PSE Lab 3: Proving Newton's Second Law with Dynamic Carts and

advertisement

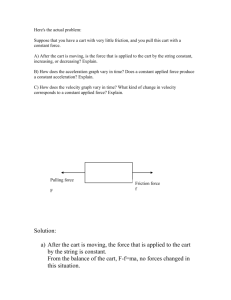

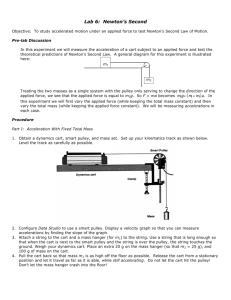

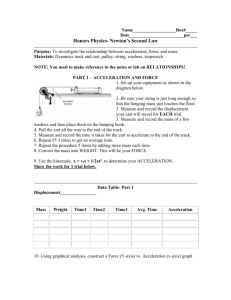

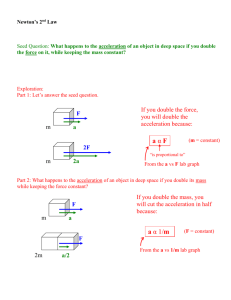

PSE Lab 3: Proving Newton’s Second Law with Dynamic Carts and Hanging Weights Archie Wheeler January 20, 2013 Abstract I set out to demonstrate Newton’s Second Law by using Pasco Dynamic Carts and Hanging Masses. The data presented in this lab were not sufficient in and of themselves to demonstrate Newton’s Law to be true. The lab was done in two phases, the first of which being more successful than the second, however both parts demonstrated a least-squares regression fit of 5% error. Contents 1 Objectives 2 2 Preliminaries 2 3 Methods 2 4 Experimental Setup 2 5 Data 5.1 Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2 Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 7 8 6 Analysis 6.1 Part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 12 7 Conclusion 14 8 Manufacturer Websites 16 1 1 Objectives I seek to demonstrate the relationship between force and acceleration per Newton’s Second Law through several different approaches. Hopefully the results of this lab will demonstrate to the reader that even though a law may be described by one equation, there are more than one direct applications of that equation. I also seek to demonstrate that I can perform Advanced-Lab-quality error analysis. 2 Preliminaries dv dp =m = ma (1) dt dt Newton’s second law gives the physicist a definition of force, namely, a force is a change in momentum per time, or an acceleration of a mass. If there is a force acting on a group of mass, the entire mass will change accelerate (changing its velocity and momentum) at a rate proportional to the force and inversely proportional to the mass. Likewise, if we know the mass of an entity and its acceleration, we can also determine the net force acting on it. F= 3 Methods This lab will be divided into two portions. In the first part of the lab, I will calibrate a force sensor and attach it to a dynamic collision cart using a force sensor adaptor plate. The force sensor will measure the tension of a string that runs horizontal to the table, off the edge, over a smart pulley, and down towards a hanging mass. The weight of the hanging mass will provide the horizontal force needed to accelerate the cart, as shown in figure 1. The average force as read by the force sensor, and the average acceleration as read by the smart pulley will be measured in table 1 for various masses. The force will be plotted against acceleration, and the slope should reveal the mass of the cart, per Newton’s second law. In the second part of the lab, we use the same basic setup, except we implement a free pulley that hangs off the table and holds the hanging mass. The other end of the string is attached to a force sensor, held by a frame built using metal rods. The tension caused by the hanging mass is split into two equal tensions on the two strings, as shown in figure 3. The force and acceleration are again recorded in a table (table 2) for various masses, and these data are plotted in a graph. 4 Experimental Setup 1. Track 2. Cart 2 3. Weights 4. Pasco Smart Pulley (Part No. 514-06266) 5. Free pulley 6. Vernier Dual-Range Force Sensor 7. Scale 8. Science workshop interface and Data Studio Software 9. Graphical Analysis software Figure 1: A free body diagram of the experimental setup for part 1 3 Figure 2: My experimental setup for part 1. See free body diagram figure 1 for labels. Ftension = T = mcart · a (2) Fweight = mg = mweight · g (3) These two equations give us a theoretical values for the forces we expect in part 1. 4 Figure 3: A free body diagram of the experimental setup for part 2 T1 = T2 = mcart · acart (4) Fweight = mweight · g = T1 + T2 (5) These two equations give us theoretical values for the forces we expect in part 2. 5 Figure 4: My experimental setup for part 2. See free body diagram figure 3 for labels. 6 5 5.1 Data Part 1 Data collected 20:00, 17 January 2013 mcart+f orcesensor = 0.640kg ± 0.006kg Mass Mean 0.0100 0.0200 0.0300 0.0400 0.0500 0.0600 0.0700 (kg) σ 0.0001 0.0004 0.0004 0.0005 0.0005 0.0006 0.0007 Force Mean 0.0890 0.1759 0.2702 0.3573 0.4212 0.4687 0.3607 (N) σ 0.0070 0.0101 0.0154 0.0077 0.0171 0.0099 0.0015 Acceleration (ms-2 ) Mean σ 0.0541 0.0082 0.2198 0.0341 0.3528 0.0229 0.4919 0.0145 0.5807 0.0199 0.6710 0.0193 0.5004 0.0126 Table 1: Force and acceleration as read by the force sensor and smart pulley respecively. The masses were compared with the scale in room 219 for accuracy. Figure 5: Graph of data run for m = 0.050kg. Note that the highlighted sections are the data where the cart was moving. The data to the left was when I was still holding the cart. The spike in the acceleration graph is when the cart hit the stop table. The rest of the data is the cart at rest. This graph is a good representative from the other graphs which were produced in this lab. 7 5.2 Part 2 Data collected 20:45, 17 January 2013 mcart = 0.504kg ± 0.0001kg mpulley = 0.0142kg ± 0.0001kg Mass Mean 0.0242 0.0342 0.0442 0.0542 0.0642 0.0742 0.0842 (kg) σ 0.0001 0.0004 0.0004 0.0005 0.0005 0.0006 0.0007 Force Mean 0.2866 0.3759 0.3835 0.4670 0.5004 0.5146 0.5407 (N) σ 0.0028 0.0092 0.0022 0.0309 0.0152 0.0401 0.0191 Acceleration (ms-2 ) Mean σ 0.1611 0.0342 0.2936 0.0254 0.3436 0.0450 0.4728 0.0636 0.5404 0.0367 0.5799 0.0523 0.6426 0.0424 Table 2: Force and acceleration as read by the force sensor and smart pulley respectively. The masses were compared with the scale in room 219 for accuracy. Figure 6: Graph of data run for m = 0.0342kg. Note that the highlighted sections are the data where the cart was moving. The data to the left was when I was still holding the cart. The spike in the acceleration graph is when the cart hit the stop table. The rest of the data is the cart at rest. This graph is a good representative from the other graphs which were produced in this lab. 8 6 Analysis Analysis for both parts began at 21:30 17 January 2013 Solving Newton’s Second equation for mass yields the following relation: F (6) a We can perform an analysis for each individual row on our data via the propagation of error technique: m= 2 df = X ∂f 2 ∂xi i 2 (∆xi ) (7) Or, for the relation in equation 6: 2 2 −F 1 2 2 (∆F ) + (∆a) dm = a a3 2 (8) Which simplifies to r dm = ∆F 2 F 2 ∆a2 + 2 a a6 9 (9) Figure 7: A plot of the force verses the acceleration. By Newton’s law, the slope should be the mass of the cart. The slope of this line is 0.6299kg and the y-intercept is 0.047766N The measured value of our cart was 0.640 ± 0.006kg. The slope of our least-squares regression fit was 1.7% below our accepted value, but all of our calculated masses were well above the accepted value, (even their error bars did not enclose the accepted value in the more accurate cases). This is likely due to a flaw in our system setup. Light weights were used that did not produce much force. This had the advantage of a relatively slow acceleration, lending itself well to pretty graphs. However, the force sensor was attached to the PASCO interface by a wire which dragged on the table as the cart was pulled along. This added friction is likely the cause behind the y-intercept of 0.047N and the reason why all of the estimated data points are above the actual. If you tied a really long rope to the back of a dog-sled, the sled dogs would think that whatever they were pulling was really heavy based on their harnesses. The same principle applies here. 10 Mass Mean 0.0100 0.0200 0.0300 0.0400 0.0500 0.0600 0.0700 (kg) σ 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 0.0001 Force Mean 0.0890 0.1759 0.2702 0.3573 0.4212 0.4687 0.3607 (N) σ 0.0170 0.0201 0.0254 0.0177 0.0271 0.0199 0.0115 Acceleration (ms-2 ) Mean σ 0.0541 0.0082 0.2198 0.0341 0.3528 0.0229 0.4919 0.0145 0.5807 0.0199 0.6710 0.0193 0.5004 0.0126 Mass of Cart (kg) Mean σ 1.6448 4.6396 0.8003 0.5730 0.7658 0.1582 0.7263 0.0564 0.7252 0.0634 0.6986 0.0421 0.7208 0.0429 Table 3: Calculated mass of cart, with propagation of error per equation 9. Note in this table, error for the Pasco Force sensor was added in pessimistically to the data presented in table 1 (±0.01N) The accuracy for a smart pulley’s timer was limited by the ADC, at about 0.1ms, well beneath the precision of these tables when the acceleration data points were averaged. 11 6.1 Part 2 Figure 8: A plot of the force verses the acceleration. By Newton’s law, the slope should be the mass of the cart. The slope of this line is .5297kg and the intercept is 0.2088N This graph striked me as odd, and I wanted to figure out why. I created a plot of the force verses the mass, and discovered that the relationship was not directly proportional (nor linear, if one were to do all of the work to sub in for a in equation 10). 12 If we take a moment to look at Newton’s Second Law, we see why: F = T1 = ma where a is the acceleration measured by the smart pulley. However, the mass is not just the mass of the cart in this system. a a (10) T1 = mcart a + mfree pulley + mhanging mass 2 2 Solving this for the mass of the cart gives us a different relationship than we saw in equation 6. mfree pulley mhanging mass T1 − + mcart = a 2 2 (11) and r ∆F 2 F 2 ∆a2 ∆m2 + + (12) a2 a6 4 Unfortunately, this relation as well did not lead to satisfying results, as the following table shows the calculated values for m based on the previous equations. dm = 13 Mass Mean 0.0242 0.0342 0.0442 0.0542 0.0642 0.0742 0.0842 (kg) σ 0.0001 0.0004 0.0004 0.0005 0.0005 0.0006 0.0007 Force Mean 0.2866 0.3759 0.3835 0.4670 0.5004 0.5146 0.5407 (N) σ 0.0128 0.0192 0.0122 0.0409 0.0252 0.0501 0.0291 Acceleration (ms-2 ) Mean σ 0.1611 0.0342 0.2936 0.0254 0.3436 0.0450 0.4728 0.0636 0.5404 0.0367 0.5799 0.0523 0.6426 0.0424 Mass of Cart Mean σ 1.7596 2.3462 1.2561 0.3823 1.0866 0.4270 0.9536 0.2941 0.8867 0.1254 0.8431 0.1628 0.7923 0.0975 Table 4: Even with the corrected equation, the mean still lies a great deal off from the accepted value. Note in this table, error for the Pasco Force sensor was added in pessimistically to the data presented in table 1 (±0.01N) The accuracy for a smart pulley’s timer was limited by the ADC, at about 0.1ms, well beneath the precision of these tables when the acceleration data points were averaged. Even though I could not find an equation that could accurately explain how to find the mass, a linear fit to the graph over the domain of m = (0.0242kg, 0.842kg) did seem to explain the data well, and the slope of the line was remarkably close (5.1% high) to the measured value of .504kg, considering the large y-intercept. The cause of this discrepancy is a bit more puzzling in this case. In part one, there was a source of friction that was more or less constant across each trial run which lended itself well to a linear fit of the form ax + b. However, in this case, the relationship is a bit more complex. I could not locate the source of error either experimentally or through equations that could explain the discrepancy in the data. 7 Conclusion Unfortunately, the objectives of this lab were not completely met. Although there were some parts of the analysis which did successfully come close to finding the mass of the cart, the set of estimations overall left much to be desired. The following list is made up of questions asked on the AU Physics Wiki for this lab that prompt the student to evelauate the lab. • Discuss the percent error (relative error) that you calculated for both graphs. In both graphs, the percent error was positive, and decreased for individual rows in the table as mass increased. This implies that as the forces grow, the effect of the y-intercept (the friction in the system) becomes less and less important. This intuitively makes since. If you want to open a door, you will pull hard on it to open it so that the friction of the door is insignificant. • Interpret the value of the intercept. 14 The intercept is the combination of all the factors in the system which drag back on the cart. These could be air resistance, friction in the tire of the cart or in the pulley, but most likely the friction of the cord being dragged along. In part 2, I was not able to determine where the large intercept came from. • Examine how the presence of constant frictional force would affect the results of the experiment. A constant frictional force will change what would be a proportional relationship (y = ax) into a linear relationship (y = ax + b) where the friction can be expressed in terms of some constant b. • Speculate on the origin(s) of error. As stated in analyses sections and previously in this conclusion, sources of error include dragging of electric cords, but also the inertia of the hanging mass. Some of the force is “used up” in being applied to other components in the system. The larger the mass, the closer the systems’ acceleration approaches to free fall. So in reality, neither of these equations are linear as mhanging weight mcart • Discuss the difference between the measured and calculated tensions. The measured tension was always less than what the calculated tension was. This is primarily because some of the force was being applied on the hanging mass, which would relieve a small amount of tension off of the string. • Mention what you learned in this experiment. LATEX, Matlab, and refresher on other technologies that make life easier. But as far as practical usage goes, I learned how to identify what things need to be set up in a system, when measurements should be taken in the flow of performing a lab, and how to research manufacturer information in order to get error results. • State which experimental method you prefer, and give justification for your preference. Both methods are flawed, primarily because the hanging masses have inertia as well. If I could work out the reason why part 2 was off, then I feel that the second part would be better, because there is no dragging of a cord along with an instrument. Furthermore, the rate of acceleration is slower, so there is a longer period in each trial, and more data points can be collected. • Include any additional comments that you think are important. White boards as tables are the greatest thing ever, because the entire surface is scratch paper for annotating, labeling, and working out equations! 15 8 Manufacturer Websites • www2.vernier.com/booklets/dfs.pdf • http://www.pasco.com/prodCatalog/ME/ ME-6838 photogate-pulley-system/index.cfm#specificationsTab 16