GE Healthcare

Life Sciences

Data file 29-0483-67 AA

Single-use mixing systems

Xcellerex™ XDM Quad Mixing System

GE Healthcare Life Sciences’ disposable mixing systems

are designed for convenient and efficient mixing of buffer,

media, intermediates and product, as well as other process

fluids. The single-use system eliminates the hassle of timeconsuming and costly clean-in-place (CIP), steam-in-place

(SIP) procedures, and cleaning validation. The result is

efficient processing and rapid batch-to-batch turnover time.

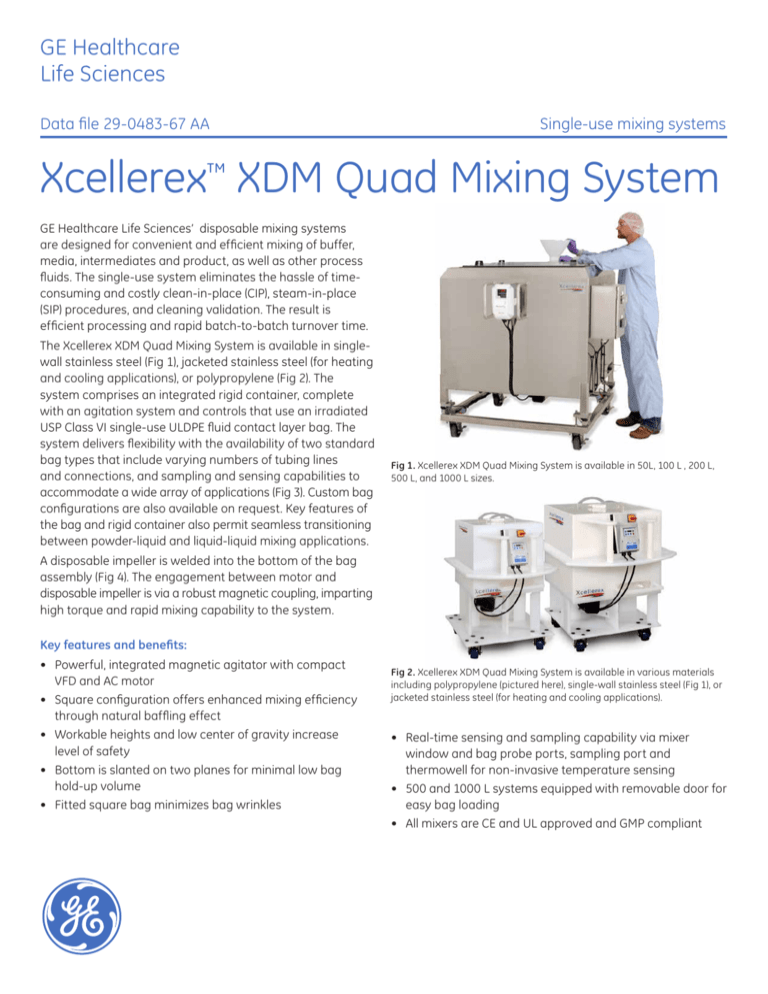

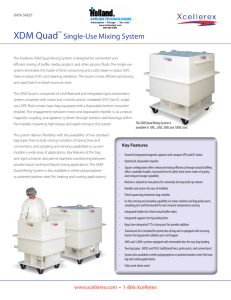

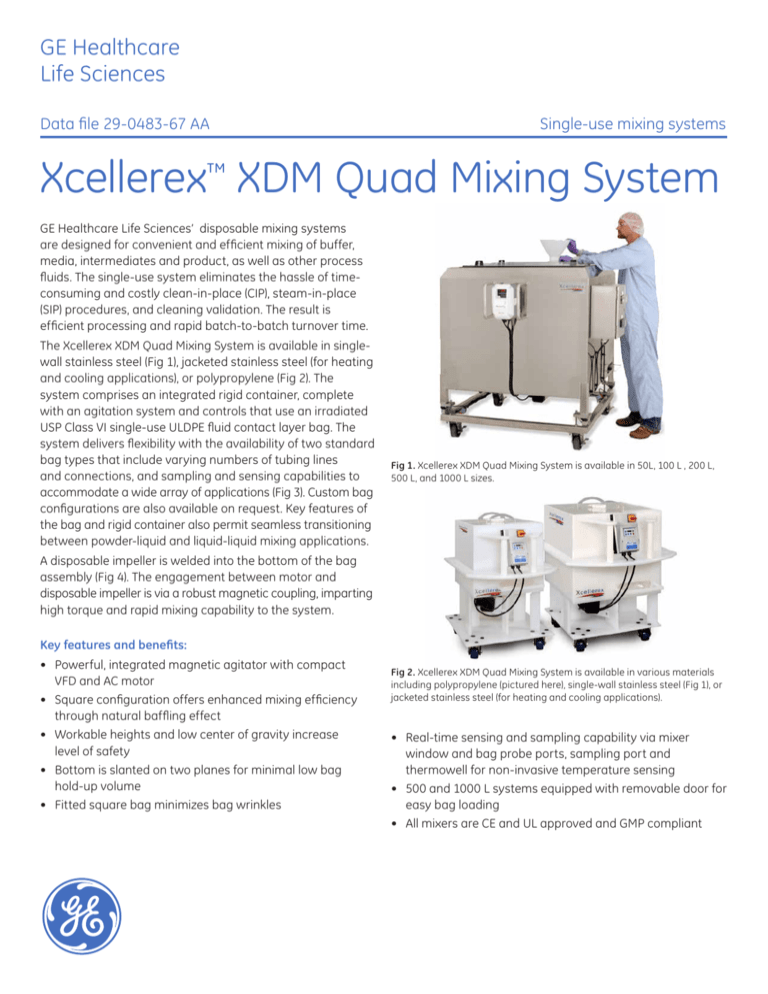

The Xcellerex XDM Quad Mixing System is available in singlewall stainless steel (Fig 1), jacketed stainless steel (for heating

and cooling applications), or polypropylene (Fig 2). The

system comprises an integrated rigid container, complete

with an agitation system and controls that use an irradiated

USP Class VI single-use ULDPE fluid contact layer bag. The

system delivers flexibility with the availability of two standard

bag types that include varying numbers of tubing lines

and connections, and sampling and sensing capabilities to

accommodate a wide array of applications (Fig 3). Custom bag

configurations are also available on request. Key features of

the bag and rigid container also permit seamless transitioning

between powder-liquid and liquid-liquid mixing applications.

Fig 1. Xcellerex XDM Quad Mixing System is available in 50L, 100 L , 200 L,

500 L, and 1000 L sizes.

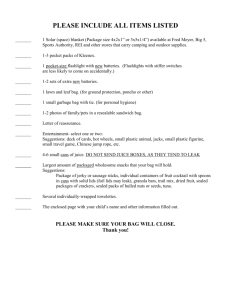

A disposable impeller is welded into the bottom of the bag

assembly (Fig 4). The engagement between motor and

disposable impeller is via a robust magnetic coupling, imparting

high torque and rapid mixing capability to the system.

Key features and benefits:

• Powerful, integrated magnetic agitator with compact

VFD and AC motor

• Square configuration offers enhanced mixing efficiency

through natural baffling effect

• Workable heights and low center of gravity increase

level of safety

• Bottom is slanted on two planes for minimal low bag

hold-up volume

• Fitted square bag minimizes bag wrinkles

imagination at work

Fig 2. Xcellerex XDM Quad Mixing System is available in various materials

including polypropylene (pictured here), single-wall stainless steel (Fig 1), or

jacketed stainless steel (for heating and cooling applications).

• Real-time sensing and sampling capability via mixer

window and bag probe ports, sampling port and

thermowell for non-invasive temperature sensing

• 500 and 1000 L systems equipped with removable door for

easy bag loading

• All mixers are CE and UL approved and GMP compliant

System specifications1

Xcellerex XDM QUAD-S (stainless steel) Mixing System

Dimensions

50 L

100 L

200 L

Exterior (W × H × D)

848 × 1067 × 544 mm 851 × 1067 × 610 mm 940 × 1067 × 673 mm 1227 × 1443 × 897 mm 1405 × 1443 × 1100 mm

(33.4 × 42 × 21.4 in)

(33.5 × 42 × 24 in)

(37 × 42 × 26.5 in)

(48.3 × 56.8 × 35.3 in)

(55.3 × 56.8 × 43.3 in)

102 × 51 mm (4 × 2 in)

Jacket volume

Weight

System weight (empty)

Construction material

Container

NA

68 kg (150 lbs)

82 kg (181 lbs)

140 kg (309 lbs)

Acrylic

Casters

SS/polyurethane (non-marring)

Type

AC motor

HP

0.26

Power rating

197 W

RPM

0 to 200

Power requirement

115 V or 230 V: (50/60 Hz)

Functionality

Run/stop, forward/break/reverse

Power cord

3.05 m (10 ft)

Washdown

Motor is IP66, CE certified/drive is IP65 NEMA 4×, CE certified

Xcellerex XDM QUAD-T (jacketed stainless steel) Mixing System

50 L

100 L

200 L

Exterior (W × H × D)

848 × 1067 × 544 mm 940 × 1067 × 681 mm 978 × 1067 × 681 mm 1280 × 1443 × 975 mm 1488 × 143 × 1207 mm

(33.4 × 42 × 21.4 in)

(37 × 42 × 26.8 in)

(38.5 × 42 × 26.8 in)

(50.4 × 56.8 × 38.4 in)

(58.6 × 56.8 × 47.5 in)

Jacket volume

System weight (empty)

102 × 51 mm (4 × 2 in)

1.2 L

2L

2.65 L

5.8 L

9.1 L

91 kg (200 lbs)

107 kg (236 lbs)

173 kg (381 lbs)

228 kg (503 lbs)

359 kg (792 lbs)

Container

304 L stainless steel

Insulation

Insulation is non-asbestos, chloride free, and coated with Thurmalox™ mastic material

Acrylic

Casters

SS /polyurethane (non-marring)

Type

AC Motor

HP

0.26

Power rating

197 W

RPM

0 to 200

Power requirement

115 V or 230 V: (50/60 Hz)

Functionality

Run/stop, forward/break/reverse

Power cord

3.05 m (10 ft)

Washdown

Motor is IP66, CE certified/drive is IP65 NEMA 4×, CE certified

Xcellerex XDM QUAD (polypropylene) Mixing System

50 L

100 L

Exterior (W × H × D)

686 × 1143 × 572 mm 838 × 1041 × 699 mm 965 × 1016 × 826 mm 1029 × 1219 × 1181 mm

(27 × 45 × 22.5 in)

(33 × 41 × 27.5 in)

(38 × 40 × 32.5 in)

(40.5 × 48 × 46.5 in)

Weight

System weight (empty)

Construction material

Container

Insulation

Lid

Casters

Type

HP

Power rating

RPM

Power requirement

Functionality

838 × 838 × 838 mm

(33 × 33 × 33 in)

~ 41.7 mm (1.64 in) per meter (3.28 ft)

102 × 51 mm (4 × 2 in)

Jacket volume

NA

52 kg (115 lbs)

65 kg (143 lbs)

83 kg (183 lbs)

138 kg (304 lbs)

Polypropylene

NA

Acrylic

SS/polyurethane (non-marring)

AC motor

0.26

197 W

0 to 200

115 V or 230 V: (50/60 Hz)

Run/stop, forward/break/reverse

Power cord

3.05 m (10 ft)

Washdown

Motor is IP66, CE certified/drive is IP65 NEMA 4×, CE certified

All specifications are subject to change without notice.

29-0483-67 AA

500 L

394 × 394 × 394 mm 508 × 508 × 508 mm 635 × 635 × 635 mm

(15.5 × 15.5 × 15.5 in)

(20 × 20 × 20 in)

(25 × 25 × 25 in)

Slope to drain

2

200 L

Container interior (W × H × D)

Caster dimensions (ø × W)

1

838 × 838 × 838 mm 1041 × 1041 × 1041 mm

(33 × 33 × 33 in)

(41 × 41 × 41 in)

~ 41.7 mm (1.64 in) per meter (3.28 ft)

Lid

Motor/VFD

1000 L

394 × 394 × 394 mm 508 × 508 × 508 mm 635 × 635 × 635 mm

(15.5 × 15.5 × 15.5 in)

(20 × 20 × 20 in)

(25 × 25 × 25 in)

Caster dimensions (ø × W)

Dimensions

500 L

Container interior (W × H × D)

Slope to drain

Motor/VFD

275 kg (606 lbs)

NA

Lid

Construction material

180 kg (397 lbs)

304 L stainless steel (SS)

Insulation

Weight

838 × 838 × 838 mm 1041 × 1041 × 1041 mm

(33 × 33 × 33 in)

(41 × 41 × 41 in)

~ 41.7 mm (1.64 in) per meter (3.28 ft)

Caster dimensions (ø × W)

Dimensions

1000 L

394 × 394 × 394 mm 508 × 508 × 508 mm 635 × 635 × 635 mm

(15.5 × 15.5 × 15.5 in)

(20 × 20 × 20 in)

(25 × 25 × 25 in)

Slope to drain

Motor/VFD

500 L

Container interior (W × H × D)

Single-use bag specifications1

50 L

100 L

200 L

394 × 369 × 394 mm

(15.5 × 14.5 × 15.5 in)

508 × 483 × 508 mm

(20 × 19 × 20 in)

635 × 609 × 635 mm

(25 × 24 × 25 in)

Maximum

55 L

125 L

246 L

571 L

1019 L

Nominal

50 L

100 L

200 L

500 L

1000 L

Minimum (for mixing)

17 L

28 L

44 L

76 L

117 L

< 20 mL

< 20 mL

< 20 mL

< 20 mL

< 20 mL

Dimensions

Dimensions (W × H × D)

Volume

Hold up

Film

Fluid contact layer

1000 L

ULDPE (USP class VI)

Pressure rating (max. operating)

Impeller

500 L

839 × 813 × 839 mm 1041 × 940 × 1041 mm

(33 × 32 × 33 in)

(41 × 37 × 41 in)

2 psi (1 psi)

Number of blades

3

Diameter

191 mm (7.5 in)

Blade height × width

107 × 64 mm (4.2 × 2.5 in)

Blade pitch

57º

Construction material

Molded HDPE impeller with ceramic bearing

Temperature range

2°C to 60ºC (May vary due to specific process conditions)

Powder port dimensions

76 mm (3 in) TC

Sterilization

Gamma irradiated

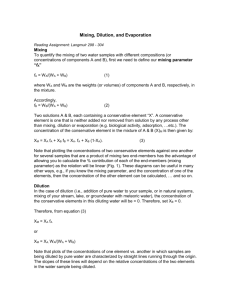

Single-use bag assemblies1

Basic bag assembly

Port description

A

Fill port: 3" tri-clamp powder addition port, capped

B

C-flex™ tubing, 4’ with clamp, plugged (ID indicated)

Plus bag assembly

50 L

100 L

200 L

500 L

1000 L

50 L

100 L

200 L

500 L

1000 L

×

×

×

×

×

×

×

×

×

×

12.7 mm 12.7 mm 12.7 mm 12.7 mm 19.1 mm 19.1 mm 19.1 mm 19.1 mm 19.1 mm 19.1 mm

(1/2 in) (1/2 in) (1/2 in) (1/2 in) (3/4 in) (3/4 in) (3/4 in) (3/4 in) (3/4 in) (3/4 in)

C

½" ID C-flex tubing, 4’ with clamp, female MPX connector, plugged

NA

NA

NA

NA

NA

×

×

×

×

×

D

1/8" ID C-Flex tubing (36”) Luer lock connection

NA

NA

NA

NA

NA

×

×

×

×

×

E, F

Probe Port: Female Kleenpack™ Connector port for probe connection

NA

NA

NA

NA

NA

×

×

×

×

×

F

Female Kleenpack Connector port for probe connection

NA

NA

NA

NA

NA

×

×

×

×

×

G

Thermowell: for non-invasive temperature sensing

NA

NA

NA

NA

NA

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

H

Sample Line: 1/8" ID sample line with clamp, and Luer lock connection

I

Harvest/Drain: C-flex tubing, 6’ with clamp, plugged (ID indicated)

1

12.7 mm 12.7 mm 12.7 mm 12.7 mm 19.1 mm 12.7 mm 12.7 mm 12.7 mm 12.7 mm 19.1 mm

(1/2 in) (1/2 in) (1/2 in) (1/2 in) (3/4 in) (1/2 in) (1/2 in) (1/2 in) (1/2 in) (3/4 in)

All specifications are subject to change without notice.

Bag assembly details

Xcellerex XDM Quad Mixing System

options and accessories

The following options are available for Xcellerex

XDM Quad Mixing systems:

• Dual pH/conductivity monitoring System

• pH probe

• Conductivity probe

Fig 3. Xcellerex XDM Quad Mixing System available with two standard bag

assembly types: Basic and Plus.

• RTD probe

• Probe sheath assemblies

• Weight monitoring1 (load cells for stainless steel units)

• Temperature control unit for heating and cooling of

jacketed stainless steel systems

• Temperature monitoring1

• Hopper for powder addition

1

Not available in polypropylene mixers.

Fig 4. The disposable impeller assembly is welded to the bottom of the bag.

29-0483-67 AA

3

Applications and performance data

The mixing systems effective mixing of common cell culture

media (Fig 7).

11.5

100

11.0

80

Corn syrup dissolved (%)

Conductivity (mS/cm)

Xcellerex XDM Quad Mixing System units demonstrate

rapid mixing of common salt solutions (Fig 5). The systems

demonstrate effective mixing even at high viscosities (Fig 6).

10.5

10.0

9.5

9.0

60

75% corn syrup, 274 cp

85% corn syrup, 561 cp

90% corn syrup, 1000 cp

40

20

0

60

120

180

240

0

300

0

20

40

Time (s)

Fig 5. Xcellerex XDM500: mixing trend 6 g/L for NaCl.

(B)

10

L-glutamine (L-Gln)

9

Component concentration

80

100

Fig 6. Xcellerex XDM200: mixing trend for 1% NaCl in 75%, 85%, and 90% corn syrup.

90

Glucose (g/L)

8

100

(mmol/L)

Component concentration (mmol/L)

(A)

60

Time (min)

7

6

5

4

3

2

1

+

Na (mmol/L)

80

70

60

50

40

30

20

10

0

0

0

60

120

180

Mix time (s)

0

300

240

60

120

180

240

300

Mix time (s)

(C)

(D)

10

400

+

K (mmol/L)

Osmo (mOsm/kg)

350

8

300

7

Osmolarity (mOsm/kg)

Component concentration (mmol/L)

9

6

5

4

3

250

200

150

100

2

50

1

0

0

60

120

180

240

0

300

0

60

Mix time (s)

120

180

240

300

Mix time (s)

Fig 7. Xcellerex XDM500: glucose and l-Gln trends for DMEM/F-12 cell-culture medium (A), sodium trends for DMEM/F-12 (B), potassium trends for DMEM/F-12 (C),

and osmolarity trend for DMEM/F-12 (D).

For local office contact information, visit

www.gelifesciences.com/contact

GE, imagination at work and GE monogram are trademarks of General Electric Company.

Xcellerex is a trademark of Xcellerex, Inc., now part of GE Healthcare.

C-Flex is a trademark of Saint-Gobain Performance Plastics. Kleenpak is a trademark of Pall Corporation.

Thurmalox is a trademark of Dampney Company, Inc.

© 2013 General Electric Company—All rights reserved. First published June 2013.

www.gelifesciences.com/xcellerex

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

All goods and services are sold subject to the terms and conditions of sale of the company within GE

Healthcare which supplies them. A copy of these terms and conditions is available on request. Contact your

local GE Healthcare representative for the most current information.

GE Healthcare UK Limited

Amersham Place

Little Chalfont

Buckinghamshire, HP7 9NA

UK

GE Healthcare Europe, GmbH

Munzinger Strasse 5

D-79111 Freiburg

Germany

GE Healthcare Bio-Sciences Corp.

800 Centennial Avenue, P.O. Box 1327

Piscataway, NJ 08855-1327

USA

imagination at work

GE Healthcare Japan Corporation

Sanken Bldg., 3-25-1, Hyakunincho

Shinjuku-ku, Tokyo 169-0073

Japan

29-0483-67 AA 06/2013