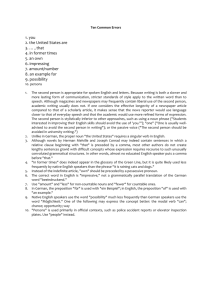

German Resource Efficiency Programme

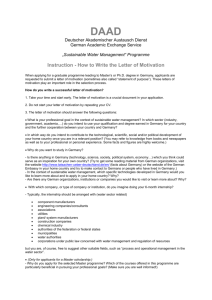

advertisement