Page 1 of 34 Training Requirements in OSHA Standards and

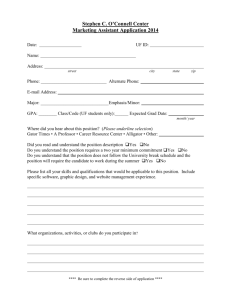

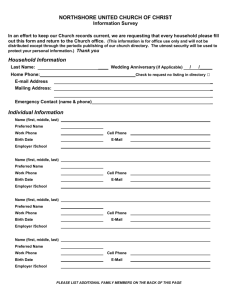

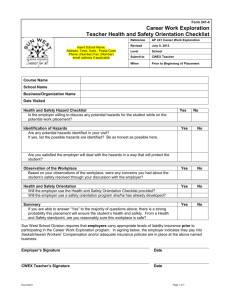

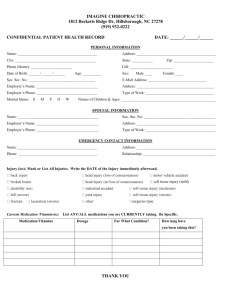

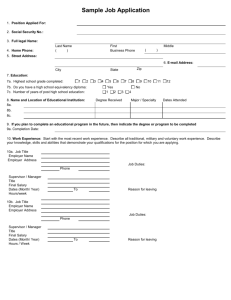

advertisement