Glycerol based solvents: synthesis, properties and applications

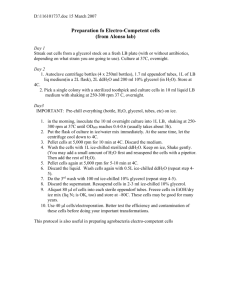

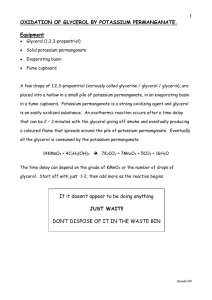

advertisement