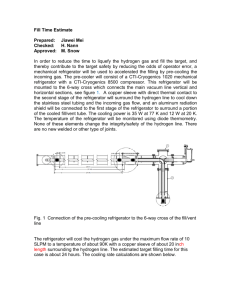

SCE Design and Engineering Services

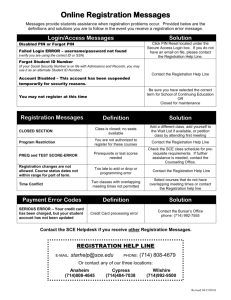

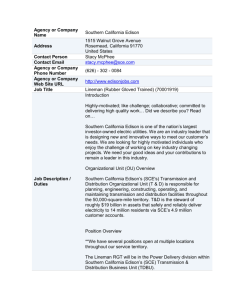

advertisement