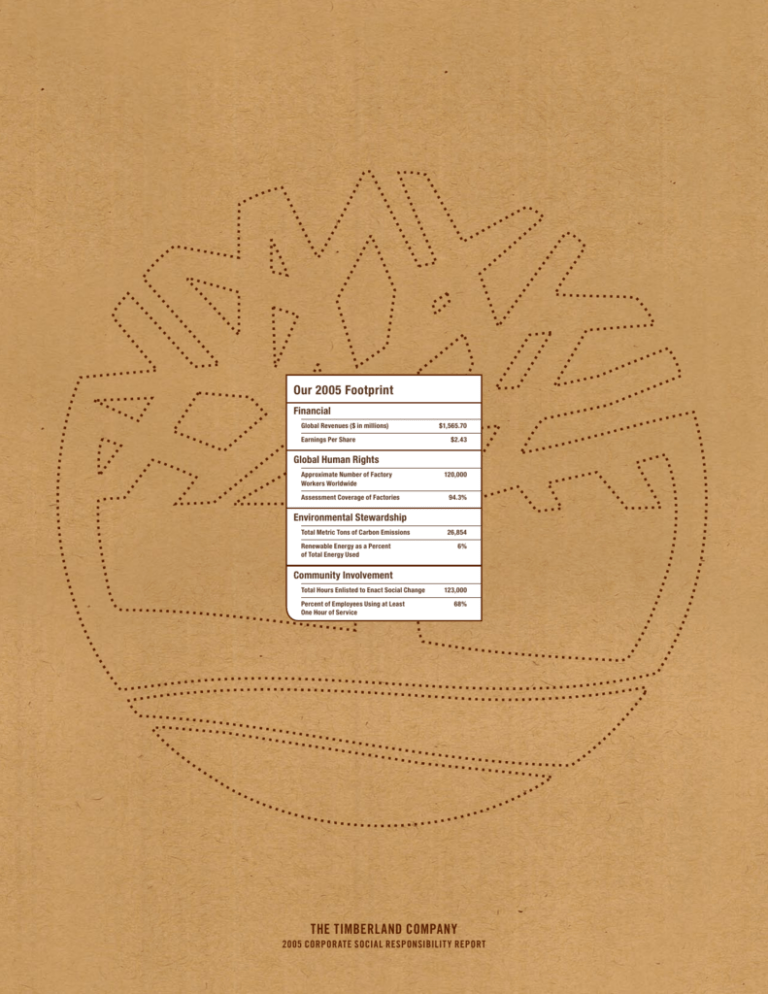

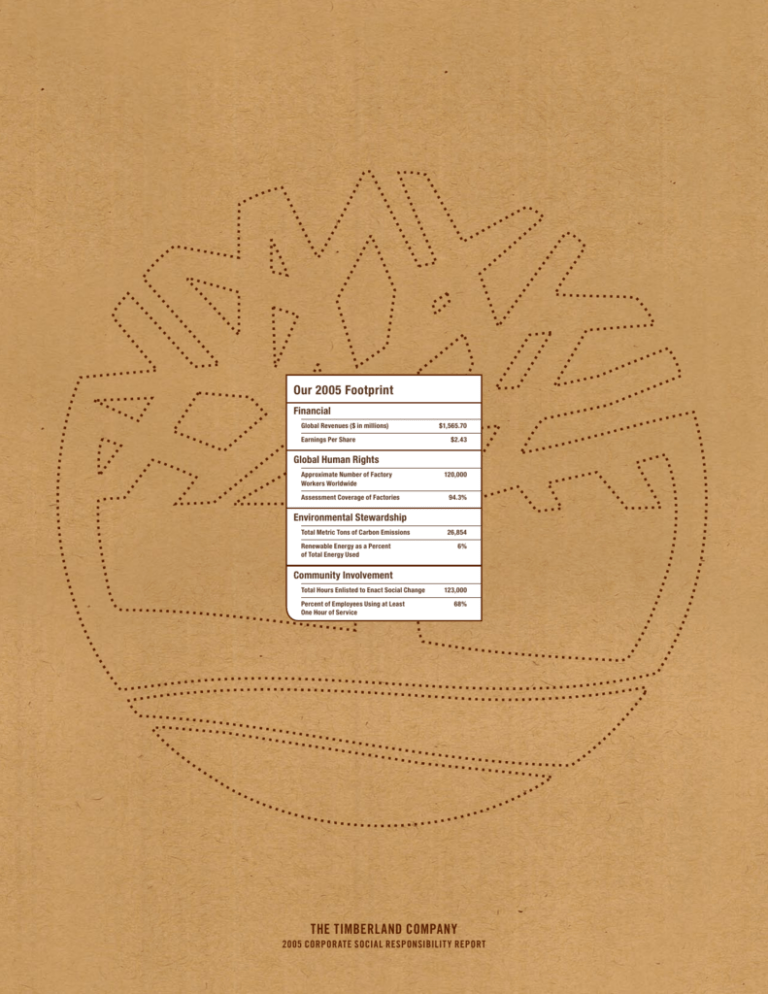

Our 2005 Footprint

Financial

Global Revenues ($ in millions)

Earnings Per Share

$1,565.70

$2.43

Global Human Rights

Approximate Number of Factory Workers Worldwide Assessment Coverage of Factories

120,000

94.3%

Environmental Stewardship

Total Metric Tons of Carbon Emissions

26,854

Renewable Energy as a Percent of Total Energy Used

6%

Community Involvement

Total Hours Enlisted to Enact Social Change

Percent of Employees Using at Least One Hour of Service 123,000

68%

THE TIMBERLAND COMPANY

2005 CORPORATE SOCIAL RESPONSIBILITY REPORT

the timberland company make it better ™

2005 csr report

Table of Contents

1.0 Letter from the CEO

2

2.0 The Timberland Footprint

3

2.1 Our Business Operations

3

2.2 Our Approach to Corporate Social Responsibility

4

CSR Defined

4

The Importance of CSR

4

Our Focus on CSR

4

Key Performance Indicators

5

2.3 Our Stakeholders

6

Who Our Stakeholders Are

6

How Our Report Was Developed

7

Our Stakeholder Summit 2006

7

3.0 Timberland Profile

8

8

3.1 Who We Are

How We Sell Our Products

8

Our Plans for the Future

8

Making Social Responsibility Part of Our Culture

9

Financial Performance

9

The Difficult Decision to Close a Factory

10

3.2 Growing the Business

11

A New Specialty Line: Miōn Aquatic Footwear

Borrowing from the Past: Timberland Boot Company 11

Our Recent Acquisition: SmartWool

11

11

™

™

3.3 What We Stand For

12

Responding to Issues

12

Responding to World Events

12

3.4 Social Responsibility: It Matters to Customers

Timberland in the News

Voices of Challenge: Seventh Generation, Inc.

13

13

14

4.0 Global Human Rights

15

15

4.1 Protecting Workers’ Rights in our Supply Chain

Our Code of Conduct

15

Our Influence in the Supply Chain

16

4.2 How We Assess Our Suppliers

17

Why We Assess Instead of Audit

17

Changes to the Process

17

How the Assessing Process Has Gone So Far

18

the timberland company make it better ™

2005 csr report

Table of Contents (continued)

4.3 Assessment Results

18

Taking Immediate Action

19

How Our Assessments Were Scored

20

4.4 Analyzing the Results

21

Assessing Our Assessors

21

Looking for Patterns

22

4.5 After Assessments—Partners in Remediation

23

4.6 Our Factories Around the World

25

4.7 How We Tackle Global Issues

26

Finding Local Partners Worldwide

26

A Focus on Working Hours

28

A Special Focus on China

28

4.8 Working Together to Tackle Tough Issues

4.9 Looking Forward

Sharing and Collaborating through the Fair Factory Clearinghouse

29

29

30

Our Goals for 2006

30

Voices of Challenge: Levi Strauss & Co.

31

5.0 Environmental Stewardship

32

5.1 Our Relationship to the Environment

32

5.2 How We’re Coping with Climate Change

33

Our Greenhouse Gas Inventory

33

How We Measure Greenhouse Gas Emissions

33

What We Plan to Do About Greenhouse Gas

34

A Focus on Renewable Energy

35

Impact of Transportation

37

5.3 Collaborating to Minimize Chemical Use

38

Plans to Eliminate PVC

38

Reconciling Commerce and Justice: Water-Based Adhesives

39

Restricting Substances from Our Products

39

5.4 Resource Consumption

40

Recycled Materials

40

The Case for Organic Cotton

40

Working to Save Our Forests

41

Sourcing Leather

42

5.5 Identifying the Ingredients for Social Responsibility

44

About the EcoFacts Label on Miōn Footwear

44

Introducing “Nutritional Labels” on Footwear

44

5.6 How We Measure Environmental Performance in Our Supply Chain

™

Keeping Score of Our Environmental Impact

5.7 Looking Forward

45

45

45

the timberland company make it better ™

2005 csr report

Table of Contents (continued)

Voices of Challenge: Patagonia, Inc.

46

6.0 Community Involvement

47

47

6.1 Working Together for a Strong Community

Making It Better in 2005

6.2 Our Approach to Community Service

47

47

The Case for “Themed” Service Events

47

The Results for 2005

48

Spotlight on Earth Day 2005

50

Spotlight on Serv-a-palooza 2005

51

Spotlight on Our Hurricane Katrina Efforts

52

6.3 Measuring the Impact of Community Service

55

6.4 Investing in the Community

56

Our Community Investments

56

6.5 Looking Forward

57

Voices of Challenge: The Home Depot

58

7.0 Timberland Employees

59

59

7.1 Our People Philosophy

Our Employees

59

Key Workforce Statistics

59

7.2 How We Manage Our Talented Staff

60

7.3 Employee Satisfaction

62

7.4 Diversity

63

7.5 What We’re Doing to Improve Health & Safety

64

New Health & Safety Initiatives for 2005

64

Addressing Health-Related Lost Work Days

64

Voices of Challenge: Harlem Children’s Zone

65

8.0 Report Scope

66

66

8.1 The Scope of this Report

The Basis of this Report

66

How this Report Was Verified

66

9.0 GRI Index

67

“There are a lot

of voices speaking

out about corporate

social responsibility

today.”

Letter from the CEO

There are a lot of voices speaking out about corporate social responsibility today. That’s a

good thing; it indicates a growing awareness of business’s ability to create impact—both

positive and negative—in our world. More good news is the fact that behind the voices there

are real, measurable, laudable efforts being made by companies around the globe to be

better citizens, to increase their positive impact, mitigate the negative and help solve the

problems that plague our society and environment.

Corporate social responsibility has become such an integral part of

In the pages of this report, you’ll hear Timberland’s voice, including

business, in fact, that we’ve all got it down to a science. We know which

information about some of the ways we’re working to take greater risks

standards we’re supposed to follow and what codes we must adhere to

and make a greater impact in our social responsibility efforts. Taking a

in order to earn our label as a “good corporate citizen.” What was once

risk can either result in success or failure, and I’m happy to report we’ve

foreign territory, creating partnerships and developing programs to meet

experienced both in our efforts over the past year. Why does this make

the needs that exist beyond our business walls, is a place we’ve grown

me happy? Success, obviously, means we’re making good progress in our

quite comfortable.

quest to Make it better, and we’ll continue to build on that progress

And there’s the challenge. Too often, with comfort comes complacency.

And while we’re busy being comfortable and complacent, the world

is spinning by us at full throttle with issues that aren’t addressed in

our standards and needs that haven’t yet made it onto our radar screen.

year over year. Failure tells me we’re not being complacent, that we are

stepping out of our comfort zone and applying our innovation and passion

to issues and areas of our world where it’s needed most. With every

failure comes an opportunity, and you’ll see we’ve identified plenty of

opportunities which we’ll pursue in earnest as we move forward.

And so, where it was once a great risk for business to step up and engage

To provide greater perspective

in matters of social justice, environmental stewardship and global

human rights, it’s time to take a greater risk—to step outside our comfort

zones and work to make our impact in these areas in ways that are

stronger, deeper, more powerful and more thoughtful. It’s incumbent

upon us to do this for two reasons:

• We have the ability. If we, as businesses, applied the same level of

innovation, passion and determination to corporate social responsibility

as we do to product development, sales and marketing, the results

In the business

world, “good

enough” rarely

is; we’re always

working to

make it better.

on the challenges we face—or

should be facing—as socially

responsible businesses, we’ve

asked five leaders to lend their

voices and insight to our report.

We asked them simply to provide

their unfiltered, unedited point

of view on the state of CSR—the

would be phenomenal. And why shouldn’t we? In the business world,

results of which you’ll see in the

“good enough” rarely is; we’re always working to make it better. There’s

“Voices of Challenge” sections

no reason why the standards should be any less for our CSR efforts.

• The world desperately needs it. Never before has the notion of

sustainability been so prevalent—the idea that we must consider the

of the report. Their thoughts are

meant to provide just that—a challenge—and to provoke action and

accountability among those of us who call ourselves good corporate citizens.

consequences of our actions not on tomorrow, but on the world we

Your voice matters just as much. If you’d like to weigh in on this CSR

leave behind for generations to come. And while making a conscious

discussion, comment on Timberland’s efforts or present your own

effort to reduce our negative impact on the environment and our

challenge to us, please email me at jswartz@timberland.com.

communities is a good first step, doing “less bad” isn’t enough. We’ve

got to start doing more good—to try to repair some of the damage that

Sincerely,

has already been done and invest in positive, sustainable change.

Jeffrey Swartz

President and CEO

The Timberland Company

the timberland company make it better ™

2005 csr report

2.0 The Timberland Footprint

[2.1] Our Business Operations

Timberland supply chain

table of

resource

suppliers

contents:

extraction

report

highlights

manufacturing distribution customerscorporate

facilitiescenters

retail

facilities

This table connects

the work that we do

in corporate social

responsibility to where

it occurs in our supply

chain. Think of it as

a graphic table of

contents for our 2005

CSR report.

tanneries

footwear

wholesale

distribution

centers

small

non-leather

franchisee

apparel

consumer

distributor

major

non-leather

licensed products

e-commerce

Factory Assessment Results pg. 18–22

Global

List of Factories Worldwide pg. 25

Human

Rights

Working Hours pg. 28

Environmental Assessments pg. 45

Use of Recycled Materials pg. 40

Organic Cotton pg. 40–41

Nutritional Label pg. 44

Climate Change pg. 33–37

Environmental Wood Procurement pg. 41

Stewardship

WBAs pg. 39

Renewable Energy pg. 35

Sourcing Leather pg. 42

Community

Involvement

PVC pg. 38

Impact of Transportation pg. 37

Community Service Statistics pg. 48–51

Service Highlights: Serv-a-Palooza, Earth Day and Hurricane Katrina pg. 50–54

Community Investments pg. 56–57

Employee Statistics pg. 59

Talent Management pg. 60

Employees

Recycled Material pg. 40

Employee Satisfaction pg. 62

Leadership Diversity pg. 63

Health & Safety pg. 64

Wood Procurement pg. 41

Hybrid Vehicles pg. 34

the timberland company make it better ™

2005 csr report

2.0 The Timberland Footprint (continued)

[2.2] Our Approach to Corporate Social Responsibility

Humanity. Humility. Integrity. Excellence. Everything we aspire to, everything we work toward each day is rooted in

our deep commitment to these four core values. They form the cornerstones of our beliefs and inform our strategic

approach to our platforms of Corporate Social Responsibility (CSR): global human rights, environmental stewardship,

community involvement, and employees. But we know that values and passion aren’t enough. Other commitments are

also essential to our mission to create sustained positive change around the world: strategic intent, integrated operating

systems, transparent measurement and industry collaboration. This report will discuss how we use these concepts in

our CSR efforts. But first, let’s begin with a basic understanding of how we see CSR at Timberland.

CSR Defined

Our Focus on CSR

To understand Corporate Social Responsibility at Timberland, it’s important

Using our view of CSR as a foundation—and keeping in mind all the

to understand first how we define it. We think that the Boston College

reasons why CSR is important—we are currently in the process of

Center for Corporate Citizenship did a good job of explaining the term.

refining our focus for our efforts in corporate social responsibility. After

Here is our four-part definition loosely based on the Boston College

internal planning sessions and consultation with our stakeholders, we

description1 of what a responsible corporate citizen will do:

have settled on these areas to concentrate our efforts to make positive

1. Minimize Risk: Reduce negative consequences of business

operations to stakeholders.

environmental and social change:

1. Business: Model Sustainability.

2. Maximize Benefits: Contribute to societal and economic well-being.

2. Community: Build Capacity for Sustained Social Change.

3. Be Accountable to Stakeholders: Build relationships with stakeholders

3. Global: Advocate to Improve the Human Condition.

and be responsive to their concerns.2

Our ultimate goal is to not only

4. Incorporate CSR into Decision-Making: Integrate values into all

operational decisions.

The Importance of CSR

Our efforts to be socially accountable do not exist in a vacuum. Social

accountability is an issue industry-wide…and worldwide. The emerging

importance of CSR in recent years can be seen in these factors:

• Communications: In an interconnected global community, information

is instantly available to every corner of the globe. Information technology

The very survival

of humanity and

our planet will

depend on the

ethical actions

of individuals

and corporations.

limit our footprint as an organization,

but also “Make it better” in places

we directly touch…and beyond.

And because we’re not the largest

organization in the marketplace,

we rely on our partnerships with

other organizations to amplify

our efforts.

This strategy provides a focus

also demands that a company be transparent and accountable in every

for our work. In local communities.

region in which it operates or sells products.

In the environment. In our supply

• Organizational Power: In this day of multinational corporations,

chain. Even in our own offices.

business can often have a greater impact than even local or national

It is a compass that guides our resources in a way that has the greatest

government. With this power—and scrutiny—comes an ethical

impact wherever we do business. We’ll continue to focus on these areas

responsibility to pursue profits in ways that don’t do harm.

as we chart our path towards corporate responsibility.

• Complex Global Needs: Poverty. National disaster. Global conflict.

Issues like these demand action. And accountability.

• Regulation: Corporate scandal and increased legislative and financial

oversight are having a profound effect on corporate behavior and

pushing companies to adopt a policy on corporate social responsibility.

• Legacy: The very survival of humanity and our planet will depend on

the ethical actions of individuals and corporations. That awareness

drives us to act responsibly every day.

1 http://www.bcccc.net/index.cfm?fuseaction=Page.viewPage&pageId=567&parentID=473

2 Timberland stakeholders are defined in section 2.3.

the timberland company make it better ™

2005 csr report

2.0 The Timberland Footprint (continued)

Key Performance Indicators

Visualize your dashboard. There are several gauges that tell you how fast you’re going. How much gas you have left.

Whether there’s a problem in the electrical system. Whether you’ve left the trunk open. Our Key Performance Indicators

are designed to give us exactly that kind of quick picture of how we’re doing in each of the four major functional

CSR areas: Global Human Rights, Environmental Stewardship, Community Involvement and Timberland Employees.

Some of these metrics may change as we further refine our system of CSR reporting. But we have tried to hit on the

indicators that best record Timberland’s efforts to “Make it better.” Explanations for these results are included in the

different sections within the report.

2005 key performance indicators

Indicator

Explanation

2004

2005

2006 Target

Percent of Factories Assessed

94%

94.3%

100%

Global Human Rights 3

Factory Coverage

Environmental Stewardship

Climate Change

Total Metric Tons of Carbon Emissions4 25,084

26,854

Verify

baseline

Resources

Organic Cotton as a Percent of Total Cotton Purchases

2.1%

2.1%

5%

Renewable Energy

Percent of Energy Purchased from a Renewable Source

4.3%

6%

10%

Benefit Utilization Rate (BUR): Percentage of employees 69.7%

68%

70%

Path of Service™

Program

who use at least one hour of service Hours Utilization Rate (HUR): The percentage of hours used for service compared to hours available Community Involvement

28.8%

31.1%

34%

Timberland Employees

Employee Satisfaction

Percent of Employees Satisfied with Position at Timberland

76%

74%

77%

Gender Inclusivity

Percent of Women in Management Roles

31%

35%

42%

Development Hours

Average Number of Training Hours per Employee

39

38

39

3 We are still working to develop more material metrics for our Global Human Rights Key Performance Indicators.

4 We are in the process of verifying a baseline for our greenhouse gas inventory. In the interim, we will report on absolute carbon emissions. For more information, see the section entitled “Our Greenhouse Gas Inventory”.

the timberland company make it better ™

2005 csr report

2.0 The Timberland Footprint (continued)

[2.3] Our Stakeholders

Timberland has a passionate commitment to engagement as a means of building sustainable, transparent and authentic

relationships that inform and enable sustainable social and environmental change. We believe in the power of this type

of engagement as a true vehicle of transformative change and industry leadership.

Who Our Stakeholders Are

Our stakeholders include groups or individuals who either can affect the achievement of Timberland’s business objectives…or are affected by them.

The chart below lists these stakeholders and describes how we work together on our CSR efforts.

Stakeholder Group

Engagement

Report Reference Section

• The Global Employee Survey

Employees

• Civic engagement: Path of Service™ program and Service Sabbatical

• Integrity Line (a 24-hour anonymous hotline)

• Surveys and focus groups

Customers

• Nutritional labels

Environmental Stewardship

• Civic engagement: Serv-a-palooza, Community Builders Tour, Community Involvement

Community Involvement

Timberland Employees

PRO Skills Tour

• Civic engagement: Community Builders Tour, Earth Day

Environmental Stewardship

Communities

• Employee membership on non-profit boards

Community Involvement

• Corporate investment

Global Human Rights

• Annual and quarterly reports

Shareholders

• Annual shareholder meetings

• Quarterly analyst calls, conferences, and regular meetings

• Factory assessments and capacity building

Suppliers and Factory Workers • Human rights initiatives

• Annual supplier summit • Direct collaboration or joint programs on CSR objectives

• Annual planning and review

Non-Governmental Organizations

• Focused feedback on CSR activities

• Meetings and conferences

Media

• Press releases

Government Entities

• Engagement on regulatory issues

• Meetings and briefings

• Adherence to laws where we operate

• Industry alliances and associations

Business Colleagues

• CSR ventures (consumer and community)

• Conferences and trainings

Timberland Profile

Global Human Rights

Environmental Stewardship

Global Human Rights

Community Involvement

Timberland Profile

Timberland Profile

Voices of Challenge

the timberland company make it better ™

2005 csr report

2.0 The Timberland Footprint (continued)

How Our Report Was Developed

Stakeholder input was invaluable in determining the content and focus

of Timberland’s 2005 CSR report. Immediately following the release of

our 2004 report, we reached out to our employees to gather feedback

about the report and how it could be improved. The key advice we

heard was that they wanted a report that was interesting to read with

Through these various methods, we have developed a report that we

hope meets all of these criteria. We’ll continue to refine our reporting

process—and we hope you’ll be a part of that effort. We invite you to

tell us how we can “Make it better” in our reporting by sending your

comments to csrinfo@timberland.com.

more data. At the same time, we also invited others to provide us

Our Stakeholder Summit 2006

with feedback. Business partners. Non-governmental organizations.

In the fall of 2006, we plan to host a one-day stakeholder summit,

Customers. Local communities. Here’s what these stakeholders wanted:

bringing 20 to 30 stakeholders together to tell us how we can “Make it

• A better explanation of Timberland’s business model,

• Information on our public policies, and

• The link between CSR and our bottom line.

better.” We’ll invite these credible, independent and recognized leaders

to join in a candid and informed dialogue based on our 2005 CSR report.

Our goal is to provide an environment that exemplifies Timberland’s

values. Builds community. Provides valuable feedback. Produces new

Timberland also pursued more formal reviews, through our membership

insights. Fosters innovation. And strengthens Timberland’s social and

in Ceres—a national coalition of investors, environmental groups and

environmental accountability, civic leadership and Bold Goal aspirations.

other public interest organizations who work with companies to address

such challenges as global climate change. (For more information, visit

www.ceres.org.) For our 2005 CSR report, a Ceres stakeholder group

reviewed both an outline and several drafts of the report. The critical

issues they identified as needing to be addressed included:

• Our work in Tanneries,

• Forward-looking goals, and

• Clarification of our assessment results.

the timberland company make it better ™

2005 csr report

3.0 Timberland Profile

3.1 Who We Are

Timberland designs, develops, engineers, markets

and distributes premium quality footwear, apparel and

accessories products for men, women and children

under these brand names:

• Timberland®

• Timberland PRO®

• SmartWool®

• Timberland Boot Company™

• Miōn™

Functional performance. Classic styling. Lasting protection from the

elements. We believe these features make our products an outstanding

value. We also think they distinguish us from the competition.

How We Sell Our Products

Our Plans for the Future

Our products are sold throughout the United States, Canada, Europe,

We want to become the brand of outdoor footwear, apparel and accesso-

Asia, Latin America and the Middle East. How? Through independent

ries that men, women and children around the world who are inspired by

retailers, better-grade department stores, athletic stores, licensees

the outdoors choose first. Quite simply, that’s our primary goal. We have

and distributors. We carefully select national retailers we believe can

a simple strategy for achieving it:

reinforce the high level of quality, performance and service that we want

consumers to associate with Timberland.

1. Target our consumers more specifically and enhance our technology

We also do some of our own retailing through Timberland® specialty

2. Increase our worldwide market share in the apparel business by

worldwide to strengthen our core footwear business.

stores, Timberland® factory outlet stores, timberland.com and franchisees

taking advantage of our rugged heritage and continuing to work to

in Europe. All are dedicated exclusively to selling Timberland® products.

earn our customers’ trust.

At the end of 2005, we had 21 specialty stores and 57 factory outlet

stores in the United States and 117 specialty stores and shops and

28 factory outlet stores in Europe and Asia. In 2005, we also launched

the Timberland® brand in China and established a new subsidiary

in Switzerland to offer products directly to customers. Overall, U.S.

Wholesale5 represented 42.1% of 2005 revenue, U.S. Consumer Direct6

represented 13.6%, and International7 was 44.3%.

3. Develop new brands such as SmartWool®, Timberland Boot

Company™ and Miōn™.

4. Expand our geographical reach.

5. Drive operational and financial excellence.

6. Set the standard for service in the communities in which we live

and work.

7. Be a global employer of choice.

5 Includes independent retailers, better-grade department stores, outdoor specialty stores, national athletic accounts, general sporting goods retailers and other national accounts

6 Includes Timberland® specialty stores, Timberland® outlet stores and timberland.com

7 We sell our products internationally through operating divisions in the United Kingdom, Italy, France, Germany, Switzerland, Spain, Japan, Hong Kong, Singapore, Taiwan, Malaysia and Canada. Timberland® products are sold elsewhere

internationally by distributors, franchisees and commissioned agents, some of which also may operate Timberland® specialty and factory outlet stores located in their respective countries.

the timberland company make it better ™

2005 csr report

3.0 Timberland Profile (continued)

Making Social Responsibility Part of Our Culture

Financial Performance

Stakeholders who read our 2004 Corporate Social Responsibility report

Our principal strategic goal is to become the authentic outdoor brand of

wanted to know just what we were doing to integrate corporate social

choice globally. To deliver against our long-term goals, we are focused

responsibility into our culture at Timberland. A successful CSR strategy

on driving progress on key strategic fronts. These include enhancing our

can’t operate at the fringes of the organization. It needs to be part of

leadership position in our core footwear business, capturing the opportunity

every decision we make. And it needs to continuously evolve to keep up

that we see for outdoor-inspired apparel, extending enterprise reach

with the changing business landscape.

through development of new brand platforms and brand building licensing

At Timberland, we think a top-down, bottom-up approach is the best

way to integrate social and environmental awareness into all levels of the

company. At the top of our organization, we have a CEO who is deeply

committed to the concept of “Commerce and Justice”—that is, a

responsibility to generate revenue while at the same time making positive

changes in the communities and environment where employees live and

arrangements, expanding geographically and driving operational and

financial excellence while setting the standard for commitment to the

community and striving to be a global employer of choice. Some high

level views of our financial performance in 2005 are included in the

graphs below. Please see our 2005 annual and 10K report for more

details on our financial performance.

work. This set of values naturally trickles down to influence all company

decisions—major and minor.

Revenue

And from the bottom up? We do everything we can to make sure that

2000

$2,000

Soon after they’re hired, every new employee at our corporate office

performs a day of service so that right away they can understand how

we partner with local communities to “Make it better.” In addition, these

new employees are exposed to our values in the form of employee-initiated

Dollars in Millions

every employee we hire is passionate about corporate social responsibility.

charity drives, volunteer service fairs, environmental “lunch and learns”

1500

1,500

1000

1,000

1,501

1,184

1,566

1,191

100,000

50,000

2001

2002

2003

2004

2005

in our cafeteria. We strive to be the Employer of Choice by attracting

people who want to do well while they are doing good. For the company.

Net Income

2000

1500

1500

1000

1000

200,000

$200,000

200,000

Public Recognition

• Eighth consecutive year on Fortune magazine’s “100 Best Companies

500

500

to Work For” list, ranked #38 and placed

in their first Hall of Fame.

0

• One of the inaugural recipients of Winslow

Management’s “Green2”

0

Dollars in Thousands

2000

For the community. And for the environment.

2.5

150,000 2.0

152,693

150,000

150,000

100,000

100,000

106,741

164,624

1.5

117,879

100,000

95,113

1.0

50,000

50,000

50,000

00

0

0.5

Award for making a positive contribution to the environment as well

2001

2002

2003

0.0

2004

2005

as to shareholders.

• S eventh consecutive year as one of Forbes magazine’s “Best Big

Companies in America.”

2.5

2.0

2.0

1.5

1.5

1.5

• Named one of Business Ethics magazine’s “100 Best Corporate

Citizens” for sixth consecutive year.

• Listed as one of Industry Week magazine’s “50 Best-Managed

Manufacturing Companies” for the second consecutive year.

2.47***

2.14

1.62

1.33

1.0

1.0

1.0

0.5

0.5

0.5

• S econd consecutive year on list of “100 Best Companies for Working

Mothers” by Working Mother magazine.

Diluted EPS*

$2.5

2.5

2.0

0.0

• S elected as one of New Hampshire’s “Best Companies to Work For”

by Business NH magazine.

• Received Clean Air—Cool Planet 2005 Climate Champion Award.

0.0

0.0

150,000

1,342

500

500

00

and the Community Impact Center which highlights recent CSR activities

200,000

2001

1.18**

2002

2003

2004

2005

* EPS have been restated to reflect 2-for-1 stock split in May 2005.

** Before cumulative effect of accounting change of $0.07.

*** Excludes restructuring charge of $0.04.

0

the timberland company make it better ™

2005 csr report

10

3.0 Timberland Profile (continued)

The Difficult Decision to Close a Factory

At Timberland, we believe it’s possible to do well and do good—that is,

Making the Link: Corporate Social

Responsibility and the Bottom Line

create a profit for our shareholders and have a positive impact on local

communities. Sometimes, though, those concepts get out of balance.

Doing well. Doing good. Can both be done at

When they do, it’s simply impossible to avoid making a painful choice.

the same time? In other words, is it possible

That’s exactly what happened at our facility in Isabela, Puerto Rico. For

24 years, the plant had manufactured Timberland® shoes. But when

to run a profitable business and still be

a tax benefit expired, our Puerto Rico production costs were no longer

responsible? To the environment. To employees.

competitive. A strategic decision was made to consolidate operations in

our Dominican Republic-based facility. It was a decision that left 316

To the local community. To the whole notion

hard-working, dedicated members of our team in Isabela without jobs.

of human rights.

For them, the decision was profound, painful and life-changing.

At Timberland, we believe the answer is yes.

Supporting Those Who Were Impacted

In fact, the foundation of our entire operations

Timberland’s CEO, COO, board members and employees made the trip

strategy is based on this premise. Commerce

to Puerto Rico for the plant closing in December 2005. We did our best

to cushion the impact of the facility closure by providing affected members

and Justice. Well and good. And we’re not the

of the Timberland family with a generous severance package that

only ones who believe in the viability of doing

included retirement enhancements for those near retirement age, skills

retraining and access to outplacement and career counseling. While

business in this manner. Innovest Strategic

we’re humbled that other organizations have asked for assistance in

Value Advisors, a New York-based multinational

modeling their programs after our benefits package, we deeply regret

investment research and advisory firm, recently

that such a package was necessary.

conducted a study of the financial performance

Continuing Our Commitment to the Community

of what they called the 2006 Global 100 Most

Outstanding craftsmanship. Service. And dedication. Our Isabela factory

Sustainable Corporations in the World. Using

workers provided that to Timberland for 24 years. In recognition of these

gifts, we have committed ourselves to providing a lasting civic tribute to

the MSCI World Index, which gathers data

our former employees. In 2006, a gift of $250,000 will be used to address

from around the world, Innovest discovered

one of the community’s critical needs: childhood athletics.

something interesting. Over a five-year period,

the socially responsible companies didn’t

just measure up financially. They actually

outperformed the World Index by 7.11%.

As you can imagine, at Timberland we’re happy

whenever we can do both. Well. And good.

the timberland company make it better ™

2005 csr report

11

3.0 Timberland Profile (continued)

[3.2] Growing the Business

The job of any business is to grow. With this as a goal, we think 2005 was a pretty solid year for Timberland. We

delivered record revenue of nearly $1.6 billion, record earnings, strong cash generation and improved returns for our

shareholders. But these are not the only metrics by which we measure ourselves. When the Timberland team speaks to

customers, employees, analysts and NGOs, we never just talk about Commerce. It is always accompanied by Justice.

Commerce and Justice. Meaning that in addition to revenue growth, Timberland has a parallel goal, and that is to

continually “Make it better.” For our employees. For our customers. And for the world we all share.

That’s why, when we start a new business venture, making money is not the sole condition we require. We want to

make sure our partners fit into our social strategy, too. In 2005, we launched three new business ventures we’re pretty

excited about.

A New Specialty Line: Miōn™ Aquatic Footwear

Sailing. Rafting. Fishing. Wet/dry adventures of all natures. That’s what

the Miōn™ brand is all about. This new and distinct brand of footwear is

focused on people who play on and around water.

At the same time, Miōn™ strives to set an

example as a steward of our planet’s

limited resources. By offsetting

100% of the energy used for

manufacturing with Green-E certified

best traditions of the post-industrial age with earlier ideals of craftsmanship.

All wrapped up in a culture of strengthening the local community. How?

Through targeted civic activities and programs at our London store. It’s just

one of the ways that we’re trying to “Make it better” wherever we operate.

Learn more about this new brand from Timberland:

www.timberlandbootcompany.co.uk

Our Recent Acquisition: SmartWool

A focus on making positive change in the world. Brands built on

renewable energy. By using a distribution center 60% powered by the

authentic products. Communities organized around worthwhile missions.

sun. By pursuing innovative clean materials in manufacturing. By

Timberland and SmartWool. They fit together like, well, boots and socks.

leveraging recycled materials in its marketing and selling tools. And

There’s a lot more to our recent acquisition than the natural match-up of

by launching the first EcoFacts label, so that you’ll know exactly how

our products, though. We wanted to grow with a company whose values

Miōn™ works to protect the environment.

fit with us, too.

Did we pique your interest? If so, go to www.mionfootwear.com

Founded only eleven years ago by a couple of ski

for more information.

instructors struggling to keep their feet warm on

New England’s chilly slopes, SmartWool

Borrowing from the Past:

Timberland Boot Company™

Quality. Authenticity. Attention to detail. Classic design that evolves with

the seasons. Think that’s all part of days gone by? Not at Timberland.

A philosophy of remembering our history while keeping an eye on the

future plays an important role in everything we do.

utes socks, apparel and accessories to more than 2,000 better

outdoor specialty stores throughout

the U.S., and to international distributors. First, we began carrying some

of their products. Then we partnered with them to develop Timberland®

performance footwear with SmartWool® linings. Along the way, we got to

know their ethic. We liked what we saw. A lot. For example, 10% of every

Take, for example, a new

brand that we launched called

Timberland Boot Company™—

a line of workwear-inspired

footwear and apparel for younger,

more style-conscious consumers

in London. In developing the

Timberland Boot Company

today designs, develops and distrib-

™

brand, our goal was to blend the

sale on SmartWool’s Web site goes to the SmartPrint Advocacy Fund

which gives to organizations that promote environmental stewardship, healthy

lifestyle choices for youth, and responsible outdoor activity participation.

This is just one of many initiatives to effect positive change in the world

which they live, play and do business. Together, we think we can do

even more toward sharing a vision of sustainable living.

Did we “sock” you in? Learn more at www.smartwool.com.

the timberland company make it better ™

2005 csr report

12

3.0 Timberland Profile (continued)

[3.3] What We Stand For

Current events. Public policy. How we interface with the world around us. The way that we deal with political issues is

important for your understanding of who we are. In a nutshell, we always try to do the right thing and be honest about

who we are and where we stand.

Responding to Issues

Responding to World Events

Our commitment to integrating social responsibility into our business

President John F. Kennedy once said that, when we’re judged by history,

seems to attract employees who have a passion for making things better.

it will be looking at “whether in our brief span of service we fulfilled our

We encourage our people to take a stand on the issues that matter. That

responsibilities.” We believe that there’s no better test of our sense of

affect their lives, here and around the world.

responsibility than a time of crisis. We’re proud of the Timberland employees

Timberland does not make contributions, directly or

indirectly, to any political party or candidate, in any

country, even if such contributions are legal in

that country. In addition, we

do not give contributions to

lobbyists or political action

committees (PACs). We

are members of many trade

associations, such as the

who have stepped up to try to “Make it better” for people in need.

Helping Stem the Genocide in Darfur

Rwanda. Armenia. The Holocaust. History continues to repeat

itself. In Darfur, a region of western Sudan, a tragedy is occurring

that very few people know about. Genocide. Systematic killing on

the basis of race. More than a million people have been driven

from their homes. Their crops ravaged. Their water supplies

poisoned. Their people raped, terrorized and murdered.

Outdoor Industry Association

Although we don’t make or sell our products in this region,

(OIA), the Federation of Euro-

we felt compelled to take action as a member of the global

pean Sports Industries (FESI)

and others.

We neither encourage nor

discourage our employees

community. At Timberland, we’re passionate about making

positive changes…and nowhere is the need for change

more urgent than in Darfur. In this spirit, a dedicated

team of our employees spearheaded an effort to:

from contributing personal

• Design a boot—“Stomp Out

financial support or personal

Genocide”—as a vehicle to

service to any domestic

communicate urgency

or international political

and compassion for

nominee, candidate, party

our brothers and

or non-profit organization.

sisters in Darfur.

However, we will not, under

• Develop a tee-shirt

any circumstances, reimburse

and hang tag to

employees for personal political

raise awareness

contributions.

and funds for Darfur.

• Lead a product seeding

But all that doesn’t mean we’re not politically active. We do

take a stand on political issues that might impact our business.

For example, in 2005 we became active in the European Community’s

leather footwear anti-dumping investigation. While we are disappointed

effort to raise awareness and activism

regarding this issue among policymakers, elected officials, journalists

and socially active entertainers.

by the decision of the European Commission to impose provisional duties

Through actions like these, we hope to mobilize citizens and offer hope

on leather upper footwear imported into Europe from China and Vietnam,

for the oppressed people of Darfur.

we will continue to work with the Commission to put forth our position

with a view to finding a constructive solution.

For a daily monitor of news and opportunities to affect change,

please visit www.savedarfur.org.

the timberland company make it better ™

2005 csr report

13

3.0 Timberland Profile (continued)

Serving the Victims of Katrina

community service. Mobilizing product on behalf of AmeriCares.

Sometimes, emergencies strike closer to home. In 2005, no crisis

And working together to help heal those in need.

facing the U.S. was greater than Hurricane Katrina, which slammed

into the Gulf coast in August. Across the country and around the world,

How We are Coping with Climate Change

the response was far-reaching and immediate. We’re proud of the 11

Climate change is real and alarming. We don’t like it, but we know we

Timberland employees who traveled to the Gulf coast to help others

contribute to greenhouse gas emissions, too. That’s why we’re working to

in need.

reduce these emissions wherever we can by improving energy efficiency

As a result of this experience, we have established mini-sabbaticals

in partnership with the Red Cross, to identify opportunities to support

on-site recovery, clean-up, relocation and long-term efforts through

and increasing the use of renewable energy. We are streamlining the

Timberland transportation network for more environmentally friendly

performance. We also launched a cash incentive program to encourage

employees to use a low-emissions hybrid vehicle when they commute.

[3.4] Social Responsibility: It Matters to Customers

How important is social and environmental responsibility to the consumer? The Natural Marketing Institute recently

conducted a study measuring just that. They found that almost 90% of American consumers agreed that it’s important for

a company to look beyond profits, to consider its impact on the environment and society, too. Just over 70% indicated

that knowing a company is mindful of that impact makes them more likely to buy its products or services. And nearly

half stated that they’re more likely to buy stock in a company that’s responsible than in one that’s not. This research

supports what we’re experiencing in our own business and in our industry: namely, public awareness of—and expectation

for—corporate social responsibility is on the rise. The media has reacted accordingly. With increased coverage of

Corporate Social Responsibility (CSR) leaders, programs and issues.

It’s a story that clearly is resounding with business partners and

consumers alike. The fact that

more mainstream media outlets are

telling the story demonstrates how

much the notion of corporate social

responsibility is finally catching on.

Of course, at Timberland, we don’t

conduct our business responsibly

and ethically just to earn plaudits

from the press. We made a commit-

Timberland in the News

Environmental stewardship. Community investment. Global human

rights. In 2005, roughly 75% of Timberland’s total corporate coverage

was focused on these CSR efforts. The “story” of CSR has long had its

place in niche media and special interest publications. Recently, though,

ment to doing well and doing good

long before the national media

began covering the phenomenon.

It’s as much a part of our business

and our heritage as building boots.

the story of our commitment to being a good corporate citizen was told

We are mentioning it here because we’re glad

in global outlets, such as:

to see that CSR is an idea whose time has come.

• TIME magazine

• The Wall Street Journal

• U.S. News & World Report

• CBS TV

• Fast Company

In the media. And in the marketplace. We’re

hoping that this level of attention will help us

develop a dialogue with our consumers. One

based on shared values and a mutual interest in

the well-being of the world around us.

Voices of Challenge: SEVENTH GENERATION, INC.

Creating New Possibilities

People often ask me what I think a “responsible business” should be. I have a simple

answer: I think it should be about believing in endless possibility and embracing the fact

that tomorrow doesn’t have to be the same as today.

That’s how I lead my own company: With a

belief that anything is possible when we are

thoughtful and inspired.

Why would anyone want to do anything less?

As I survey the landscape of well-meaning organizations from land

conservation and global warming groups to animal rights, health care

With our planet at greater risk today than ever

reform, hunger, and poverty non-profits, I see everyone working from

before, I know that we can harness this attitude

their own disconnected bunker. No common vision unites us. To help

to seize the opportunities to create a better

create that common vision, business needs to get clear that being

future than we’re capable of imagining today.

responsible requires three things:

We must. Because while companies celebrate reduced CO2 emissions

in an effort to slow global warming, reduce reliance on sweatshops, use

a smaller number of toxic chemicals in our products, pay less obscene

wages to CEO’s, or keep retail giants in check—that’s just less of the

same. And quite frankly the world is way too screwed up and in too

much danger for us to aspire to simply do less damage.

1. A commitment to redefining the purpose of business and thinking

about the next 100 years, not the next 100 days.

2. Engaging directly in progressive public policy. Sustainable development

is not just about eliminating environmental impacts. It’s about systemically

ensuring that social justice and equity are made to work for all people.

To accomplish this, progressive businesses must engage directly in

We need a vision of the world we want to create after we reverse global

public policy, something they’ve traditionally left to traditional “old

warming, eliminate toxic chemicals and transform Wal-Mart into the world’s

economy” companies. No more. We must lobby aggressively for publicly

leading creator of lower class wealth. We need to pursue possibilities

financed elections, a health care system that is a right and not a privilege,

that fulfill our highest potential and ensure forever a sane, safe and

a tax code that reverses the flow of wealth from the poor to the rich,

decent place for our children and grandchildren to play. We need to

and full cost accounting that stops the externalization of health and

envision a world yet to be.

environmental costs. Without progress in these areas there will be no

future in which any company can claim it is “responsible.”

And quite frankly the

world is way too screwed

up and in too much danger

for us to aspire to simply

do less damage.

3. Ensuring that everyone who works is provided the opportunity to

reach their highest potential as a human being. This is not about

developing skills or advancement opportunities. This is about creating

a corporate culture that thinks systemically, believes there are no limits,

and educates its team members to see that 99% of what’s possible lies

outside the patterns, systems, and thinking that have gotten us where

we are today. We must foster a culture where everyone is actively

engaged in a process of discovery and growing all the time. For it is

only by making who we were yesterday less important than who we

will become tomorrow that we can we hope to be the change the

world needs us to be.

Jeffrey Hollender,

President & Chief Inspiration Officer

Seventh Generation, Inc.

the timberland company make it better ™

2005 csr report

15

4.0 Global Human Rights

[4.1] Protecting Workers’ Rights in our Supply Chain

Fair. Safe. Non-discriminatory. We strongly believe people everywhere deserve those basic rights in the workplace. It’s

not always easy to accomplish—especially when you’re dealing with more than 120,000 workers in 33 countries worldwide.

Because we own only one of the approximately 227 factories that manufacture Timberland® products, we don’t always

have direct control over the practices of our vendors and suppliers. But we do work hard to choose business partners

who share our beliefs, then work with them to operate under the standards set forth by our Code of Conduct. Protecting

the rights of workers. Improving working conditions. And collaborating with non-governmental organizations and agencies,

to help raise labor standards, one community at a time.

The goals for our Code of Conduct team in 2005 were to (1) Improve lives through innovation, (2) Drive workplace

quality and make sure it can be sustained and (3) Broaden industry collaboration.

Our Code of Conduct

Timberland is known for its casual boots, shoes, clothes and gear. But

there is something we’re very formal about: our Code of Conduct. About

a decade ago, we decided that we needed a Code of Conduct written

into all legal agreements, to make sure our vendors, tanneries and major

suppliers “Make it better” for all workers, by offering employment that:

• Is voluntary and free of harassment and abuse,

• Prohibits child labor, and

• Meets standards for free association, labor hours, compensation,

health and safety, and environmental compliance.

We also monitor our business partners, agents, licensees and distributors

to make sure these standards are being upheld. Language is no barrier.

Our Code of Conduct has been translated into more than 20 languages

and is provided to factories in their local language.

the timberland company make it better ™

2005 csr report

4.0 Global Human Rights (continued)

Our Influence in the Supply Chain

Our stakeholders told us they want Timberland to be more transparent

with regard to our supply chain, and to describe the level of influence our

supply chain: Sphere of influence

supply chain: footwear

resource extractionsuppliersmanufacturing facilities

brand and others have within that channel. We’re using this Corporate

Social Responsibility report to do just that. It’s helpful to understand that

we have three types of relationships in the supply chain: the factory we

major

non-leather

own, direct influence and indirect influence. The graphics to the right

illustrate these relationships as they are found in our Footwear,

DR footwear

distribution

center, then on

tanneries

Apparel and Licensee/Distributor supply chains.

Our Own Factory

The only factory in our supply chain that we own and control is our

to consumer

all other footwear

small

non-leather

footwear factory in the Dominican Republic. The rest of the factories

are contract facilities that have a written agreement with us (or an

intermediary) to manufacture products based on Timberland specifications.

In these relationships, Timberland influences the environmental and

Supply chain: Apparel

resource extractionsuppliersmanufacturing facilities

social impacts of the factories through different methods, either directly

or indirectly.

Direct Influence

major

suppliers

distribution

Direct influence means that we perform periodic assessments and

center, then on

remediation on site to determine workplace safety and environmental

performance.

to consumer

apparel

small

suppliers

Indirect Influence

Indirect influence means that Timberland does not perform an assessment

on the factory, but can influence it through other means. This relationship

often occurs with suppliers to our manufacturing facilities. In this situation,

our contract stipulates that we have the ability to refuse product from any

Supply chain: licensee and distributors

resource extractionsuppliersmanufacturing facilities

organization that is supplied by a company that violates the global human

rights or environmental standards set by our Code of Conduct. Through this

agreement, we can influence the behavior of our suppliers.

distribution

all

suppliers

center, then on

licensee and

distributor factories

to consumer

Timberland owns this facility and has control of decision making

Direct influence through assessments and remediation

Indirect influence through on-site visits (no official assessments performed)

Indirect influence through dialogue and purchasing decisions

16

the timberland company make it better ™

2005 csr report

17

4.0 Global Human Rights (continued)

[4.2] How We Assess Our Suppliers

What do degrees in sociology, public relations, law, mechanical engineering and chemical engineering have in common?

Or what about the ability to speak English, French, Japanese, Turkish, Cantonese, Mandarin, Spanish and Thai?

They’re all part of the skills, talents and experience of the assessor team at Timberland. We believe it is important for

us to structure an assessment process that taps into this endless well of talent. This is one reason why we changed

our audit process in 2005 to engage our workers in a more meaningful way. But it wasn’t the only reason.

Why We Assess Instead of Audit

In 2005, we decided that we wanted to take a new approach to

monitoring our factories. While our process was making improvements

for our workers, we were finding that sometimes the improvements

wouldn’t last. Upon reflection, we realized that nothing necessarily

The shift to assessments has also introduced the concept of “Immediate

Actions.” When specific violations are found, such as forced labor,

harassment, or pregnancy testing, factories are immediately given the

“high priority” designation and an immediate response is required. Additional detail about Immediate Actions is included later in this section.

changes in a factory when an audit takes place—change occurs during

We’ve also formalized the corrective action plan for managers (known

the remediation process. Lasting change was happening when the

as the Management Action Plan [MAP]). Called “Action Planning,” the

factory took ownership of the situation and addressed the root cause of

process provides assessors with step-by-step instructions for working

the problems, not just the symptoms. The best way to create a lasting

with factory managers to achieve lasting improvement. (The chart below

impact was through collaboration. So we made that the focus of our

has further details.)

process. Consulting and partnering with our suppliers, rather than

policing them. Working together with factories to improve workplace

quality. Making sweeping, systemic changes. From the ground up.

Action Planning Process

ACTION PLANNING

That’s why we’ve moved from audits to assessments. Assessments are

of just asking for compliance. We believe our new assessment process is

a much more effective tool for creating positive, sustainable change.

ASSESSOR

about collaboration, worker involvement and providing remedies instead

Step 1

cause of whatever the issue might be. This means our assessors group

individual findings into larger root causes and focus their remediation

efforts on these larger systematic problems at the factory.

Step 2

Finding List

Step 3

Root Causes

1. Procedure/Policies?

Describe Current/Future State

2. Who is involved?

3. Communication/Trainings?

Step 5

FACTORY

process. We’ve revamped our factory evaluation to focus on the root

Step 8

Review and

Approve

Step 4

Changes to the Process

To do this, we had to take a step back and redesign our monitoring

Assessment

Step 6

Step 7

Cause & Effect Analysis

Why is the current state the way

it is? (Brainstorm)

4. Measurement?

1. Corrective

2. Communication

Identify Necessary Actions

3. Resistance

4. Measurement

Timeline/Summary

In addition, we have employed the “participatory approach” to the interviews

5. Celebration

we conduct with factory workers during the assessment process. Using

the participatory approach, our sessions are facilitated, free-flowing

conversations as opposed to formal question and answer interviews.

Whatever changes we make in these processes, though, you may be

Whether in groups or with individuals, facilitation tools/methods are

sure that the foundation of our global human rights work remains rooted

used to create a non-interview atmosphere and spark active dialogue/

in our Code of Conduct.

participation of the workers. Participatory methods involve sets of tools

used for different purposes: issue identification; ranking; causal analysis and

action planning. Such tools engage the workers by having them participate

in role playing or in exercises of mapping, sequencing, listing, comparing,

counting, scoring, sorting and linking matters of concern/interest.

the timberland company make it better ™

2005 csr report

18

4.0 Global Human Rights (continued)

How the Assessing Process Has Gone So Far

We began implementing our new assessment process late last year

and have had some successes…and some failures. One bright spot has

new MAP process on-site. Our assessors now spend two to five days

on-site at the factory (it used to be only one or two). This way, they have

a deeper understanding of the situation at each factory.

been our ability to gather more information directly from workers using

Probably the biggest challenge with the new process is that we can’t

the participatory approach. This method encourages engagement and

compare the new data with data from previous years. And in order to

gets workers involved. This level of comfort helps them to open up—and

measure our impact, we need to be able to identify trends. We are

allows our assessor to learn more about their situation. In fact, these

committed to new process, however, and are confident that we’ll be

discussions have often turned into informal conversations with the assessor

able to report a more concrete analysis in our next Corporate Social

after the session is over.

Responsibility report.

But as in any new process, there’s a learning curve. It took longer than

In the meantime, we continue to shift the focus from reactive to proactive.

we expected to train both our assessors and those who were being as-

From policing to collaboration. And from management to worker.

sessed. It took time to adjust. But we continue to train. To educate. To

Ultimately, placing the worker at the center is what Timberland’s Code

improve. And we’ve adjusted our expectations. We’ve allowed more time

of Conduct is all about.

to introduce the concept to factory management and work through the

[4.3] Assessment Results

Timberland is a multinational company. Last year, our products were made in 33 countries, by more than 120,000

workers — with over 40% of these workers in China and 27% in Southeast Asia (Cambodia, the Philippines, Thailand

and Vietnam). Plus, our supply chain includes approximately 227 factories in five of the seven continents. That’s a

lot of territory to cover, but it’s important that we cover it.

Yet, even given the enormity of the project, we managed to roll out our

Geographic Dispersion of Factory Workers

0.5%

5.4%

new assessment process around the globe in the second half of last

year—to 214 of these factories, or 94% of our active factories. What

3.3%

8.4%

Greater China

East Asia

1.0%

3.7%

40.6%

9.1%

27.1%

1.0%

about the other 13 factories? (Good question—we weren’t satisfied with

that coverage either). It is important for us to have a full understanding

Southeast Asia

why we did not hit our stated goal of 100%. For several of our sched-

Indian Sub-Continent

uled assessments, there was a massive flood that prohibited entry to the

North Africa and Middle East

region where the factory was located. In another situation, there was a

Sub-Saharan Africa

car wreck involving some of our external auditors. (Fortunately, none of

Europe

the assessors was seriously hurt.) For additional detail, please see the

US and Canada

“Missed Assessments in 2005” sidebar below. We are happy to report

Mexico, C. America, Caribbean

that by February 2006, all 13 of the remaining factories had received

South America

their rescheduled assessment.

Missed Assessments in 2005

CountryNumber of Factories

ReasonDate Receiving Assessment?

India

9

Series of assessments missed due to major flooding in the area

8 in January 2006,1 in Feb 2006

Pakistan

3

Series of assessments missed due to major flooding in the area

All in January 2006

USA

1

Assessors traveling to this factory were involved in a car accident January 2006

which caused them to postpone assessment

the timberland company make it better ™

2005 csr report

4.0 Global Human Rights (continued)

Taking Immediate Action

One of the cornerstones of our new assessment process is the identification of “Immediate Actions.” These violations

are the most serious, pose the most risk to the worker and generally cannot be tolerated. They are violations

of basic human rights. To be treated humanely. To be treated equally. And to be treated with respect and honesty.

The list of immediate actions includes:

Frequency of Immediate Actions

3%

2%

2% 1%

3%

4%

17%

49%

19%

Immediate ActionDescription

Working Hours

Total hours exceed 60 hours per week, 12 hours per day, or more than 6 days consecutively

Ethics

Falsification of documents, willful violation of law, unethical business or financial practices

Minimum Wage

Legal minimum wage not being paid

Harassment Verbal, physical, or psychological

Discrimination

Based on race, religion, gender, color, age, or other personal characteristics

Minimum Age

Under the country minimum age or 16, whichever is higher

Forced Labor

Prison or debt-bonded labor

Refuse Assessment

Factories refuse an assessment

Pregnancy Testing

Performed or results used in workplace for employment applications, promotions, etc.

Freedom of Association

Denied the right to freely associate and bargain collectively

19

the timberland company make it better ™

2005 csr report

20

4.0 Global Human Rights (continued)

If an assessor finds one of these violations, the factory receives an

These scores are based on eight factors. For example, the risk associated

automatic “High Priority” designation—alerting Timberland management

with the findings. The skills and capabilities of the suppliers’ management

of the severity of the violation(s). He or she then asks the factory for an

team. And their willingness to go above and beyond what’s expected of

immediate commitment to resolve the problem as quickly as possible. With

them. The results for 2005 are illustrated in the pie chart below. As you

that commitment, the supplier’s remediation activities and progress are

can see, over 50% of our factories fall into the “High Priority” category.

monitored closely by the assessor and the Timberland sourcing manager.

These results are far from acceptable, but they are to be expected as we

Through the remediation process, our assessors aim for sustainable

roll out our new collaborative process. As we put our Management Action

change to improve the lives of the workers. We will invest the necessary

Plans and remediation plans to work in 2006, we expect to see improve-

time, energy and resources to see that the factory’s remediation plan is

ments over last year and will report our findings in the next CSR report.

successful. However, when a factory fails to commit—fails to invest in a

sustainable solution—alternative sourcing is our only choice.

High Level Assessment Results

Assessors identified 176 violations requiring immediate action among

the 214 factories that received an assessment in 2005. In some cases,

25%

assessors found more than one Immediate Action per factory. Three

Partner

issues were consistently found in the assessment results—accounting

for 85% of the “High Risk” violations:

Acceptable

54%

High Priority

• Working Hours

21%

• Ethics

• Wages

In 2006, we’re dedicating extra resources to root out the underlying

We also plan to improve something else—consistency around the globe.

cause of these untenable—and all too frequent—violations. As a

Different regions pose different challenges for our assessors in the field.

start, we have included a deeper analysis on working hours, the most

We feel it’s important to look at absolute results, as well as regional ones.

frequently found violation, later in this section.

The graph below shows the results of our assessments by region. As

you’ll see, the Asian regions received the most consistently low scores,

How Our Assessments Were Scored

while North and South America and the Indian Sub-Continent received

Under the new assessment process, a factory receives a score that

higher scores. (When you look at the Sub-Saharan Africa results, please

places it in one of three categories:

keep in mind that we have only one factory in the region and it received

an acceptable rating.)

• Partner: No Immediate Actions found and infrastructure for continuous

and sustainable workplace improvements exists.

• Acceptable: No Immediate Actions found, but improvements are needed.

• High Priority: Immediate Action violation found in the factory.

Regional Assessment Scores

100%

3.57%

18.18%

32.14%

80%

22.73%

Partner

18.18%

18.18%

45.45

%

37.50%

40.74%

60%

29.17

100

41.67%

%

10.00%

40%

59.09%

63.64%

64.29%

62.50%

40.91%

66.67%

55.56%

40.00%

29.17%

0%

Greater ChinaEast AsiaSoutheast AsiaIndian North Africa &Sub-SaharanEurope

U.S. &Mexico,South

(86)

(11)

(28)Sub-Continent Middle EastAfrica

(27)CanadaC. America &America

(22)

(16)

(1)

(10)Caribbean

(24)

(9)

Region (number of factories)

Acceptable

High Priority

50.00%

3.70%

13.64%

20%

33.33%

%

the timberland company make it better ™

2005 csr report

21

4.0 Global Human Rights (continued)

[4.4] Analyzing the Results

In order to chart a path towards sustainable improvement in our supply chain, we must step back and take a look

at the assessment results from 2005. The better we understand the assessment results, the better we can implement

programs to improve working conditions. This section dives a little deeper into the data.

Assessing Our Assessors

There are several possible explanations for these results:

Of course, when you look at the data, it’s only fair to look at how it was

1. Many of Timberland’s internal assessors have been evaluating factories

collected, too. As we mentioned, we started our new assessment process

based on our Code of Conduct for many years. Because of their experience

mid-year and we needed outside help. We turned to Cal Safety Compliance

with Timberland’s Code of Conduct, they’re generally better equipped

Corporation (CSCC) to help us. CSCC is a global organization that provides

to find violations than CSCC assessors. In addition, the CSCC assessors

auditing services to all market sectors concerned with corporate social

only had limited exposure to the participatory approach required by the

responsibility and accurate information gathering. By the end of the

new assessment process.

year, they had performed 81 assessments, or about 38% of the 214

Solution: We’re including CSCC trainers in all of our internal assessor

assessments that were performed last year.

trainings. As they get up to speed on our approach and Code, we expect

Working with an organization like CSCC allows us to benchmark our

there will be less disparity in the scoring.

assessors against external auditors. Also, CSCC brings additional industry

insight to factory engagements. Finally, we used them for practical

2. Specific violations are more prevalent in some regions than in others.

and cost reasons—to help us perform assessments in places where

For example, we have found that ethics violations are more common in a

Timberland doesn’t have staff or local knowledge.

specific country than in most other countries—and this is a region visited

mainly by Timberland’s internal assessors. Situations like this can skew

Because we relied so heavily on CSCC, we wanted to see how much

the overall results.

difference there was between our internal and external assessments. As

the charts below show, external assessors seemed to be more likely to

Solution: We’ll continue to monitor our results to make sure the assessment

give a factory a partner score (that is, our highest score) than internal

process is being applied equally—among internal or external assessors

assessors. In addition, internal assessors found more instances (on a

alike. We believe that, when our Code of Conduct is followed consistently,

normalized basis) of all top three Immediate Actions. But as we know

we can focus our efforts on addressing the root causes of human rights

from some factory visits, appearances can sometimes be misleading.

abuses in the workplace.

Internal vs. External: Factory Scoring

PartnerAcceptable

High Risk

3. The assessment results represent a relatively brief period of time—

approximately six months. We will be more confident about conclusions

that come from larger samples when more time has been spent on training

and field application of new assessment techniques.

External 42.0%

13.6%

44.4%

Internal

15.0%

25.6%

59.4%

Solution: Timberland commits to report on this data in our 2006 CSR report.

While we have not yet pinpointed the exact reason for the differences between

internal and external assessor results, we continue to work to create an even

Internal vs. External: Number

of Immediate Actions Found 8

Internal

External

Hours

59

46

Ethics

27

10

Wages

19

18

8 We normalized the results from the two groups so that we could compare results.

playing field for our factories during the assessment process.

the timberland company make it better ™

2005 csr report

22

4.0 Global Human Rights (continued)

Looking for Patterns

actions. (Four different regions, with three different assessors, representing

Another way to analyze the results is to look for patterns where Immediate

Actions were found. Did they relate to what the factory was producing?

Or was it tied more to where the factory was located? Here are two charts

that look at these categories:

both internal and external work made the findings, so we think we can