Food Control 12 (2001) 229±234

www.elsevier.com/locate/foodcont

The use of quantitative risk assessment in HACCP

E. Hoornstra *, M.D. Northolt, S. Notermans, A.W. Barendsz

TNO Nutrition and Food Research Institute, P.O. Box 360, 3700 AJ Zeist, Netherlands

Abstract

During the hazard analysis as part of the development of a HACCP-system, ®rst the hazards (contaminants) have to be identi®ed

and then the risks have to be assessed. Often, this assessment is restricted to a qualitative analysis. By using elements of quantitative

risk assessment (QRA) the hazard analysis can be transformed into a more meaningful managerial tool. In this way the eect of

control measures can be quanti®ed, so the occurrence of contaminants in the endproducts can be estimated. Also, the quantitative

risk assessment is a tool to derive or validate control measures and critical limits at process steps (CCPs). The practical use of

quantitative risk assessment is demonstrated by two examples: the risk of raw fermented sausages and the risk of a pressurized meat

product. It can be concluded that quantitative risk assessment is a powerful combination of food microbiology, modelling and

applied statistics. It is recommended as the input for managing food safety issues as an extension or validation of the HACCPsystem. Ó 2001 Elsevier Science Ltd. All rights reserved.

1. Introduction

In the HACCP-plan, hazard analysis is the collection

and evaluation of information, characteristics and data

of contaminants and conditions leading to food safety

risks. The result of the hazard analysis is the identi®cation of control measures which are essential to (i) prevent

contamination, (ii) prevent unacceptable increase of

contaminants and (iii) reduce contaminants to acceptable levels. Next, the process steps at which control can

be applied and is essential to reduce a food safety risk are

de®ned as the critical control points (CCPs) in a HACCP-plan.

The identi®cation of risk factors is an important step

in hazard analysis. Risk factors contribute to the probability of occurrence of hazards in a product. At a risk

factor the hazard is introduced or there is a probability of

increase or decrease. To know the impact of a risk factor

the eect can be determined in a qualitative or in a

quantitative way. In most HACCP-systems a qualitative

approach is used. This results in a poor underpinning of

the need and eect of control measures. Using a quantitative approach, either a worst-case, what-if or statistical approach can be applied. The disadvantage of a

worst-case approach is the assumption that all unfa*

901.

Corresponding author. Tel.: +31-30-6944-729; fax: +31-30-6944E-mail address: hoornstra@voeding.tno.nl (E. Hoornstra).

vourable events occur at the same time. This will lead to

an overestimation of the risk and thus to conservative

control measures. Using what-if scenarios, dierent values (e.g. averages) can be chosen resulting in a more realistic approach. However, no account is made for

variability. In most cases it is the variability of a parameter that determines the risk. In the statistical approach monitoring results, expert knowledge, literature

data and well-reasoned assumptions about the various

risk factors are incorporated in probability distribution

functions. This means that calculations are not based

on one value, e.g. the average or an extreme value, but on

several values each with a probability. In the calculations

values are sampled from the probability distribution

functions (Monte Carlo sampling). A quantitative approach gives more insight in the need and eect of control measures than a qualitative approach.

Using risk assessment, it can be calculated how well

the endproduct meets the speci®cations, and also the

probability of exceeding a criterion can be calculated.

The criteria and speci®cations are set by governments

(Food Safety Objectives), by clients or by the company

itself. The producer has to translate these endproduct

criteria to subcriteria and critical limits in order to adhere to the criteria set. For the design and/or validation

of the critical limits use can be made of quantitative

risk assessment. If food producers want to perform a

risk assessment use can be made of the method of risk

assessment as de®ned by the Codex Alimentarius

0956-7135/01/$ - see front matter Ó 2001 Elsevier Science Ltd. All rights reserved.

PII: S 0 9 5 6 - 7 1 3 5 ( 0 1 ) 0 0 0 1 9 - 6

230

E. Hoornstra et al. / Food Control 12 (2001) 229±234

Commission. In principle, this approach is used by

governments for the development of Food Safety Objectives (criteria). These formal risk assessments take a

lot of eort, in terms of several man years. In the literature a few formal risk assessments are described (Cassin, Lammerding, Todd, Ross, & McColl, 1998; Marks,

Coleman, Jordan-Lin, & Roberts, 1998; Notermans et

al., 1997; Notermans, Dufrenne, Teunis, & Chackraborty, 1998; Whiting & Buchanan, 1997).

2. Risk assessment

Risk assessment according to the Codex Alimentarius

Commission is a scienti®c evaluation of known or potential adverse health eects resulting from exposure to

(food borne) hazardous agents. The process consists of

the following steps: (i) hazard identi®cation, (ii) hazard

characterization, (iii) exposure assessment and (iv) risk

characterization.

In hazard identi®cation, the signi®cant hazards for

the endproduct are identi®ed systematically. Not all

hazards can be addressed in detail in the risk assessment

or in the HACCP-plan. Therefore, only the most important hazards have to be selected. In a risk assessment

for governments mostly use is made of epidemiological

data. In a risk assessment for food companies mostly use

is made of product and process information. It can be

useful to combine hazards in a group depending on the

type of product and production process used. Examples

of groups are: sporeforming bacteria, toxin producing

bacteria, etc. Sometimes a hazard has to be de®ned

speci®cally, if it has certain speci®c characteristics (e.g.,

acid tolerance, heat stability). This systematical identi®cation of signi®cant hazards should also be done in

hazard analysis, but from experience it is known that in

HACCP-systems it is often done insucient. However,

it is the basis of a clear organized and transparant risk

assessment and should therefore be documented well

(Van Gerwen, de Wit, Notermans, & Zwietering, 1997).

Hazard characterization is the qualitative and/or

quantitative evaluation of the nature of the adverse

health eects associated with biological, chemical, and

physical agents which may be present in the food. Factors that are considered include virulence, microbial

variability and consumer sensitivity. For micro-organisms the so far developed dose-response-relations are

poor, with a large uncertainty (Buchanan, Damert,

Whiting, & van Schothorst, 1997; Coleman & Marks,

1998; Teunis, Medema, Kruidenier, & Havelaar, 1997).

In a HACCP-system it cannot be expected to make use

of quantitative health eects. In principle, only the

speci®cations (endproduct criteria) are used which are in

general based on adverse health eects. It is assumed as

a starting point that concentrations of hazards below the

criteria do not result in signi®cant health eects and

concentrations above the limit lead to an increased

probability of an adverse health eect. If criteria are

absent they have to be set, which might take much more

eort.

Exposure assessment is the qualitative or quantitative

evaluation of the likely intake of hazardous biological,

chemical and physical agents via food. The risk factors

in exposure assessment depends on the quality of the

raw materials, the process steps and the process environment, as well as the composition, packaging and

storage conditions of the product. Many of these risk

factors can and should be controlled by the food company. To evaluate the consumer's risk, it is also necessary to calculate the concentration of contaminants until

the moment of consumption and to know the quantity

of consumption. Determining this is far too complicated

for a HACCP-plan especially if a food company is not at

the end of a food chain. It suces to evaluate the

probability of occurrence of contaminants in the endproduct of the food company.

Risk characterization is the combination of hazard

characterization and exposure assessment leading to a

risk estimate. The risk estimate is the probability of

occurrence of hazardous agents in food, in quantities

leading to an adverse health eect. Quantities exceeding

the criteria are considered to result in an adverse health

eect.

Traditionally risk assessment has mostly been viewed

to set criteria for endproducts. The objective was to

protect the consumer. However, it also allows the understanding of a production process and to provide insights how to best manage the risk, and identify what

critical information is lacking in the understanding of

the risk situation. Therefore, the results of risk assessment have to be communicated clear and transparent to

the risk manager. A description of the risk pro®le and

the results of scenario analysis might support the decision making by the risk manager (i.e., government or

food company).

The objective of risk assessment for food companies

is to derive or validate critical limits at critical control

points. Although HACCP is meant for food safety, also

spoilage risks can be incorporated in risk assessment.

Spoilage micro-organisms are mostly more resistant to

heat, acid, etc. Therefore, spoilage risks, also potentially

leading to claims and recalls, are food company risks as

well. In the following examples the two types of risk

assessment are worked out. In the ®rst case of raw fermented sausages the risk manager is the government. In

the second case of a pasteurized meat product the risk

manager is the food company. In that case also spoilage

risks are taken into account.

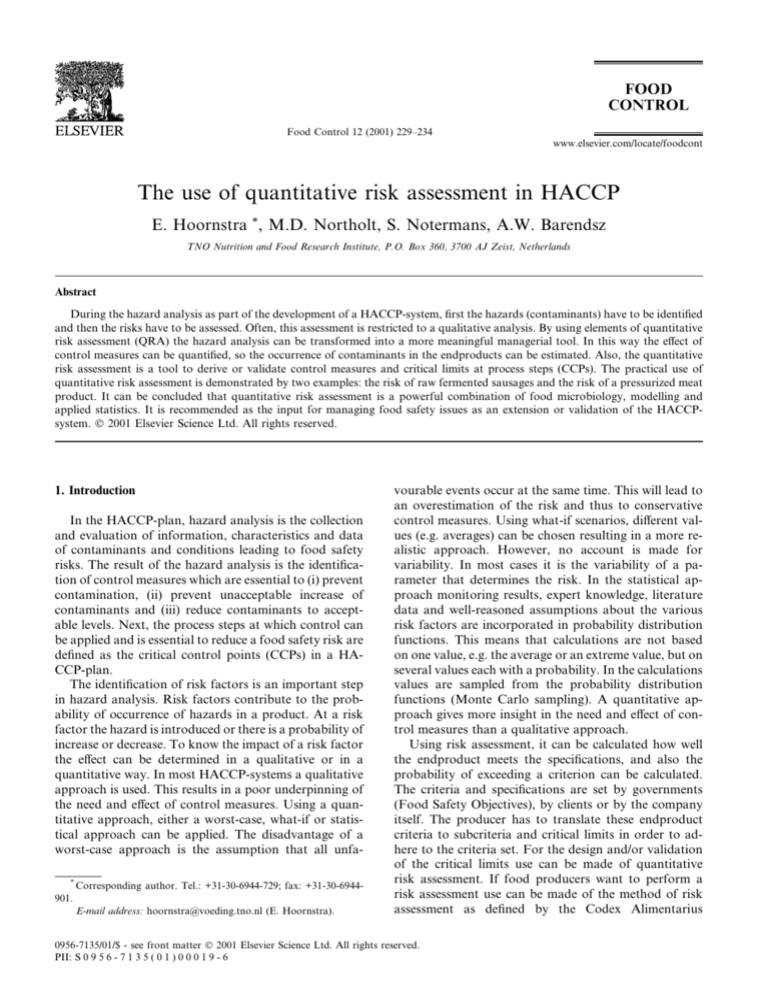

Example 1 (Quantitative risk assessment of raw fermented meat products). In the recent past in the USA

and Australia a few outbreaks of E. coli O157:H7 in raw

E. Hoornstra et al. / Food Control 12 (2001) 229±234

fermented sausages have occurred (Centers for Disease

Control & Prevention, 1995a,b). In the USA a 5D performance standard (at least 5 log reduction) is accepted

as criterion for the fermentation process. In order to

underpin if this could be a realistic criterion for the

Dutch meat industry, a quantitative risk assessment is

done, based on literature data, challenge tests and other

microbiological information and assumptions together

with the use of applied statistics. For two dierent types

of sausages a risk assessment is done. For the sausage

with a relative low water activity and high pH the results

are described below.

Hazard identification.E. coli O157:H7 is identi®ed as

most signi®cant hazard for raw fermented sausages,

based on the outbreaks and on the fact that E. coli

O157:H7 can be relative acid tolerant.

Hazard characterization. Very little information is

known about the infective dose of E. coli O157:H7.

Therefore, the dose-response relation of Shigella dysenteriae is used which has a comparable infection

mechanism. This dose-response relation contains a lot of

uncertainty, because it is based on a human feeding

study with healthy volunteers who consumed high

numbers of Shigella.

Exposure assessment. First, the risk contributing

factors in the food chain are identi®ed. Most important

are the prevalence and concentration of E. coli O157:H7

in feces of bulls, (cross-)contamination during slaughtering, reduction during fermenting and during storage

and the amount of consumption. The impact of every

single risk factor is quanti®ed using probability distribution functions. The probability distribution of E. coli

O157:H7 on meat trimmings has a variability between 0

and 1000 per g strongly skewed to the left. Because the

sausages have a certain limited mass, not all sausages

will contain E. coli O157:H7. The positive sausages will

have a heterogeneous contamination. During the fermentation and storage, from the challenge tests a reduction of 2±3 D was observed (Fig. 1). The number of

E. coli O157:H7 in the product can be calculated from

the probability distribution functions by performing socalled Monte Carlo simulations. This is done by running

100,000 iterations in @RISKe using the Latin hypercube method. Fig. 2 shows the probability distribution

of E. coli O157:H7 on meat from positive bulls before

and after fermentation. It can be seen that not only the

numbers of E. coli O157:H7 decrease (X-axis) but also

the probability that numbers occur decrease (Y-axis).

The time of consumption determines the achieved reduction during storage. Finally, the probability distribution of E. coli O157:H7 in the product at the time of

consumption is calculated (results in Table 1). This

probability of occurrence is multiplied with the amount

of consumption to assess the exposure.

Risk characterization. The dose±response relation is

combined with the exposure data to estimate the risk.

231

Fig. 1. Reduction/survival of E. coli O157:H7 in raw fermented sausage

during processing (14 days) and storage (from 14 to 78 days). The

numbers at day 35 are between 0 and 2 log (negative with counting

method, positive after enrichment of 1 g). The numbers at day 78 are

between )1.4 and 0 log (negative after enrichment of 1 g, positive after

enrichment of 25 g).

Because of the high variability in dose±response relation

the variability of risk was also high.

Risk management. The hazard identi®cation was

based on some incidental epidemiological data. Because

the data describing the hazard characterization was

poor, no well-underpinned risk characterization was

possible. Therefore, the exposure assessment was the

most important element of this risk assessment. Decision making was only justi®ed based on the estimation

of the probability of occurrence of E. coli O157:H7 in

the endproduct at the time of consumption. Because of

the low percentage of positive sausages and the low

numbers potentially present in positive sausages, it was

decided that there was no need for a performance

standard of 5D. Another important feature of the model

is the fact that the data can be held up-to-date and that

measures for improvement can be incorporated into the

Fig. 2. Probability distribution of E. coli O157:H7 on meat from

positive bulls before () and after (+) fermentation (for a better

readability the numbers lower than 10 E. coli O157:H7 per sausage

(with a high probability) and higher than 100 E. coli O157:H7 per

sausage (with a low probability) are not presented in the graph).

232

E. Hoornstra et al. / Food Control 12 (2001) 229±234

Table 1

Probability of occurrence of number of E. coli O157:H7 (Nt) in raw

fermented sausages at time of consumption

Number of E. coli O157:H7 in a sausage

Probability

Nt 0

Nt P 1

Nt P 10

99.7 %

0.3 %

0.002 %

(1 in 50,000)

<1 in 109

Nt P 100

model. The quantitative eect of these measures can be

predicted, which is essential for risk management. This

scenario-analysis can be combined with a cost±bene®t

calculation to improve the situation if necessary.

Example 2 (Quantitative risk assessment of a pasteurized

meat product). A food company wants to validate their

hazard analysis and derive a critical limit for the pH of

the meat product. The meat product consists of meat,

spices and herbs and other ingredients. It contains nitrite

salt and has a water activity of 0.97. The product is

pasteurized (P-value of 40 min at 70°C). The pH used to

be 6.3, which gave a self-stable product at a maximum

storage temperature of 7°C. The food company would

like to consider storage at ambient temperatures for 5

days. In order to prevent spoilage and safety risks a risk

assessment is conducted. Two pH levels are chosen, 5.7

and 5.3. Also a treatment of the spices and herbs as an

addition measurement is taken into account. It is assumed that the storage temperature is 20°C.

Hazard identification. Raw meat can be contaminated

with a lot of pathogens. Spices and herbs can have high

levels of sporeforming bacteria. It can be concluded that

the initial contamination level is high. The pasteurization process is sucient to inactivate all vegetative micro-organisms. To underpin this statement, a relatively

heat-stable vegetative pathogenic and spoilage bacterium should be taken into account in the risk assessment: Listeria monocytogenes and Streptococcus faecalis.

The sporeforming microorganisms are able to survive

the pasteurization process. However, the combination of

pH and salt (nitrate) prevent the pathogens Bacillus

cereus, Clostridium perfringens and Clostridium botulinum from growing. The pH and salt content are determined as CCPs and should be well-controlled according

to the HACCP-system. The important micro-organisms

with respect to spoilage are dierent Bacillus spp. of

which Bacillus subtilis is frequently occurring and relatively fast-growing. This bacterium is therefore signi®cant to determine whether or not there are any risks

during storage at higher temperatures.

Hazard characterization. For Listeria monocytogenes

a criterion of 100 per g is assumed, taken from the Dutch

Food Commodity Act. For spoilage bacteria, normally it

suces to take an assumed spoilage limit into account,

e.g., 7 log cfu per g. However, Bacillus subtilis can also

act as pathogen if present in high numbers. Therefore,

the critical limit at the time of consumption is set together with the risk manager at 5 log cfu per g.

Exposure assessment. For Listeria monocytogenes

even in the worst case situation there is no probability of

survival during the pasteurization process, with a theoretical number of decimal reductions of 133D (ICMSF,

1996). The most heat resistant vegetative micro-organism Streptococcus faecalis will be reduced by 13D in the

mean situation and 5D in the worst-case (Magnus,

McCurdy, & Ingledew, 1988; Incze, K

ormendy,

K

ormendy, & Zsarn

oczay, 1999). Therefore, no further

assessment is done for vegetative micro-organisms. For

Bacillus subtilis a detailed risk assessment is done.

The use of probabilities gives insight in the distribution of Bacillus subtilis in the raw materials, resulting in

a probability of occurrence in the mixed raw product

(Fig. 3). The growth characteristics of the organism is

modelled, resulting in a lag-time of 48 h (mean) and a

generation time of 1.7 h (mean) at 20°C (Food MicroModel, 1999). From these inputs the number of Bacillus

subtilis during storage at 20°C can be calculated at the

pH of 6.3. Monte Carlo simulations are done in

@RISKe by running 10,000 iterations (Latin Hypercube) from the probability density functions.

Risk characterization. From the growth data of Bacillus subtilis at 20°C the probability of exceeding the

critical limit (spoilage by Bacillus subtilis) after ®ve days

is calculated. The situation will result in spoilage of

every meat product (risk is 100%) during storage at 20°C

within ®ve days. The company wants to know the eect

of a change of the pH of the product to 5.3 or 5.7. A

lower pH increases the lag time and generation time.

Another option is to treat the spices which contribute to

the initial contamination level with Bacillus subtilis. The

results of the measures for improvement are given in

Table 2.

Risk management. An acceptable risk can be achieved

by lowering the pH to 5.3 or lower. This might have an

Fig. 3. Probability distribution of Bacillus subtilis in the mixed raw

meat product directly after processing.

E. Hoornstra et al. / Food Control 12 (2001) 229±234

233

Table 2

Probability of spoilage by Bacillus subtilis of a meat product during ®ve days storage at 20°C with a pH of 6.3, 5.7 and 5.3, and with and without

treatment of the spices

Current situation

Option 1

Option 2

Option 3

Option 4

Option 5

Treatment spices and herbs

pH of the product

Probability of spoilage

Spoilage: 1 on . . .

No

Yes

No

Yes

No

Yes

6.3

6.3

5.7

5.7

5.3

5.3

100%

99.99%

99.18%

0.08%

0.06%

<10 7 %

1

1

1

1250

1667

>10,000

adverse eect on the ¯avour of the product. In combination with the treatment of the spices and herbs the pH

can be set higher. The risk manager, i.e., food company,

can make a decision based on the risk relating to costs of

the treatment of the spices and herbs and the acidity of

the product (¯avour).

The risk assessment model can be extended with other

scenarios. It may be interesting to predict the eect of

unfavourable events, like a higher storage temperature

(e.g., during transport) or the risks of contamination

with vegetative bacteria after pasteurization. Also, other

product and process development activities can be predicted, like the eect of modi®ed atmosphere packaging.

agement. This is more accurate than the worst-case approach, but still a manager can decide which approach

he thinks is best. From the exposure assessment it can be

concluded which risk factors are most important. Also

the impact of measures of improvement can be predicted

so a cost±bene®t analysis of options is possible. All these

advantages make it possible to manage food safety

problems in a quantitative way. This makes the quantitative assessment of microbiological risks a powerful

tool for food companies as an extension or validation of

the HACCP-system.

References

3. Discussion

The production of safe food is increasingly based on

the use of risk analysis. It is used to set (internationally)

Food Safety Objectives. It is also used by food companies to guarantee that the criteria are met and to derive

critical limits in order to meet the criteria in a cost-ecient way. Although food companies have the aim to

come close to a zero risk, it is known that this can never

be achieved. Carrying out a formal risk assessment as

de®ned by Codex Alimentarius Commission may take

years. Some elements can be used by food companies to

estimate the probability of occurrence of contaminants

in the endproducts. This will lead to an assessment of

the food company's risks, which can be done in a period

of weeks or months. Most important elements are a

systematic hazard identi®cation and an assessment of

the exposure. A worst-case and what-if approach is

necessary for a ®rst start in risk assessment. From these

results it can be concluded for which hazards a more

detailed assessment should be done. The statistical approach is recommended when quantitative information

about the risk is desirable. Although there is not always

much data at a risk factor, uncertainty can also be taken

into account. Further, information in literature, in existing models and from experts can all be incorporated

in the probability distribution functions. In this way it is

possible to use all the information there is in risk man-

Buchanan, R. L., Damert, W. G., Whiting, R. C., & van Schothorst,

M. (1997). Use of epidemiologic and food survey data to estimate a

purposefully conservative dose±response relationship for Listeria

monocytogenes levels and incidence of listeriosis. Journal of Food

Protection, 60(8), 918±922.

Cassin, M. H., Lammerding, A. M., Todd, E. C. D., Ross, W., &

McColl, R. S. (1998). Quantitative risk assessment for Escherichia

coli O157:H7 in ground beef hamburgers. International Journal of

Food Microbiology, 41, 21±44.

Centers for Disease Control and Prevention. (1995a). Escherichia coli

O157:H7 outbreak linked to commercially distributed dry-cured

salami. Morbidity and Mortality Weekly Report, 44(9), 157±160.

Centers for Diseese Control and Prevention. (1995b). Community

outbreak of hemolytic uremic syndrome attributable to Escherichia

coli O111:NM - South Australia. Morbidity and Mortality Weekly

Report, 44(29), 550±551, 557±558.

Coleman, M., & Marks, H. (1998). Topics in dose±response modeling.

Journal of Food Protection, 61(11), 1550±1559.

Food MicroModel. (1999). version 3.02, Ministry of Agriculture

Fisheries and Food.

Van Gerwen, S. J. C., de Wit, J. C., Notermans, S., & Zwietering, M.

H. (1997). An identi®cation procedure for foodborne microbial

hazards. International Journal of Food Microbiology, 38, 1±15.

ICMSF. (1996). Listeria monocytogenes In Micro-organisms in foods 5.

ICMSF.

Incze, K., K

ormendy, L., K

ormendy, I., & Zsarn

oczay, G. (1999).

Considerations of critical microorganisms and indicator enzymes in

connection with the pasteurization of meat products. Meat Science,

51, 115±121.

Magnus, C. A., McCurdy, A. R., & Ingledew, W. M. (1988). Further

studies on the thermal resistance of Streptococcus faecium and

Streptococcus faecalis in pasteurized ham. Canadian Instititute of

Food Science and Technology Journal, 21, 209±212.

234

E. Hoornstra et al. / Food Control 12 (2001) 229±234

Marks, H. M., Coleman, M. E., Jordan-Lin, L. C. T., & Roberts, T.

(1998). Topics in microbial risk assessment: dynamic ¯ow tree

process. Risk Analysis, 18(3), 309±328.

Notermans, S., Dufrenne, J., Teunis, P., Beumer, R., te Giel, M., &

Peeters-Weem, P. (1997). A risk assessment study of Bacillus cereus

present in pasteurized milk. Food Microbiology, 14(2), 143±151.

Notermans, S., Dufrenne, J., Teunis, P., & Chackraborty, T. (1998).

Studies on the risk assessment of Listeria monocytogenes. Journal of

Food Protection, 61(2), 244±248.

Teunis, P. F. M., Medema, G. J., Kruidenier, L., & Havelaar, A. H.

(1997). Assessment of the risk of infection by Cryptosporidium or

Giardia in drinking water from a surface water source. Water

Research, 31(6), 1333±1346.

Whiting, R. C., & Buchanan, R. L. (1997). Development of a

quantitative risk assessment model for Salmonella enteritidis in

pasteurized liquid eggs. International Journal of Food Microbiology,

(36), 111±125.