Formulas and Units

advertisement

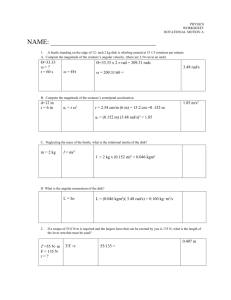

Formulas and Units Transmission technical calculations – Main Formulas Size designations and units according to the SI-units Linear movement: s v= t s = v× t sa = a= 1 2 × a × ta 2 Rotation ω = 2× π ×f rad/s m/s v = ω × r = 2× π ×f × r m/s m M = F× r Nm P = M×ω W & M = J×ω Nm J × ω2 W= 2 Ws or J J = m× r2 kgm2 m v ta m/s2 P = F× v W F = m×a N W = F×s Ws W= m × v2 2 Ws Units used v = velocity in m/s F= force in N M = mass in kg W = work in Ws = J = Nm P= power in W = ang. velocity in rad./sec. s = length in m f = frequency in rev./sec. t = time in sec. r = radius in m a = acc. in m/s 2 J = Rotational mass moment of inertia in kgm2 & = angular acc. in rad/s2 ω Ma= acceleration torque in Nm M = torque in Nm ta = acc. time in sec. 1 LA0011-01GB Formulae for the transmission technique Power Rotational Movement: Ps = M × ω ω = π ×n 30 Linear Movement: W (without loss) rad/s P= P= M×n π × η 30 W P= M×n π 1 × × η 30 1000 kW Torque M = F× r MA = P × 9550 ×η n P = F× v× 1 η F× v 1 × 1000 η W kW Lead screw: M= F× p 2000 × π × η Nm Toothed belt: Nm v = π × D× n Nm m= D z D= z×t π m/min Units used: M = torque in Nm = angular velocity in rad/s n = revolutions/min. = efficiency (motor) F = force in N z = number of teeth t = distance between teeth in mm v = velocity in m/min MA = delivered torque in Nm r = radius in m P= power in kW or W D= diameter in m m = module p = pitch in mm/rev Ps = transmitted shaft power P= necessary motor power 2 LA0011-01GB Acceleration torque J×n π Ma = × ta 30 Nm For operation of electrical motors with gear transmission: Ma = J red × n π × ta 30 Nm Reduction of rotational mass moment of inertia J red n2 1 = 2 ×J = 2 ×J n mot i kgm2 Linearly moveable masses is reduced to the number of revolutions of the motor according to: J red = 91.2 × m × v2 n 2 kgm2 mot Rotational mass moment of inertia of a solid cylinder: 1 J = × m × r2y 2 kgm2 Units used: Ma = acceleration torque in Nm J = rotational mass moment of inertia in kgm2 Jred = reduced rotational mass moment referred to the motor shaft in kgm2 nmot = number of revolutions of motor in rev/min. n = number of revolutions in rev./min. m = mass in kg ta = acceleration time in s ry = outer radius of solid cylinder v = velocity in m/s i= n mot gear ratio n 3 LA0011-01GB Acceleration and deceleration time ta = J×n 9.55 × M a s Braking work A= Mb J × n 2 mot × red Mb + ML 182.4 Ws Necessary power for linear movement P= F× v 1000 × η kW Force at sliding friction F = m×g×µ N Units used: Ma = acceleration torque in Nm = friction coefficient Mb = braking torque in Nm ML = load torque reduced to the motorshaft in Nm ta = acceleration time in s J = rotational mass moment of inertia in kgm2 Jred = reduced rotational mass moment of inertia referred to the motor shaft nmot = number of revolutions of motor in rev/min. P = power in kW F = force in N n = Number of revolutions in rev./min. v = linear velocity in m/s W = work in Ws or J m = load in kg g = gravity (9.81 m/s2) = efficiency of linear movement 4 LA0011-01GB Frictional force during linear movement using wheels or rails F= 2× m×g d × (µ1 × + f) × µ 2 N D 2 By approximate calculations it is often simple to use the specific running resistance R in N/ton carriage weight by calculation of the required power. P= R ×q×v 1000 × η kW Heavier carriages on rails, roller bearings R = 70 – 100N/ton Lighter carriages on rails, roller bearings R = 100 – 150N/ton Units used: F = force in N m = load in kg g = gravity D = wheel- or roller diameter in m f = rolling friction radius 1 = bearing friction 2 = rail- or side friction v = velocity in m/s = efficiency q = load in ton d = shaft diameter in m Rolling friction radius, f (m): Steel against steel Steel against wood Hard rubber against steel Hard rubber against concrete Inflated rubber tire against concrete f = 0.0003 – 0.0008 f = 0.0012 f = 0.007 – 0.02 f = 0.01 – 0.02 f = 0.004 – 0.025 Bearing, rail- and side friction: Roller bearings 1 = 0.005 Sliding bearings 1 = 0.08 – 0.1 Roller bearings 2 = 1.6 Slide bearings 2 = 1.15 Sideguides with rollerbearings 2 = 1.1 Roller guides side friction 2 = 1.8 5 LA0011-01GB SI - Units SI basic units For Motion Control Symbol Measure Unit m kg s A K length mass time electrical current temperature metre kilogram second ampere Kelvin Designation Measure Unit Symbol a distance angle angle diameter height length radius distance volume linear acceleration angular acc. frequency gravity revolutions per unit angular velocity time constant time linear velocity metre radian degree metre metre metre metre metre cubic-metre m rad Newton Newton N N 2 kgm Newtonmetre kilogram Watt Joule Nm kg W J i force weight force Rotational mass moment of inertia torque mass power energy efficiency friction coefficient gear ratio I P R S,Ps U current active power resistance appearent power voltage Ampere Watt Ohm Voltampere Volt A W , d h l r s V a & ω f g n w T t v Mechanical F G J M m P W Electrical Hertz rev./min. second second m m m m m 3 m 2 m/s 2 rad/s Hz 2 m/s 1/s rad/s s s m/s W, VA V 6 LA0011-01GB The rotating mass moment of inertia of rotating bodies Body Rotation Symbol Rotational mass moment of inertia, J in kgm2 m × r2 Hollow cylinder Around own axis Homogeneous cylinder Around own axis m 2 ×r 2 Thickwalled cylinder Around own axis m × (r 21 + r 2 2 ) 2 Disc Around own axis Disc Around own plane Sphere Around own center m 2 ×r 2 m 2 ×r 4 2× m 2 ×r 5 Thinwalled sphere Around own center 2× m 2 ×r 3 Thin rod Perpendicular around own axis m 2 ×l 12 Steiners Equation Rotational mass moment of inertia relative to a parallel shaft in the distance a J = J0 + m × r 2 J0 = rotational mass moment of inertia relative to the center of gravity axis kgm2 kgm2 m = mass of the body kg r = shaft distance m 7 LA0011-01GB Correlation between rotational mass moment of inertia and rotating mass J = m × rJ 2 kgm2 Units used: J = rotational mass moment of inertia in kgm2 m = mass in kg rJ = inertial radius in m The efficiency for different types of drives are often values obtained by experience: Some normal values for parts with rollerbearings: Drive belt with 180 force transmitting angle Chain with 180 force transmitting angle Toothed rod Transporting belt with 180 transmitting angle Wire with 180 transmitting angle = 0.9 – 0.95 = 0.9 – 0.96 = 0.8 – 0.9 = 0.8 – 0.85 = 0.9 – 0.95 The friction values are difficult to give correctly and are dependant on surface conditions and lubrication. Some normal values: Steel against steel static friction, dry dynamic friction, dry static friction, viscous dynamic friction, viscous = 0.12 – 0.6 = 0.08 – 0.5 = 0.12 – 0.35 = 0.04 – 0.25 Wood against steel static friction, dry Dynamic friction, viscous = 0.45 – 0.75 = 0.3 – 0.6 Wood against wood Static friction, dry Dynamic friction, viscous = 0.4 – 0.75 = 0.3 – 0.5 Plastic against steel static friction, dry Dynamic friction, viscous = 0.2 – 0.45 = 0.18 – 0.35 8 LA0011-01GB The twisting torque on a shaft from a pulling force is according to the following: M = F× r × η = F× d0 ×η 2 Nm Efficiency, Toothed wheel = 0.95 Chain wheel = 0.95 Toothed belt = 0.80 Flat belt = 0.40 Flat belt, pre-tensed = 0.20 Units used: F = cross force M = twisting torque do = effective diameter on toothed wheel or chain wheel = efficiency r = radius in m 9 LA0011-01GB