How Hovercrafts work:

advertisement

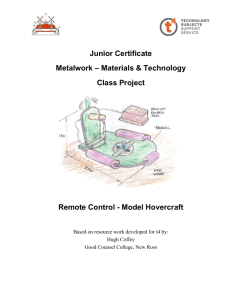

How Hovercrafts work: When building a hovercraft, a firm understanding of simple physics is required, but hovercrafts are relatively simple. In fact, the time and capital required to build one of our grade is three months and about one thousand dollars respectively. Although Mike has written an extensive essay on the history of hovercrafts, some background may still be necessary. Feel free to skip this paragraph if you have already read his portion. In the 1950, Christopher Cockerell patented the first vessel that was “neither an airplane, nor a boat, nor a wheeled land craft.” In 1959, one of his commercially built hovercrafts crossed the English Channel.1 Today hovercrafts are primarily used for recreation. They have been found particularly useful by the military when deploying troops on beach heads. This is due to their versatility on both land and sea. Hovercrafts work primarily on the principles of lift using air pressure differences. In this way they are similar to airplanes. The main difference is that hovercrafts generate their own lift, while airplanes require velocity to create the air pressure differences. Hovercrafts use motors and fans to force air under the hovercraft itself. The air is forced into an air chamber called the plenum chamber or better known as the air box. If the pressure in the plenum chamber is greater then the force pushing the hovercraft down (i.e. the weight of the hovercraft plus the load it is carrying) the hovercraft will rise off the ground. 1 http://www.neoterichovercraft.com/general_info/historyof.htm The box in green in the motorized fan. The red arrows represent air flow. The fan continually increases the pressure of the plenum chamber. When the pressure of the plenum chamber becomes greater than the force pushing it down, the hovercraft rises, causing air to escape until the pressure is equal to the force pushing down. Since the motor is continually running, the hovercraft is continually rising and falling. The two forces acting on each other is vital in why hovercrafts work. The air must escape from the bottom of the craft. The air separates the bottom of the hovercraft form the ground. This gap is called the air cushion. The air cushion allows there to be no friction between the ground and the craft itself. The craft is able to glide freely. Now a bit about the advantages and disadvantages of hovercrafts relative to other vehicles. Hovercrafts can travel faster than automobiles of equivalent horsepower, and are more fuel efficient than helicopters of equivalent weight. Since hovercrafts do not touch the ground, their braking system is sub par. Some hovercrafts just slow their propeller and glide to a stop. The most effective and complex stopping is accomplished through turning 180 degrees and using the propellers trust to work against the hovercrafts inertia. This is a particularly complex maneuver and is accomplishable only because the craft maintains its forward momentum, even when it is spinning about. That can not be done in a car. The propulsion fan is a vital element in moving forward. In blue is the fan itself. The green area represents the shroud, and once again, the red arrows represent the air flow, as I cannot draw. The fan we built was powered by a four horse power chipper motor. It used a belt drive with gear reduction on the fan for a higher air volume displacement. The gear ratio is a delicate item to tamper with. Too low a gear reduction and one may not get the maximum RPMS the motor will offer. Too high a gear ratio, and the motor may struggle to carry the load. The RPM of the fan is just one of many factors that determines total air displacement, however. Other factors include total surface area of the blades, the pitch of the blades, and the length of the blades. To figure out the propeller tip speed knowledge of the length of the blade and the RPMs is all that is required. Simply multiply the diameter of the propeller by pi, and then by the RPM to figure out how fast the tip of the blade is traveling. Another necessary component in any hovercraft is the skirt. The skirt is an inflatable ring that elevates the craft and increases the plenum chamber. The skirt should consist of free-flowing material that has no form of its own. The purpose of the skirt is to allow the craft to glide over obstacles that create differences in altitude: i.e. rocks, sticks, uneven pavement, waves, bananas, robots, pizza, and larger robots. The skirt must be free-flowing as it will mend to the shape of the obstacles. When choosing material for a hovercraft skirt three factors are important to consider. First, the bendable of the material, as discussed. Second the integrity of the material. A skirt must be able to contain large volumes of air, and high air pressure without popping. Furthermore, it must not rip when it is dragged against rough material such as cement and gravel. Ideally it wont even scuff, of show physical signs of damage. Lastly, the skirt must be slick and smooth. Even though there will usually be a cushion of air separating the skirt and the ground, it is almost inevitable that during some point the skirt will come into contact with the ground. When this occurs, it is vital the skirt is smooth enough that it does not disrupt the inertia of the craft. The green box is the lift motor, the orange portion represents the directional tubing, the blue part is the skirt itself, and the red part is the air flow. As one can see, the air is forced from the motor to the directional tubing and into the skirt. In the skirt it is free to exit into the plenum chamber. If the pressure is greater in the skirt, the air will travel into the plenum chamber. However, if there is more pressure in the plenum chamber than the skirt, some of the air will inflate the skirt. This phenomenon can be noted in the hovercraft we built. If one were to run the lawn mower motors and not the leaf blowers, the skirt does indeed inflate. The skirt we used consists of nylon coated polyester. It is inflated by two leaf blowers. Each leaf blower is divided in to two directions. One leaf blower provides air for the left and front portion of the skirt, while the other provides air toward the back and right portions. There are small PVC pipes that offer drainage of the excess air. There are 12 of them located throughout the craft and divided among the two leaf blowers. The area of one of the leaf blower nasals is equal to about 24 times the area of the PVC. Therefore, each PVC has about four times as much air displacement as the leaf blowers. Steering is an interesting issue when it comes to hovercraft building. Traditional steering requires the adjustment of the direction of wheels. This principle relies on friction between the wheels and the road. That is why sometimes it is difficult to turn on ice, or other smooth material. Hovercrafts have no wheels. The Steering method implemented in hovercrafts is similar to that of a boat. Boats use rudders to direct water flow and consequently change the direction of the boat. Hovercrafts use rudders (generally located directly behind the propulsion motor) to direct the air, and consequently change the direction of the hovercraft. There are three basic factors in determining the effectiveness of rudders. First, the placement of the rudders. Rudders must be positioned where the highest air flow is. The obvious choice is directly behind the propulsion fan. Since there is a fairly high velocity and magnitude of air being propelled through a relatively small area, small adjustments made to the shroud will change the course of the hovercraft. The next factor is surface area. Not much knowledge in fluid dynamics is required to determine the higher surface area will more greatly effect the efficiency of the rudders. Lastly, the pitch radius can have drastic effects on the turning radius. The yellow region is the rudder. Notice that the fan and the shroud work together to greatly increase the air pressure on the rudder. Any veering to the left or right will adjust the course of the craft respectively. One particular trend in modern hovercraft motor is shortened rudders and more of them. The larger number of rudders makes up for the shortness of them. In this way, surface area is still maintained. Also the short rudders turn easier, often have a higher turning pitch, and can generally fit better over shrouds, which are often circular. Picture modern rudders as the air directors of car air conditioners. The blades fit neatly over the vent, and when the blades are pushed all the way down the vent closes. Perhaps hovercraft rudders need not extend that far, they still must extend a good distance. Because of restrictions in finances and talent, our craft has a duel rudder system. In all honesty I can not tell you how well it works, since this is the only major part we have yet to build. I assume it will work, but I am particularly concerned with the turning radius. Of course the rudders will be longer than usual to increase surface area, but I do not know if that will be enough. The shroud is also important in increasing air pressure in the propulsion motor. The shroud’s function is two fold. First it directs the air. Without the shroud, the air forced out the back wouldn’t travel in any particular direction. Secondly, the shroud increases the air pressure since it is tapered at the exiting end. In this way the shroud acts as a jet engine. How much the shroud should be tapered is a difficult question. Too little and the fan wont offer enough pressure to move the craft, or at least not allow it to travel quick enough. Too much and the air pressure will be too condensed. One will lose some steering capabilities. If the shroud is very condensed, the lower area will cancel out the higher pressure, and the whole shroud will be pointless.