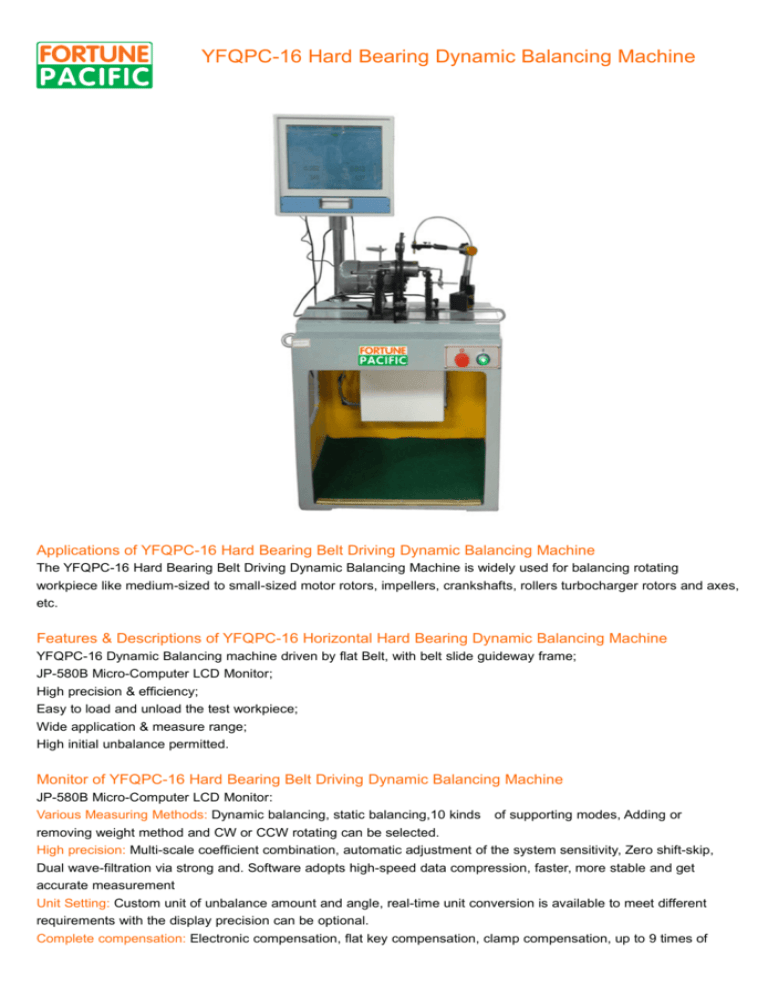

Hard Bearing Dynamic Balancing Machine YFQPC16

advertisement

YFQPC-16 Hard Bearing Dynamic Balancing Machine Applications of YFQPC-16 Hard Bearing Belt Driving Dynamic Balancing Machine The YFQPC-16 Hard Bearing Belt Driving Dynamic Balancing Machine is widely used for balancing rotating workpiece like medium-sized to small-sized motor rotors, impellers, crankshafts, rollers turbocharger rotors and axes, etc. Features & Descriptions of YFQPC-16 Horizontal Hard Bearing Dynamic Balancing Machine YFQPC-16 Dynamic Balancing machine driven by flat Belt, with belt slide guideway frame; JP-580B Micro-Computer LCD Monitor; High precision & efficiency; Easy to load and unload the test workpiece; Wide application & measure range; High initial unbalance permitted. Monitor of YFQPC-16 Hard Bearing Belt Driving Dynamic Balancing Machine JP-580B Micro-Computer LCD Monitor: Various Measuring Methods: Dynamic balancing, static balancing,10 kinds of supporting modes, Adding or removing weight method and CW or CCW rotating can be selected. High precision: Multi-scale coefficient combination, automatic adjustment of the system sensitivity, Zero shift-skip, Dual wave-filtration via strong and. Software adopts high-speed data compression, faster, more stable and get accurate measurement Unit Setting: Custom unit of unbalance amount and angle, real-time unit conversion is available to meet different requirements with the display precision can be optional. Complete compensation: Electronic compensation, flat key compensation, clamp compensation, up to 9 times of dislocation of clamps. Technological algorithm for Balancing: Indexing Algorithm, Drilling Algorithm, milling Algorithm and Crankshaft Algorithm Consummate Scaling Process: Specialized scaling interface provides more convenience for maintenance. Up to 10 scaling stages, real-time verification of scaling with linear chart. Sensor disconnection alarm: Automatic diagnosis of sensor disconnection, prompt evading of false balance Language Display: English. Convenient Operation: Numeric and vector-combined display of measured values. Hint for the parameter defining and the domain setup Large storage of data: Database storage. Limitless storage of Rotor data, clamp compensation data and 10000 items of measured loop records Record: Auto record of the past measured value, Optional methods of recording. Excellent commonness of data: Database files can be opened in Windows Office. Operation like “Find”, “Stats” “Filter”, “Classify” and “Readout” are available via the ancillary software Multiple Measuring report Form: Measuring report-form, Balancing Report-form, Single-plane Measuring Report-form, etc.( Note: information for rotor data can be added anytime and displayed in report-form). Partial View of YFQPC-16 Horizontal Hard Bearing Belt Driving Dynamic Balancer Technical Specifications of YFQPC-16 Horizontal Hard Bearing Dynamic Balancing Machine Model Unit Monitor YFQPC-16 JP-580B LCD Max weight of Workpiece kg 16 Max Diameter of Workpiece mm Φ300 Distance between Two Support Bearings mm 60-400 Journal Diameter Scope of Workpiece mm Φ5~40 Diameter Scope of Driving Belt mm Φ15~150 Balancing workpiece rotary speed (When the workpiece with the diameter Φ100mm) rpm 0-1200 (Stepless Speed Regulating) Motor Power kW 0.25 g.mm/kg 0.3 Min Achievable Residual Unbalance Amount Imbalance amount (Uneven URR)decrease rate 90% Gross weight kg 260 Package Dimension :L x W x H mm 900x700x1300