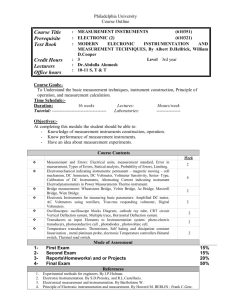

lecture notes

advertisement

DEPARTMENT OF ELECTRICAL & ELECTRONICS ENGINEERING

COURSE: ELECTRICAL MEASUREMENTS

BRANCH: Electrical and Electronic Engineering

CLASS: III/I Sem.

YEAR: 2013-14

LECTURE NOTES

SHRI VISHNU ENGINEERING COLLEGE FOR WOMEN

VISHNUPUR, BHIMAVARAM - 534202

CONTENTS

UNIT NO. TITLE

PAGE NO.

UNIT I Measuring Instruments………………………………………………

02-11

UNIT II Instrument transformers and Special Meters................................

12-19

UNIT III Measurement of Power and Energy………………………………

20-27

UNIT IV Potentiometers……………………………………………………

28-33

UNITV Resistance Measurement……………………………………………

34-42

UNIT VI AC Bridges………………………………………………………

43-47

DEPARTMENT OF EEE - SVECW

Page 1

UNIT-I

Measuring Instruments

DEPARTMENT OF EEE - SVECW

Page 2

UNIT-I

1.1. METHODS OF MEASUREMENTS AND MEASURING INSTRUMENTS

The measurement methods can be analog or digital methods, deflection or null methods,

active or passive methods, direct or indirect methods and absolute or secondary methods.

Measurement generally involves an instrument as a physical means of determining an

unknown quantity or a variable called the parameter. The instrument is a means for

determining the value or magnitude of the measurand. The instruments can also be

divided into separate classes according to several criteria as, analog or digital

instruments, deflection or null type instruments, power operated (active) or self

generating (passive) instruments, contacting or non-contacting instruments, mechanical

or electrical instruments and monitoring or control instruments.

Signals which vary continuously with the change in the measurand are analog

signals and the devices producing them are analog instruments. The deflection

type dynamometer type wattmeter is a good example of an analog instrument. As

the input value changes, the moving system or pointer exhibits a smooth

continuous motion. The signals which vary in discrete steps and have only finite

number of values in any given range are digital signals and the associated devices

are digital instruments. A digital instrument has an output varying in discrete

steps. An electronic counter is an example of a digital instrument.

If the quantity is to be directly measured, then deflection methods are used. For

e.g., ammeter, voltmeter, etc. acting as meters indicating the value of the

measurand by the deflection of a pointer over a graduated and calibrated scale.

Alternatively, if the value is measured based on the null balance conditions, then

it is a null method. Null methods are used only to detect the null condition of a

measurand through a given path or circuit. AC/DC Bridge measurements for

measurement of resistance, inductance, capacitance, frequency, etc. are null

methods. They involve balance detection by using null detectors, such as,

Galvanometer, Vibration Galvanometers and Head Phones. Null instruments are

more accurate than the deflection instruments.

If the output of the instrument is entirely produced by the measurand, then it is an

active instrument. These are the power operated instruments requiring some

source of auxiliary power for their operation such as compressed air, electricity

and hydraulic supply. On the other hand, if the measurand modulates the

magnitude of some external power source, then it is a passive instrument. Passive

instruments are self generating instruments where the energy requirements are

met entirely from the input signal.

The direct methods involve measuring the measurand by comparison against its

own standard. They are very common for measurement of physical quantities

such as length, mass and time. They are less sensitive and inaccurate since they

involve human operators. Thus direct methods are not usually preferred. On the

other hand, indirect methods use measuring systems, which are the systems

having a transducer to convert the measurand into its analogous form. This

converted signal is processed, fed to the end devices to obtain the results.

Absolute methods give the magnitude of the quantity under measurement in terms

of the physical constants of the instrument. They do not require calibration. They

are used only for calibration of other instruments. For e.g., Tangent

Galvanometer, Rayleigh's current balance and potentiometers. Secondary methods

are so constructed that the desired quantity is measured only by observing the

DEPARTMENT OF EEE - SVECW

Page 3

output of the instrument, which needs to be calibrated. Thus, they measure the

quantity in terms of their deflection, for which they are already calibrated. These

are the ones which are the most commonly used. For e.g., Voltmeters,

Thermometer, Pressure gauge, etc. Secondary methods work on either Analog

mode or Digital mode and hence lead to analog or digital methods.

Contacting type instruments are those which are kept in the measuring medium

itself. For e.g., clinical thermometer. A non-contacting or proximity type

instrument measures the desired input even though it is not in close contact with

the measuring medium. For e.g., optical pyrometer measuring the temperature of

a blast furnace, variable reluctance tachometer measuring the speed of a rotating

body, etc.

Mechanical instruments are very reliable for static conditions. Their parts are very

bulky, rigid and have a heavy mass. Hence they cannot respond rapidly to

measurements of dynamic and transient conditions. Besides, many of them are the

potential sources of noise. On the other hand, electrical instruments are very rapid

in response. However, their operating mechanism normally depends on a

mechanical meter movement as an indicating device.

Monitoring instruments are useful for monitoring functions. If their output is in a

form that can be directly included as part of an automatic control system, then

they become control instruments.

1.2. Requirements of Instruments

A measuring instrument should possess some of the following important characteristic

features:

• It should have a very high instrument efficiency which is the ratio of the quantity

being measured to the power utilized by the instrument at full scale.

• It should have a high sensitivity which is the ratio of the magnitude of the output

signal to the magnitude of the quantity being measured. The inverse of this ratio is

the Inverse Sensitivity or Deflection Factor.

• The output of the instrument should be linearly proportional to the input. In such

cases, the scale will be uniform and hence easier to calibrate.

• It should have a very low threshold which is the minimum value of below which

the change in output cannot be detected by the instrument.

• It should have lowest dead time which is the minimum time required for the

instrument to respond to a change in the quantity being measured.

• It should virtually have no dead zone where dead zone is the largest change of the

input quantity for which there is no output of the instrument. Dead zone is caused

due to friction, hysterisis, backlash, etc.

• It should have perfect reproducibility (precision) which is specified in terms of

the scale readings over a given period of time. This is different from repeatability

which is defined as the variation of scale readings and is random in nature.

• It should not have any drift. For an instrument, perfect reproducibility means that

the instrument has no drift. This means that for a given input, the measured values

are constant and do not vary with time.

• It should have minimum noise. Noise is any signal that does not convey any

useful information. Noise is due to extraneous disturbances caused by many

sources such as stray fields, shocks and thermal stresses.

• It should be modifiable and properly priced.

All the indicating instruments require three important torques for their operation:

deflecting torque-Td, controlling torque-Tc and damping torque-TD.

DEPARTMENT OF EEE - SVECW

Page 4

The deflecting torque is responsible for the movement of the pointer in proportion

to the value of the measurand. It is provided by the different effects of electric

current on which the operation of the given instrument depends.

The controlling torque is responsible for controlling the movements of the

pointer. It is very high at the null position of the pointer. When the pointer gets

deflected due to the deflecting torque exerted on it, the controlling torque

provides the retarding torque and the two torques are equal at the equilibrium

position of the 5

pointer. The controlling torque is provided by spring or gravity control. This also

ensures the zero setting of the pointer when the deflecting torque is absent.

The damping torque provides the forces required to damp out the oscillatory

movements of the pointer, if any, due to the inertia of the system. The damping

torque is provided by eddy current, air friction or fluid friction methods.

1.3. Classification of Instruments

Various effects of electric current are made use of by electrical instruments for

their operation, such as, magnetic effect, heating effect, chemical effect,

electrostatic effect and electromagnetic induction effect.

Since the instruments using magnetic effect, such as, ammeter, voltmeter and

wattmeter, are simpler, cheaper, and could be commonly adopted on both ac and

dc circuits, they are more common.

The instruments using heating effect are not much used due to their cost and

comparable inaccuracies.

The instruments using chemical effect, such as, energy meters, are also not very

common, due to their cost and complications involved.

The electrostatic effect is made use of in voltmeters, both on ac and dc. Though

expensive, the electrostatic voltmeters are very useful for high voltage

measurements.

Electromagnetic induction forms the basis for many instruments, though on only

AC. The common meters using the electromagnetic induction effect of current

are: ammeter, voltmeter, wattmeter and energy meter. Of these, the wattmeter and

energy meter are more common, although they are costlier.

Instruments can also be classified in a more general way as indicating

instruments, recording instruments and integrating instruments.

Indicating instruments provide information about the measuring quantity in terms

of the deflection of a pointer over a pre-calibrated scale. For e.g., ammeter,

voltmeter, wattmeter, etc.

Recording instruments make a record of the unknown quantity, usually on a

paper, against time or any other variable. For e.g., strip-chart temperature

recorder. The recording instruments are usually used in power houses and

substations, where a continuous record of the current, voltage, power or energy is

required.

Integrating instruments always record the unknown quantity in an integrated

manner indicating the total cumulative value of the measurand at any instant of

time. For e.g., energy meters and ampere-hour meters.

General Theory Permanent Magnet Moving Coil (PMMC) Instruments

The general theory of moving-coil instruments may be dealt with considering a

rectangular coil of turns, free to rotate about a vertical axis. N

DEPARTMENT OF EEE - SVECW

Page 5

Fig. shows the basic construction of a PMMC instrument. A moving coil

instrument consists basically of a permanent magnet to provide a magnetic field

and a small lightweight coil is wound on a rectangular soft iron core that is free to

rotate around

its vertical axis. When a current is passed through the coil windings, a torque is

developed on the coil by the interaction of the magnetic field and the field set up

by the current in the coil. The aluminum pointer attached to rotating coil and the

pointer moves around the calibrated scale indicates the deflection of the coil.

To reduce parallax error a mirror is usually placed along with the scale. A

balance weight is also attached to the pointer to counteract its weight (see Fig.).To

use PMMC device as a meter, two problems must be solved. First, a way must be

found to return the coil to its original position when there is no current through

the coil. Second, a method is needed to indicate the amount of coil movement.

The first problem is solved by the use of hairsprings attached to each end of the

coil as shown in Fig.

These hairsprings are not only supplying a restoring torque but also

provide an electric connection to the rotating coil. With the use of hairsprings, the

coil will return to its initial position when no current is flowing though the coil.

The springs will also resist the movement of coil when there is current through

coil. When the developing force between the magnetic fields (from permanent

magnet and electro magnet) is exactly equal to the force of the springs, the coil

rotation will stop. The coil set up is supported on jeweled bearings in order to

achieve free movement.

DEPARTMENT OF EEE - SVECW

Page 6

1.4. Construction and Basic principle operation of Moving-iron Instruments :

We have mentioned earlier that the instruments are classified according to the principles

of operation. Furthermore, each class may be subdivided according to the nature of the

movable system and method by which the operating torque is produced. Specifically, the

electromagnetic instruments are sub-classes as (i) moving-iron instruments (ii) electrodynamic or dynamometer instruments, (iii) induction instruments. In this section, we will

DEPARTMENT OF EEE - SVECW

Page 7

discuss briefly the basic principle of moving-iron instruments that are generally used to

measure alternating voltages and currents. In moving –iron instruments the movable

system consists of one or more pieces of specially-shaped soft iron, which are so pivoted

as to be acted upon by the magnetic field produced by the current in coil. There are two

general types of moving-iron instruments namely (i)

Repulsion (or double iron) type (ii) Attraction (or single-iron) type. The brief description

of different components of a moving-iron instrument is given below.

• Moving element: a small piece of soft iron in the form of a vane or rod

• Coil: to produce the magnetic field due to current flowing through it and also to

magnetize the iron pieces.

• In repulsion type, a fixed vane or rod is also used and magnetized with the same

polarity.

• Control torque is provided by spring or weight (gravity)

• Damping torque is normally pneumatic, the damping device consisting of an air

chamber and a moving vane attached to the instrument spindle.

• Deflecting torque produces a movement on an aluminum pointer over a graduated

scale.

1.5. Construction of Moving-iron Instruments

The deflecting torque in any moving-iron instrument is due to forces on a small

piece of magnetically ‘soft’ iron that is magnetized by a coil carrying the operating

current. In repulsion (Fig.) type moving–iron instrument consists of two cylindrical soft

iron vanes mounted within a fixed current-carrying coil. One iron vane is held fixed to

the coil frame and other is free to rotate, carrying with it the pointer shaft. Two irons lie

in the magnetic field produced by the coil that consists of only few turns if the instrument

is an ammeter or of many turns if the instrument is a voltmeter. Current in the coil

induces both vanes to become magnetized and repulsion between the similarly

magnetized vanes produces a proportional rotation. The deflecting torque is proportional

to the square of the current in the coil, making the instrument reading is a true ‘RMS’

quantity Rotation is opposed by a hairspring that produces the restoring torque. Only the

fixed coil carries load current, and it is constructed so as to withstand high transient

current. Moving iron instruments having scales that are nonlinear and somewhat crowded

in the lower range of calibration.

DEPARTMENT OF EEE - SVECW

Page 8

1.6.

Extension of Range

Shunts are used for the extension of range of

Ammeters. So a good shunt should have the

following properties:1- The temperature coefficient of shunt should

be low

2- Resistance of shunt should not vary with time

3- They should carry current without excessive temperature rise

4- They should have thermal electromotive force with copper

* ‘Manganin’ is used for DC shunt and ‘Constantan’ as AC shunt.

Ammeter:- PMMC is used as indicating device. The current capacity of PMMC is small.

It is impractical to construct a PMMC coil, which can carry a current greater than 100

mA. Therefore a shunt is required for measurement of large currents.

Rm = Internal resistance of movement (coil) in Ω

Rsh = Resistance of shunt in Ω

Im = Ifs = Full scale deflection current of movement in

Amperes Ish = Shunt current in Amperes

I = Current to be measured in Amperes

Since the shunt resistance is in parallel with the meter movement, the voltage drop

DEPARTMENT OF EEE - SVECW

Page 9

across shunt and movement must be same.

1.7. Multi Range Ammeter:- Let m1, m2, m3, m4 be the shunt multiplying powers for

current I1, I2, I3, I4.

Multi Range Voltmeter:

DEPARTMENT OF EEE - SVECW

Page 10

Voltmeter & Ammeter by Moving Coil Instrument:- Same process as applied in PMMC.

Electrodynamic type Voltmeter & Ammeter:- Shunt is connected across the circuit for

ammeter and multiplier resistance is connected in series for voltmeter.

DEPARTMENT OF EEE - SVECW

Page 11

UNIT-II

INSTRUMENT TRANSFOMERS

AND SPECIAL METERS

DEPARTMENT OF EEE - SVECW

Page 12

2.1. Instrument Transformers:

Instrument Transformers Basics

Why instrument transformers?

In power systems, currents and voltages handled are very large.

Direct measurements are not possible with the existing equipments.

Hence it is required to step down currents and voltages with the help of instrument

transformers so that they can be measured with instruments of moderate sizes

Instrument Transformers

Transformers used in conjunction with measuring instruments for measurement purposes

are called “Instrument Transformers”.

The instrument used for the measurement of current is called a “Current Transformer” or

simply “CT”.

The transformers used for the measurement of voltage are called “Voltage transformer”

or “Potential transformer” or simply “PT”.

Fig 1. Current Transformer

Fig 2. Potential Transformer

Fig 1. indicates the current measurement by a C.T. The current being measured

passes through the primary winding and the secondary winding is connected to an

ammeter. The C.T. steps down the current to the level of ammeter.

Fig 2. shows the connection of P.T. for voltage measurement. The primary winding

is connected to the voltage being measured and the secondary winding to a

voltmeter. The P.T. steps down the voltage to the level of voltmeter.

Merits of Instrument Transformers:

1. Instruments of moderate size are used for metering i.e. 5A for current and

100 to 120 volts for voltage measurements.

2. Instrument and meters can be standardized so that there is saving in costs.

Replacement of damaged instruments is easy.

3. Single range instruments can be used to cover large current or voltage ranges,

when used with suitable multi range instrument transformers.

4. The metering circuit is isolated from the high voltage power circuits. Hence

isolation is not a problem and the safety is assured for the operators

5. There is low power consumption in metering circuit.

6. Several instruments can be operated from a single instrument

DEPARTMENT OF EEE - SVECW

Page 13

Nominal Ratio: It is the ratio of rated primary winding current (voltage) to the rated

secondary winding current (voltage).

Turns ratio: This is defined as below

Burden of an Instrument Transformer:

The rated burden is the volt ampere loading which is permissible without errors

exceeding the particular class of accuracy.

DEPARTMENT OF EEE - SVECW

Page 14

2.2. Current Transformer equivalent circuit:

X1 = Primary leakage reactance

R1 = Primary winding resistance

X2 = Secondary leakage reactance

Z0 = Magnetizing impedance

R2 = Secondary winding resistance

Zb = Secondary load

Note: Normally the leakage fluxes X1 and X2 can be neglected

2.3. Current transformer, simplified equivalent circuit:

DEPARTMENT OF EEE - SVECW

Page 15

2.4. Current transformer: Phase displacement and current ratio error :

2.5. Construction of CT

Construction of Current Transformer:

Current transformers are constructed in various ways. In one method there are two

separate windings on a magnetic steel core. The primary winding consists of a few turns

of heavy wire capable of carrying the full load current while the secondary winding

consist of many turns of smaller wire with a current carrying capacity of between 5/20

amperes, dependent on the design. This is called the wound type due to its wound

primary coil.

2.6. Wound Type

DEPARTMENT OF EEE - SVECW

Page 16

Phasor Diagram

Angle by which the reversed I2 differs in phase from the I1vector

Ideally the I2should lag the I1by 1800and hence the phase angle is ZERO

In practice this angle is < 1800due to magnetizing and loss component of the I1

Potential Transformer Basics

Potential transformers are normally connected across two lines of the circuit in which the

voltage is to be measured. Normally they will be connected L-L (line-to-line) or L-G

(line-to-ground). A typical connection is as follows:

DEPARTMENT OF EEE - SVECW

Page 17

2.8. Phasor Diagram of Potential Transformer:

The theory of a potential transformer is the same as that of a power transformer. The

main difference is that the power loading of a P.T. is very small and consequently the

exciting current is of the same order as the secondary winding current while in a power

transformer the exciting current is a very small fraction of secondary winding load

current.

DEPARTMENT OF EEE - SVECW

Page 18

DEPARTMENT OF EEE - SVECW

Page 19

UNIT III

Measurement of Power and Energy

DEPARTMENT OF EEE - SVECW

Page 20

UNIT-III

POWER MEASUREMENTS

3.1. INTRODUCTION

Electric power is the rate of doing work. It is expressed in Watts. The higher units of

power used in practice include kilowatts, megawatts, etc. PWatts = VI COS φ , i.e., a power

of one watt is said to be expended when a source of one volt passes a current of one

ampere through a load resistance/ impedance of one ohm at unity power factor.

The power measurements are made with the help of a wattmeter. Wattmeter is an

indicating deflecting type of instrument used in laboratories for measurement of power in

various ranges. A wattmeter consists of two coils as shown in the schematic

representative figure 3.1

Current coil (CC): connected in series

with circuit and carries the load current.

It is designed such that it is wound with

2 to 3 turns of thick wire and hence it

has a very low resistance.

Voltage or Pressure or Potential coil (PC):

connected across the load circuit and

hence carries a current proportional to

the load current. The total load voltage

appears

across the PC. It is designed such that it is

Fig. 3.1 Wattmeter Connections

wound with several turns of thin wire and

hence it has a very high resistance.

The wattmeter can be a UPF meter or LPF meter depending on the type of the load

connected in the measuring circuit. For power measurements in AC circuits, the

wattmeter is widely adopted. In principle and construction, it is a combination of those

applicable for an ammeter and a voltmeter.

The electrical power can be of three forms:

Real power or simply, the power is the power consumed by the resistive loads on the

system. It is expressed in watts (W). This is also referred as true power, absolute power,

average power, or wattage.

Reactive power is the power consumed by the reactive loads on the system. It is

expressed in reactive volt-amperes (VAr).

Apparent power is the vector sum of the above two power components. It is expressed in

volt-amperes (VA).

Fig.3.2 The Power Triangle

Thus, it is observed from the power triangle shown in figure 3.2, that more is the

deviation of power factor from its unity value, more is the deviation of real power from

the apparent power. Also, we have

DEPARTMENT OF EEE - SVECW

Page 21

VA2 = W2 + VAr2

(3.1)

And power factor, cos ϕ = ( Watts / VA )

(3.2)

3.2 SINGLE PHASE REAL POWER MEASUREMENTS

3.2.1 Electrodynamometer Wattmeter

An electrodynamometer wattmeter consists of two fixed coils, FA and FB and a moving

coil M as shown in figure 3.3. The fixed coils are connected in series with the load and

hence carry the load current. These fixed coils form the current coil of the wattmeter. The

moving coil is connected across the load and hence carries a current proportional to the

voltage across the load. A highly non-inductive resistance R is put in series with the

moving coil to limit the current to a small value. The moving coil forms the potential coil

of the wattmeter.

Fig. 3.3 Electrodynamometer Wattmeter

The fixed coils are wound with heavy wire of minimum number of turns. The fixed coils

embrace the moving coil. Spring control is used for movement and damping is by air.

The deflecting torque is proportional to the product of the currents in the two coils.

Theses watt meters can be used for both DC and AC measurements. Since the deflection

is proportional to the average power and the spring control torque is proportional to the

deflection, the scale is uniform. The meter is free from waveform errors. However, they

are more expensive.

3.2.2. Expression for the deflection torque:

Let iC, iP : Current in the fixed and moving coils

respectively, M : Mutual inductance between the two

coils,

θ : Steady final deflection of the instrument,

K: Spring constant,

V, I : RMS values of voltage and current in the measuring circuit and

RP : Pressure coil resistance.

Instantaneous voltage across pressure coil, v = √2 V sin wt

Instantaneous current in the pressure coil, iP = √2 V/RP sin wt = √2 IP sin wt

Instantaneous current in the current coil, iC = √2 I sin (wt-ϕ)

Instantaneous torque is given by: Ti = iC iP ( d M / d θ )

= [ √2 I sin (wt-ϕ) ] [ √2 IP sin wt ] ( d M / d θ )

T

DEPARTMENT OF EEE - SVECW

(3.3)

Page 22

Average deflecting torque, Td = (1/T) ∫ Ti d wt

0

T

= (1/T) ∫ IP I [ cos ϕ - cos (2wt - ϕ ) ] ( d M / d θ ) d wt

0

= ( V I / RP ) cos ϕ ( d M / d θ )

(3.4)

Since the controlling torque, Tc=Kθ, we have at balance of the moving pointer, Td=Tc, so

that,

θ = [ V I cos ϕ / ( K RP ) ] ( d M / d θ )

= ( K’ d M / d θ ) P

(3.5)

Where K’ = K RP and P is the power consumption. Thus the deflection of the wattmeter

is found to be the direct indication of the power being consumed in the load circuit.

3.2.3 Low Power Factor Wattmeter

If an ordinary electrodynamometer wattmeter is used for measurement of power in low

power factor circuits, (PF<0.5), then the measurements would be difficult and inaccurate

since:

• The deflecting torque exerted on the moving system will be very small and

• Errors are introduced due to pressure coil inductance (which is large at LPF)

Thus, in a LPF wattmeter, special features are incorporated in a general electrodynamometer wattmeter circuit to make it suitable for use in LPF circuits as under:

(a) Pressure coil current:

The pressure coil circuit is designed to have a low value of resistance so that the current

through the pressure coil is increased to provide an increased operating torque.

(b) Compensation for pressure coil current:

On account of low power factor, the power is small and the current is high. In this

context, there are two possible connections of the potential coil of a wattmeter as shown

in figure 4.4. The connection (a) can not be used, since owing to the high load current,

there would be a high power loss in the current coil and hence the wattmeter reading

would be with a large error. If the connection (b) is used, then the power loss in the

pressure coil circuit is also included in the meter readings.

Thus it is necessary to compensate for the pressure coil current in a low power factor

wattmeter. For this, a compensating coil is used in the instrument to compensate for the

power loss in the pressure coil circuit as shown in figure 3.5.

(c) Compensation for pressure coil inductance:

At low power factor, the error caused by the pressure coil inductance is very large.

Hence, this has to be compensated, by connecting a capacitor C across a portion of the

DEPARTMENT OF EEE - SVECW

Page 23

series resistance in the pressure coil circuit as shown in figure 3.5.

(d) Realizing a small control torque:

Low power factor wattmeters are designed to have a very small control torque so that

they can provide full scale deflection (f.s.d.) for power factor values as low as 10%. Thus,

the complete circuit of a low power factor wattmeter is as shown in figure 3.5.

3.3 REACTIVE POWER MEASUREMENTS

A single wattmeter can also be used for three phase reactive power measurements. For

example, the connection of a single wattmeter for 3-phase reactive power measurement in

a balanced three phase circuit is as shown in figure 4.6.

Fig. 4.6 Reactive power measurement circuit

The current coil of the wattmeter is inserted in one line and the potential coil is connected

across the other two lines. Thus, the voltage applied to the voltage coil is VRB= VR-VB,

where, VR and VB are the phase voltage values of lines R and B respectively, as

illustrated by the phasor diagram of figure 4.7.

DEPARTMENT OF EEE - SVECW

Page 24

Phasor diagram for reactive power measurements

The reading of the wattmeter, W3ph for the connection shown in figure 3.6 can

be

obtained based on the phasor diagram of figure 34.7, as follows:

Wattmeter reading,

Wph = Iy VRB

= Iy VL cos (90+Ø)

= - √3 Vph Iph sin Ø

= - √3 (Reactive power per phase)

Thus, the three phase power, W3ph is given by,

W3ph = (VArs/phase)

= 3 [Wph /- √3]

= - √3 (wattmeter reading)

(3.6)

(3.7)

3.4 THREE PHASE REAL POWER MEASUREMENTS

The three phase real power is given by,

P3ph= 3 Vph Iph cos Ø

or

P3ph= √3 VL IL cos Ø

(3.8)

The three phase power can be measured by using either one wattmeter, two wattmeters or

three wattmeters in the measuring circuit. Of these, the two wattmeter method is widely

used for the obvious advantages of measurements involved in it as discussed below.

3.4.1 Single Wattmeter Method

Here only one wattmeter is used for measurement of three phase power. For circuits with

the balanced loads, we have: W3ph=3(wattmeter reading). For circuits with the

DEPARTMENT OF EEE - SVECW

Page 25

unbalanced loads, we have: W3ph=sum of the three readings obtained separately by

connecting wattmeter in each of the three phases. If the neutral point is not available (3

phase 3 wire circuits) then an artificial neutral is created for wattmeter connection

purposes. Instead three wattmeters can be connected simultaneously to measure the three

phase power. However, this involves more number of meters to be used for

measurements and hence is not preferred in practice. Instead, the three phase power can

be easily measured by using only two wattmeters, as discussed next.

3.4.2 Two Wattmeter Method

The circuit diagram for two wattmeter method of measurement of three phase real power

is as shown in the figure 34.7. The current coil of the wattmeters W1 and W2 are inserted

respectively in R and Y phases. The potential coils of the two wattmeters are joined

together to phase B, the third phase. Thus, the voltage applied to the voltage coil of the

meter, W1 is VRB= VR-VB, while the voltage applied to the voltage coil of the meter, W2

is VYB=VY-VB, where, VR, VB and VC are the phase voltage values of lines R, Y and B

respectively, as illustrated by the phasor diagram of figure 3.8. Thus, the reading of the

two wattmeters can be obtained based on the phasor diagram of figure 4.8, as follows:

Hence,

And

So that then,

W1 = IR VRB

= IL VL cos (30 - Ø)

W2 = IY VYB

= IL VL cos (30 + Ø)

W1+W2 = √3 VL IL cos Ø = P3ph

W1-W2 = VL IL sin Ø

(3.9)

(3.10)

(3.11)

(3.12)

Tan Ø = √3 [W1-W2]/ [W1+W2]

(3.13)

Where Ø is the lagging PF angle of the load. It is to be noted that the equations (3.11) and

(3.12) get exchanged if the load is considered to be of leading PF.

Two wattmeter method of 3-phase power measurement

Phasor diagram for real power measurements

DEPARTMENT OF EEE - SVECW

Page 26

The readings of the two wattmeters used for real power measurements in three phase

circuits as above vary with the load power factor as described in the table 3.1.

Variation of wattmeter readings with load PF (lag)

PF angle

φ (lag)

00

300

600

>600

W1

W2

W3ph=W1+W2

PF

cos φ VLILcos(30-φ) VLILcos(30+φ) √3VLILcosφ

UPF

2W1 or 2W2

√3/2 VLIL

√3/2 VLIL

0.866

VLIL

VLIL/2

1.5W1 or 3W2

√3/2 VLIL

0.5

ZERO

W1 alone

<0.5

W1

DEPARTMENT OF EEE - SVECW

W2 reads

negative

W1+(-W2)

Remarks

Gen. Case (always W1≥W2)

W1=W2

W2=W1/2

W2 reads zero

For taking readings, the PC

or

CC connection of W2 should

be reversed) (LPF case)

Page 27

UNIT-IV

Potentiometers

DEPARTMENT OF EEE - SVECW

Page 28

4.1. Potentiometers

Before the introduction of the moving coil galvanometer, potentiometers were used

in measuring voltage, hence the '-meter' part of their name

Today this method is still important in standards work

The null-balance principle of measurement is also used in other areas of electronics

The potentiometer used for measurement is a type of bridge circuit for measuring

voltages by comparison between a small fraction of the voltage which could be

precisely measured, then balancing the two circuits to get null current flow which

could be precisely measured

Types

Main Classification

Constant current potentiometer

Constant resistance potentiometer

Microvolt potentiometer

Thermocouple potentiometer

Other

DC

AC

4.2. Construction of potentiometers

DEPARTMENT OF EEE - SVECW

Page 29

DEPARTMENT OF EEE - SVECW

Page 30

DEPARTMENT OF EEE - SVECW

Page 31

DEPARTMENT OF EEE - SVECW

Page 32

DEPARTMENT OF EEE - SVECW

Page 33

UNIT-V

Resistance Measurement

DEPARTMENT OF EEE - SVECW

Page 34

5.1 INTRODUCTION

A resistance is a parameter which opposes the flow of current in a closed electrical

network. It is expressed in ohms, milliohms, kilo-ohms, etc. as per the ohmic principle, it is

given by;

R = V/I; with temperature remaining constant.

(1)

If temperature is not a constant entity, then the resistance, R2 at t20C is given by;

R2 = R1 [1+ α (t2-t1)] (2) Where t= t1-t2, the rise in temperature from t10C to t20C, α

is the temperature coefficient of resistance and R1 is the temperature at t10C.

Resistance can also be expressed in terms of its physical dimensions as under:

R = ρl/A (3) Where, l is the length, A is the cross sectional area and ρ is the specific

resistance or resistivity of the material of resistor under measurement.

To realize a good resistor, its material should have the following properties:

• Permanency of its value with time.

• Low temperature coefficient of resistance

• High resistivity so that the size is smaller

• Resistance to oxidation, corrosion, moisture effects, etc.

• Low thermo electric emf against copper, etc.

No single material can be expected to satisfy all the above requirements together. Hence, in

practice, a material is chosen for a given resistor based on its suitability for a particular

application.

5.2 CLASSIFICATION OF RESISTANCES

For the purposes of measurements, the resistances are classified into three major groups

based on their numerical range of values as under:

• Low resistance (0 to 1 ohm)

• Medium resistance (1 to 100 kilo-ohm) and

• High resistance (>100 kilo-ohm)

Accordingly, the resistances can be measured by various ways, depending on their range of

values, as under:

1. Low resistance (0 to 1 ohm): AV Method, Kelvin Double Bridge, potentiometer,

doctor ohmmeter, etc.

2. Medium resistance (1 to 100 kilo-ohm): AV method, wheat stone’s bridge,

substitution method, etc.

3. High resistance (>100 kilo-ohm): AV method, Fall of potential method, Megger,

loss of charge method, substitution method, bridge method, etc.

5.3.

MEASUREMENT OF MEDIUM RESISTANCES

(a) AV Method

Here an ammeter and a voltmeter are used respectively in series and in parallel with the

resistor under measurement. Various trial readings are obtained for different current

values. Resistances are obtained for each trial as per ohmic-principle, using equation (1).

DEPARTMENT OF EEE - SVECW

Page 35

The average value of all the trails will give the measured value of resistance.

This method is also reefed as the potential drop method or VA method. Here, the meter

ranges are to be chosen carefully based on the circuit conditions and the resistance value to

be obtained. This method suffers from the connection errors.

(b) Wheatstone’s bridge

This bridge circuit has four resistive arms: arm-AB and arm-BC the ration arms with

resistances R1 and R2, arm-AD with the unknown resistance R3 and arm CD with a

standard known variable resistance R4, as shown in figure-1 below. The supply is fed

across the arm-AC and the arm-BD contains a galvanometer used as a detector connected

across it.

Fig.1 Wheatstone bridge

The bridge is said to be balanced when the galvanometer current is zero. This is called as

the position of null reading in the galvanometer, which is used here as a null detector of the

bridge under the balanced conditions.

Thus under the balance conditions of the bridge, we have,

Ig = 0; VAB = VAD and VBC = VCD, so that,

I1R1 = I2R3 and I1R2 = I2R4

(4)

Solving further, we get, R1/R2 = R3/ R4 and R1R4 = R2R3

(5)

This is the balance equation of the bridge.

Thus, unknown resistance, R3 = R1R4/ R2 ohms.

(6)

5.4.

Expression for Galvanometer current

In a WS bridge PQRS as shown in figure 2, below, under the unbalanced conditions of the

bridge, the current flowing in the galvanometer is given by:

Ig = ETh/ [RTh+Rg]

(7)

Where,

RTh = {PQ/(P+Q) + RS/(R+S)}

ETh = E {P/(P+Q) - R/(R+S)}

(8)

DEPARTMENT OF EEE - SVECW

Page 36

Fig.2 Wheatstone bridge PQRS

5.5.

Errors in WS bridge measurements

(i) Limiting errors: In a WS bridge PQRS, the percentage limiting error in the measurand

resistance, R is equal to the sum of the percentage limiting errors in the bridge arm

resistances P, Q and S.

(ii) Errors due to heating of elements in the bridge arms:

Rt = R0 [1+ αt]; P = I2R Watts; Heat= I2Rt Joules

The I2R loss occurring in the resistors of each arm might tend to increase the temperature,

which in turn can result in a change in the resistance value, different from the normal

value.

(iii) Errors due to the effect of the connecting wires and lead resistors: the connecting

lead wire resistance will affect the value of the unknown resistance, especially when it is a

low resistance value. Thus, the connecting lead wire resistances have to be accounted for

while measuring a low resistance.

(iv) Contact resistance errors: The contact resistance of the leads also affects the value of

the measurand resistance, just as in point (iii) above. This resistance value depends on the

cleanliness of the contact surfaces and the pressure applied to the circuit.

1.3.3 Limitations of WS bridge

The WS bridge method is used for measurement of resistances that are numerically in the

range of a few ohms to several kilo-ohms. The upper limit is set by the reduction in

sensitivity to unbalance caused by the high resistances, as per the equation (7).

1.3.4 Sensitivity of WS bridge

In a WS bridge PQRS as in figure 2, with the resistance S in an arm changed to S+ S, the

bridge becomes unbalanced to the extent of the resistance change thus brought about. This

is also referred as the unbalanced operation of the WS bridge. Under such circumstances,

with Sv as the voltage sensitivity of the galvanometer, we have,

θ = Sv e = Sv [ES R/(R+S)2]

Galvanometer Deflection,

(10)

S

=

θ/(

R/R)

Bridge Senstivity,

(11)

B

DEPARTMENT OF EEE - SVECW

Page 37

Rearranging, we get,

SB = Sve/{(R/S)+2+(S/R)}

(12)

Thus, the WS bridge sensitivity is high when (R/S)=1. It decreases as the ratio (R/S)

becomes either larger or smaller than unity value. This also causes a reduction in accuracy

with which the bridge is balanced.

1.4 MEASUREMENT OF LOW RESISTANCES

Of the various methods used for measurement of low resistances, the Kelvin’s Double

Bridge (KDB) is the most widely used method. Here, the bridge is designed as an

improved or modified WS Bridge with the effect of contact and connecting lead wire

resistances considered. The circuit arrangement for KDB is as shown in figure 3 below. R

is the low resistance to be measured, S is the standard low resistance, r is the very small

link resistance between R and S, called the yoke resistance, P,Q,p,q are the non inductive

resistances, one set of which, Pp or Qq is variable. The bridge is supplied with a battery E

and a regulating resistance RC. A galvanometer of internal resistance Rg, connected as

shown, is used as a null detector.

Fig.3 Kelvin’s Double Bridge

1.4.1 Balance Equation of KDB

The balance equation of KDB can be derived as under. Using star-delta conversion

principle, the KDB circuit of figure 3 can be simplified as shown in figure-4 below.

(a)

(b)

(c)

Fig. 4 Simplified circuits of KDB

DEPARTMENT OF EEE - SVECW

Page 38

It is thus observed that the KDB has now become a simplified WS bridge-ABCD as shown

in figure 4(c). It is to be noted that the yoke resistance r1 is ineffective now, since it is in

the zero current branch, in series with the galvanometer. Thus, under balance conditions,

we have,

P (S+r3) = Q (R+r2)

(13)

Where,

r1 = pq / (p+q+r)

r2 = pr / (p+q+r)

r3 = qr / (p+q+r)

(14)

Using (13) and (14), we get,

PS + Pqr / (p+q+r) = QR + Qpr / (p+q+r)

(15)

Simplifying (15), we get the final balance equation of the Kelvin Double Bridge as:

R = [P/Q] S + [qr / (p+q+r)] [(P/Q) – (p/q)]

(16)

1.4.2 Significance of balance equation of KDB

From the balance equation (16), it can be observed that,

• If the yoke resistance is negligible, (r=0), then R = [P/Q]S, as per the WS bridge

balance equation.

• If the ratio arm resistances are equal, i.e., [(P/Q) = (p/q)], then again, R=[P/Q]S, as

per WS bridge principle.

1.4.3 Unbalanced KDB

Further, if the KDB is unbalanced due to any change in resistances R or S (by R or S), then

the unbalanced galvanometer current during the unbalanced conditions is given by:

Ig = I. S [P/(P+Q)]/ {Rg+ pq/(p+q)+ PQ/(P+Q)}

(17)

1.4 MEASUREMENT OF HIGH RESISTANCES

Of the various methods used for measurement of high resistances, the fall of potential

method is widely used. Also, very high resistances of the order of mega-ohms can be

measured by using an instrument called MEGGER, also called as the insulation resistance

tester. It is used as a high resistance measuring meter as also a tester for testing the earth

resistances.

1.5 SOLVED PROBLEMS

1

Calculate the current through the galvanometer for the Wheatstone bridge circuit

shown below in figure P1.

R1 = 2 k

R2 = 4 k

R3 = 7 k

R4 = 20 k

Rg = 300

V = 8.0 V

Fig. P1

DEPARTMENT OF EEE - SVECW

Page 39

Solution:

The Thevenin’s equivalent circuit is used to find Ig. To find ETh, remove Rg as

shown in figure P1(a).

VTh = VCD = I2x4 k – I1x2k

I1= 8 / [ (2+7)103] = 8.888(10-4) A

I2 = 8 / [ (4+20)103] = 3.333(10-4) A

Thus, VTh = 3.333(10-4) x4(103)– 8.888(10-4) x2(103)

V

= - 0.4444 V, i.e., point C is negative.

Fig. P1(a)

To find RTh, short the battery as shown in figure P1(b). The points A and B are

shorted and can be represented by a single point as shown in figure P1(c).

RTh = [2(7)/(2+7)]

+ [4(20)/(4+20)]

= [1.555 + 3.333] k

= 4.888 k

Fig. P1(b)

Fig. P1(c)

Ig = VTh / [Rg+RTh]

= 0.4444 / [4.888x103+300]

= 85.65 µA - from D to C

as shown in

figure P1(d)

aside

Fig. P1(d)

2

A KDB is balanced with the following constants: outer ratio arms: 100 and 1000.

Ohms, inner ratio arms: 99.92 and 1000.6 ohms, link resistance: 0.1 ohm, standard

resistance: 3.77 milliohms, find the unknown resistance.

Solution:

The KDB circuit is as shown in figure P2.

P = 100 ohms Q

= 1000 ohms p =

99.92 ohms q =

1000.6 ohms r =

DEPARTMENT OF EEE - SVECW

Page 40

0.1 ohm

S = 3.77(10-3) ohms

= 0.00377 ohms

Fig. P2

The unknown resistance R is given by:

R = [P/Q] S + [qr / (p+q+r)] [(P/Q) – (p/q)]

By substituting the specified values, we get,

R=

[100/1000]0.00377+[1000.6(0.1)/(99.92+1000.6+0.1)][(100/1000)–

(99.92/1000.6)]

= 0.382712 milliohms.

3

The ratio arms of a KDB are 1000 ohms each. The galvanometer has a resistance of

1000 ohms and a sensitivity of 0.003 µA/mm. A current of 10 A is passed by a 2.2

V battery in series with a rheostat. The yoke resistance is negligible. The standard

resistance is 0.1 ohm. The galvanometer gave a deflection of 25 mm. by how much

the unknown differs in resistance from the standard one.

Solution :

The KDB circuit with the specified values of all the parameters of the bridge is as

shown in figure P3.

Fig.P3

I = kθ = 0.003µA/mm (25 mm) = 0.075 µA

R = (P/Q)S = [1000/1000] (0.1) = 0.1 ohm.

Ig = I. R [P/(P+Q)]/ {Rg+ pq/(p+q)+ PQ/(P+Q)}

By substituting the

specified values, we get,

0.075(10-6) = 10 R [1/2]/[1000+500+500]

Thus, solving for R, we ger,

R = 30 µ

4

Given that, in a KDB circuit, with the usual notations, P=Q=p=q=1000 ohms,

E=100V, RC=5 ohms, Rg=500 ohms and the bridge is balanced with S=0.001 ohm,

what is the approximate value of current through S, at balance? Also find the value

of galvanometer current Ig, if S is changed by 1% of its value at balance.

DEPARTMENT OF EEE - SVECW

Page 41

Solution :

Here, it is assumed that the yoke resistance is zero, i.e., r=0, so that

then, R=(P/Q)S = 0.1 ohm.

(i) I ≈ E/{R+Rc+r+S}

= 100/ [0.001+5+0+0.001] = 20 A

(ii) S = (0.01) S = 0.01(0.001) = 10 µ

Thus,

Ig = Ig = I. S [P/(P+Q)]/ {Rg+ pq/(p+q)+ PQ/(P+Q)} = 0.0667 µA

5

The ratio arms of a KDB are 1000 each, Rg=500 , k=200 mm/µA, R=0.1002 and

S=0.1 . A DC of 10 A is passed through R & S from a 2.2 V battery in series with a

rheostat. The link resistance is negligible. (i) Find the galvanometer deflection (ii)

Find the resistance unbalance to produce the deflection of 1 mm and (iii) Obtain the

total internal resistance of the battery circuit.

Solution :

(i) R = (P/Q)S = 0.1 ohm

Thus, R = 0.1002-0.1 = 200 µ

Hence,

Ig = I. S [P/(P+Q)]/ {Rg+ pq/(p+q)+ PQ/(P+Q)} = 1.6667 µA

And θg = k Ig = 333.33 mm

(ii) θg = 1 mm, -6Ig = θ/k = 1/200 = 0.005 µA

Thus, 0.005(10 ) = 10 R(0.5)/[(500+50+50]

Simplifying and solving, we get, R = 0.6 µ

(iii) I ≈ E/{R+Rc+r+S}

10 = 2.2 / [0.1002+RC+0.1+0]

Solving, we get, RC = 0.0198 ohm.

6

A KDB is as follows: P=p=10000 , Q=q=1000 , R=0.0997 , S=0.01 , Rg=1000 ,

r=0.01 and k=0.005 µA/mm. A battery of 2.25 Volts and internal resistance 0.0053

is connected across the bridge circuit. Find the galvanometer deflection.

Solution :

R = (P/Q)S = 0.1 ohm (since P/Q = p/q)

Thus, R = Rtrue – Rmeasured = 0.0997 – 0.1 = 300 µ

I ≈ E/{R+Rc+r+S}

= 2.25 / [0.0997+0.0053+0.01+0.01]

= 18 A

Ig = I. S [P/(P+Q)]/ {Rg+ pq/(p+q)+ PQ/(P+Q)} = 1.742 µA

And

θg = Ig/k = 91.742 µA)/(0.005 µA/mm)

= 348.4 mm.

1.6 EXERCISES

Standard text books listed in the syllabus are to be referred for the worked examples on the

topics covered so far for better understanding of the problem solving techniques on

resistance measurements.

DEPARTMENT OF EEE - SVECW

Page 42

UNIT-VI

AC Bridges

DEPARTMENT OF EEE - SVECW

Page 43

UNIT-VI

5.1 General Form of the AC Bridge

5.2 Maxwell Bridge

The Maxwell bridge measures an unknown inductance in terms of a known

capacitance.

The maxwell bridge is limited to the measurement of medium-Q coils (1<Q<10).

DEPARTMENT OF EEE - SVECW

Page 44

5.3 Hay Bridge

The Hay circuit is more convenient for measuring high-Q coils

Hay bridge for inductance measurements

for Q>10 : Lx= R2R3C

5.4 Schering Bridge:

The Schering bridge, one of the most important bridges, is used extensively for the

measurement of capacitors.

Schering bridge for measurement of capacitance

DEPARTMENT OF EEE - SVECW

Page 45

5.5 Wien Bridge :

Applications :

– Frequency measureent

– Notch filter

– Frequency-determining element

Frequency measurement with the Wien bridge

5.6 Anderson Bridge:

In the Anderson Bridge the unknown inductance is measured in terms of a known

capacitance and resistance.

this method is capable of precise measurements of inductance over a wide range of

values from a few micro-henrys to several henrys and is the best bridge method

5.7 Capacitance Bridge:

We will consider only De Sauty bridge method of comparing two capacitances the bridge has

DEPARTMENT OF EEE - SVECW

Page 46

maximum sensitivity when C2 = C3.

The simplicity of this method is offset by the impossibility of obtaining a perfect

balance if both the capacitors are not free from the dielectric loss.

A perfect balance can only be obtained if air capacitors are used. as shown in fig

DEPARTMENT OF EEE - SVECW

Page 47