storage for hydrocarbon and the possible use of Very Large Floating Structure (VLFS) for oil products are on the way in this region. (Su, Philip., 2007) Figure 1: Crude Oil Prices, 1996-March 2008 2 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. 2 PROSPECTIVE OF THE PETROLEUM TERMINAL The main problem emerged due to the increasing pressures on the existing terminals to be effective, efficient and improve their throughput volume optimize the available facilities and resources to meet the current storage demand without compromising the safety and security of the terminal. Special attentions are needed in the process of cargo movement, storage and handling of products with combustive properties and high market value that are in the custody and responsibility of the terminal. Furthermore, the terminal must be ready to face stiff competition proactively with the tremendous increase in number of new entrants and continuous expansion in storage capacity in the petroleum terminalling industry globally. In order to attract terminal users, the terminal are required to reduce the vessel turnaround time that reflects the ability and capability of the terminal in productivity and performance. Therefore, the objectives of this study will be focusing on how vessel turnaround time is being measured, to determine the terminal operation processes that had impact on the vessel turnaround time, to identify which operation processes are controllable and which are not controllable by the terminal. Finally, to establish a regression model that relates vessel turnaround time with the terminal operations processes. . The study will be limited to this 1.3 million barrels facilities in West Port, Port Klang on the handling of inbound and outbound petroleum products via 5 public marine jetties. Its existence as main service-provider of marine bunker fuel is expected to contribute towards Port Klang’s development as a container hub (Port Klang Authority, 2008). Literature reviews on related and correlated research are discussed below showing the lack of a significant model that relates vessel turnaround time with operation processes of the petroleum terminal making it difficult to determine and monitor improvement of the significant processes that contribute to the terminal’s performance and vessel turnaround time. Thus, the proposed design and methodology of the study will be formulated in order to achieve the above-mentioned objectives and aimed at improving the operational efficiency which can be translated to the following strength for the terminal to capture the opportunity in the high demand of such facilities. By lower operating cost where terminal could offer more competitive rate; faster turnaround time for a vessel in port means more number of voyages can be made within the time charter periods for the charterers of the vessels which are our terminal users in reducing their overall logistics shipping cost; and increase its throughput due to faster turnaround of time without further berthing constraints on the high occupancy of five (5) public jetties that cater for a total of 10 liquid bulk terminals in Port Klang would be most desirable. 3 TERMINAL & PORT CAPABILITY. It is noted that many researches were conducted on the performance and efficiency Sanchez et al., (2003); Kek C.C. (1993); Strandenes S.P (2004); Talley (1994) but it would not be surprised to find there is limited amount of literature available on liquid bulk terminal industry particularly on its operations and performance as every port in the world today could truly be said to be involved in the container resolution. (Oram R.B. & Baker C.C.R., 1971). But however, container terminals have many in common particularly the way the performance of the marine facilities being measured. In the study of the terminal in handling inbound and outbound petroleum product via sea, the most basic importance of a marine infrastructure is the jetty. Generally, the jetty demands firstly deep-water quay alongside which is a constant level of water or where tidal conditions do not inhibit the working of a vessel. (Oram R.B. & Baker C.C.R., 1971) The jetty structure, length, depth of the jetty and channel of the port limits are the determinants of the size of vessel of the jetty can accommodate. In this case, the petroleum terminal is utilizing common public jetties managed by privatized port operator for its marine inbound and outbound of products and the share on the use of jetties is a common scenario for public marine facilities worldwide. Port Authorities and port operators in the highly developed maritime nations are very now conscious of the need for improvement in ship’s turnaround. Unfortunately, the tradition of “first come first served” irrespective of the different vessels contribution to port revenue in the berth allocation. (Strandenes S.P. & Marlow P.B., 2000) are still in practice in this port. Each terminal will run their own pipelines to the jetties on the common pipe gantry provided by the jetty operator. The speed at which the physical transfers of product via pipeline take is the criterion of the terminal’s efficiency. Such inbound and outbound physical transfers speed determines the berth occupation or utilization, commonly known as the throughput cargo. (Oram R.B. & Baker C.C.R. 1971). However the speed varies from one terminal to another depending on the many factors which including designed pump capacity, pressure drop as a result of distance of the terminal away from the jetty front and of the diameter of the pipes 3 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. size. In the liquid bulk industry, cargoes are mostly discharged from vessel with the use of vessel’s pumps and loaded using the terminal’s pumps. In terminal where the distance between the jetty and terminal is very far, booster pumps are usually installed at installed between the jetty and the terminal for both discharging and loading operation. Figure 2 shows the operation processes flowchart for the petroleum terminal. The flow consists of inbound and outbound of products. The discharging or inbound commences with discharge products from vessel to the shore tanks. Whereas, for loading or outbound commences with the product being loaded into the vessel from the shore tanks. The time period from the time the vessel berthed to the time, the pumping operation started are referred to as “pre-loading time” or “pre-discharging time” depending the nature of product transfer operation.. Similarly, the time upon completion of pump operation to the time vessel unberthed are referred to as “postloading time” or “post-discharging time”. In this study, the researcher will concentrate on the only qualitative aspect of the terminal operation processes in establishing the relationship between significant operation processes and the turnaround time of tanker. Therefore, turnaround time (TT) can be summarised as below: TT = f (Operation Process) (1.1) From the literature available on Report of the National Working Group on Normative Cost Based Tariff for Container Related Charges, berth occupancy level of 60% is ideal for single berth configuration, beyond which port congestion may start. However, certain ports are reaching the berth occupancy level of more than 70%, while in certain ports it is as low as 10%. The ports which are new and yet to pick up the traffic volume, are bound to have low occupancy levels. The vessel waiting for berth time ratio is expected to increases very rapidly with higher berth occupancy. Thus a relatively small reduction of the berth stay time may have considerable reduction on the expected vessel waiting for berth time and hence increasing the productivity and cargohandling performance which eventually lead to substantial saving in ship-turnaround time. (Strandenes S.P. & Marlow P.B., 2000). 4 VESSEL TURNAROUND TIME The Port Performance Indicators suggested by (UNCTAD, 1976) are still in use globally by many ports to determine the port financial (Table 1) and operational (Table 2) performance. . “The ship turnround time is the duration of the vessel's stay in port and is calculated from the time of arrival to the time of departure. Traditionally expressed in days, it is now common to express turnround time in hours.” (Kek C.C., 1993). Figure 3 shows the standard stages of a vessel’s passage through the port where the first and foremost measure of ship productivity through a port will concern the total turnaround time in port of a given vessel on a given call. However the total time value is not absolutely meaningful if it does not present total turnaround time in port as a function of total cargo quantity handled during that call. (G. De Monies, 1987) According to Strandenes S.P. & Marlow P.B.,( 2000), the time or duration of the port stay and the punctuality are seen as quality factors. The duration depends on the time for handling vessels and cargoes, while quality class defines the punctuality requirements. This quality dimension can be specified, as a guarantee on total handling time for the vessels and the total time needed for the goods to pass through the port. The value of speed and punctuality reflects the opportunity cost to ship-owners of fewer fixtures per period and to shippers of having to wait for the goods to be delivered. These opportunity costs vary with the length of the delay and the value of the goods in their final use. Similarly, .Oram R.B. & Baker C.C.R., (1971) also stressed the importance of turnaround of ships with the statement “No single cause more directly affects the cost of living of a maritime country than the speed with which ships are turned around in her ports”. “Cost and efficiency in cargo handling depend not only on containerisation, but also on port efficiency in loading, unloading and forwarding the products to its final destination Both port and ship efficiency are influenced by the pricing structure and the scheduling procedure used by ports. The port efficiency is dependent on jetty capacity and cargo handling capacity”. (Strandenes S.P., 2004) By improve port efficiency, increasing throughput and reducing terminal cost, operators are able to provide competitive rate and to compete globally. Furthermore, the efficiency of petroleum terminals are equally important in the maritime supply chain of bunkers to vessels, break bulking and for the competitiveness of short-sea shipping towards rail and road transport for supply chain of fuels for industrial and domestic uses without compromising the “safety aspect of product handling” (Long, C., 2007) and “security”.( UNCTAD-ISPS, 2007). There has been much speculation about security costs and its impacts over the performance especially over the implementation of ISPS Code. 4 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. ADDITIONAL INBOUND PROCESSES COMMON PROCESSES Vessel Berth Authorities Inspection & Free Pratique Clearance ISPS/ Flag State/Safety Checklist inspection & Documentation Failed Tank/Cargo Inspection Critical Test Analysis Passed Loading Arm/Hose Connection Lining up piping system Pumping Operation Not within tolerance Tank/Cargo Inspection Quantity against nomination Within tolerance Pumping Operation Final shipping Documentation Vessel Unberth Figure 2: Operation Processes Flowchart of A Petroleum Terminal (Source: KIC Oil Terminal Sdn Bhd) 5 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. A fair assessment of the ISPS Code implementation and compliance costs by UNCTAD, indicates that as for bulk trades, fewer security-related investments are required especially for larger ports as most of the security infrastructure do exist which require very little upgrading or improvements. Despite larger total reported annual operating costs, higher cargo volumes result in lower unit costs due to the economies of scale. As for ISPS Code-related impact on various port performance measures, the combined effect on various performance indicators reported by respondent ports and highlighted above suggest that, overall, the ISPS Code had either no impact or had a positive effect as it achieved strategic objectives other than enhancing security. ” ( UNCTADISPS, 2007). Lastly, the changes in ship efficiency from any reduction in the turnaround time in port and the time waiting for port access are of vital importance to the vessels’ owners or charterers which in most cases are also the terminal users. Faster turnaround time of vessels in port means less berthing cost and thus more voyages can be achieved within a stipulated time. Nevertheless, the costs of vessels waiting for berth due to port congestion reduce the net revenue of ship’s owners will definitely have adverse effect on the terminal user’s shipping costs. (Strandenes S.P. and Maslow P.B.2000) “In addition, the port’s asset utilization performance and the assessment of a port’s performance from the point of view of port users” should not be ignored. Kek C.C. (1993) Source: UNCTAD-Port Performance Indicator Source: UNCTAD-Port Performance Indicator 6 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. Total time in port Departure after registering Pre & post Pre-berthing berthing waiting time waiting time Time at berth Time in berth Operational time at berth Operational time in berth Arrival at port Sailing delay Pre-berthing waiting time Leaving port after registering Return to port Arrival at berth Start of operation Finish of operation Leaves berth Leaves port Source: UNCTAD Figure 3: Breakdown of ship’s time in port. 5 DESIGN & METHOD OF STUDY The research methodology adopted to conduct this study is based on objectives of the study after the above process of reviewing the related literature and identifying the problem statement. Then, proceed to define the boundary of the research with information on problem statement, objective and scope of the study. As the population involved for this study are small and restricted to the operational personnel from the operating terminal, the berth planning personnel of the port operator and boarding Shipping Agents. Census will be carried out to collect data and information by mean of face to face interviews with the research questionnaires developed. A pilot study will be conducted on a few members of the population and the information collected will be beneficial in determining the suitability of the sampling method and to assess the reliability and validity of the pilot survey results. At the same time, adjustment can be done before the actual data collection being performed should the result of pilot study do not meet the research requirements. Finally, when everything is in proper order, the researcher will start off with the actual survey. The face to face interviews with the balance of the population related to operation processes of the terminal will be performed. At the same time, the researcher will proceed with the collection of secondary data for the duration of 6 months from January 1 to June 30, 2008. The secondary data will then be obtained from the Terminal Operation & Coordination Department on the details of the importation and exportation operations. The secondary data of the inbound and outbound shipments comprising of the jetty where the shipments were effected; time log taken for each operation processes including all delays taken place; and the equipment used. With these huge amounts of data in hand, there will be a need to identified the software and coding for data analysis. The most critical part of this survey is the analysis of the data. The scientific techniques and statistic software program need to be identified. There are quite a number of statistic programs available but the most simplest and popularly used is Statistical Packages for Social Sciences. Firstly, the use of measures of location such as mode, median and mean; and measures of dispersion such as range, variance and standard deviation to analyze these variables and produce descriptive statistic. This will then be followed by identify the relationship that exists between two quantitative data using the correlation coefficient r where its magnitude indicates the strength of such relationship. (Figure 5) A correlation coefficient of +1.00 indicates a positive perfect correlation and -1.00 indicates a negative perfect correlation. The significant of regression correlation test on hypothesis statement 7 EASTS International Symposium on Sustainable Transportation incorporating Malaysian Universities Transport Research Forum Conference 2008 (MUTRFC08). Universiti Teknologi Malaysia. 12-13 August 2008. will then be performed. Finally, to explains the relationship between two quantitative variables in a causal pattern through the use of a linear regression equation. The methodology of this paper is derived from multiple linear regression as it is entails the use of the method of least squares for estimating among other statistical relationships between variable. REFERENCES Bryman, Alan & Bell, Emma. (2003). Business Research Methods, Second Edition. Oxford University Press. De Monie, G. UNCTAD Monographs on Port Management 6 – Measuring and Evaluating Performance and Productivity. UNCTAD in collaboration with International Association of Ports and Harbors (IAPH) International Chamber of Shipping (ICS), Oil Companies International Marine Forum (OCIMF) & International Association of Ports And Harbors (IAPH). (2006). International Safety Guide for Oil Tankers and Terminals, Fifth Edition. ISBN-10 1856092917 Kasypi Mokhtar & Dr Muhammad Zaly Shah (2006). A Regression Model for Vessel Turnaround Time. Tokyo Academic Industry & Culture Integration Tour 2006, Shibaura Institute of Technology, Japan. Kek, C.C. (1993). Port Performance Indicator. Transportation, Water and Urban Development Department, The World Bank, Published Dec 1993, Transport No. PS-6, Annex A. Long, Chris (2007). Tanker Jetty Safety – Management of the Ship/Shore Interface. A Witherbys Seamanship Publication. ISBN 10: 1856093271 Oram R.B. & Baker C.C.R., (1971). The Efficient Port, Pergamon Press Ltd, Oxford. Port Klang Authority, (2008) http://www.pka.gov.my/general_services.htm Report of the National Working Group on Normative Cost Based Tariff for Container Related Charges. http://tariffauthority.gov.in/htmldocs/normative%20cost-final.pdf. Sanchez, R. J., Hoffmann, J., Georgina, Micco A., Pizzolitto, V., Sgut, M., and Wilsmeier, G. (2002). Port Efficiency and International Trade: Port Efficiency as a Determinant of Maritime Transport Cost. IAME Panama 2002 Conference Proceedings. Stebbin, Paul. (2006). World Bunkering Outlook – Singapore International Bunkering Conference. Strandenes S.P. (2004). Port Pricing Structures and Ship Efficiency. Review of Network Economic Vol. 3 Issue 2 – June 2004 Strandenes, S. P. and P. B. Marlow (2000) Port Pricing and Competitiveness in Short Sea Shipping, International Journal of Transport Economics, 27 Su, Philip. (2007). Overview of Singapore & Asian Market – A Look to Future Development. StocExpo First Asian Conference in Singapore. Talley, W. K. (1994). Performance Indicators and Port Performance Evaluation. Logistic and Transportation Review. 30 (4) The International Convention for the Prevention of Pollution from Ship (MARPOL), The Protocol of 1997 (Annex VI – Regulations for the Prevention of Air Pollution from vessel) enforced in 19 May 2005 The International Convention for the Prevention of Pollution from Ship (MARPOL), (Regulation 20 Annex I) – Double hull and double bottom requirements for oil tankers delivered before 6 July 1996. The International Convention for the Prevention of Pollution from Ship (MARPOL), (Regulation 21 Annex I), –Prevention of oil pollution from oil tankers carrying heavy grade oil as cargo. Tiwari, P.; Itoh, H.; Doi, M. Containerised Cargo Shipper’s Behavior in China – A Discrete Choice Analysis. Bureau of Transportation Statistic, US Department of Transport. Traver, S.R. (2007). Current Refining Capacity and Future Storage Requirements in Singapore - Asia Bulk Liquid Storage Transportation & Terminals Conference in Singapore. UNCTAD (2007). Maritime Security: ISPS Implementation, Costs and Relating Financing (UNCTAD/SDTE/TLB/2007/1) UNCTAD. (1976). Port Performance Indicator, TD/B/C4/131/Supp.1/Rev. 1 Wikipedia, (2008), http://en.wikipedia.org/wiki/oil_price_increase_of_2004_2006 8