Technical product documentation and specification

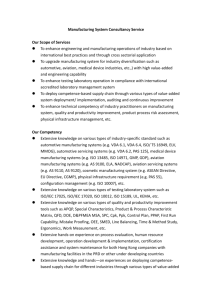

advertisement