Piaggio X10 500 - ScooterSales.com.au

advertisement

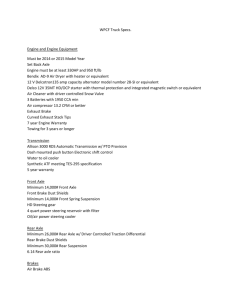

Piaggio X10 500 Proven Power – 500cc Twin Spark Master Engine. Exceptional Balance and Stability – Infinitely Variable Hydraulic Rear Suspension Preload Adjustment and ASR Traction Control. Unparalleled Stopping Power – Integrated Braking System with ABS. State of the Art Lighting, Rider Controls and Instrumentation. d Bluetooth Multimedia Connectivity with Piaggio Multimedia Platform. Rear Suspension Rear Suspension Horizontal Mono‐shock with electrically operated hydraulic preload. 2 Rear Suspension p Infinitely variable preload with instrument panel preload icon. Preload Adjustment – “on the move”. 3 USB Accessory Socket Output voltage: 5V ± 0.25 Max. charge current: 1A 12 Volt Accessory socket Output voltage: Nom 12 ‐ 14V Max power: 180 W Max. power: 180 W 4 Side Stand Parking Brake ABS / ASR with integrated braking system / 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Front/rear brake master cylinder Front/rear brake master cylinder ABS unit Front/rear brake master cylinder ABS unit Front brake master cylinder Left hand front brake calliper Right hand front brake calliper Distributor valve Line from distributor valve ‐ right hand front brake calliper ‐ rear brake calliper Line from ABS unit ‐ rear brake calliper Rear brake calliper Line from ABS unit ‐ front left hand brake calliper ABS control unit Line from ABS unit – distributor valve 6 MAB Mk2‐2 ASR Status ASR System ASR System & Indicators ASR Control ASR (Traction Control) is integrated with the ABS system and monitors speed and acceleration of the front and rear wheels to detect loss of rear wheel traction. The ASR controller is monitored by the engine ECU and if wheel slip is engine ECU and if wheel slip is detected the ASR indicator will flash and the system will trim first the ignition timing and then the injection volume to decrease engine output until traction is restored. il i i d Vespa 946 / Piaggio X10 500 PMP (PIAGGIO MULTIMEDIA PLATFORM) PMP – (PIAGGIO MULTIMEDIA PLATFORM) Seamless connection to vehicle CAN, Analog and K‐line data and any 3G or 4G digital network via iPhone g and Android devices. • • • • • • • • Road Speed Engine Speed Battery Voltage Average Speed Torque at Rear Wheel Nm q Longitudinal «g» Acceleration Current Fuel Consumption Average Fuel Consumption • • • • Engine Output kW Engine Torque Nm Turn Indicator Alert Vehicle Bank Angle* *(iPhone ( 4 and 4S)) SCHEDULED MAINTENANCE TABLE I: CHECK AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY. C: CLEAN, R:REPLACE, A: ADJUST, L:LUBRICATE * Replace every 2 years X10 500 km x 1,000 1 10 Safety fasteners I I 20 30 40 I 50 60 I 70 80 I Spark plugs R R R R R R R R Centre stand L L L L L L L L Drive belt R R R R R R R R A A A A A A A A C I C I C I C I Throttle control A Air filter Engine oil filter R R R R R R R R R Parking brake A A A A A A A A A Valve clearance I I I I Electrical system I I I I I I I I I Coolant level * I I I I I I I I I Brake oil level* I I I I I I I I I Engine oil R R R R R R R R R Hub oil R I R I R I R I R Brake p pads I I I I I I I I I R R R R R R R R Sliding shoes / CVT rollers Brake pumps R R Tyre pressure and wear I I I I I I I I I Vehicle test and brake test - Road test I I I I I I I I I I I I I I I I I I I I I I I I I I 105 190 220 350 220 190 380 190 220 Suspension Steering Operation time (minutes) X10 500 VEHICLE TECHNICAL DATA Specification Desc /Quantity Desc./Quantity Frame A closed double cradle in steel tubes Front suspension Hydraulic telescopic fork Ø 41 mm rear suspension Single shock absorber with electrical preloading adjustment system. Front brake Double disc Ø280 with hydraulic control actuated by the right lever; braking assisted by ABS system. Integral brake Disc Ø240 with hydraulic control actuated by the left lever; the front disc Ø280 is served by a pressure relief valve; braking assisted by ABS system. Wheel rim type Light alloy wheel rims. Front wheel rim 3.50"x15" 3.50 x15 Rear wheel rim 4.00"x13" Front tyre 120/70-15" M/C 56S Tubeless Rear tyre 150/70-13" M/C 64S Tubeless Front tyre pressure (with passenger) 2.3 2 3 bar (2 (2.3 3 bar) Rear tyre pressure (with passenger) 2.4 bar (2.6 bar) Kerb weight 229 kg Maximum weight allowed 420 kg Battery SEALED 12V/12Ah ENGINE TECHNICAL DATA X10 500 Specification Desc./Quantity Type Single-cylinder, 4-stroke Engine capacity 493 cm³ Bore x Stroke 94 x 71 mm Compression ratio 10.5:1 Engine idle speed 1,500 rpm Timing g system y Four valves,, single g overhead camshaft,, chain-driven. Valve clearance Intake: 0.15 mm Exhaust: 0.15 mm Max. power 30 kW at 7250 rpm MAX. torque 46 Nm at 5250 rpm Transmission CVT expandable pulley variator with torque server, V-belt, self-ventilating dry automatic centrifugal g clutch and transmission housing g with forced-circulation air cooling. g Final reduction gear Gear reduction unit in oil bath. Lubrication Engine lubrication with lobe pump (inside crankcase), chain-driven, with double filter: mesh and paper. Cooling Forced coolant circulation system. Electric starter Ignition Highly efficient electronic inductive ignition, integrated with the injection system, with variable advance, separate HV coil and double spark plug. Ignition advance Three-dimensional map managed by control unit Spark plug NGK CR7EKB Electrode gap 0.7 ÷ 0.9 mm Fuel system Electronic injection with electric fuel pump. Fuel Unleaded petrol (95 RON) Exhaust silencer Absorption-type exhaust muffler with catalytic converter and lambda probe. Emissions compliance EURO 3 X10 500 FLUIDS AND CAPACITY Fluid Specification Quantity Engine oil 5W – 40 Full Synthetic to API SL – JASO MA/MA2 1.7 Litres Transmission oil 80W – 90 Mineral Gear Oil to API GL-4 250 cc Cooling system fluid Ethylene Glycol Base 1.75 Litres Fuel 95 Octane (RON) = Premium Unleaded 95 in Australia 15.5 Litres ± 0.5