Advanced Placement Biology

®

292

AP Biology

Lab 12

EDVO-Kit #

Dissolved Oxygen &

Aquatic Primary Productivity

Storage:

Store entire experiment at room temperature

EXPERIMENT OBJECTIVE

The objective of this experiment is to understand:

1) the factors that affect the solubility of dissolved

gases in aquatic environments, 2) the effects of

light and nutrients on photosynthesis, and 3) the

relationship between dissolved oxygen, photosynthesis and respiration. Students should be able to

describe a method to measure dissolved oxygen,

and define primary productivity and factors which

influence it.

EDVOTEK, Inc. • 1-800-EDVOTEK • www.edvotek.com

EVT 005057AM

2

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Biology

Table of Contents

Lab #

12

Page

Experiment Components

3

Experiment Requirements

Background Information

3

4

Experiment Procedures

Experiment Overview

Part A. The Winkler Method for Dissolved Oxygen

7

8

Part B. Primary Productivity

Laboratory Extensions

13

20

Study Questions

27

Instructor's Guidelines

Notes to the Instructor

Pre-Lab Preparations

Study Questions and Answers

Material Safety Data Sheets

Advanced Placement (AP) Program is a

registered trademark of the College Entrance

Examination Board. These laboratory materials

have been prepared by EDVOTEK, Inc. which

bears sole responsibility for their contents.

EVT 005057AM

1-800-EDVOTEK • www.edvotek.com

29

30

33

34

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

3

AP

Biology

Experiment Components

This experiment

is designed for

10 lab groups

A

B

C

D

E

F

G

Sodium iodide

Sodium hydroxide

Manganese sulfate

Starch solution

Sodium thiosulfate

Nitrogen enrichment solution, concentrate

Phosphorous enrichment reagents

Pipets

Lab #

Storage:

Store entire

experiment at

room temperature.

Requirements

All components are

intended for

educational research

only. They are not to

be used for

diagnostic or drug

purposes, nor

administered to or

consumed by

humans or animals.

EDVOTEK, The

Biotechnology

Education Company,

and InstaStain are

registered

trademarks of

EDVOTEK, Inc.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Plastic window screens

Sealable containers or BOD bottles, 50

Grow lights

Pond/lake water

Goggles

Sulfuric acid, concentrated

Glass pipets

Burettes

Flasks

Beakers

Gloves

Filter paper

Linear graph paper

Aluminum foil

EDVOTEK - The Biotechnology Education Company ®

1-800-EDVOTEK • www.edvotek.com

FAX: (301) 340-0582 • email: edvotek@aol.com

EVT 005057AM

12

4

EDVO-Kit # 292

AP

Biology

Lab #

Background Information

12

Dissolved Oxygen & Aquatic Primary Productivity

Dissolved Oxygen & Aquatic Primary Productivity

Oxygen plays a major role in the biochemical reactions used by

organisms to produce energy for life. During oxidative phosphorylation

and electron transport, it is generally the final electron acceptor. The

greatest number of ATP’s are produced per mole of glucose when

oxygen is available. Its concentration in the environment can limit the

maximal rates of metabolism. In air, there is ample concentration of

oxygen available for utilization by living organisms. It represents nearly

20% of the total gases in the air. There is approximately 200ml of O2 per

liter of air, which is 9 mM O2 /L. The situation in aquatic environments is

quite different.

In aquatic environments, oxygen is not very soluble and its solubility is

directly affected by the concentration of dissolved ions such as salt,

the pH, and the temperature. Salinity is the content of dissolved salts in

water. It is usually expressed in parts per thousand (ppt). The solubility

of O2 is inversely proportional to the concentration of salt and temperature. As the salt concentration and temperature increase, the

solubility of O2 decreases. Even at its maximum solubility, which is in

fresh water at 0°C, its concentration is only 25% of the amount in air. In

practical situations, the concentration of O2 in aquatic environments

usually does not exceed 3-4% of the concentration of O2 in air. This is

only 6.0ml O2/L or 0.3 mM O2 /L. In salt water, O2 concentration would

be less since oxygen is less soluble in solutions of increasing ionic

strength.

Since the maximum concentration of dissolved O2 in water is dependent upon other components dissolved in water, O2 level is often used

in water quality and pollution testing. The higher the level of dissolved

oxygen (DO), the better the water quality. Because of the low concentration of O2 in aquatic environments, it has been suggested that

O2 is a major limiting nutrient for life. It is interesting to note that the

largest aquatic animals, the whales, are air breathing mammals.

In addition to the chemical factors that influence dissolved oxygen,

biological processes such as photosynthesis and respiration affect the

maximum amount of aqueous oxygen concentrations. There are both

biological demands and chemical demands placed on the oxygen

available in water. These are often called the Biological Oxygen

Demand (BOD), and the Chemical Oxygen Demand (COD). Photosynthesis in aquatic environments performed by plants, and small phytoplankton which are one-celled plants, will increase the concentration of DO in the water. Respiration will decrease the concentration of

DO in an aquatic environment. Therefore during the day, when

photosynthesis is at a maximum, the concentration of DO will increase.

During the night, the concentration of DO will decrease.

Ecologists will often study an ecosystem by measuring or estimating the

“primary productivity”. Energy to support the life requirements of

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

5

Dissolved Oxygen & Aquatic Primary Productivity

Dissolved Oxygen & Aquatic Primary Productivity

animals, plants, and bacteria generally enters an ecosystem as light energy,

which is converted by photosynthetic organisms to chemical energy.

Primary productivity is defined as the rate at which plants assimilate the

energy of sunlight. This rate directly affects the growth of plants and other

chlorophyll containing organisms. This in turn affects the growth of animals

that feed on plants and others which are at higher trophic levels. Primary

productivity therefore is at the base of the trophic structure ( the organization of feeding relationships) in an ecosystem.

AP

Biology

Lab #

12

The equation for primary productivity, which is the utilization of carbon

dioxide and water to produce glucose and oxygen during photosynthesis is;

6 CO2 + 6 H2O

→

C6 H12 O6 + 6 O2

The accumulation of organic matter through the growth and reproduction

of the plant is not the only productivity possible. A significant portion of the

sugar produced by photosynthesis is used by the plant for other synthetic

and maintenance reactions during respiration. Therefore, the gross primary

productivity (GPP) is the sum of the organic material produced plus the

respiration rate (Rs) of the plant or GPP = NPP + Rs. Net primary productivity

(NPP) equals the gross productivity minus the respiration rate (Rs) or

NPP = GPP – Rs. Net productivity is therefore a measurement of growth and

reproduction. Gross productivity is a measurement of growth and reproduction plus the respiration rate.

In terrestrial environments, plant primary productivity is usually measured in

terms of the increase in the amount of plant Biomass. In aquatic environments, we measure the plant primary productivity by gas exchange, since

the concentration of dissolved oxygen in water is easily determined. The

classical method for determining the productivity of an aquatic environment

is the light and dark bottle procedure. In a natural setting, for example,

sealed bottles containing samples of pond water would be suspended at

different depths beneath the surface of the pond. A clear “light” bottle

which allows sunlight to enter, and a “dark” bottle which excludes sunlight,

would be suspended at each depth. In the laboratory, one can simulate

the attenuation of sunlight, which increases as depth increases, by wrapping

the light bottles with screens. We will assume that the respiration is equal at

all depths. In the light bottles, the production of oxygen by photosynthesis

and the consumption of oxygen occur simultaneously. Therefore the

change in oxygen levels in the light bottles is a direct measure of the “net

productivity”. In the dark bottles, oxygen is consumed since only respiration

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Background Information

From the above equation, the amount of oxygen produced can be directly

related to the amount of carbon dioxide consumed. For each mole of O2

produced, one mole of CO2 is consumed. One milliliter of O2 gas contains

1.432 mg of oxygen. Therefore, based on formula weights, one can calculate that for each milliliter of oxygen produced, approximately 0.536 mg of

carbon has been consumed.

6

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Biology

Dissolved Oxygen & Aquatic Primary Productivity

Lab #

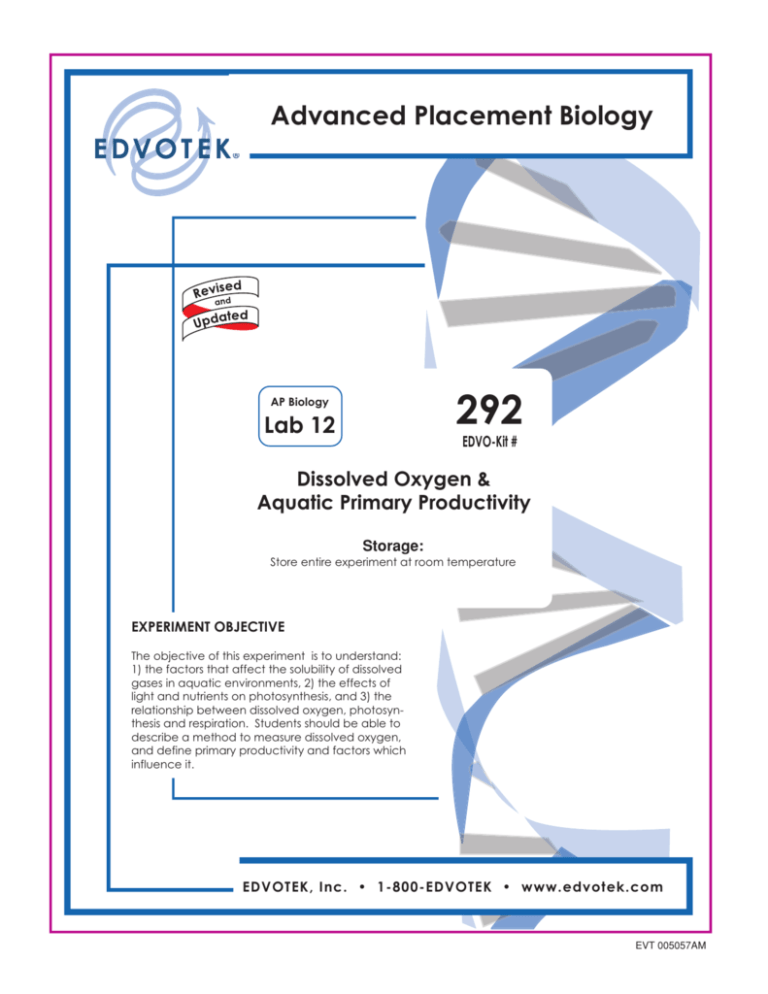

occurs. Therefore, the change in oxygen levels in the dark bottles is a

measure of respiration (Figure 1). Addition of the amount of oxygen

consumed by respiration in the dark bottle and the oxygen produced

in the light bottle, yields gross productivity. The respiration rate includes

that of plants, animals, and bacteria. Therefore, only the gross productivity measurement is totally valid.

12

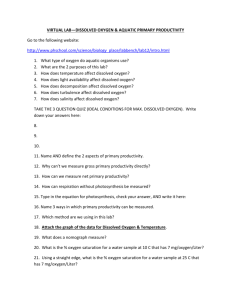

Figure 1:

Gross Productivity

Determined by Light/Dark

Bottle Method

The level of dissolved oxygen (DO) in water is a direct measurement of

the quality of the water. This is affected by physical conditions such as

temperature, salinity, and pH. In addition, it is dramatically affected by

both the Biological Oxygen Demand (BOD), and Chemical Oxygen

Demand (COD). Lakes loaded with decaying matter have low levels

of oxygen, and a high BOD, since the oxygen is being consumed by

bacteria and algae. This exercise demonstrates the methodology

used for measuring dissolved oxygen and determining the primary

productivity of a natural body of water.

( L )ight Bottle

Net

Productivity

DO2 (ml O2/L)

Background Information

The Winkler method is used to determine dissolved oxygen. This

procedure is an iodometric method. The iodide ion is an effective

reducing agent which has been widely used for the quantitative

analysis of many oxidants. Generally, sodium thiosulfate is used to

titrate the iodine liberated by the chemical reaction. The endpoint is

determined by the loss of color during titration. This procedure is

explained in detail under Part A, Student Experimental Procedures.

( I )nitial Bottle

Gross

Productivity

Respriation

( D )ark Bottle

0

24

L - I = Net Productivity

I - D = Respiration

L - D = Gross Productivity

Incubation Time (Hours)

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

7

Dissolved Oxygen & Aquatic Primary Productivity

AP

Experiment Overview

Biology

EXPERIMENT OBJECTIVES:

Students will:

Understand the factors that affect the solubility of dissolved gases in

aquatic environments

2.

Understand the effects of light intensity and nutrients on the rate of

primary productivity

3.

Understand the relationship between dissolved oxygen and the

processes of photosynthesis and respiration and the affect on primary

productivity

4.

Be able to describe a method to measure dissolved oxygen, and

define primary productivity and factors which influence it .

WORKING HYPOTHESIS

If light intensity and the addition of nutrients affect the rate of photosynthesis in aquatic environments, then primary productivity will also be

affected.

LABORATORY SAFETY

Gloves and safety goggles should be worn routinely as good laboratory

practice.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

12

Experiment Procedure

1.

Lab #

8

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Biology

Lab #

Experiment Procedure

12

Part A: The Winkler Method for Dissolved Oxygen

THE WINKLER METHOD FOR DISSOLVED OXYGEN

The Winkler method will be used to determine the concentration of

dissolved oxygen in water samples. The samples are first treated with

an excess of manganese sulfate, sodium iodide, and sodium hydroxide. The white manganese (II) hydroxide precipitate that forms will

rapidly react with the dissolved oxygen in the samples to form manganese (III) hydroxide. When the samples are acidified by the addition of

sulfuric acid, the manganese (III) oxidizes iodide to iodine. The concentration of the liberated iodine, I2, is titrated with sodium thiosulfate

in the presence of a starch indicator solution.

It is important to note that the starch is added after the bulk of the

iodine has been reduced. In acidic solutions, the starch would be

decomposed by a large excess of iodine. For fine analysis, the starch

is added after the titration has begun, near the point when the

solution has become a faint, pale yellow color. For purposes of this

laboratory, the starch can be added at the beginning of titration to

facilitate end point detection.

The balanced equations for the series of chemical reactions used in

the Winkler method are shown below.

4 Mn (OH)2 (s) + O2 + 2 H2O →

4 Mn (OH)3 (s)

When acidified by addition of sulfuric acid;

2 Mn (OH)3 (s) + 2 I- + 6 H+

→

I2 + 6 H2O + 2 Mn2+

The liberated iodine is titrated to endpoint with sodium thiosulfate as

shown below.

2 (S2 O3)-2 + I2

→

S4 O6-2 + 2I-

When the titration is nearly complete, the solution will begin to change

from a purple/brown color to a colorless solution. As can be seen from

the above reactions, four moles of sodium thiosulfate titrant, Na2S2O3,

are required per mole of dissolved oxygen, O2. The concentration of

the sodium thiosulfate titrant has been adjusted so one milliliter of

sodium thiosulfate solution equals one milligram of dissolved oxygen

per liter of sample, 1 mg DO/L.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

9

Dissolved Oxygen & Aquatic Primary Productivity

AP

Part A: The Winkler Method for Dissolved Oxygen

Forming the Manganese (III) Hydroxide Precipitate

1.

Obtain a water sample from the instructor. Samples should be at

either 5°, 20° or 30°C. Record the temperature of the water with a

thermometer. Different groups will use water at different temperatures.

2.

Place the water sample into your 250-300ml “BOD” (Biological Oxygen

Demand) bottle. Any container which can be closed with an airtight

seal is appropriate.

Allow the sample to overflow the container so that it will be

completely filled.

•

Close the container. Turn the container upside down and use a

paper towel to remove any water which is around the outside of

the stopper or lid.

Create manganese hydrogen precipitate in your water sample:

•

Open the container and carefully pipet 2ml of manganese sulfate

into the container. Make sure the pipet tip is below the water

surface in the container.

•

With a fresh pipet, add 2ml of the NaOH/NaI (alkaline-iodide)

solution into the sample in the container. Make sure the pipet tip

is below the surface of the water in the container.

•

Stopper or seal your container. Carefully invert the bottle to allow

for complete mixing of the sample, manganese sulfate, and

NaOH/NaI.

•

This precipitate is critical to the determination of dissolved oxygen. If a precipitate fails to form, repeat procedure.

•

Allow the precipitate to settle for 10-15 minutes or until approximately 50% of the volume in the container is occupied by the

precipitate.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Lab #

12

Experiment Procedure

3.

•

Biology

10

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Part A: The Winkler Method for Dissolved Oxygen

Lab #

Setting up the Burette

12

4.

While waiting for the manganese hydroxide precipitate to settle,

set up your burette.

•

•

5.

Test the proper functioning and seal of the petcock at the bottom

of the burette.

•

Experiment Procedure

•

•

6.

Label a beaker ‘Burette Waste Solution’ and place it under the

tip of the burette.

Close the petcock and fill the burette with distilled water.

Open and close the petcock. When open, the water should

flow out. When closed, the water should not leak out of the

burette tip or around the petcock assembly. Ask your instructor for help if the burette leaks. Practice slightly opening the

petcock so that the water just drips out slowly.

Completely drain the burette. Close the petcock.

•

•

•

7.

Attach a burette to a ring stand with a clamp.

Adjust so it is vertical and the volume gradations are easily

visible. Allow enough space under the burette for a 500ml

flask.

To remove any residual water, fill the burette with 3ml of the

sodium thiosulfate solution.

Open the petcock and allow the sodium thiosulfate solution to

drain from the burette. Again, practice opening the petcock

so that the sodium thiosulfate solution just drips out slowly.

Completely empty the burette. Close the petcock.

After closing the petcock, completely fill the burette with the

sodium thiosulfate solution.

Addition of the Hazardous Concentrated Sulfuric Acid

8.

Go to the station set up by the instructor for pipeting the Concentrated Sulfuric Acid.

•

•

Caution!

This should be performed by the

instructor. The instructor will be

wearing gloves and goggles.

Exercise extreme caution!!

•

•

Open your container and place it on the lab bench.

Standing away from the container, have the instructor pipet

2 ml of the concentrated sulfuric acid directly into your

container. The tip of the pipet should be below the surface of

the solution in your container.

Stopper the container and mix by carefully inverting the

container several times.

Mix occasionally. You should observe that the precipitate

begins to dissolve and the sample will become yellowish as

free iodine, I2, is formed in the container. Remember that the

quantity of free I2 released in this step is directly equivalent to

the concentration of dissolved oxygen in your sample.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

11

AP

Part A: The Winkler Method for Dissolved Oxygen

Titration of the Free I2

9.

Wait 5 minutes and then remove exactly 200ml of solution from the

container with a graduated cylinder and transfer the solution to a

500ml flask.

Biology

Lab #

12

10. Add 1.0ml of starch solution to the pale yellow solution in the 500ml

flask. The solution will immediately become purple. Swirl the flask

gently to completely mix.

11. Place the 500ml flask under your burette tip. Adjust the burette if

necessary. Record the initial starting volume of the sodium thiosulfate

in the burette.

12. Slowly and carefully open the petcock of the burette until the sodium

thiosulfate begins to drip out of the burette tip.

•

•

Continually swirl the 500ml flask to insure thorough mixing of the

sodium thiosulfate with the sample.

Close the petcock when the solution in the flask is a pale yellow

color.

13. Open the petcock carefully so that the sodium thiosulfate solution

drips out slowly. Continue to gently swirl the flask to insure complete

mixing.

14. Be careful when adding the titrant. When the solution starts to lighten

in color, it should only take another 2-3 drops of titrant. Try not to miss

the endpoint. The endpoint is reached when the solution has gone

from purple to completely clear. Immediately close the petcock to

stop addition of the sodium thiosulfate solution.

15. At this point, all of the free I2 has been converted to sodium iodide by

reaction with the sodium thiosulfate. The solution is colorless, since

there is no longer any I2. Record the final position of the meniscus of

sodium thiosulfate in the burette.

Record the ending volume here. ___________

Determine the total volume of sodium thiosulfate which was used to

titrate your sample to the endpoint. Calculate the difference between the starting volume recorded in Step 11 and the ending

volume recorded above.

Record the total volume of sodium thiosulfate used here in ml.

___________

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Experiment Procedure

Record the starting burette volume here. __________

12

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Part A: The Winkler Method for Dissolved Oxygen

Lab #

16. For the sensitivity required in this laboratory experiment, the total

volume in milliliters of the sodium thiosulfate solution used to titrate

the sample to the endpoint is exactly equivalent to the dissolved

oxygen concentration in milligrams of dissolved oxygen (DO) per

liter of sample solution, mg DO/L.

12

17. Record the temperature of your sample and the amount of

dissolved oxygen in the chart. Use the nomogram of oxygen

saturation graph on this page to determine the % saturation of DO

in the sample. If your temperature lies between these values,

estimate the % saturation of DO. Record the value in Table 1.

Experiment Procedure

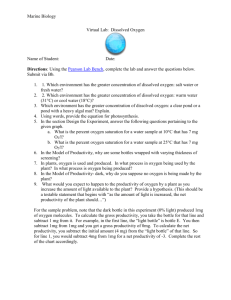

TABLE 1: Temperature/DO Data

Temperature Your DO mg/L

0

5

%DO Saturation Class Mean DO

(from nomogram)

mg/L

Class Mean DO Saturation

(from nomogram)

18. Determine the class

average data for the water

samples at the three

temperatures which were

available. Record the

values in Table 1.

10

15 20 25 30

Water Temperature °C

ion

rat

00

40

50

60

70

80

120

140

%

u

Sat

19. Using linear graph paper or

Graph #1 provided on

page 18, plot Both the lab

group and class means

percent saturation as

function of temperature.

1

90

30

20

10

0

2

3

4

5

6

7

8

9

10

11

12 13 14

15 16

17

Oxygen (mg per liter)

Figure 2:

Nomogram of Oxygen Saturation

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

13

AP

Biology

Part B: Primary Productivity

PRIMARY PRODUCTIVITY

For Part B., samples of natural water will be used to determine gross

productivity, net productivity, and respiration rates. To mimic the light

attenuation found as one goes deeper beneath the surface of a body

of water, screens will be used to reduce the light intensity. Review the

Background section of this laboratory for a complete discussion of

Primary Productivity.

Lab #

12

Day One

1.

Obtain 7 clean “BOD” (Biological Oxygen Demand) containers. Any

container which holds approximately 250-300ml and which can be

closed with an airtight seal is appropriate.

•

2.

Completely fill each bottle with water sample from the lake or

pond. Allow the sample to overflow the container so that it will

be completely filled.

Stopper or close the container. Turn the container upside down

and use a paper towel to remove any water which is around the

outside of the stopper or lid.

Label the 7 bottles as follows:

#1 - Initial

#2 - Dark

#3 - 100%

#4 - 65%

#5 - 25%

#6 - 10%

#7 - 5%

3.

Bottle #1 is the initial starting bottle and serves as a baseline.

4.

Wrap Bottle #2 in aluminum foil, for it serves as the dark (no light)

control. Place in a dark place. No photosynthesis, only respiration,

will occur here.

5.

Bottles #3 –#7 will simulate the depth in a body of water that natural

light will attenuate This is done by wrapping each bottle with a

different number of screens. Bottle #3 will have no screens with 100%

attenuation of light, Bottle #4 has 1 screen with 65% attenuation,

Bottle #5 has 3 screens with 25% attenuation, Bottle #6 has 5 screens

with 10% attenuation, and Bottle #7 has 7 screens with 5% attenuation. Cover the bottoms of the bottles so that no light can enter.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Experiment Procedure

•

14

AP

Biology

EDVO-Kit # 292

Part B: Primary Productivity

Lab #

12

Dissolved Oxygen & Aquatic Primary Productivity

6.

NOTE:

Each group will be assigned

one of the following number

of screens for Bottles 3, 4,

& 5.

Record the starting time here. ________________.

7.

Experiment Procedure

Percent Number of

Light

Screens

100

65

25

10

2

0

1

3

5

8

Put bottles #3-7, labels down, on their sides exposed to a constant source of light. Your teacher will indicate where they should

be placed. Leave these bottles overnight.

You will fix the amount of dissolved oxygen in the Bottle labeled

‘#1 Initial’. This serves as the starting level of dissolved oxygen in

the lake water sample. You will perform step 3 from the Winkler

procedure used in Part A of this laboratory.

•

Open the container labeled “#1 Initial” and carefully pipet

2 ml of manganese sulfate into the container. Make sure the

pipet tip is below the surface of the water in the container.

•

With a fresh pipet, add 2ml of the NaOH/NaI (alkaline-Iodide)

solution into the sample in the container. Make sure the pipet

tip is below the surface of the water in the container.

•

Stopper or seal your container. Firmly hold the stopper or lid of

your container. Carefully invert the bottle to allow for complete mixing of the sample, manganese sulfate, and NaOH/

NaI. A precipitate will form.

•

Let the bottle sit on the laboratory bench overnight. Finish

processing it with the rest of the bottles tomorrow.

Optional Activity

If directed by the instructor, place several drops of the pond water on

a microscope slide and cover with a coverslip. Observe the organisms

found in the natural water sample. Draw what is observed and try to

identify the organisms.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

15

AP

Part B: Primary Productivity

Biology

Lab #

Day Two

1.

Fix the dissolved oxygen in Bottles #2, 3, 4 , 5, 6 , 7. This is the beginning of the Winkler procedure.

12

Record the time you begin here. __________

•

•

•

2.

Repeat procedure in step 1 above with Bottles #3, 4, 5, 6, 7.

3.

While precipitate is settling in Bottles #2, 3, 4, 5, 6 and 7, review the

Winkler procedure used in Part A. Obtain Bottle #1.

4.

You should clean and set up the burettes as outlined in Part A,

steps 4-7.

5.

Begin processing all of the Bottles, #1 - #7, using the Winkler procedure for the determination of dissolved oxygen from Part A. Part A

Step 3, the fixing of the dissolved oxygen, has already been completed for all of the bottles. Now continue with Part A Step 8. Continue through steps 16. Record DO values in the appropriate table Table 2 or 3.

TABLE 2: Respiration

Individual Data

Class Mean

DO, Initial

DO, Dark Bottle

Respiration Rate

(Initial - Dark)

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Experiment Procedure

Open Bottle #2 and carefully pipet 2ml of manganese sulfate into

the bottle. Make sure pipet tip is below surface of the water in

the container.

With a fresh pipet, add 2ml of the NaOH /NaI (alkaline-iodide)

solution to the sample in the bottle. Make sure pipet tip is below

surface of water in the container.

Stopper or seal the bottle. Firmly hold the stopper or lid and

carefully invert the bottle to allow for complete mixing of the

sample, Manganese sulfate, and NaOH/NaI. A precipitate will

form.

16

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Part B: Primary Productivity

Lab #

12

TABLE 3: Productivity of Screen-Wrappen Samples

Experiment Procedure

# of

Screens

%

Light

0

100

1

65

3

25

5

10

7

5

DO

INDIVIDUAL DATA

Gross

Productivity

6.

Net

Productivity

CLASS MEAN PRODUCTIVITY

DO

Gross

Productivity

Net

Productivity

In reporting the data for productivity, the concentration of dissolved oxygen which has been determined, will be converted

from mg/L to ml/L using the following conversion factor: 1 mg

DO/L = 0.698ml DO/L. Therefore,

[0.698ml D0/L]

X (#mg D0/L) = #ml D0/L

1mg D0/L

7.

Calculate and record the gross and net productivity for the

natural water samples using the following equations. Productivity

is a rate term, therefore, divide by the number of hours the experiment ran to arrive at a value of ml DO/L per hour.

•

Gross Productivity = (Light Bottle (#3, #4, #5, #6, or #7) ml

DO/L - Dark Bottle (#2) ml DO/L)/hours

•

Net Productivity = (Light Bottle (#3, #4, #5, #6. Pr #7) ml DO/L Initial Bottle (#1) ml DO/L) /hours

•

Respiration rate = (Initial Bottle (#1) ml DO/L - Dark Bottle (#2)

ml DO/L) /hours

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

17

AP

Biology

Part B: Primary Productivity

8.

Record the values for the individual experiment conditions here.

•

Respiration rate = __________ml DO/L/hour.

•

Bottle 3

Lab #

12

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

•

Bottle 4

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

Bottle 5

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

•

Bottle 6

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

•

Bottle 7

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

9.

Record the individual and class average values for respiration in

Table 2 and for light of different intensities in the Table 3. The values

should be reported in ml DO/L/hour.

10. Record the average class value for the Respiration rate here.

__________.

11. Using linear graph paper or Graph #2 provided on page 19, plot the

average gross and net productivity on the Y-axis in ml DO/L/hr versus

the percent of Light Intensity on the X-axis.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Experiment Procedure

•

18

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Analysis of Results - Graph #1

1.

12

Graph both the lab group and class means percent saturation as

function of temperature.

2.

Title the Graph_________________________________________________

3.

Determine the independent variable (horizontal (X) axis). Label

the graph.

4.

Determine the dependent variable (vertical (Y) axis). Label the

graph.

5.

What hypothesis is being tested in this experiment?

Experiment Procedure

Lab #

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

19

AP

Analysis of Results - Graph #2

1.

Graph the average gross and net productivity values for samples as a

function of light intensity (%).

2.

Title the Graph_________________________________________________

3.

Determine the independent variable (horizontal (X) axis). Label the

graph.

4.

Determine the dependent variable (vertical (Y) axis). Label the

graph.

5.

What hypothesis is being tested in this experiment?

Biology

Lab #

12

Experiment Procedure

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

20

AP

Biology

Lab #

Experiment Procedure

12

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Laboratory Extensions

I.

EFFECT OF ADDITION OF NITROGEN AND PHOSPHORUS

ON PRODUCTIVITY

The availability of inorganic nutrients such as nitrogen and phosphorous may also affect primary productivity in aquatic environments.

Nutrients are removed during primary productivity. When a nutrient is

no longer present in sufficient quantity, a slowing of productivity will

result. The addition of specific nutrients may result in an increase in

productivity provided all the other necessary nutrients are present in

adequate amounts. As in Part B., samples of natural water will be

used to determine gross productivity, net productivity, and respiration

rates. This experiment will determine the effect of the nutrients nitrogen and phosphorus on primary productivity. Review the Background

section of this laboratory for a complete discussion of Primary Productivity.

Day One

1.

2.

Obtain 5 clean “BOD” (Biological Oxygen Demand) containers.

Any container which holds approximately 250-300ml and which

can be closed with an airtight seal is appropriate.

•

Completely fill each bottle with water sample from the lake or

pond. Allow the sample to overflow the container so that it

will be completely filled.

•

Stopper or close the container. Turn the container upside

down and use a paper towel to remove any water which is

around the outside of the stopper or lid.

Label 5 bottles as follows:

#1 Initial

#2 Dark

#3 Light + Nitrogen Addition

#4 Light + Phosphorous Addition

#5 Light Alone

3.

Bottle #1 is the initial starting bottle and serves as a baseline.

4.

Wrap Bottle #2 in aluminum foil, for it serves as the dark (no light)

control.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

21

AP

Laboratory Extensions

Biology

Lab #

Bottle #3 is supplemented with a source of nitrogen and exposed to

light. With a pipet, add 1.0ml of nitrogen enrichment solution to Bottle

#3. The instructor may have set up a pipeting station for this step.

6.

Bottle #4 is supplemented with a source of phosphorous and exposed

to light. With a pipet, add 1.0ml of phosphorous enrichment solution

to bottle 4. The instructor may have set up a pipeting station for this

step.

7.

Bottle #5 is a control which receives no nutrient supplementation, but

is exposed to light.

8.

Put Bottle #2 in a dark place and Bottles #3, #4, and #5 so that they

are exposed to a constant source of light. Your teacher will indicate

where they should be placed. Leave these bottles overnight.

Record the starting time here. ________________

9.

You will fix the amount of dissolved oxygen in the bottle labeled

‘#1 Initial’. This serves as the starting level of dissolved oxygen in the

lake water sample. You will perform step 3 from the Winkler procedure used in Part A of this laboratory.

•

Open the container labeled “#1 Initial” and carefully pipet 2ml of

manganese sulfate into the container. Make sure the pipet tip is

below the surface of the water in the container.

•

With a fresh pipet, add 2ml of the NaOH/NaI (alkaline-Iodide)

solution into the sample in the container. Make sure the pipet tip

is below the surface of the water in the container.

•

Stopper or seal your container. Firmly hold the stopper or lid of

your container. Carefully invert the bottle to allow for complete

mixing of the sample, manganese sulfate, and NaOH/NaI. A

precipitate will form.

•

Let the bottle sit on the laboratory bench overnight. Finish

processing it with the rest of the bottles tomorrow.

Optional Activity

If directed by the instructor, place several drops of the pond water on a

microscope slide and cover with a coverslip. Observe the organisms

found in the natural water sample. Draw what is observed and try to

identify the organisms.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

12

Experiment Procedure

5.

22

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Biology

Lab #

12

Laboratory Extensions

Day Two

1.

Fix the dissolved oxygen in Bottles #2, #3, #4 and# 5. This is the

beginning of the Winkler procedure.

Record the time you begin here. __________

•

•

Experiment Procedure

•

Open Bottle #2 and carefully pipet 2ml of manganese sulfate

into the container. Make sure pipet tip is below surface of the

water in the container.

With a fresh pipet, add 2ml of the NaOH /NaI (alkaline-iodide)

solution into the sample in the bottle. Make sure pipet tip is

below surface of water in the container.

Stopper or seal the bottle. Firmly hold the stopper or lid and

carefully invert the bottle to allow for complete mixing of the

sample, Manganese sulfate, and NaOH/NaI. A precipitate will

form.

2.

Repeat procedure in step 1 above with Bottles #3, #4, and #5.

3.

While precipitate is settling in Bottles #2, #3, #4, and #5, review the

Winkler procedure used in Part A. Obtain Bottle #1.

4.

You should clean and set up the burettes as outlined in Part A,

steps 4-7.

5.

Begin processing all of the Bottles #1, #2, #3, #4, and #5 using the

Winkler procedure for the determination of dissolved oxygen from

Part A. Part A Step 3 , the fixing of the dissolved oxygen, has

already been completed for all of the bottles. Now continue with

Part A Step 8.

6.

In reporting the data for productivity, the concentration of dissolved oxygen which has been determined, will be converted

from mg/L to ml/L using the following conversion factor: 1 mg

DO/L = 0.698ml DO/L. Therefore,

[0.698ml D0/L]

1mg D0/L

7.

X (#mg D0/L) = #ml D0/L

Calculate and record the gross and net productivity for the

natural water samples using the following equations. Productivity

is a rate term, therefore, divide by the number of hours the

experiment ran to arrive at a value of ml DO/L per hour.

•

•

•

Gross Productivity = (Light Bottle (#3, #4, or #5) ml DO/L Dark Bottle (#2) ml DO/L)/hours

Net Productivity = (Light Bottle (#3, #4, or # 5) ml DO/L - Initial

Bottle (#1) ml DO/L) /hours

Respiration rate = (Initial Bottle (#1) ml DO/L - Dark Bottle (#2)

ml DO/L) /hours

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

23

AP

Biology

Laboratory Extensions

8.

Record the values for the individual experiment conditions here.

•

Respiration rate = __________ml DO/L/hour.

•

Nitrogen enriched Bottle 3

Lab #

12

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

•

Phosphorous enriched bottle 4

Gross Productivity rate = ___________ ml DO/L/hour

•

Un-enriched Bottle 5

Gross Productivity rate = ___________ ml DO/L/hour

Net Productivity rate = ____________ ml DO/L/hour

9.

Record the class average values for Respiration Rate in Table 4 and

for nitrogen and phosphorous enriched samples in Table 5. The values

should be reported in ml DO/L/hour.

10. Record the average class value for the Respiration rate here.

__________.

11. Using linear graph paper or Graph #3 on page 25, plot the average

gross and net productivity on the Y-axis in ml DO/L/hr versus nitrogen

enriched, phosphorous enriched, and un-enriched samples on the Xaxis.

TABLE 4: Respiration

Individual Data

Class Mean

DO, Initial

DO, Dark Bottle

Respiration Rate

(Initial - Dark)

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Experiment Procedure

Net Productivity rate = ____________ ml DO/L/hour

24

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Biology

Laboratory Extensions

Lab #

Experiment Procedure

12

TABLE 5: Productivity of Pond Samples - Nitrogen or Phosphorous Added

Sample

Treatment

%

Light

Nitrogen

Added

100

Phosphorous

Added

100

Unenriched

100

Little Winter Pond

% Light

Depth in

Intensity

Meters

100

0

65

25

0.3

1.0

10

2

3.0

5.0

INDIVIDUAL DATA

DO

Gross

Productivity

Intensity

Meters

100

0

65

25

3.5

9

10

2

15

25

DO

Gross

Productivity

Net

Productivity

From the results in Part B of this laboratory, compare the productivity

of two separate ponds located in Massachusetts. This exercise is a

simulation. In Little Winter Pond, water is murky and filled with algae

and weeds. Light does not penetrate far beneath the surface. In Big

Winter Pond, a clear pond high in the mountains, light is not attenuated much until you get to a very deep spot near the middle of the

lake. The Little and Big Winter Pond have the values as shown in the

Tables at left. The values for these two hypothetical ponds will be

used for plotting the data.

Big Winter Pond

Depth in

Net

Productivity

II. PRODUCTIVITY SIMULATION FROM 2 PONDS

1.

% Light

CLASS MEAN PRODUCTIVITY

To simulate the productivity in the two ponds, convert your gross

productivity data for the un-enriched sample (5) in ml DO/L/hour

to ml DO/L/day. Simply multiply by 24 to get the value per day.

# ml DO/L

hour

2.

X

24 hour

day

=

# ml DO/L

day

Next, convert the gross productivity values in ml DO/L/day to

carbon productivity in mg C/m3/day. For each ml of oxygen

produced, 0.536 mg of carbon has been consumed. Therefore,

simply multiply the ml DO/L/day values by 0.536 to get the carbon

productivity in mg C/m3/day. Also convert the respiration rate to

carbon values, again in mg C/m3/day.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

25

AP

Analysis of Results - Graph #3

1.

Graph the average gross and net productivity values for nitrogen

enriched, phosphorous enriched and un-enriched samples.

2.

Title the Graph_________________________________________________

3.

Determine the independent variable (horizontal (X) axis). Label the

graph.

4.

Determine the dependent variable (vertical (Y) axis). Label the

graph.

5.

What hypothesis is being tested in this experiment?

Biology

Lab #

12

Experiment Procedure

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

26

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Optional Analysis of Results - Graph #4

1.

12

Graph the converted carbon assimilation values versus depth

related to light intensity for Little and Big Winter ponds.

2.

Title the Graph_________________________________________________

3.

Determine the independent variable (horizontal (X) axis). Label

the graph.

4.

Determine the dependent variable (vertical (Y) axis). Label the

graph.

5.

What hypothesis is being tested in this experiment?

Experiment Procedure

Lab #

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

27

AP

Biology

Study Questions

How does temperature affect the solubility of oxygen in water?

2.

How does salinity affect the solubility of oxygen in water?

3.

Would you expect boiled water to contain a large amount of dissolved oxygen ?

4.

How many moles of sodium thiosulfate are required to completely

titrate 6 moles of oxygen.

5.

Why is the starch usually added after the titration has begun?

6.

From Graph #2 (page 19), were any of the samples from Part B limited

by the available light?

7.

Were any samples limited by the available nutrients?

8.

Explain why the DO concentration of water samples taken from a

lake in early morning would be lower than the DO concentration of

water samples taken in late afternoon.

9.

Explain why the DO concentration of water samples taken from a

swiftly flowing stream would be higher than the DO concentration of

water samples taken from a lake.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Lab #

12

Experiment Procedure

1.

28

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Notes:

Lab #

Experiment Procedure

12

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

AP

Notes to the Instructor

Biology

OVERVIEW OF LABORATORY INVESTIGATIONS

The "hands-on" laboratory experience is a very important component of

the science courses. Laboratory experiment activities allow students to

identify assumptions, use critical and logical thinking, and consider

alternative explanations, as well as help apply themes and concepts to

biological processes.

www.edvotek.com

ORGANIZING AND IMPLEMENTING THE EXPERIMENT

Visit our web site for

information about

EDVOTEK's complete

line of experiments for

biotechnology and

biology education.

Class size, length of laboratory sessions, and availability of equipment

are factors which must be considered in the planning and the implementation of this experiment with your

students. These guidelines can be adapted

to fit your specific set of circumstances.

Technical Service

Department

E

O

DV

-TE

C H S E RV I C E

Mon - Fri

9:00 am to 6:00 pm ET

If you do not find the answers to your

questions in this section, a variety of resources are continuously being added to

the EDVOTEK web site.

www. edvotek.com

1-800-EDVOTEK

(1-800-338-6835)

FAX:

(301) 340-0582

web: www.edvotek.com

ET

email: edvotek@aol.com

pm

Mo

-6

Please have the following information:

n - Fri 9 am

In addition, Technical Service is available

from 9:00 am to 6:00 pm, Eastern time zone.

Call for help from our knowledgeable

technical staff at 1-800-EDVOTEK (1-800-3386835).

• The experiment number and title

• Kit Lot number on box or tube

• The literature version number

(in lower right corner)

• Approximate purchase date

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Lab #

12

Instructor's Guide

EDVOTEK experiments have been designed to provide students the

opportunity to learn very important concepts and techniques used by

scientists in laboratories conducting biotechnology research. Some of

the experimental procedures may have been modified or adapted to

minimize equipment requirements and to emphasize safety in the

classroom, but do not compromise the educational experience for

the student. The experiments have been tested repeatedly to

maximize a successful transition from the laboratory to the classroom

setting. Furthermore, the experiments allow teachers and students

the flexibility to further modify and adapt procedures for laboratory

extensions or alternative inquiry-based investigations.

Online Ordering

now available

29

30

AP

Biology

Lab #

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Pre-Lab Preparations

•

Part A requires 2 liters each of fresh tap water at 5°, 20°, and 30°C.

The water should be held covered at these temperatures the day

before the laboratory.

•

A natural source of water such as lake, pond, seawater, or an

algal culture of Chlorella will work for Part B. Depending on the

size of the bottles or flasks to be used, collect 15 liters of natural

source water.

•

The solutions should be prepared 1 or 2 days before the laboratory. The sodium thiosulfate should be prepared the day before

and stored in the refrigerator. Working stocks are made on the

day of the laboratory.

12

Instructor's Guide

Part A. The Winkler Method for Dissolved Oxygen

1.

Preparation of the sodium thiosulfate solution:

•

Boil 4 liters of distilled water for 10-15 minutes (to be completed before lab session).

•

On the day of the first laboratory session, add all of the

sodium thiosulfate (component E) to boiled and cooled

distilled water to make 2 liters final volume. Boiling depletes

the oxygen in the water so that it will not interfere with the

analysis.

•

Store carefully sealed in the refrigerator.

2.

The thiosulfate solution will not be standardized since fine “analytical” results are not needed. When the thiosulfate is properly

measured on a balance, titration is not necessary for classroom

results.

3.

Just prior to the titration step in Part A, Student Experimental

Procedures:

4.

•

Prepare the sodium thiosulfate working solution for the class.

•

Add 250ml of the working stock solution to 750ml of boiled

and cooled distilled water.

On the day of the lab, set up measuring/pipeting stations for:

•

•

•

•

•

•

Tap water (250-300ml)

Manganese Sulfate (2ml)

NaOH/NaI (2ml)

Sodium thiosulfate (50ml)

Concentrated sulfuric acid (2ml)

Starch solution (1ml)

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

31

AP

Biology

Pre-Lab Preparations

Lab #

5.

6.

Prepare the manganese sulfate solution:

•

Add all of the manganese sulfate (component C) to a total

volume of 250ml of distilled water.

•

Filter with #1 filter paper and store covered at room temperature.

Wearing gloves and goggles, prepare the NaI/NaOH solution:

Add all of the NaOH pellets (component B) to a large beaker.

•

Add distilled water to a volume of 150 - 175ml. Caution: The

solution will get hot.

•

Add all of the NaI (component A) and adjust to a final volume of

250ml with distilled water. Mix.

•

Store covered at room temperature.

2.

3.

4.

On the day of the lab, prepare a working nitrogen enrichment solution

for the class:

•

Add 10ml of the stock solution (component F) to 500ml of distilled

water.

•

Store covered in the refrigerator. Students will use 1ml of the

working solution to provide nitrogen enrichment for their sample.

Prepare the phosphorous enrichment stock solution:

•

Add all the contents of component G to 100ml distilled water. Mix.

•

Store covered in the refrigerator.

On the day of the lab, prepare a working phosphorous enrichment

solution for the class:

•

Add 10ml of stock solution to 500ml of distilled water.

•

Students will use 1ml of the working solution to provide phosphorous enrichment for their sample.

Part B will require 50 BOD type bottles (250-300ml). You may substitute

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Instructor's Guide

•

Part B. Primary Productivity

1.

12

32

AP

Biology

EDVO-Kit # 292

Dissolved Oxygen & Aquatic Primary Productivity

Pre-Lab Preparations

Lab #

12

250ml Erlenmeyer flasks. Small juice bottles with caps can also be

used successfully.

5.

Based on Table 1, assign each group a different light percentage

(corresponding number of screens). The screens will be used to

cover Bottles 3, 4, and 5.

6.

On the day of the lab, set up measuring/pipeting stations for:

•

•

•

•

•

Instructor's Guide

7.

Pond water (250-300ml)

Nitrogen enrichment solution (1ml)

Phosphorous enrichment solution (1ml)

Manganese sulfate (2ml)

NaOH/NaI (2ml)

Set up microscopes if the optional activity in Student Experimental

Procedures B. #11 is to be done by students.

1-800-EDVOTEK • www.edvotek.com

Duplication of this document, in conjunction with use of accompanying reagents, is permitted for classroom/

laboratory use only. This document, or any part, may not be reproduced or distributed for any other purpose

without the written consent of EDVOTEK, Inc. Copyright © 1996,1997, 1998, 1999, 2000, 2001, 2005,2007

EDVOTEK, Inc., all rights reserved.

EVT 005057AM

Please refer to the kit

insert for the Answers to

Study Questions

Section V - Reactivity Data

Material Safety Data Sheet

IDENTITY (As Used on Label and List)

Emergency Telephone Number

Manufacturer's Name

EDVOTEK, Inc.

Incompatibility

(301) 251-5990

(301) 251-5990

Date Prepared

14676 Rothgeb Drive

Rockville, MD 20850

09-18-2002

ACGIH TLV

Sulfur oxides

Conditions to Avoid

May Occur

X

Will Not Occur

Section VI - Health Hazard Data

Inhalation?

Ingestion?

Skin?

Yes

Yes

Yes

Causes eye and skin irritation. Material is irritating to mucous

membranes and upper respiratory tract.

Health Hazards (Acute and Chronic)

IARC Monographs?

NTP?

OSHA Regulation?

No data

Signs and Symptoms of Exposure A stolid mask-like appearance of face, sleepiness d weakness

skin and eye irritation, irritating to mucous membranes and upper respiratory

Section II - Hazardous Ingredients/Identify Information

OSHA PEL

Hazardous

Polymerization

Carcinogenicity:

Signature of Preparer (optional)

Hazardous Components [Specific

Chemical Identity; Common Name(s)]

Strong acids

Hazardous Decomposition or Byproducts

Route(s) of Entry:

Telephone Number for information

Address (Number, Street, City, State, Zip Code)

X

Stable

Note: Blank spaces are not permitted. If any item is not

applicable, or no information is available, the space must

be marked to indicate that.

Manganese Sulfate Monohydride

Section I

Conditions to Avoid

Unstable

Stability

May be used to comply with OSHA's Hazard Communication

Standard. 29 CFR 1910.1200 Standard must be consulted for

specific requirements.

®

Medical Conditions Generally Aggravated by Exposure

Other Limits

Recommended

% (Optional)

Emergency First Aid Procedures

CAS # 10034-96-5

Flush eyes or skin with copious amounts of water for atleast 15 minutes while

removing contaminated clothing and shoes. Remove to fresh air.

Section VII - Precautions for Safe Handling and Use

Section III - Physical/Chemical Characteristics

Boiling Point

No data

Vapor Pressure (mm Hg.)

No data

Vapor Density (AIR = 1)

No data

Steps to be Taken in case Material is Released for Spilled

Specific Gravity (H 0 = 1)

2

2.950

Melting Point

No data

Evaporation Rate

(Butyl Acetate = 1)

No data

Sweep up, place in a bag and hold for waste disposal. Avoid raising dust.

Ventilate area and wash soil site after material pick up is complete.

Waste Disposal Method

The material should be dissolved in 1) water 2) acid solution 3) Oxidized to a water-soluble state.

Solubility in Water

Precautions to be Taken in Handling and Storing

Keep tightly closed , wash thoroughly after handling

Appearance and Odor

Other Precautions

White to pale-pink powder

None

Section IV - Physical/Chemical Characteristics

Flash Point (Method Used)

LEL

Flammable Limits

No data

UEL

Extinguishing Media

Noncombustible-use extinquishing media appropriate to surrounding fire condition

Special Fire Fighting Procedures

Section VIII - Control Measures

Respiratory Protection (Specify Type)

X

Eye Protection

Chemical resistant gloves

Other Protective Clothing or Equipment

Emits toxic fumes under fire conditions

Other

Mechanical (General)

Protective Gloves

Unusual Fire and Explosion Hazards

Special

Yes

Local Exhaust

Ventilation

Wear SCBA and protective clothing to prevent contact with skin and eyes.

Safety goggles

SCBA, safety gloves and goggles

Work/Hygienic Practices

Material Safety Data Sheet

Section V - Reactivity Data

May be used to comply with OSHA's Hazard Communication

Standard. 29 CFR 1910.1200. Standard must be consulted for

specific requirements.

Stability

Unstable

IDENTITY (As Used on Label and List)

Note: Blank spaces are not permitted. If any item is not

applicable, or no information is available, the space must

be marked to indicate that.

Sodium Iodide

Section I

14676 Rothgeb Drive

Emergency Telephone Number

301-251-5990

Telephone Number for information

301-251-5990

Rockville, MD 20850

Date Prepared

09-19-2002

EDVOTEK

Address (Number, Street, City, State, and ZIP Code)

Conditions to Avoid

Stable

Incompatiblity (Materials to avoid)

Manufacturer's Name

NIOSH/MSHA approved respirator

X

Incompatibles

Alkali metals, bromine triflouride, strong oxidizers, perchloric acid, perchloryl

Hazardous Decomposition or Byproducts

thermal decomposition products may include toxic and corrosive fumes of iodides

May Occur

Hazardous

Polymerization

Will Not Occur

X

Section VI - Health Hazard Data

Route(s) of Entry:

Inhalation?

Skin?

Yes

Yes

Ingestion?

Yes

Health Hazards (Acute and Chronic)

May cause irritation. Chronic ingestion may result in hypothyroidism.

Signature of Preparer (optional)

Carcinogenicity:

NTP?

IARC Monographs?

None

OSHA Regulation?

No Data

Section II - Hazardous Ingredients/Identity Information

Hazardous Components

(Specific Chemical Identity; Common Name(s))

OSHA PEL

CAS # 7681-62-5

No Data

ACGIH TLV

Other Limits

Recommended

Signs and Symptoms of Exposure

% (Optional)

Inhalation: mucous membrane irritation Eye/skin contact: flush w/ water

Medical Conditions Generally Aggravated by Exposure

No data

Contains no hazardous components

Emergency and First Aid Procedures

Treat symptomatically and supportively. Eye/skin contact: flush w/ water

Inhalation: remove to fresh air.

Section III - Physical/Chemical Characteristics

Boiling Point

1304ϒC

1.91

Vapor

Pressure (mm Hg.)

Specific Gravity (H20 = 1)

Section VII - Precautions for Safe Handling and Use

at 25ϒC

Melting Point

1

Vapor Density (AIR =1)

N.D. = No Data

N.D.

3.667

Steps to Be Taken in case Material Is Released or Spilled

Sweep up, place in a bag and hold for waste disposal. Avoid raising dust.

661ϒC

Evaporation Rate

(Butyl Acetate =1)

N.D.

Ventilate area and wash spill site after pickup.

Waste Disposal Method

Follow federal, state and local regulations.

Solubility in Water

184% at 25ϒC

Precautions to be Taken in Handling and Storing

Appearance and Odor

odorless, white powder

Section IV - Fire and Explosion Hazard Data

Flash Point (Method Used)

Extinguishing Media

Flammable Limits

Other Precautions

LEL

Store away from incompatibles

Avoid contact

UEL

Section VIII - Control Measures

Use suitable agent for type of surrounding fire

Special Fire Fighting Procedures

Move container from fire area if possible. Avoid breathing vapors or dust.

Unusual Fire and Explosion Hazards

None

Respiratory Protection (Specify Type)

NIOSH/MSHA approved respirator

Special

Yes

No

Mechanical (General) No

Other

None

Protective Gloves

Eye Protection Safety goggles

PVC gloves

Other Protective Clothing or Equipment

Impervious clothing and equipment to prevent contact

Ventilation

Work/Hygienic Practices

Local Exhaust

Avoid contact

Section V - Reactivity Data

Material Safety Data Sheet

IDENTITY (As Used on Label and List)

Manufacturer's Name

EDVOTEK, Inc.

(301) 251-5990

(301) 251-5990

Date Prepared

14676 Rothgeb Drive

Rockville, MD 20850

09-19-2002

Sodium Hydroxide

CAS # 1310-73-2

2mg/m3

ACGIH TLV

Ingestion?

Skin?

Yes

Yes

Yes

None identified

IARC Monographs?

NTP?

OSHA Regulation?

None identified

Call physician. Ingestion: Do not induce vomiting. Give water followed by vinegar, juice or egg white

Inhalation: Move to fresh air. Skin/eye contact: flush with water

Section VII - Precautions for Safe Handling and Use

Steps to be Taken in case Material is Released for Spilled

1390°C

Specific Gravity (H 0 = 1)

2

2.13

Vapor Pressure (mm Hg.)

20°C

Melting Point

318°C

NO data

Evaporation Rate

(Butyl Acetate = 1)

NO data

Dispose of properly

Wear SCBA and protective clothing. Carefully place material into clean, dry container and cover.

Waste Disposal Method

Follow all federal, state, and local laws.

Precautions to be Taken in Handling and Storing

Keep container tightly closed. Store in corrosion-proof area. Store in a dry area.

Isolate from incompatible materials.

10% appreciable

Other Precautions

Appearance and Odor

White pellets, odorless

None

Section IV - Physical/Chemical Characteristics

Flash Point (Method Used)

Flammable Limits

LEL

UEL

NA

Extinguishing Media

Inhalation?

Health Hazards (Acute and Chronic)

Emergency First Aid Procedures

No data

Boiling Point

Solubility in Water

Section VI - Health Hazard Data

Medical Conditions Generally Aggravated by Exposure

% (Optional)

Section III - Physical/Chemical Characteristics

Vapor Density (AIR = 1)

X

No data

No data

No data

Signs and Symptoms of Exposure Ingestion: Severe burns to mouth, throat, and stomach, nausea & vomiting