thermoset composites and en 45 545 standard

advertisement

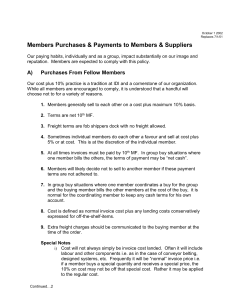

T H ema | 15 THERMOSET COMPOSITES AND EN 45 545 STANDARD SMC, BMC, HL1,HL2, HL3, M1, F0, F1, Fire, Smoke, Fire retardancy, Windows frames, luggage rack, pillar, side panels, seats, electrical boxes, railways marker, electrical insulation, Innovation. I DI’s Thermoset BMC and SMC are already IDI PRODUCTS BEFORE EN 45 545-2 being used in the production of a large va- meet stringent criteria (FIRST criteria) in terms of Flame spread, Ignitability, Rate of riety of train and railway parts. One of the Each country has its own standard and classi- heat release, Smoke opacity and Toxicity many reasons for this is their adaptability, al- fication for train transportation application emitted during a fire. lowing them to be moulded to produce high presented in the table below with the differ- volumes of small parts (grammes) or larger ent Products from IDI Composites Europe. parts (kilos). Another advantage of course is that both SMC and BMC can be used when a high level of fire retardancy is needed. Category Standard Fire SMC and BMC are intrinsically, insulating materials which present excellent thermal Smoke SMC BMC M1 IDI Trans B BS 476 Class1 IDI Trans C The operation and design (type of train or SR2 IDI Trans D metro or tramway) categories defined in F0 IDI Trans E Part 1 are used to establish hazard levels BS 6853 Class Ib IDI Trans F (HL1 less severe to HL3 most severe) which rosion resistance. IDI’s products also have IDITrans is a family of grades dedicated to Train Transportation application. pigmented in an assortment of colours flooring, ceilings, etc.) - R1 to R25 category. are used as the base of a classification system. For each hazard level, Part 2 specifies the test methods, test conditions and re- ter batch. EN 45545 REQUIREMENTS & NEW PRODUCTS Parts moulded using IDI’s Thermoset The new European Fire and Smoke regula- Composites can be produced in a wide range tion EN 45545 will be applied early this year. of thicknesses. Wall thicknesses within the The goal of this standard is to guarantee part can be varied and reinforcements can the safety and evacuation of passengers, be integrated and inserted. The moulded accompanying staff and to cover potential item is easily cleanable and can be bored, emergencies. action to fire performance requirements. Operation Category 1 2 3 4 Design category N A D S or DS HL1 HL1HL1HL2 HL2 HL2HL2HL2 HL2 HL2HL2HL3 HL3 HL3HL3HL3 IDI PRODUCTS NOW! bonded and painted and has a high quality surface. applications (electrical equipment, seating, IDI Trans A and shades ensuring uniformity batch af- classify the products according to their final S4 and dimensional stability with a high corthe added benefit of being able to be mass The fire reaction tests aim to qualify and The European standard is divided into the following seven categories: IDI’s R&D team have been busily developing All these characteristics allow molders to Part 1: General innovative solutions for you in accordance produce a very large range of parts for train Part 2: Requirements for fire behaviour of with the new European fire and smoke and railways applications. Windows frames, materials and components standard EN 45 545. These products are luggage rack, pillar, side panels, seats, Part 3: Fire resistance requirements for fire available from our plant in Vineuil, France. electrical boxes, but also railways mark- barriers – rejected, revision and partitions er, electrical insulation parts are currently Part 4: Fire safety requirements for rolling produced. For train transport application stock design SMC, BMC permit designers to develop spe- Part 5: Fire safety requirements for electri- cial parts with high level of fire retardancy! cal equipment These characteristics are reached using Part 6: Fire control and management green raw materials in accordance with systems RoHS and REACH regulation (100 % of SMC Part 7: Fire safety requirements for flam- and BMC IDI production are halogen-free). mable liquid and flammable gas installations HL1 HL2 HL3 IDI TRANS HL1 IDI TRANS HL2 IDI TRANS HL3 SMC or BMC SMC or BMC SMC or BMC More information The new European fire and smoke standard has been studied by IDI and R&D project has Part 2 – EN 45545-2 – defines the demands, been managing in order to propose innova- in terms of reaction to fire, that railway tive solutions to our customers. products should meet. All materials must IDI CompositeS Europe VineUil (41) - France J. Mantet-Gay / H. Magnaud Phone: 00332 54 55 55 54 Mail: sales-europe@idicomposites.com www.idicomposites.com EURAILmag B­usiness & Technology /// ISSUE 27