Operational Manual

advertisement

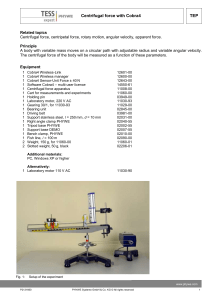

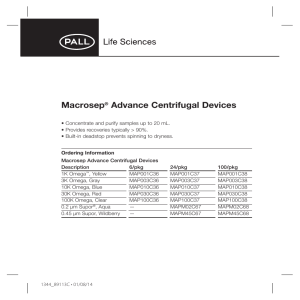

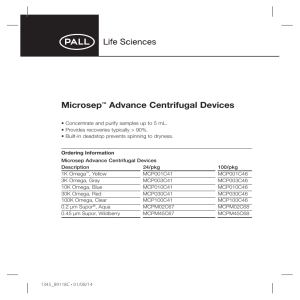

@TecQuiprnent Ltd 1999 No part of this publicationmay be reproducedor transmittedin any form or by any means,electronicor mechanical,including photocopy, recording or any information storageand retrieval systemwithout the expresspermissionof TecQuipmentLimited. All due care has been taken to ensurethat the contentsof this manualare accurateand up to date. However,if any errorsare discoveredpleaseinform TecQuipmentso the problem may be rectified. A Packing Contents List is supplied with the equipment. Carefullycheckthe contentsof the package(s)againstthe list. If any items are missing or damaged, contact your local TecQuipmentagent or TecQuipmentLtd immediately. Educational PRODUCTS CONTENTS Section 1 INTRODUCTION 1 2 DESCRIPTION OF THE APPARATUS 3 3 THEORY 5 4 EXPERIMENTAL PROCEDURE Electrical Connections Procedure Results 7 7 7 8 SECTION 1 INTRODUCTION Figure 1 Centrifugal force apparatus The appreciationof centrifugal force has always been regarded as one of the most important engineering topics in the field of mechanics.Its effectscan be most useful in somedesignapplications,but may also be the causeof drasticfailures in rotating components. An automaticclutch is a very good exampleof using centrifugal force for power transmission.The unit is usually installed between the motor shaft and the machinerywhich it drives. It comprisestwo or more 'shoes' which are pivoted on the driving shaft. When this shafthasreacheda certainspeed,centrifugaleffects overcomethe force exerted by the restraining springs. The shoesthen move outwardsto pressagainstthe inner surfaceof the rim of an annulusmountedon the driven shaft, and thereby rotate the machinery.The speedat which the clutch engagesdependson the stiffnessof the restraining springs and the mechanicaldesign of the clutch. When the shafts are not in motion, the restraining springs retract the 'shoes' to their Static position and the machinery is completely disengaged from the motor. This type of automatic clutch is particularly useful when the driven machineryrequiresa high startingtorque. On high speed machinery such as turbines, the centrifugal force due to a small out of balance componentcan causeseriousvibrationswhich may lead to failure of vital components. The rotating parts thereforehave to be balancedto a fine limit and made strong enough to withstand the centrifugal effects involved. Since rotational speed is always a critical factor in modem machinery,a considerableamountof researchwork hasbeendoneto find new materialssuch as carbon fibre plastics and titanium alloys. These materialshavemuch lower densityto give exceptionally high specificstrength. The TQ Centrifugal Force Apparatus allows the magnitudeof the centrifugal force acting on a body to relate to its rotational speedand radius. The apparatus hasprovisionsfor varying the massof the body, radius and rotational speed,and the results shown to accord with theory. SECTION 2 DESCRIPTION OF THE APPARATUS The TQ Centrifugal Force Apparatus is designed to demonstratethe relationshipbetweencentrifugal force, massof a rotating body, its distancefrom the axis and its angular velocity. It consistsof two pivoted counter balanced bell-cranks housed in slideable blocks, as shown in Figure 2. Various combinationsof accurately machinedmassesfit to the endsof the bell-crank arms. Sufficient massesare pivoted to enable the mass on each arm to be increasedby between25 and 175g in incrementsof 25 g. The slideable blocks are held in position by locating pins. Each block fits in five different radial positions correspondingto five equally spaced holes in each end of the horizontal rotating member. Horizontal rotating member Counter-balanced bell-aank Masses A transparent safety dome covers the rotating assembly.Removalof the dome disconnectsthe motor from the power supply. Figure 3 shows the horizontal rotating member carrying two counter-balancedbell-cranks. The bellcrankspivot in brackets,which can fix at severalpoints along the rotating member. When the unit rotates,the upper massesM. tend to move outwards under the actionof centrifugalforce. With the upper massesat radius r and rotating at rad/s,the force on eachmassis: F = M.ro2r Gravitational force on the lower massesMb restrains any movement of the bell-cranks until the centrifugal force balances this gravitational force. At this point. the upper masses will move outwards. Taking moments about the pivot point at the condition of balance: MatJr x 0.04 = M.,g x 0.04 F = Ma~r Baseunit Figure 2 The rotating member is belt driven from a variable speed 12 V d.c. electric motor contained in the base unit. The motor control is via the SpeedController. An optical tachometersensoris also incorporated,and on the front of the module unit is an output socket for connectingto the TachometerUnit. = M.,g Thus, the centrifugal force at the condition of balance is equal to the weight of the lower mass Mb' The angular velocity ro can be determined by measuring the speed of rotation when the upper masses move outwards. The theoretical centrifugal force can then be calculated and compared with the measured value M.,g. The independent relationships between centrifugal force F and each of the variables: mass, angular velocity and radius can be demonstrated. These relationships are: F« ~ for constant Ma and r F «M. F« r for constant rand ro for constant M. and ro It must be stressed at this point that the masses M. and Mb are not simply the masses placed on the weight hangers a and b. The bell crank, with its attendant weight hangers, also has a mass subject to gravitational acceleration and centrifugal acceleration and this acts through the centre of gravity of the bell crank assembly. To have any value in the experiment the mass of the bell crank assembly must be equated to an equivalent mass acting at the weight hangers a and b. This is calculated at 15 g and is marked on the plate adjacent to each weight hanger. Hence, M. = Mass placed on weight hanger a + 15g Mb = Mass placed on weight hanger b + 15g The relationshipbetweencentrifugal force and angular velocity canbe detenninedsimply by varying the values of Mb with both M. and r constant.To demonstratethe other two relationshipsrequires a series of tests for varying the massesof the bodies A and B and varying the radius.By plotting the resultsand readingoff values at constant angular velocity, separategraphs can be drawn showing the variation of radial force with mass M. and with radiusr. SECTION 3 THEORY Considera body moving in a circular path of radius r, with an angularvelocity (I) as shown in Figure 1. When the body movesthrough a small angle 09, the velocity vector,v changesdirection asshownin Figure4. If the changein direction of velocity takesplacein time 01, and the change of velocity is ov, representedby vectorAB in Figure 5, then Acceleration = Ov ~t (1) If the angle50 is small, we canwrite: Of= -50. and ov=v09 Substitutingthesevalues of Sv and Sf in Equation (1) above: Acceleration= V(J) Finally, by noting that v = (JYwe obtain: Acceleration= roZr Figure 4 This accelerationis termed the centripetal, or centre seeking,accelerationbecausethe massis continuously acceleratedtowardsthe centre.From Newton's Second Law of Motion, a force must act on the massm in the direction of this accelerationi.e. a centripetal force of magnitudemroZr.The inertia force is in the opposite sense,i.e. acting outwardsfrom the centre.This force is termedcentrifugalforce.