Carey's Well Kaolin Project

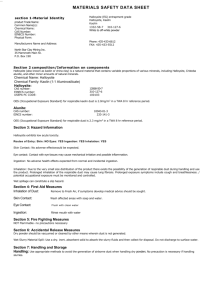

advertisement

MINOTAUR INDUSTRIAL MINERALS Carey’s Well Kaolin Project KEY FEATURES Well Measured Resource of 16.3 million tonnes of “bright white” kaolinised granite with an • Carey’s ISO Brightness R cut-off of 75 for minus 45 micron kaolin product. • • • • • • • 457 Exceptional quality of refined hydrous and calcined product proven from pilot plant testing of bulk samples. Deposit close to surface and open to both the southeast and northeast. Process recovery of ~30% kaolin for fully refined product from ROM kaolinised granite demonstrated in pilot plant. Recovery of ~ 75% kaolin for semi-refined (dry processed) product. A range of halloysite: kaolinite feedstock from zero to pure halloysite available for blending to suit customer’s requirements. Deposit is close to road corridors, light gauge rail, and HV transmission line. Number of port options for shipment of product. No environmental impediments from flora survey. Poochera is a kaolin district of global significance. It contains many kaolin deposits with unique characteristics, including the deposit of “bright white” kaolin at Carey’s Well, some 45km east of Streaky Bay on western Eyre Peninsula in South Australia ( Figure 1). Figure 1: Location of Poochera Kaolin Lease. 1 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N The Carey’s Well deposit lies within Exploration Licence (EL) 4575 in South Australia. EL 4575 is held by Minotaur Exploration Ltd (Minotaur) through its wholly owned subsidiary, Great Southern Kaolin Pty Ltd. There are five kaolin deposits within EL 4575; Carey’s Well, Condooringie Well, Karcultaby South, Tomney and Tootla ( Figure 2). Figure 2: Distribution of Poochera kaolin deposits showing drillholes. On 3rd May 2012 2 a regional Exploration Target 3 was announced for the Poochera Kaolin Project. The Exploration Target is estimated at 570 to 810 million tonnes of white kaolinised granite containing 40% to 60% minus 45 micron kaolin (kaolinite ± halloysite) with high ISO brightness (R457 * 80). For Carey’s Well the Exploration Target is estimated at 50 to 60 million tonnes. The Exploration Target is in addition to the Carey’s Well Measured Resource of 16.3 million tonnes. Carey’s Well Resource Carey’s Well has a Measured Resource 1 of 16.3 million tonnes of “bright white” kaolinised granite with very low iron and titanium content. The 16.3 million tonnes of “bright white” kaolinised granite contains 8.0 million tonnes of -45 micron raw kaolin, subdivided into a number of bodies of differing brightness categories ( Table 1). 1 Minotaur Exploration L td ASX announcement 8 February 2012 Maiden Measured Resource for SA Kaolin Project. 2 Minotaur Exploration L td ASX announcement 3 May 2012 Major Exploration Target Established for Poochera Kaolin Project South Australia. 3 The term “Exploration Target” should not be misconstrued as an estimate of Mineral Resources and Reserves as defined in the JORC Code (2004), and the term has not been used in that context. The term is conceptual in nature and it is uncertain if further exploration will result in the determination of a Mineral Resource. Refer Clause 18 of the JORC Code (2004). 2 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N - 45µm kaolin ISO BRIGHTNESS R 457 JORC Category Kaolinised Granite TONNES 1 (million) AVERAGE - 45µm kaolin content (%) Contained - 45µm kaolin TONNES (million) AVERAGE 2 Fe % AVERAGE 2 Ti % >84 Measured 6.9 59 4.1 0.28 0.21 High >80 <84 Measured 4.9 54 2.6 0.33 0.23 Moderate >75 <80 Measured 4.5 29 1.3 0.42 0.19 >75 Measured 16.3 49 8.0 0.32 0.21 Brightness Category Ultra High Total Bright White 1 Tonnage calculated based on Specific Gravity of dry kaolinised granite of 1.7 (as determined from 7 samples of Carey’s Well kaolinised granite). 2 Average Fe% and Ti% determined from Australian Laboratory Services Pty Ltd (ALS) ICP-MS data. Table 1: Carey’s Well Measured Resource. The resource estimates are based on data obtained from an air core drilling program carried out at Carey’s Well in 2011. The measured resource is open to both the southeast and the northeast; additional close spaced drilling will be required to fully define northern, southern and eastern limits of the resource. Location The Carey’s Well resource is located approximately 21km from the small township of Poochera (population ~190). Poochera is located on the Eyre Highway about 635km by road from Adelaide and 65km east of Streaky Bay. Poochera is some 140km by road from the port of Thevenard ( Figure 1) and 283km from Port Lincoln. A narrow gauge rail line connects Poochera with Thevenard and Port Lincoln. The area is flat to gently undulating and much of the land is cleared for sheep and cattle grazing and cereal crops, with remnant patches of mallee open scrub vegetation ( Figure 3). There are no permanent water courses in the area. Average winter temperature is 18˚C and summer 28˚C. The annual mean rainfall for Streaky Bay is 378mm (330mm for Poochera). Evaporation is ~2300mm per year (measured at Ceduna). The Carey’s Well deposit is located in the District Council of Streaky Bay area. The district covers an area of 6232km 2 and has a population of ~2190, with the Streaky Bay town population around 1150 people. Streaky Bay is the major service centre for the surrounding rural district. The Council and the Streaky Bay community continue to be very supportive of the proposed project. Figure 3: Bulk sample drilling showing farmland and remnant vegetation at Carey’s Well. 3 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N Streaky Bay Pilot Plant Test Results Minotaur has operated a pilot plant at Streaky Bay since November 2010 to produce hydrous kaolin. A rotary kiln was installed in February 2012 to produce calcined kaolin. The pilot plant processed bulk samples from large diameter drill holes in 160kg batches. The results from the pilot plant confirmed the purity and exceptional brightness and whiteness qualities of Carey’s Well kaolin. It has the potential for use in high value kaolin markets that include paints, paper coatings, polymer industries and special ceramics. Test work showed that gangue minerals; quartz, minor mica, secondary iron oxides and accessory anatase, can all be easily removed by conventional wet processing resulting in a pure, white kaolin product with low free silica, mica and feldspar content. The Carey’s Well deposit displays systematic variation in halloysite : kaolinite ratio with some 50% of samples analyzed to date recording low halloysite (<10%) levels. Other parts of the deposit have moderate to high levels of halloysite making them more suited to applications requiring higher green strength such as ceramics. Initial samples prepared for market evaluation are approximately 50:50 halloysite : kaolinite. Carey’s Well kaolin products are clearly physically competitive with global market leading products on key quality and purity measures ( Table 2). Property Hydrous Kaolin Calcined Kaolin Minotaur Carey's Well KaMin™ Minotaur Carey's Well KaMin™ PW90B HYDRAFINE® 90 1 PB80 KaMin™ 2000C 2 Brightness (ISO R457) 90.0 ±0.5 88.5-90.0 (equivalent to 90-91.5 TAPPI GE brightness) 95.5 ±0.5 91.5 (equivalent to 93 TAPPI GE brightness) Yellowness (CIE b*) 1.8 Not quoted 0.81 Not quoted Minus 2µm (wt %) 92 90-96 80 Not quoted Screen Residue (325 mesh = +45µm) <0.01% 0.005% 0.15% (unmilled) 0.01% Fe 2 O 3 3 0.35% Not quoted 0.43% Not quoted TiO 2 3 0.03% Not quoted 0.04% Not quoted Al2 O 3 3 38.10% Not quoted 44.88% Not quoted Pb 4 6ppm Not quoted 7ppm Not quoted Free Silica <1% Not quoted <0.4% <0.1% SG 2.6 Not quoted 2.6 2.63 1 HYDRAFINE® 90 is a premium quality, high brightness, fine particle size clay. Link: www.kaminllc.com 2 KaMinTM 2000C is KaMin’s highest brightness, finest particle size, calcined kaolin clay. Link: www.kaminllc.com 3 XRF determinations by CSIRO 4 ICP-MS analysis by ALS Table 2: Hydrous and Calcined Kaolin Comparison Table. 4 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N Project Development Project development solutions will depend on the extent of processing undertaken at the mine site. Options are to mine only and transport raw material to a processing plant (in Australia or overseas) through to full processing into refined kaolin products at the mine site. Mining The measured resource at Carey’s Well lies within a zone of kaolinised granite that is about 4km long by 2km wide and varies in thickness from a few metres to over 25m. It is overlain by 8-25m of loosely consolidated Quaternary – Tertiary clay, silt and sand. The measured resource comprises exceptionally white, very fine grained crystalline kaolinite with varying amounts of halloysite. Based on the anticipated initial production rate it is envisaged that mining would be undertaken on a campaign basis using excavators and trucks to haul ore and waste to respective stockpiles. Broadly, 2.5 tonnes of raw material is to be excavated in order to produce 1 tonne of refined kaolin product. Processing The capacity of the processing plant will be governed by the ability of the market to absorb an additional high quality kaolin source. The size of the deposit is not a limiting factor on production since the measured resource is of sufficient size to allow mining at any scale to take place over many years. For the option of a processing plant at the mine site, it is envisaged that a small hydrous plant would initially be built and expanded over four years to reach ultimate capacity, with a calcining circuit commencing operation in Year 3. A low cost start-up option consists of production of semi-refined (dry processed) product for further refining at an established kaolin refining plant. There is also an opportunity for sand sales for building purposes as the kaolinised granite consists of about equal amounts of kaolin and medium- to coarse-grained quartz (sand). Infrastructure Water There are no permanent water courses and no identified groundwater supplies outside the proscribed Robinson Basin (which supplements the town water supply of Streaky Bay). Given this situation, a focus on recycling of water and minimising evaporation losses is critical. Two potential sources of water exist. The first is a SA Water pipeline in close vicinity to Carey’s Well with potential to supply water for the initial processing plant. The second potential supply point is adjacent to Paddy’s Vent at Lake Purdilla. This salt water lake is fed via Paddy’s Vent from seawater in the Great Australian Bight. A remotely monitored and operated reverse osmosis (RO) plant could provide desalinated water to the required quality which would be pumped ~55km to the process plant storage tanks at Carey’s Well. If required, a second RO plant could be located at the process plant site to further refine the water to the final water quality &/or to treat process water for recycling. A number of RO plant suppliers have expressed interest in providing a ‘package plant’. 5 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N Project Development Infrastructure continued Electricity SA Power Network’s 66kV overhead transmission line runs from Wudinna through Chandada to Streaky Bay. The overhead line is ~6km at the closest point from the proposed site of the processing plant. Alternatively LPG or diesel fired generation equipment could be used. Gas Liquified Petroleum Gas (LPG) could be used to fire the calcining kiln. LPG would be delivered by truck to a storage bullet on site. Origin Energy has expressed interest in supplying LPG to the project. Product Logistics Packaging and transport options for kaolin product will depend on handling/distribution requirements at the final destination, the particular product, the customer packaging preference and any port/ship restrictions. For fully refined products packaging will most likely consist of 20-25kg bags shrink wrapped on pallets and ‘bulk’ bags. There are three existing ports potentially capable of handling kaolin product – Port Thevenard, Port Lincoln and Port Adelaide. Port Thevenard currently handles grain and industrial minerals in bulk. Channel depth limits ships to ~30,000 DWT. Port Lincoln is 305km and Adelaide 660km from the proposed plant site. Road or road/rail delivery are options for both these port destinations. Another option is a new port facility south of Streaky Bay and just 62km by road from the mine site. A multi-user port could be developed at this site which has deep water in close proximity to the shoreline. Environmental A baseline flora study, which forms part of the environmental investigation necessary to obtain a Mining lease, was undertaken by Rural Solutions SA in 2011. The study found that: • • • • none of the three identified vegetation associations are of conservation significance, all being considered moderately or well conserved in South Australia; four grass species with a state conservation rating of rare were observed in the Spear Grass Grassland (a rating which does NOT trigger referral under the Commonwealth EPBC Act); the condition of the remnant vegetation is moderate, with significant disturbance along the edges from grazing and weed invasion, and from pests; no declared weed species or weeds of national significance were found. 6 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N Figure 4: Streaky Bay pilot plant showing operation of the wet pilot plant (top) and the rotary calcining kiln (bottom). 7 MI N OTAUR I N D USTRI A L MI N ER A LS – C A REY’S WELL K A O LI N Competent Person Statement: Information in this report that relates to Exploration Results, Mineral Resources and Exploration Targets is based on information compiled by Mr Lewis Barnes, a Member of the Australian Institute of Geoscientists, who has sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity which he is undertaking to qualify as a Competent Person as defined in the 2004 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’ (the ‘JORC Code’). Mr Barnes is a contract employee of Minotaur Exploration Ltd and he consents to inclusion in the document of the matters based on his information in the form and context in which they appear. Disclaimer: Tables 1 and 2 include representative data for Minotaur's kaolin products and should not be construed as specifications or absolute maximum/minimum values. The above information is believed to be accurate but Minotaur makes no warranties regarding merchantability or fitness for a particular purpose, or any other express or implied warranty. Contact: Minotaur Exploration Ltd Minotaur Industrial Minerals Pty Ltd ( as Agent for Great S outhern Kaolin Pty L td) Level 1, 8 Beulah Road Norwood South Australia Australia 5067 Tel: +61 8 8132 3400 Fax: +61 8 8132 3499 email: tbelperio@minotaurexploration.com.au 8