EXPERIMENT C Bernoulli's Theorem Demonstration

advertisement

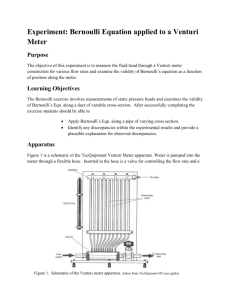

KNC 1101: CHEMICAL ENGINEERING LABORATORY I LABORATORY MANUAL EXPERIMENT C Bernoulli’s Theorem Demonstration Faculty of Engineering Department of Chemical Engineering & Energy Sustainability Semester 2_ 2013/2014 KNC 1101: Chemical Engineering Laboratory I 2013/2014 INTRODUCTION Bernoulli's law states that if a non-viscous fluid is flowing along a pipe of varying cross section, then the pressure is lower at constrictions where the velocity is higher, and the pressure is higher where the pipe opens out and the fluid stagnate. Many people find this situation paradoxical when they first encounter it (higher velocity, lower pressure). This is expressed with the following equation: p v2 z h * Constant g 2g Where, p ρ g v z = Fluid static pressure at the cross section = Density of the flowing fluid = Acceleration due to gravity = Mean velocity of fluid flow at the cross section = Elevation head of the center at the cross section with respect to a datum h* = Total (stagnation) head The terms on the left-hand-side of the above equation represent the pressure head (h), velocity head (hv ), and elevation head (z), respectively. The sum of these terms is known as the total head (h*). According to the Bernoulli’s theorem of fluid flow through a pipe, the total head h* at any cross section is constant. In a real flow due to friction and other imperfections, as well as measurement uncertainties, the results will deviate from the theoretical ones. In this experimental setup, the centerline of all the cross sections are considering lie on the same horizontal plane (which we may choose as the datum, z = 0, and thus, all the ‘z’ values are zeros so that the above equation reduces to: p v2 h * Constant g 2g This represents the total head at a cross section Prepared by Mohamed Afizal Mohamed Amin 2 KNC 1101: Chemical Engineering Laboratory I 2013/2014 Objective of the Experiment 1) To demonstrate Bernoulli’s Theorem Prior Knowledge 1) Fluid dynamics (fluid in motion) 2) Bernoulli’s law : Venturi Meter Materials and Equipment 1) Bernoulli’s Theorem Demonstration Unit (Model: FM24) 2) Tap water 5 1 6 2 7 3 8 4 9 Figure 1: Parts Identification Diagram 1. 2. 3. 4. 5. 6. 7. 8. 9. Manometer Tubes Test Section Water Inlet Unions Air Bleed Screw Flow Control Valve Gland Nut Hypodermic Probe Adjustable Feet Prepared by Mohamed Afizal Mohamed Amin 3 KNC 1101: Chemical Engineering Laboratory I 2013/2014 Air bleed screw Manometer tubes Unions Gland Nut Hypodermic probe Water inlet Test section Adjustable feet Figure 2: Front View of Bernoulli’s Theorem Demonstration Unit Water outlet Flow control valve Additional tapping Figure 3: Top View of Bernoulli’s Theorem Demonstration Unit The unit consists of the followings: a) Venturi The venturi meter is made of transparent acrylic with the following specifications: Throat diameter : 16 mm Upstream Diameter : 26 mm Designed Flow Rate : 20 LPM b) Manometer There are eight manometer tubes; each length 320 mm, for static pressure and total head measuring along the venturi meter. The manometer tubes are connected to an air bleed screw for air release as well as tubes pressurization. Prepared by Mohamed Afizal Mohamed Amin 4 KNC 1101: Chemical Engineering Laboratory I 2013/2014 c) Baseboard The baseboard is epoxy coated and designed with 4 height adjustable stands to level the venturi meter. d) Discharge Valve One discharge valve is installed at the venturi discharge section for flow rate control. e) Connections Hose Connections are installed at both inlet and outlet. f) Hydraulic Bench Sump tank : 120 litres Volumetric tank : 100 litres Centrifugal pump : 0.37 kW, 50 LPM METHODOLOGY A. General Start-up Procedures The Bernoulli’s Theorem Demonstration (Model: FM 24) is supplied ready for use and only requires connection to the Hydraulic Bench (Model: FM 110) as follows: 1. Ensure that the clear acrylic test section is installed with the converging section upstream. Also check that the unions are tighten (hand tight only). If necessary to dismantle the test section then the total pressure probe must be withdrawn fully (but not pulled out of its guide in the downstream coupling) before releasing the couplings. 2. Locate the apparatus on the flat top of the bench. 3. Attach a spirit level to baseboard and level the unit on top of the bench by adjusting the feet. 4. Fill water into the volumetric tank of the hydraulic bench until approximately 90% full. 5. Connect the flexible inlet tube using the quick release coupling in the bed of the channel. 6. Connect a flexible hose to the outlet and make sure that it is directed into the channel. 7. Partially open the outlet flow control valve at the Bernoulli’s Theorem Demonstration unit. 8. Fully close the bench flow control valve, V1 then switch on the pump. 9. Gradually open V1 and allow the piping to fill with water until all air has been expelled from the system. 10. Also check for “Trapped Bubbles” in the glass tube or plastic transfer tube. You would need to remove them from the system for better accuracy. Prepared by Mohamed Afizal Mohamed Amin 5 KNC 1101: Chemical Engineering Laboratory I 2013/2014 Note: To remove air bubbles, you will have to bleed the air out as follow: a. Get a pen or screw driver to press the air bleed valve at the top right side of manometer board. b. Press air bleed valve lightly to allow fluid and trapped air to escape out. (Take care or you will wet yourself or the premise). Allow sufficient time for bleeding until all bubbles escape. 11. At this point, you will see water flowing into the venturi and discharge into the collection tank of hydraulic bench. 12. Proceed to increase the water flowrate. When the flow in the pipe is steady and there is no trapped bubble, start to close the discharge valve to reduce the flow to the maximum measurable flow rate. 13. You will see that water level in the manometer tubes will begin to display different level of water heights. If the water level in the manometer board is too low where it is out of visible point, open V1 to increase the static pressure. If the water level is too high, open the outlet control valve to lower the static pressure. Note: The water level can be adjusted facilitate by the air bleed valve. 14. Adjust V1 and outlet control valve to obtain a flow through the test section and observe that the static pressure profile along the converging and diverging sections is indicated on its respective manometers. The total head pressure along the venture tube can be measured by traversing the hypodermic tube. Note: The manometer tube connected to the tapping adjacent to the outlet flow control valve is used as a datum when setting up equivalent conditions for flow through test section. 15. The actual flow of water can be measured using the volumetric tank with a stop watch. B. Experiment 1. Perform the General Start-up Procedures in Section A. 2. Check that all manometer tubings are properly connected to the corresponding pressure taps and are air-bubble free. 3. Adjust the discharge valve to a high measurable flow rate. 4. After the level stabilizes, measure the water flow rate using volumetric method. 5. Gently slide the hypodermic tube (total head measuring) connected to manometer #G, so that its end reaches the cross section of the Venturi tube at #A. Wait for some time and note down the readings from manometer #G and #A. The reading shown by manometer #G is the sum of Prepared by Mohamed Afizal Mohamed Amin 6 KNC 1101: Chemical Engineering Laboratory I 2013/2014 the static head and velocity heads, i.e. the total (or stagnation) head (h*), because the hypodermic tube is held against the flow of fluid forcing it to a stop (zero velocity). The reading in manometer #A measures just the pressure head (hi) because it is connected to the Venturi tube pressure tap, which does not obstruct the flow, thus measuring the flow static pressure. 6. Repeat step 5 for other cross sections (#B, #C, #D, #E and #F). 7. Repeat step 3 to 6 with three other decreasing flow rates by regulating the venturi discharge valve. 8. Calculate the velocity, ViB using the Bernoulli’s equation where; Vi 2 g (h8 hi ) 9. Calculate the velocity, ViC using the continuity equation where Vi_Con = Qav / Ai 10. Determined the difference between two calculated velocities. C. General Shut-down Procedures 1. Close water supply valve and venturi discharge valve. 2. Turn off the water supply pump. 3. Drain off water from the unit when not in use. RESULTS AND DISCUSSION Using Bernoulli Equation Cross Section h*=hG (mm) hi (mm) ViB = √[2*g*(h* - hi )] (m/s) Using Continuity Equation Ai = ¶ Di2 / 4 (m2) ViC = Qav / Ai (m/s) Difference ViB-ViC (m/s) A B C D E F Additional Information: Throat Diameter, D3 (mm) = 16.0 Inlet Diameter, D3 (mm) = 26.0 Throat Area, At (m2) = 2.011 x 10-4 Inlet Area, Ai (m2) = 5.309 x 10-4 g (m/s2) = 9.81 ρ (kg/m3) = 1000 Prepared by Mohamed Afizal Mohamed Amin 7