020-1051 Organizational Structuring and Project Team Structuring

advertisement

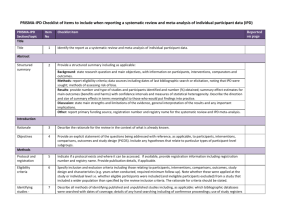

020-1051 Organizational Structuring and Project Team Structuring in Integrated Product Development Project Rupak Rauniar, University of Houston- Victoria, Department of Management, School of Business, 3007 North Ben Wilson, Victoria, TX 77901, rauniarr@uhv.edu, 713 436 3677 Greg Rawski, Department of Management, University of Evansville, 1800 Lincoln Ave. Evansville, Indiana 47722, gr17@evansville.edu, 419 270 2300 POMS 22nd Annual Conference Reno, Nevada, U.S.A. April 29 to May 2, 2011 1 Organizational Structuring and Project Team Structuring in Integrated Product Development Project Rupak Rauniar, University of Houston- Victoria, Department of Management, School of Business, 3007 North Ben Wilson, Victoria, TX 77901, rauniarr@uhv.edu, 713 436 3677 Greg Rawski, Department of Management, University of Evansville, 1800 Lincoln Ave. Evansville, Indiana 47722, gr17@evansville.edu, 419 270 2300 ABSTRACT For a superior project result, integrated product development project needs to have a well structured management approach that promotes the downstream team effort across concurrent execution of the project with the upstream strategic planning phase of such project. In the current study we focus organizational level variable, organizational structuring, with IPD project level variable, project team structuring to study the impact on product design glitches and project performance. We hypothesize that managing IPD projects with organizational structuring and project team structuring can lead to reduced product glitches which can enhance overall IPD project performance. We define organizational structuring of the IPD project to the extent to which the project is provided with legitimacy and a corporate priority through strategic alignment, and the upfront appointment of the heavyweight product manager. Similarly, we define project team structuring of IPD projects to the extent to which the cross-functional teams of IPD project have a shared project mission, cross-functional teams are integrated, and have clarity of project targets and tradeoffs. INTRODUCTION Concurrent engineering has become a popular method to speed up the new product development projects and help manufacturing firms seek competitive advantage (Hayes, Wheelright and Clark, 1988; Meyer, 1993; Patterson, 1993; etc.). Such concurrent product development project, where project activities and stages are executed simultaneously, is generally facilitated by the deployment of cross-functional team (Barczak and Wilemon, 1992; Griffin, 1997; McDonough, 2 2000; Sarin and Mahajan, 2001; Sarin and McDermott, 2003; Ulrich and Eppinger, 1995; Wind and Mahajan, 1997; Jayaram and Malhotra, 2010, Koufteros, Rawski, and Rauniar, 2010; etc.). The IPD project‟s initial stage is referred as front end stage that include activities such as idea generation, assessments of competition, market, and technology, project justification, action plan, etc. that are generally strategic and conceptual in nature (Khurana and Rosenthal, 1998). According to the authors, front end stage requires organizational level analysis and planning. Once the organization validates the new product concept to be congruent with organizational strategic agenda, the project enters into the development and implementation stage that involve concurrent activities of detailed functional and technical design of parts and components, prototype developments, internal and external testing of components, system testing, manufacturing process design and development, etc. (Bingham and Quigley, 1990). Despite its advantages, management of IPD projects is proven to be very challenging (Crawford, 1979; Wheelright and Clark, 1992; Moffat, 1998), especially for complex products such as automobiles, which involves thousands of engineers and non-engineers of developmental firm, client, and suppliers who spend years of designing, testing, and integrating hundreds of thousands of parts (Gokpinar, Hopp and Irvani, 2010). Several recommendations at individual, team, and firm-levels have been provided in the extant literatures in regard to the effective management and critical performance factors of new product development. Overall these recommendations have called for management attention to factors related to individual, team and project, and organizational levels. 3 For example, Backhouse and Brookes (1996) have suggested that project implementation can be improved through a good fit of the development firm‟s process and structure along with management focus, change, and proficiency. Hart (1995) grouped the determinants of new product development performance into strategic level and project level variables. Strategic level determinants included organizational culture, organizational strategy, organizational structure, and top management involvement and orientation. Project level variables represented factors that related to the specific new product development project under consideration, including processes and how they were performed, project structure, cooperation between departments, and the involvement of suppliers in new product development process. The meta-analysis of Henard and Szymanski (2001) identified four main groups of antecedents of new product development performance: firm strategy characteristics, firm process characteristics, product characteristics, and marketplace characteristics. Others have pointed out organizational issues (Bailey, 1999), team member selection (Gerwin and Moffat, 1977; Stahl et al, 1997); individual member‟s characteristics (King and Majchrzak, 1996), information sharing and decision making (Krishnan, 1996, Rauniar et al, 2007) to be determinant of project success. During concurrent detail design and developmental stages of the IPD project, project team leaders and members are involved in intensive problem solving and decision making process. These design, development, and tradeoff decisions made across the various stages have to be consistent and coherent with organizational purpose and its targeted customers‟ needs. Conflicting and inconsistent decisions to the engineering design solutions at different concurrent stages of IPD project can lead to design and development of product plagued with problems, or glitches that can have substantial impact on project performance, such as re-work, scrap, poor 4 resource utilization, cost-overruns, poor quality of design, poor quality of conformance, etc. The extent of product design glitches from the knowledge management perspective have been reported by Rauniar et al (2007). Similarly the study of Koufteros, Rawski, and Rauniar (2010) on product glitches highlights the importance of supplier and customer integration with the project team. Based on the existing literature that emphasize the role of organizational contextual variables (for example, Hart, 1995; Backhouse and Brookes, 1996; Krishnan, 1996; Henard and Szymanski, 2001; etc.) , it appears that the broader reasons of many of project failures is a mismatch between: (a) the organizational processes at the front end, planning stage of product development project, (b) necessary team and project characteristics during project implementation , and (c) inconsistent decisions and design related technical problem across the various stages of the IPD project. To be successful, an IPD project needs to have a well structured management approach that aligns and promotes the downstream design and development effort with the upstream strategic planning stage. In their meta-study, Henard and Szymanski‟s (2001) points that the product development literature has generally directed attention at capturing the effect of project process characteristics, and thereby, ignoring the organizational level variables. Our current study is directed toward improving IPD performance by simultaneously addressing management issues of IPD project with the organizational level at the front end stage and the project team level characteristics at the development and implementation stages. There are primarily two objectives of our current paper in the area of IPD project. First, it integrates the impact of organizational variables of front end stage to the project level variables 5 of the project execution stage. In the current study we focus organizational level variable, organizational structuring, with IPD project level variable, project team structuring. We hypothesize that managing IPD projects with organizational structuring and project team structuring can lead to reduced product glitches that, in turn, can enhance overall IPD project performance. We define organizational structuring of the IPD project to the extent to which the IPD project has strategic alignment and the upfront appointment of the heavyweight product manager to lead the project. Similarly, we define project team structuring of IPD projects to the extent to which the cross-functional teams of IPD project have a shared project mission, are integrated, and have clarity of key project target tradeoffs. In the current study, we focus organizational structuring at the front end, planning stage of the project, while we focus project team structuring issues at the development and implementations stages. The second contribution of the current study is that we study the extent of project team structuring on product glitches. Product glitches are the design related problems and bugs in the new product development process because of poor team structuring. In the current study we analyze the cause and effect of product design glitches from more of a work integration perspective. In studying the IPD project performance, we focus on the negative consequence of product design glitch on overall IPD project performance. LITERATURE REVIEW In order to achieve competitive performance, business needs to have a proper fit between its strategy and structure (Chandler, 1962; Rumelt, 1974; Venkatraman and Camillus, 1984). The classical theory in strategic management in regard to strategy-structure-performance has also been extended in the areas of innovation (Teece, 1998). Our current study extends this thinking 6 of strategic alignment with structure to explain superior management and performance of IPD project. We identify two separate structural issues surrounding the IPD project based on the hierarchical distinction between the organizational and IPD project level factors. Organizational Structuring at Front End Stage The initial, front end stage of IPD project includes all activities from the time the opportunity for a new product idea is conceived, until the final decision to finance the project is made by the organizational executives. This stage includes concept identification and selection; preliminary market and customer need identifications and analyses (Kim and Wilemon, 2002; Biyalogorsky, Boulding, and Staelin, 2006). According to Khurana and Rosenthal (1998), such frontend stage of the project represents the most critical stage, and if not managed carefully, can negatively impact the overall project and organizational performances. Management issues at the front end stage of the project has been highlighted by Jassawalla and Sashittal (2000) in terms of product strategy, goals, project milestones, powerful project leader, and cross-functional team. This is the stage where the concept of design-of-quality (Garvin, 1987; Deming, 1986) plays a detrimental role in defining product success. Such importance of quality at entry in developmental project has been emphasized in many studies, as noted by Morris (2009) and Miller and Lessard (2001). Such quality based approach to serve the targeted customers better requires requires a clear understanding of developmental firm‟s capabilities, priorities, and customer‟s needs. Shortage of top management engagement and lack of organizational attention at the early stage of the project can lead to poor performance (Sosa et al, 2007). While we recognize the complexity and uncertainty surrounding such early stage of the project, our study posits that management needs to pay attention two important issues of establishing and ensuring a strategic fit of the project and providing a heavyweight product manager leadership to the project. In our current study, collectively these two variables are conceptualized to constitute organizational structuring important for managing the front end stage of IPD project. Strategic Fit 7 New product strategy has been widely recognized as vital business priority by high performing businesses (Booz, Allen and Hamilton, 1982; Cooper, 2001; Griffin, 1997; Mercer, 1994).The new product strategy should clearly establish the strategic need and fit of the IPD project with the overall organizational strategy. Strategic fit is the extent to which a firm‟s overall business, product, and technology guide the product development content and processes (Wheelwright and Clark, 1992). Top management‟s strategic view of designing and building a new product is consistent with the principles of project value management which advocate a shared process by project stakeholders to examine function within the organization-wide context and optimize new design solutions to meet project objectives (Neasbey et al. 1999). Heavyweight Product Manager According to Wheelwright and Clark (1992), a key dimension to differentiate the different types of lightweight, heavyweight, and autonomous teams is the role of team leader. Compared to the lightweight leader, who functions more as a coordinator than a leader, the heavyweight team leader is directly responsible to senior management for all the work done by the product development team (Wheelwright and Clark, 1992). In their study, Clark and Fujimoto (1990) found that the key to product integrity is leadership from heavyweight managers who focus on devising processes to create powerful product concepts, and making sure that the concepts are translated into design and manufacturing process details. They are generally the chief engineers with substantial expertise and formal and informal influence in product development projects (Schilling and Hill, 1998). Fujimoto et al. (1996) reported that heavyweight managers help organizations to formulate product concepts and implement them coherently across organizational functions. The innovation literatures emphasize the importance of “promotion” leader who is knowledgeable about the organization needs and supports the innovation process (Hauschildt and Gemuenden, 1999; Hauschildt and Kirchmann, 2001). Benefits of heavyweight include product innovation (Koufteros and Marcoulides, 2006); internal coordination, product planning, and concept development (Zhang and Doll, 2001), customer and supplier integration with development team (Koufteros, Rawski and Rauniar, 2010) and reduced ambiguity and uncertainty (Koufteros et al., 2005). Such IPD project leaders provide objective advice to the 8 cross-functional team about emergent questions, interpret needs, balance different points of view, and arbitrate when conflicts of interest arise (Topalian, 2000). They become the guardian of the concept and not only react and respond to the interests of others, but also see that the choices made across the concurrent processes are consistent and in harmony with the basic design concept (Clark and Wheelwright, 1992). Project Team Structuring at Development and Implementation Stages Once the organizational level decisions are made to move on with a particular product concept, the IPD project enters into the subsequent stages of detailed product design, development and implementation where the cross-functional teams are deployed to execute concurrent activities. Coordination and integration theorists (Thompson, 1967; Van de Ven and Koenig, 1976) argue that cross-functional interaction across distinct temporal phases (planning, development and manufacturing) requires unique integration mechanisms. The IPD project execution requires ongoing problem solving, decision making, and information sharing regarding partial or complete solution. As each concurrent stages progress, cross-functional teams exchange their respective final status with others. Based on such coordination, the teams update their assumptions and iterate in parallel until no one sees any further need to change its solutions (Mihm et al, 2010). At each design iterations, re-configurations or changes (Eisenhardt and Tabrizi, 1995), the development teams face tradeoff decisions among competing cost, quality, and time considerations that are essential to maintain the internal and external product integrity (Clark and Fujimoto, 1990). Lack of clear targets decisions can lead to several problems for the cross functional team, including lack of engagement (Katzenbach, 1998), difficulty in resolving conflict (Amason, 1996), lack of commitment (Wooldridge and Floyd, 1990), and difficulty in reaching closure in a timely fashion (Harrison, 1996). Therefore, from the project management perspective, the issues of cross-functional team integration and the characterization of such 9 teams by a clear understanding of project needs and expectations seems to be crucial for a successful IPD project management and outcome. Shared Project Mission Crawford (2002) and Clark and Wheelwright (1992) argue that project mission is captured in an explicit, measurable project charter and is usually articulated even before the team is selected. Shared project mission refers to the extent of the acceptance of the IPD project mission by the cross-functional team (Rauniar et al, 2008). A shared sense of organizational identity is emphasized by Ouchi‟s (1979) thought on “clan control” in terms of a high degree of shared goals, visions, values, and beliefs. Once the IPD project has been strategically justified, the overall project mission of a specific IPD project needs to be communicated, articulated, and rationalized so that it can provide the IPD cross-functional team members with an identity and overall direction of the project. This should take place at the early stage of the development stage in order to mitigate the cross-functional team member‟s competing social identities and loyalties (Holland et al., 2000; Webber, 2001). Lack of common purpose can otherwise lead to each function members (production, R&D, marketing, engineering, etc.) operating in a fragmented and separated manner who will tend to identify strongly with its own function. Barriers of communication can exist and, complex problems may not get resolved in a timely and consistent manner (Ashforth and Mael, 1989). Clear Project Target Tradeoffs The extent of a clear understanding among cross-functional team members about project target specifications in terms of cost, quality and time can be referred to as clarity of project targets tradeoffs (Rauniar et al, 2007). While a shared mission establishes the common road map for the 10 cross-functional team, clarity of IPD targets establishes the stepping stones to fulfill the overall IPD shared mission. In order to avoid any conflicts and to enhance work integration within the cross-functional team, IPD project‟s clear target needs to be established in the early stage of the project. Clarity of project target tradeoffs not only can help in identifying the best solution for design problems, but can also help to identify new opportunities (Enright, 2001). Clear understanding of project target can ensure that no functional goals and objectives take precedence over the overall IPD project‟s needs. Clarity of project targets requires unambiguous definition, rich communication, and common understanding of project targets among team members (Marquardt and Reynolds, 1996). Murmann (1994) argues that having clear targets from the early stage may be critical in improving cycle time (i.e. time to market), teamwork, and overall process productivity because it enables members to focus resources faster and more effectively. Lack of clear decisions can lead to several problems for the cross functional team, including lack of engagement (Katzenbach, 1998), difficulty in resolving conflict (Amason, 1996), lack of commitment (Wooldridge and Floyd, 1990), and difficulty in reaching closure in a timely fashion (Harrison, 1996). Larson and LaFasto (1989) found that every effectively functioning team had a clear understanding of its objectives. The research of Gupta et al. (1992) revealed how R&D, marketing, and manufacturing managers in NPD make trade-off decisions among clearly specified critical project measures. Cross-functional Team Integration Henke et al. (1993) and Burke et al. (2006) reminds us that the most often cited barriers of effective product development team functioning is when there is a mismanagement of the internal dynamics of the team in the project. As cross-functional team engages in concurrent 11 activities, the issue of conflict resolution (Pinto, Pinto, and Prescott, 1993; Song, Xie, and Dyer, 2000), collaboration (Jassawalla and Sashittal, 1998; Pinto, Pinto, and Prescott, 1993), and communication (e.g., Ancona and Caldwell, 1992b; Griffin and Hauser, 1992) behavior of the cross-functional team can have a tremendous influence on IPD project performance. When partial solutions are being developed across the concurrent activities, there is a great need for more collaboration (March and Simon, 1958; Thompson, 1967), and hence, for very frequent intra-team problem-solving and communication. Teams perform well when all the different tasks and interdependencies among the team members are coordinated (Wageman, 2001). In concurrent activities healthy internal dynamics are essential for effective cross-functional teams and, consequently, for the successful development of new products (Burke et al., 2006). Integrated team facilitates team learning and shared knowledge through joint problem solving and information sharing. Further, Jassawalla and Sashittal (1998) suggest that team integration in new product development project is indicative of general integrative and supportive interpersonal cooperation among team members. Product Glitch In the concurrent and iterative processes of IPD projects, any changes, redesign, or updates in a concurrent activity needs to be coordinated in a timely manner in order to preserve the overall integrity of the product being developed. Typically, such changes or correction to the parts or components during the developmental stage require an issuance of engineering change order (Gopinkar, Hopp, and Irvani, 2010). Past studies (for example, Clark and Fujimoto, 1991; Huang and Mak, 1999, Loch and Terwiesch, 1999; Koufteros, Rawski, and Rauniar, 2010; Gopinkar, 12 Hopp, and Irvani, 2010) cites some of the major reasons for engineering change order to be when an individual part or component fail to meet the design specification, or when a product changes are made that affect part designs, or when two or more parts have interface problems. Glitches are problematic because the design fails to meet the requirements for a particular constituent group(s) such as customers, part suppliers, and/ or manufacturing and fabrication requirements. Glitches or problems in new product development project can be design related (Hoopes, 2001) or development or production related (Hendricks and Singhal, 2003) which is similar to the concepts of quality of design and quality of conformance popular in quality literatures. In this study, we focus primarily on the problems stemming from product design related issues in the cross-functional team environment of IPD project. A well managed IPD project that minimizes design glitches can provide more benefits to the project or to the organization than the project that is plagued with design glitches across various stages of development and implementations. IPD Project Performance The purpose of the development project should be "better, faster, and cheaper"(US DoD, 1996). In order to assess the impact of our recommendations of organizational structuring, project team structuring and reduced glitches in IPD projects, we define IPD project performance in terms of shortened product development time, reduced product cost, and high customer satisfaction. This is consistent with Griffin‟s (1997) widely accepted recommendation of product development performance in terms of schedule, cost, and quality measures. Past studies on concurrent engineering have reported the benefits of lowering product costs and achieving improvements in quality (Takeuchi and Nonaka, 1986; Clark, 1989), and also lowering time to market as well (Clark and Fujimoto, 1991; Millson, Raj, and Wilemon, 1992; Rosenthal and Tatikonda, 1993). 13 Product development time is the time required from product concept to product introduction (Gupta et al., 1992; Clark and Fujimoto, 1991; Gupta and Wilemon, 1990; Dyer et al., 1999; etc.). Product cost is the total cost associated with the IPD project to develop and manufacture new products. Product cost includes materials, labor (e.g. fabrication and assembly cost) and overhead (e.g. development cost, equipment cost) (Garrison and Noreen, 1997). An effective product development team reduces the costs of material and labor through simplifying the manufacturing processes and reducing the numbers of component parts (Clark, 1989; Clark and Fujimoto, 1991). Customer satisfaction measures the satisfaction of the customer for a product designed for a certain target market (Cooper and Kleinschmidt, 1987). RESEARCH FRAMEWORK In project-based activities, teams are the prevalent structures that fulfill organizational goals (Edmondson and Nembhard, 2009). Organizational structuring through strategic alignment and presence of a heavyweight product manager at the onset of the project can contribute to a better cross-functional team dynamics during the downstream activities through shared project mission, clear project target tradeoffs and cross-functional team integration in several ways. According to McDonough and Griffin (2000), firms with consistent, high new product development performance established a strategy and made sure to clearly articulate that strategy to team members so that they understood it. As developmental activities iterate, more insight is gained and the interdependent, concurrent activities need to be re-aligned to reflect any changes. To assess and accept such changes, team needs to clearly understand the contribution of such 14 changes to project targets and overall mission. When there is a common, agreed upon goals, agreements to the decisions are made more readily (Leenders et al., 2007). Project leaders are primarily responsible for defining team goals and for developing and structuring the team to accomplish missions (Nygren and Levine, 1996; Zaccaro, Rittman, and Marks, 2001). They are the ones who can help the team with assigned mission into a workable plan to accomplish several objectives for the team (Fleishman et al., 1991; Hackman and Walton, 1986). In cross-functional teams the leader is often in the unique position of being able to see the whole picture and understand how different sources of expertise fit together (Wheelwright and Clark, 1995). A positive influence of the team manager on team effectiveness and consequently on IPD performance is expected because such individuals effectively facilitate the problemsolving communication from „outside‟. Therefore we offer following hypothesis: H1: Organizational structuring through strategic fit and heavyweight product manager is positively related to IPD project team structuring. An IPD team with shared project mission and clear project target tradeoffs would be able to readily identify and establish the new product solutions, concurrent task needs, requirements and interdependencies. Such shared project mission and clear project targets provides an „„enabling performance situation for task performance strategies that are appropriate to the work, and to the setting in which it is performed‟‟ (Hackman and Walton, 1986). Sharp et al. (2000) propose that shared mission, purpose, goals and direction are among the key characteristics of a highperformance team. Providing teams with clear, consistent targets can be a way to create 15 boundaries for the cross-functional team so that the team is not continually redefining its direction (Bowen et al., 1994) and wasting valuable project resources. We argue that, in a poorly structured IPD environment, cross-functional team members will tend to optimize a “local” performance measure, specific to their task and process. But concurrent interdependence of material, work outputs, design, and information requires coordination and communication process among other team members (Mihm, Loch, and Huchzermeier, 2003). A poorly structured team can be engaged in myopic, selfish behavior and sacrifice too many solution qualities during problem-solving activities as they fail to perceive and take into consideration of other‟s view (Mihm et al, 2003; Rivkin and Siggelkov, 2003). On the other hand, project team structuring through shared project mission, clear project targets, and integrated cross-functional team encourages team members to share problems, work cooperatively toward the common overarching goal (McDonough, 2000), engage in functional conflict resolutions (Antonioni, 1996), and creates a learning environment within the team (Sarin and McDermott, 2003). Overall, such team characteristics should encourages and help in collectively addressing and reducing glitches. Therefore, we propose: H2: Project team structuring is negatively related to product design glitches. In a loosely coordinated IPD team, individual members may not know what other members of the team know or doing and are likely to rely on noisy and often incorrect signals of expertise (Bunderson 2003). Decisions based on such incorrect information can lead design and development related glitches where the design solutions fail to meet customers‟ expectations and needs. The severity of product glitch to the IPD project performance, i.e., cost, customer 16 satisfaction, and development time, will depend on when and where such product glitch occurred in the project. The negative consequences of glitches in overlapped stages are amplified when glitches go undetected to a later stage of the project. Once the team identifies the glitches internally, information among the interdependent teams needs to be quickly exchanged and processed so that proper corrective action is taken to resolve the glitch and works among the interdependent concurrent tasks are adjusted (Hoegl et al., 2004). In order to fix the glitch, the IPD team may have to revisit various interdependent stages of the IPD process to investigate the cause(s) and effect(s) of a particular glitch for the remedy. These changes, if observed late in the developmental projects, can have “snowball” effects from one component to another, in some cases in cycles, causing long resolution times (Terwiesch and Loch, 1999; Sosa et al., 2004). Fixing glitches require rework often entails delays and additional development costs (Ball et al., 1998). If not identified or resolved during the product design and development, glitches can lead to inaccurate forecasting, poor planning, parts shortage, quality problems, capacity shortfall, or operational constraints (Fisher and Raman, 1996). Overall, product glitches have been reported to affect a firm‟s short- and long-term profitability (Hendricks and Singhal, 2003). Therefore, we propose H3: Product glitches are negatively related to IPD project performance. 17 Figure 2 represents our research model that identifies the relationships between the organizational structuring, project team structuring, product glitches, and IPD project performance. Organizational Structuring: -Project Strategic Fit -Heavyweight Product Manager H1: + + H3: - H2: Project Team Structuring: Design -Shared Project Mission Glitches IPD Performance: -Development Time -Clear Project Targets -Development Cost -Team Integration -Customer Satisfaction Figure 2: Proposed Research Model PROPOSED RESEARCH METHOD Based on the previous literature review, the conceptual model proposed in Figure 2 provides the foundation for the empirical research for this study. An extensive literature review, case studies and structured interviews with product development professionals (managers and teammembers) and academicians will help to define the domain of constructs and facilitate item generation. For most items, a five-point Likert scale would be used; where 1 = strongly disagree, and 5 = strongly agree. A different scale would be used for the general demographic questions. Modified items from previous studies would be presented to product development managers, product development team members, and academicians for their feedback. Items would be added, modified, deleted and finalized on the basis of their qualitative feedback. For our research, we will contact the Society of Automotive Engineers (SAE) to provide us with mailing list of professionals in the automotive industry involved in IPD projects. A survey would be 18 administered for the large-scale sample to empirically investigate the proposed conceptual research model of Figure 2. Statistical analysis of our large-scale data included tests for reliability, factorial validity, and test for discriminant validity. We then used structural equation modeling to test our measurement and structural model to investigate our hypothesized model of Figure 2. CONCLUSION In this theoretical paper, we have specified a number of fundamental components necessary for superior IPD project management and performance. These are succinctly categorized in terms of organizational structuring needed to manage the early, front end stage of the project, project and team structure that is crucial for managing development and implementation stages, product design glitches, and IPD project performance. In spite of vast literatures in new product development, there are few conceptual frameworks that identify critical management factors at two distinct stages of IPD projects. Accordingly, we have identified strategic alignment of the IPD project and presence of heavyweight product mangers as important management activities during the planning stage of the project. Similarly, during the detailed design, development, and implementation stages, our theory suggest shared project mission, clear project target tradeoffs, and cross-functional team integration can provide proper project and team structuring that can drive product design glitches low. We also posit that lower product design glitches will drive higher IPD project performance. REFERNCES Bebb, B. (1989). Quality design engineering: the missing link in US competitiveness 19 Bhaskaran, S. (1998). Simulation analysis of a manufacturing supply chain, Decision Sciences 29 (3), 663-657 Blackburn, J. (1991). Time Based Competition, Business One, Irwin, Homewood, IL Bonaccorsi and Lipparini (1994) "Strategic partnerships in new product development: an Italian case Study", Journal of Product Innovation Management, Vol. 11, 134-145 Brown, W. and Eisenhardt, K.M. (1995). „Product Development: Past Research, Present Findings and Future Directions‟, Academy of Management Review, 20, 343-378 Browne, M. W. and Cudek, R. (1993). „Alternative Ways of Assessing Model Fit‟, K. A. Bollen and J. Scott Long (eds) Testing Structural Equation Models, Newbury Park, CA: Sage Publications Calantone, R.J., Vickery, S.K. and Droge, C. (1995). „Business Performance and Strategic New Product Development Activities: An Empirical Investigation‟, Journal of Product Innovation Management, 12(3), 214-223 Clark, K.B. and Fujimoto, T. (1991). Product Development Performance, Harvard Business School Press, Boston Clark, K. B. and S. C. Wheelwright, "Organizing and Leading 'Heavyweight' Development Teams," California Management Review, Vol. 34, No. 3, Spring 1992, pp. 9-28 Clark, K. and Wheelwright, S.C. (1993). Managing New Product and Process Development, Free Press, New York Culley S.J., Boston O.P., and Christopher A. (1999). „Suppliers in New Product Development: Their Information and Integration‟, Journal of Engineering Design, 10(1). 59-75 Crosby, Phillip B. Quality is Still Free: Making Quality Certain in Uncertain Times. New York: Mc-Graw-Hill Book Company, 1996. Deming, W. Edwards. Out of the Crisis. Cambridge, MA: Massachusetts Institute of Technology Center for Advanced Engineering Study, 1986. Dahan, E., & Hauser, J.R (2002), “The Virtual Customer: Communication, Conceptualization, and Computation“, Journal of Product Innovation Management, 19(5): 332-353 Davenport, T., Jarvenpaa, S. and Beers, M. (1996). „Improving Knowledge Work Process‟, Sloan Management Review, (Winter) 43-57 20 Dowlatshahi, S. (1998). „Implementing Early Supplier Involvement: A Conceptual Framework‟, International Journal of Operations & Production Management, 18(2), 143-167 Eisenhardt K.M., and Tabrizi B.N.(1995). Accelerating adaptive processes: product innovation in the global computer industry‟. Administrative Science Quarterly 40, 84-110 Fisher, M. and Raman, A. (1996). „Reducing the cost of uncertainty through accurate response to early sales‟, Operation Research, 44, 87-99 Garvin, D.A. (1988), Managing Quality, New York: Free Press. Garvin, D. A. (1993). „Building a Learning Organization‟, Harvard Business Review, 71(4), 7891 Donald Gerwin and Nicholas J. Barrowman, "An Evaluation of Research on Integrated Product Development," Management Science, Vol. 48, No. 7, July 2002, pp. 938-953. Griffin, A. and Hauser, J. R. (1992). „Patterns of Communication Among Marketing, Engineering, and Manufacturing – A Comparison Between Two Product Teams‟, Management Science, 38(3) 360-373 Griffin, A. and Hauser, J. R. (1992). „Patterns of Communication Among Marketing, Engineering, and Manufacturing – A Comparison Between Two Product Teams‟, Management Science, 38(3) 360-373 Gruner, K. E. and Homburg, C. (2000). „Does Customer Interaction Enhance New Product Success?‟, Journal of Business Research, 49, 1-14 Gupta, A. & Souder, W. (1998), “Key Drivers of Reduced Cycle Time”, Research Technology Management, 41(4): 38-43 Gupta, A.K., and V. Govindarajan (2000), Knowledge Flows Within Multinational Corporations, Strategic Management Journal, 21(4), 473-496 Gupta, A.K. and D.L. Wilemon (1990), Accelerating the Development of Technology-Based New Products, California Management Review, 22, 24-44 Hakansson, H. and Snehota, I. (1995). „Developing Relationships in Business Networks‟, Journal of Applied Psychology, 74, 884-891 Handfield, R. B. (1994), Effect of Concurrent Engineering on Make-To-Order Products, IEEE Transaction on Engineering Management, 41(4), 384-393 21 Hartley, J.R. (1990), Concurrent Engineering Shortening Lead Times, Raising Quality and Lowering Costs, Productivity Press Hendricks, K.B. and Singhal, V.R. (2003). „The effect of supply chain glitches on shareholder wealth‟, Journal of Operations Management, 501-522 Holak, S.L. and Lehmann, D.R. (1990). „Purchase Intentions and the Dimensions of Innovation: An Exploratory Model‟, Journal of Product Innovation Management, 7(1), 59-73 Hong, P., Doll, W.J. and Nahm, A. (2004). „Project Target Clarity In An Uncertain Project Environment Uncertainty of Project‟, International Journal of Operations and Production Management, 24(12), 1269-1291 Hoopes, D.G. (2001). „Why are the glitches in product development?‟, R&D Management, 31, 4, 381-389 Hoopes, D.G. and Postrel, S. (1999). „Shared knowledge, “glitches”, and product development performance‟, Strategic Management Journal, 20, 837-865 Hu, L. and Bentler, P. M. (1999). „Cutoff Criteria for Fit Indices in Covariance Structure Analysis: Conventional Versus New Alternatives‟,Structural Equation Modeling, 6, 1-55 Huang, G.Q. and Mak, K.L. (1999), „Web-Based Morphological Charts for Concept Design in Collaborative Product Development‟, Journal of Intelligent Manufacturing Juran, Joseph M. Juran on Planning for Quality. New York: The Free Press, 1988. Kessler, E.H., Bierly, P. and Gopalakrishnan, S. (1998) „Internal vs. external learning in new product development: effects on speed, costs and competitive advantage‟, Proceedings of the 5th International EIASM Conference ‘Product Development Management‟, Como, 25-26 May Kodama F. (1992). "Technology Fusion and the New R&D" Harvard Business Review, MarchApril, pp. 70-78. Kogut, B. and Zander, U. (1992). „Knowledge of the firm, combinative capabilities and the eplication of technology‟, Organization Science, 3(3) 383–397 Koufteros, X.A. (1995). Time-Based Competition: Developing a Nomological Network of Constructs and Instrument Development. Doctoral Dissertation, College of Business, University of Toledo, OH X.A. Koufteros, M.A. Vonderembse, W.J. Doll, Integrated product development practices and competitive capabilities: the effects of uncertainty, equivocality, and platform strategy, Journal of Operations Management 20 (4) (2002) pp. 331-355. 22 Koufteros, X.A., Vonderembse, M.A., and Jayaram, (2005). Internal and External Integration for Product Development: The Contingency Effects of Uncertainty, Equivocality, and Platform Strategy, Decision Sciences, 36(1), 97-133 Krishnan, V. and Ulrich, K. (2001). „Product Development Decisions: A Review of the Literature‟, Management Science, 47(1), 1-21 Maidique, M. and Ziger,B. (1985). „The New Product Learning Cycle‟, Research Policy, 14(6), 299-313 Millson, M.R., Raj, S.P. and Wilemon, D. (1992). „A Survey of Major Approaches for Accelerating New Product Development‟, Journal of Product Innovation Management, (3), 5369 McDonough E. F., Kahn K. B., Barczak G., “An Investigation of the Use of Global, Virtual, and Colocated NPD Teams,” The Journal of Product Innovation Management, Vol. 18, pp. 110-120, 2001. Nielsen, J. (1993), Usability engineering, San Diego: Academic Press. Nonaka, I. (1994). „A dynamic theory of organizational knowledge creation‟, Organizational. Science, 5(1) 14–37 O‟Neal, C. (1993), „Concurrent Engineering with Early Supplier Involvement: A CrossFunctional Challenge‟, International Journal of Purchasing and Materials Management, Vol.29, No.2, pp.3-9 Prahalad, C.K. & Ramaswamy, V. (2000), “Co-opting Customer Competence”, Harvard Business Review, 78(1): 79-87 Prahalad, C.K. & Ramaswamy, V. (2002), “ The Co-Creation Connection”, Strategy+Business, Second Quarter, 27: 1-12 Rauniar, R. (2005), Knowledge Integration in Integrated Product Development: The Role of Mutual Trust, Mutual Influence, Team Vision on Shared Knowledge, Doctoral Dissertation, College of Business, University of Toledo, Toledo –OH Rosenthal, S.R. (1992), Effective product design and development, How to cut lead time and increase customer satisfaction, Business One Irwin, Homewood, Illinois Sakakibara, Kiyonori and D. Eleanor Westney (1992), "Japan‟s Management of Global Innovation: Technology Management Crossing Borders", reprinted in Managing Strategic Innovation and Change, eds. Tushman and Anderson, New York: Oxford University Press Segars, A. H. (1997). „Assessing the Unidimensionality of Measurement: A Paradigm and Illustration Within the Context of Information Systems Research‟, Omega 25 (1) 23 Simon, H. (1991) „Bounded rationality and organisational learning‟, Organization Science, 2, 125–134 Söderquist, K. (1997). Inside the Tier Model: Product Development Organization and Strategies in Automotive Expert Supplier Firms, Doctoral Dissertation, Henley Management College, Groupe ESC Grenoble, Brunel University Song, X.M. and Parry, M.E. (1993). „R&D-Marketing Integration in Japanese High-Technology Firms: Hypotheses and Empirical Evidence‟, Journal of Academy of Marketing Science, 21 (2), 125-133 Sobrero, M., Roberts, E.B. (2002) Strategic Management of Supplier-Manufacturer Relations in New Product Development. Research Policy, 31, 159-182. Sureyskar, K., Ramesh, B (2001). On managerial incentives for process knowledge capture and reuse, Proceedings of the Thirty-Fourth Annual Hawaii International Conference on Systems Sciences, IEEE Computer Society Press Swink, M. (1999) Threats to New Product Manufacturability and the Effects of Development Team Integration Processes, Journal of Operations Management, 17(6) Syamil, A. (2000). International Benchmarking of integrated product development practices in the Auto industry supply chain: A multigroup invariance analysis. Doctoral Dissertation, College of Business, University of Toledo, OH Takeishi, A. (2001). „Bridging Inter- and Intrafirm Boundaries: Management of Supplier Involvement in Automobile Product Development‟. Strategic Management Journal, 22, 403-433 Takeuchi, H. and Nonaka, I. (1986). „The New New Product Development Game‟. Harvard Business Review 86(1): 137-146 Terwiesch C. and C.H. Loch (1998). „Communication and Uncertainty in Concurrent Engineering‟, Management Science, 44(8), 1032-1048 R. Jeffrey Thieme, X. Michael Song, and Geon-Cheol Shin (2003), "Project Management Characteristics and New Product Survival," The Journal of Product Innovation Management, 20 (2) , March, 104-119. Thomke, S. and Fujimoto, T. (2000). „The effect of "Front-Loading" Problem-Solving Product Development Performance‟, Journal of Product Innovation Management, 17, 128-142 Venkatraman, N. (1989). „Strategic Orientation of Business Enterprises: The Construct, Dimensionality and Measurement‟, Management Science, 35, 942–962 24 von Hippel, E. (1988). The Sources of Innovation, Oxford University Press, Oxford, UK von Hippel, E. (2002), “Open Source Software Projects as User Innovation Networks”, MIT Sloan School of Management Working Paper, June Wheelwright, S. and Clark, K. (1992). Revolutionizing Product Development., The Free Press, New York S.S.A. Willaert, R. de Graaf, S. Minderhoud, Collaborative engineering: A case study of Concurrent Engineering in a wider context, Journal of Engineering and Technology Management 15 (1) (1998) pp. 87-109. Zairi, M. (1994), Benchmarking: The Best Tool for Measuring Competitiveness, Benchmarking for Quality Management and Technology, 1, 11-24 Zirger, B.J. and M.A. Maidique (1990) A Model of New Product Development: An Empirical Test. Management Science, 36: 867-883. 25