Grade 8 - Spanelas

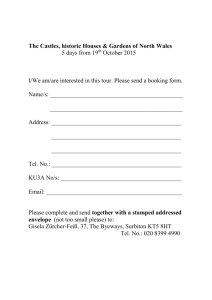

advertisement

Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Warnings Working load limit table for Grade 8 Alloy sling chains Chain Ø 2 leg sling 1 leg sling 0°<ß≤ 30° 0°<α≤ 60° 30°<ß≤ 45° 60°<α≤ 90° Safety Factor 1.73 Safety Factor 1.4 3 or 4 leg sling Endless sling 45°<ß≤ 60° 90°<α≤ 120° 0°<ß≤ 30° 0°<α≤ 60° 30°<ß≤ 45° 60°<α≤ 90° 45°<ß≤ 60° 90°<α≤ 120° Safety Factor 1.0 Safety Factor 2.6 Safety Factor 2.1 Safety Factor 1.5 Safety Factor 1.6 mm t t t t t t t t 6 7 8 10 13 16 20 22 26 32 1.12 1.50 2.00 3.15 5.30 8.00 12.50 15.00 21.20 31.50 1.94 2.60 3.46 5.45 9.20 13.80 21.60 26.00 36.70 54.50 1.60 2.12 2.80 4.25 7.50 11.20 17.00 21.20 30.00 45.00 1.12 1.50 2.00 3.15 5.30 8.00 12.50 15.00 21.20 31.50 2.90 3.90 5.20 8.20 13.80 20.80 32.50 39.00 55.00 82.00 2.36 3.15 4.25 6.70 11.20 17.00 26.50 31.50 45.00 67.00 1.70 2.24 3.00 4.75 8.00 11.80 19.00 22.40 31.50 47.50 1.80 2.50 3.15 5.00 8.50 12.50 20.00 23.60 33.50 50.00 α: Maximum angle at the top between two legs. It is important to refer to norm EN818-4 for more detailed specifications and assembly instructions of grade 8 slings. This European norm harmonises with the requirements of the Machine Directive. When using our components with wire rope or webbing slings, please refer to the corresponding norms. Each component of a chain sling must conform to following standards: EN818-2 for the chain and EN1677 for the other components (master links, hooks, connectors, etc.). Slings must be assembled so that accidental disassembly of any component can not occur. For a chain sling, the mechanically assembled connectors must have a working load limit (WLL) which is not less than the WLL of the chain they are to be connected to. The components of the chain sling must conform to the instructions given in the previous paragraph. The WLL of the multi leg slings must be calculated only for symetric loads, in accordance with the above mentioned table. Each sling must have a WLL for angles between 0° and 45° or complementary WLL for angles from 45° to 60°. Each chain sling must have an identification tag permanently connected to the master link, and must show the following information: ➩ the WLL in tonnes (and the angles for the multi leg slings from 0° to 45° ). i.e. 16t 0° to 45°. ➩ the identification batch of the sling (mentioned in the certificate). ➩ the sling grade, i.e. 8. ➩ the name or the symbol of the sling manufacturer. ➩ the number of legs. The chain diameter can be indicated if it is optionally requested. For multi leg slings, the identification tag can indicate the WLL applicable for an angle of 45° to 60°. Each sling must be delivered with a dated certificate conforming to EN818-4 and indicating the following: ➩ the name of the sling manufacturer or supplier, ➩ the date of establishing the certificate and its authentication, ➩ the number and relevant section of EN818, ➩ the number or the symbol which identifies the sling, ➩ a description of the components of the sling, ➩ the size and length of the chain and grade 8, ➩ the WLL, ➩ the name of the competent person or the company having made the visual inspection (in the case of a mechanically assembled sling not submitted to proof load after assembly). Instructions for use concerning each type and grade of chain, must be delivered with the chain, and must conform to the corresponding clauses of the EN818-6. 8 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 The welded master links are designed for the 1 or 2 leg (code MS) and 3 or 4 leg slings (code MTS). They have a flat in order to make assembly with omega links (code CO) easier. MS ■ Welded master link Norm EN 1677-4 Chain Ø Code 1 leg Dimensions in mm 2 legs ß 45˚ 60˚ 30˚ WLL BF Weight t Kg A B ØC E t MS 13 6/7 - 6 6/7 100 60 13 6.6 1.6 6.4 0.32 MS 16 8 7 7/8 8 120 70 16 6.8 3.1 12.4 0.59 MS 18 10 8 10 10 135 75 18 8.8 4.5 18.0 0.82 MS 20 13 10 - 13 150 90 20 8.8 6.2 24.8 1.14 MS 22 16 - 13 16 150 90 22 11 8.0 32.0 1.41 MS 25 18 13 - 18 170 95 25 13 10.6 42.4 2.03 MS 28 19 - 16 19 200 120 28 13 12.0 48.0 3.02 MS 30 20/22 16 18 20/22 200 120 30 16 15.0 60.0 3.51 MS 36 - 18/19 19/20 - 250 150 36 16 20.0 80.0 6.27 MS 38 26 20 22 26 250 150 38 20 25.0 100.0 7.05 MS 44* - 22 26 - 280 170 44 20.5 30.0 120.0 9.60 MS 45* 32 26 - 32 300 200 45 22 37.0 148.0 12.12 MS 50** - 32 - 300 200 50 - 50.0 200.0 15.21 MS 55** - 32 - - 350 200 55 - 63.0 252.0 20.50 MS 70** - - - - 400 250 70 - 100.0 400.0 39.30 MS 80** - - - - 400 250 80 - 125.0 500.0 52.80 - Example: Marking of the MS13 * unpainted. ** without flat and unpainted. ß: see on page 8. 8 CE 13 CC Z Grade 8 CE marking Diameter C Manufacturer symbol Batch MTS ■ Master link assembly Code MTS 16 Chain Ø ß 30˚ 45˚ 60˚ - Norm EN 1677-4 Dimensions in mm WLL BF Weight A B ØC E a b Dia t t Kg 6 6/7 120 70 16 6.7 100 60 13 2.5 10.0 1.20 MTS 18 6 7 8 135 75 18 7.4 100 60 16 3.5 14.0 1.80 MTS 22 7/8 8 10 150 90 22 8.9 120 70 18 6.5 26.0 2.90 MTS 25 10 10 13 170 95 25 10.6 120 70 20 8.5 34.0 3.90 200 120 28 11.0 120 70 20 10.0 40.0 4.90 200 120 30 13.4 135 75 22 13.0 52.0 6.00 18/19 250 150 36 16.6 135 75 25 17.0 68.0 9.60 20 250 150 38 17.1 170 95 28 20.0 80.0 12.60 16/18 18/19/20 22 280 170 44 18.0 200 120 33 27.0 108.0 19.70 300 200 45 20.0 200 120 36 30.0 120.0 22.50 26 300 200 50 21.0 150 90 38 40.0 160.0 24.50 32 300 200 55 23.0 150 90 38 50.0 200.0 28.00 - 350 200 58 - 150 90 42 60.0 240.0 34.60 - 400 250 70 - 300 150 55 80.0 320.0 74.70 - 400 250 80 - 300 150 58 100.0 400.0 92.40 MTS 28 - MTS 30 - MTS 36 MTS 38 MTS 44* MTS 45* MTS 50* MTS 55* MTS 58** MTS 70** MTS 80** 13 19 - - 13 116 16 - 20/22 22 26 32 26 32 - - * unpainted. ** without flat and unpainted. ß: see on page 8. 9 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 MP ■■ Pear shape link The pear shape link is designed for use in one leg slings. This clevis eliminates the need for a connecting link. It can be used in a sliding sling. Code WLL Chain Ø Dimensions in mm BF Weight t mm A B C t Kg MP 5/6 1.12 5/6 82 33 64 4.5 0.13 MP 7/8 2.00 7/8 90 41 70 8.0 0.27 MP10 3.15 10 110 50 87 12.6 0.61 MP 13 5.30 13 147 66 116 21.2 1.38 MP 16 8.00 16 185 84 148 32.0 2.71 12.50 18/20 242 104 198 50.0 4.20 MP 18/20 C ■■ Lifting Chain Grade 8 Norm EN 818-2 Excel chain features: - Elongation 20% minimum - Available in yellow or black painted finishes. - Delivered in complete drums or in cut lengths on request Code WLL t D Links/m Length per drum BF Weight t Kg/m 500-600 m* 4.5 0.81 A B C6 1.12 6 18 8 54.9 C7 1.50 7 21 9.1 46.9 500 m 6.0 1.10 C8 2.00 8 24 10.8 41.0 350 m 8.0 1.43 C 10 3.15 10 30 13.8 32.7 250 m 12.6 2.24 C 13 5.30 13 39 17.5 25.0 150 m 21.2 3.78 C 16 8.00 16 48 21.5 20.2 100 m 32.0 5.73 C 20 12.50 20 60 27 16.0 60 m 50.0 8.95 C 22 15.00 22 66 29.5 14.5 50 m 60.0 10.80 C 26 21.20 26 78 35 12.2 30-25 m* 84.8 15.10 C 32 31.50 32 96 43.5 25-20 m* 126.0 22.72 * According to deliveries. 10 Dimensions in mm 9.75 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 CO ■■ Omega link Norm EN 1677-1 The omega link is an alternative to the connecting link (code MJ). It is an easy and safe connection between the chain and the components. It is more compact than a connecting link. Code WLL Chain Ø Dimensions in mm BF Weight t mm A B C t Kg CO 5/6 1.12 5/6 25 20 9 4.5 0.07 CO 7/8 2.00 7/8 34 23 16 8.0 0.16 CO 10 3.15 10 41 31 17 12.6 0.28 CO 13 5.30 13 54 40 21 21.2 0.63 CO 16 8.00 16 64 48 26 32.0 1.13 18/20 82 59 35 50.0 2.03 CO 18/20 12.50 MJ ■■ Chain Connector Norm EN 1677-1 These connectors provide fast, easy assembly without the need for special tools or skills. Designed for attaching hooks, master links and other end fittings to Grade 8 alloy steel chains. Code WLL Chain Ø Dimensions in mm BF Weight t mm A B C t Kg MJ 6 1.12 6 45 40 15 4.5 0.14 MJ 7/8 2.00 7/8 54 52 20 8.0 0.15 MJ 10 3.15 10 63 65 25 12.6 0.32 MJ 13 5.30 13 84 82 30 21.2 0.68 MJ 16 8.00 16 104 103 36 32.0 1.26 MJ 18/20 12.50 18/20 127 120 45 50.0 2.02 MJ 22 15.00 22 155 144 51 60.0 3.18 MJ 26 21.20 26 160 172 57 84.8 4.52 MJ 32 31.50 32 174 197 69 126.0 8.20 11 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 Thanks to its unique design, the single hook has incomparable qualities. Its forged latch is fitted with a s/s spring and a high resistance pin, which corresponds to the current norms. CSO ■■ Eye sling hook Norm EN 1677-2 The over dimensioned eye enables easy assembly on wire rope slings (with thimbles). The flat on the eye makes assembly with an omega link (code CO) easier. Code WLL Chain Ø Dimensions in mm BF t mm A B C P CSO 5/6 1.12 5/6 86 24 15 28 CSO 7/8 2.00 7/8 102 26 19 CSO 10 3.15 10 121 35 22 CSO 13 5.30 13 154 41 CSO 16 8.00 16 190 Weight t Kg 4.5 0.25 31 8.0 0.53 30 12.6 0.90 31 39 21.2 1.75 53 39 47 32.0 2.83 5.20 CSO 18/20 12.50 18/20 235 61 42 64 50.0 CSO 22 15.00 22 271 71 50 71 60.0 8.20 CSO 26* 21.20 26 251 48 54 83 84.8 10.30 CSO 32* 31.50 32 292 59 67 118 126.0 16.40 * Different shape from Excel type with non forged latch. CSC ■■ Clevis sling hook Norm EN 1677-2 The clevis type enables a direct connection to the grade 8 chain (code C). 12 Code WLL Chain Ø t mm A B P t Kg CSC 5/6 1.12 5/6 73 16 28 4.5 0.26 CSC 7/8 2.00 95 20 29 8.0 0.49 CSC 10 3.15 10 110 24 31 12.6 0.94 CSC 13 5.30 13 138 32 40 21.2 1.80 CSC 16 8.00 16 162 40 47 32.0 3.00 7/8 Dimensions in mm BF Weight CSC 18/20 12.50 18/20 192 44 64 50.0 4.90 CSC 22 15.00 22 230 49 60 60.0 8.52 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 CSE ■■ Swivel sling hook Norm EN 1677-2 The large eye enables easy assembly on wire rope slings (with thimbles). There is also a flat on the eyes to fit omega links (code CO). All of these hooks have a needle roller thrust bearing in the swivel as a standard. This feature enables smooth, easy rotation under load. Code WLL Chain Ø t mm A D E P t Kg CSE 5/6 1.12 5/6 101 30 33 28 4.5 0.40 CSE 7/8 2.00 7/8 121 32 31 29 8.0 0.77 CSE 10 3.15 10 147 37 40 31 12.6 1.41 CSE 13 5.30 13 185 48 46 40 21.2 2.53 CSE 16 8.00 16 211 58 58 47 32.0 3.90 18/20 265 73 56 64 50.0 6.81 CSE 18/20 12.50 Dimensions in mm CSEC BF Weight ■■ Swivel sling hook with clevis Norm EN 1677/2 This hook combines ease of attachment via a clevis (direct assembly to the chain), with the advantages of a ball bearing swivel system, which rotates under full load. Code of Waterpro WLL Chain Ø Dimensions in mm BF Weight t mm A B C P t Kg CSEC 6 1.12 5/6* 111 15 34 28 4.5 0.44 CSEC 7/8 2.00 7/8 172 20 40 29 8.0 0.85 CSEC 10 3.15 10 210 24 47 31 12.6 1.55 CSEC 13 5.30 13 260 31 60 40 21.2 2.78 CSEC 16 8.00 16 301 34 72 47 32.0 4.30 * For 5 mm chain, special pin with flat. 13 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 XL self-locking hooks are traditional sized hooks (compared to the more compact GK models). The larger release mechanism makes them easier to use with gloves and are therefore recommended for the construction industry. Its rivetted assembly process makes it the safest on the market. XLO ■■ Eye self locking hook Norm EN 1677-3 The large eye enables easy assembly on wire rope slings (with thimbles). The flat on the eyes makes assembly with omega links (code CO) easier. t Chain Ø mm A B C D P t Kg XLO 0 1.12 5/6 113 16 26 24 32 4.5 0.48 XLO 1 2.00 7/8 132 24 31 29 44 8.0 0.90 XLO 2 3.15 10 167 32 37 36 49 12.6 1.69 XLO 3 5.30 13 194 37 47 47 64 21.2 3.28 XLO 4 8.00 16 244 39 57 60 78 32.0 6.04 XLO 5 12.50 18/20 284 51 59 70 92 50.0 9.40 Code WLL Dimensions in mm XLC BF Weight ■■ Clevis self locking hook Norm EN 1677-3 The clevis enables a direct connection to grade 8 chain (code C). Code WLL t 14 Chain Ø mm Dimensions in mm Weight B C D P t Kg 5/6 92 16 26 28 32 4.5 0.47 7/8 111 24 31 32 44 8.0 0.90 141 32 37 41 49 12.6 1.72 13 167 37 47 53 64 21.2 3.21 16 205 39 57 64 78 32.0 5.93 18/20 234 51 59 80 92 50.0 9.10 XLC 0 1.12 XLC 1 2.00 XLC 2 3.15 10 XLC 3 5.30 XLC 4 8.00 XLC 5 12.50 A BF Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 The GK range of hooks are more compact than traditional self locking hooks. For example, the GKO2 is similar in dimensions to the XLO1 making it much lighter and easy to handle, but with the WLL of 7/8 mm chain. Its rivetted assembly process makes it the safest on the market. GKO ■■ Eye self locking hook Norm EN 1677-3 A flat on the eye enables assembly with omega links (code CO). t Chain Ø mm GKO 1 2.00 7/8 GKO 2 3.15 10 134 24 30 30 44 12.6 0.95 GKO 3 5.30 13 171 32 37 40 47 21.2 1.85 GKO 4 8.00 16 207 37 47 49 64 32.0 3.52 GKO 5 12.50 18/20 257 43 66 61 78 50.0 7.33 GKO 6 15.00 22 284 52 61 72 92 60.0 9.63 Code WLL Dimensions in mm BF Weight A B C D P t Kg 115 16 26 25 33 8.0 0.52 GKC ■■ Clevis self locking hook Norm EN 1677-3 The clevis enables a direct connection to grade 8 chains (code C). t Chain Ø mm GKC 1 2.00 7/8 GKC 2 3.15 10 113 24 30 42 44 12.6 0.95 GKC 3 5.30 13 140 32 37 53 47 21.2 1.90 GKC 4 8.00 16 167 37 47 64 64 32.0 3.45 GKC 5 12.50 18/20 216 43 66 79 78 50.0 7.20 GKC 6 15.00 22 234 52 61 98 92 60.0 11.00 Code WLL Dimensions in mm A B C D 96 16 26 32 BF Weight P t Kg 33 8.0 0.53 15 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 XLE ■■ Swivel self locking hook Norm EN 1677-3 The large swivel eye makes assembly to wire rope slings (with thimbles) easier. There is also a flat on the eyes that enables assembly with omega links (code CO). All of these hooks have a needle roller thrust bearing in the swivel as a standard. This feature enables smooth, easy rotation under load. Code WLL Chain Ø Dimensions in mm BF Weight t mm A B C D E P t Kg XLE 0 1.12 5/6 122 16 26 30 34 32 4.5 0.73 XLE 1 2.00 7/8 148 24 31 32 40 44 8.0 1.35 XLE 2 3.15 10 183 32 37 37 49 49 12.6 2.45 XLE 3 5.30 13 214 37 47 48 60 64 21.2 4.38 XLE 4 8.00 16 268 39 57 58 59 78 32.0 7.86 XLE 5 12.50 18/20 350 51 59 73 90 92 50.0 12.50 XLT ■ Shank type self locking hook Norm EN 1677-3 These hooks are supplied with unthreaded shanks to enable machining according to your requirements. Code 16 WLL Chain Ø t mm Dimensions in mm BF Weight A B C D E P t Kg XLT 0 1.12 5/6 95 16 26 26 20 32 4.5 0.52 XLT 1 2.00 7/8 113 24 31 36 24 44 8.0 1.00 XLT 2 3.15 10 129 32 37 53 29 49 12.6 1.84 XLT 3 5.30 13 153 37 47 60 34 64 21.2 3.32 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 GKE ■■ Code WLL t Chain Ø mm A B C D E P 7/8 Dimensions in mm A The large swivel eye makes assembly to wire rope slings (with thimbles) easier. There is also a flat on the eyes that enables assembly with omega links (code CO). All of these hooks have a needle roller thrust bearing in the swivel as a standard. This feature enables smooth, easy rotation under load. E Norm EN 1677-3 P BF Weight t Kg GKE 1 2.00 122 16 26 32 33 33 8.0 0.78 GKE 2 3.15 10 148 24 30 37 41 44 12.6 1.37 GKE 3 5.30 13 182 32 37 48 49 47 21.2 2.50 GKE 4 8.00 16 211 37 47 58 62 64 32.0 4.51 GKE 5* 12.50 18/20 268 43 66 73 62 78 50.0 8.71 GKE 6 15.00 22 350 52 61 82 90 92 60.0 14.50 C Swivel self locking hook D B * No needle roller thrust bearing type. GKT ■ Shank type self locking hook Norm EN 1677-3 These hooks are supplied with unthreaded shanks, to enable machining according to your requirements. t Chain Ø mm GKT 1 2.00 7/8 GKT 2 3.15 10 115 24 30 32 24 44 12.6 1.00 GKT 3 5.30 13 125 32 37 53 28 47 21.2 1.85 GKT 4 8.00 16 152 37 47 60 34 64 32.0 3.42 GKT 5 12.50 18/20 200 42 55 69 40 78 50.0 8.71 Code WLL Dimensions in mm BF Weight A B C D E P t Kg 94 16 26 28 22 33 8.0 0.59 17 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 XLR ■■ Shortening self locking hook Norm EN 1677-3 The combination hook-shortener gives better productivity with a quick shortening action at the bottom of the sling. Code WLL Chain Ø Dimensions in mm BF t mm A B C D E P t Kg XLR 7/8 2.00 7/8 173 24 31 51 153 44 8.0 1.10 XLR 10 3.15 10 218 32 37 64 192 49 12.6 2.29 XLR 13 5.30 13 267 37 47 83 235 64 21.2 4.20 GC-GCV Weight ■■ Shortening clutch Norm EN 1677-1 Shortening clutches are an essential part of chain slings, used to shorten the lengths of the chain legs and prevent instability of the loads. Shortening clutches are also available with a locking system, designed to prevent accidental disengagement of the chain. Code Code Chain Ø Dimensions in mm BF Weight t mm A B t Kg GC 6 GCV 6 1.12 6 54 22 4.5 0.22 GC 7/8 GCV 8* 2.00 7/8 65 30 8.0 0.41 GC 10 GCV 10 3.15 10 77 38 12.6 0.75 GC 13 GCV 13 5.30 13 105 49 21.2 1.63 GC 16 GCV 16 8.00 16 131 60 32.0 3.15 GC 18/20 GCV 20** 12.50 18/20 143 76 50.0 4.06 Without lock With lock * Only for 8 mm chain. ** Only for 20 mm chain. GCV only yellow painted. 18 WLL Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 Used to shorten or hold a length of chain. An extra deep, narrow throat engages chain between the links. Cradle grab hooks provide better chain support than standard grab hooks. Its specific form makes accidental disengagement of the chain difficult. For intensive use however, we recommend using a shortening clutch (code GC or GCV). Caution: for correct-safe use, a shortener must be assembled to the master link via 3 links of chain and be independent of the loaded chain leg. CRO ■■ Eye grab hook Norm EN 1677-1 Code WLL Chain Ø t mm CRO 7/8 2.00 CRO 10 3.15 CRO 13 5.30 CRO 16 Dimensions in mm BF Weight A B C P t Kg 51 20 21 10 8.0 0.28 10 54 29 29 12 12.6 0.55 13 89 39 44 15 21.2 1.60 8.00 16 104 42 45 19 32.0 2.43 CRO 20* 12.50 20 122 37 37 22 50.0 4.00 CRO 22* 15.00 22 121 45 45 25 60.0 4.73 CRO 26* 21.20 26 158 48 48 30 84.8 9.51 CRO 32* 31.50 32 210 57 57 38 126.0 18.20 7/8 * Different shape from Excel type. CRC ■■ Clevis grab hook Norm EN 1677-1 Code WLL Chain Ø Dimensions in mm BF Weight t mm A P t Kg CRC 7/8 2.00 7/8 63 10 8.0 0.30 CRC 10 3.15 10 75 12 12.6 0.57 CRC 13 5.30 13 102 15 21.2 1.54 CRC 16 8.00 16 130 19 32.0 2.61 19 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 Our range of lifting eyes comprises 2 types: The AL and EL models are designed for direct vertical lifting, whereas the OL, PAS, AAN and ADA types are articulated and can be used for either vertical lifting or lateral pulling. AL ■ Eye bolt Our extensive range of alloy steel lifting eyes, incorporates 22 different ISO standard threads. Other special threads such as UNC, Whitworth, etc. are available on request. These lifting eyes can be used only in their axis (angle must be less than 30°), never in oblique. This length makes the use of a grade 8 nut possible. WLL is stamped on the bodies. The minimum factor of safety is 5:1. Code WLL t Ø ISO M x Pitch mm Unmachined Ø A B L C t Kg M6 x 1.00 12 18 20 20 6 1.0 0.05 BF Weight AL 6 0.20 AL 8 0.40 M8 x 1.25 12 16 20 24 7 2.0 0.05 AL 10 0.70 M10 x 1.50 14 19 22 30 8 3.5 0.07 AL 12 1.00 M12 x 1.75 16 23 27 36 10 5.0 0.13 AL 14 1.20 M14 x 2.00 18 28 30 40 14 6.0 0.24 AL 16 1.50 M16 x 2.00 22 30 35 55 14 7.5 0.36 AL 18 2.00 M18 x 2.50 22 30 35 54 14 10.0 0.38 AL 20 2.50 M20 x 2.50 26 34 40 59 16 12.5 0.55 AL 22 3.00 M22 x 2.50 29 38 45 66 19 15.0 0.73 AL 24 4.00 M24 x 3.00 30 40 55 84 20 20.0 1.08 AL 27 5.00 M27 x 3.00 30 42 55 81 20 25.0 1.18 AL 30 6.00 M30 x 3.50 40 49 60 100 24 30.0 1.87 AL 33 7.00 M33 x 3.50 40 49 60 100 24 35.0 1.99 AL 36 8.00 M36 x 4.00 41 45 68 118 25 40.0 2.44 AL 39 9.00 M39 x 4.00 41 45 68 118 25 45.0 2.58 AL 42 10.00 M42 x 4.50 50 56 80 135 31 50.0 3.97 AL 45 15.00 M45 x 4.50 50 56 80 135 31 75.0 4.23 AL 48 18.00 M48 x 5.00 72 63 97 145 42 90.0 8.33 AL 52 20.00 M52 x 5.00 72 63 97 145 42 100.0 8.80 AL 56 25.00 M56 x 5.50 72 63 97 145 42 125.0 9.00 AL 60 30.00 M60 x 5.50 72 63 97 145 42 150.0 9.50 AL 64 36.00 M64 x 6.00 72 63 97 145 42 180.0 9.75 Safety factor 5. Special thread on request. 20 Dimensions in mm Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 EL ■ Eye nut These eye nuts are Grade 8 alloy steel and have a flat section that is designed to accommodate omega links (code CO). They have ISO metric threads as standard, however other thread types can be supplied on request. (UNC, Whitworth) Code Type WLL t Ø ISO M x Pitch mm Dimensions in mm BF Weight Kg A B C D t M6 x 1.00 45 30 11 16 1.0 0.40 M8 x 1.25 45 30 11 16 2.0 0.70 M10 x 1.50 45 30 11 16 3.5 7/8 1.00 M12 x 1.75 48 32 12 17 5.0 7/8 1.20 M14 x 2.00 48 32 12 17 6.0 EL 6 5/6 0.20 EL 8 5/6 EL 10 5/6 EL 12 EL 14 EL 16 10 1.50 M16 x 2.00 60 37 14 18 7.5 EL 18 10 2.00 M18 x 2.50 60 37 14 18 10.0 EL 20 10 2.50 M20 x 2.50 60 37 14 18 12.5 EL 22 13 3.00 M22 x 2.50 75 48 16 23 15.0 EL 24 13 4.00 M24 x 3.00 75 48 16 23 20.0 EL 27 13 5.00 M27 x 3.00 75 48 16 23 25.0 EL 30 16 6.00 M30 x 3.50 88 58 19 28 30.0 EL 33 16 7.00 M33 x 3.50 88 58 19 28 35.0 EL 36 18/20 8.00 M36 x 4.00 105 73 24 42 40.0 EL 39 18/20 9.00 M39 x 4.00 105 73 24 42 45.0 EL 42 18/20 10.00 M42 x 4.50 105 73 24 42 50.0 EL 45 22 15.00 M45 x 4.50 121 82 25 43 75.0 EL 48 22 18.00 M48 x 5.00 121 82 25 43 90.0 0.15 0.25 0.40 0.67 1.20 1.50 3.00 Safety factor 5. ALS ■ Safety lifting eye These eye nuts are Grade 8 alloy steel. They rotate 360°. You have to screw them with a dynamometric key. The cylindric head of the screw prevents any catch by rotation of the eye nut. They have a flat section that is designed to accommodate omega links (code CO). They have ISO metric threads as standard. t Ø ISO M x Pitch mm A B C D L t Kg ALS 8 5/6 0.40 M8 x 1.25 38 30 11 26 17 8 2.0 0.22 ALS 10 5/6 0.70 M10 x 1.50 36 30 11 28 17 8 3.5 0.24 ALS 12 7/8 1.00 M12 x 1.75 37 32 12 31 21 8 5.0 0.30 ALS 14 7/8 1.20 M14 x 2.00 35 32 12 33 26 8 6.0 0.45 Code Type WLL Dimensions in mm Hex key BF Weight ALS 16 10 1.50 M16 x 2.00 43 37 14 40 26 10 7.5 0.53 ALS 18 10 2.00 M18 x 2.50 41 37 14 42 26 10 10.0 0.68 ALS 20 13 2.50 M20 x 2.50 53 48 16 50 30 12 12.5 0.72 ALS 22 13 3.00 M22 x 2.50 51 48 16 52 35 12 15.0 1.20 ALS 24 16 4.00 M24 x 3.00 64 58 19 57 37 14 20.0 1.80 ALS 27 16 5.00 M27 x 3.00 61 58 19 60 47 14 25.0 1.90 Safety factor 5. Delivery with screw on request. 21 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 ADA ■ Hoist ring These hoist rings are Grade 8 alloy steel. They can rotate 360° and pivot 180°. They have ISO metric threads as standard. The cylindric head of the screw prevents jamming during rotation of the shackle. The WLL indicated hereunder are given in the worst conditions of use, i.e. 90°. It is necessary to check the free moving of the pivoting shackle. Code WLL ADA 8 0.40 ADA 10 0.70 M10 x 1.5 ADA 12 ADA 14 1.30 M14 x 2.0 ADA 16 t Ø ISO mm Dimensions in mm TorHex que Key L N.m A B C D E F G I M8 x 1.25 34 35 15 13 34 44 68 13 18 34 37 15 13 34 44 68 16 18 8 1.00 M12 x 1.75 34 39 15 13 34 44 68 18 23 10 34 41 15 13 34 44 68 21 23 1.60 M16 x 2.0 34 43 15 13 34 53 68 24 ADA 18 2.00 M18 x 2.5 34 45 15 13 34 53 68 ADA 20 2.50 M20 x 2.5 34 47 15 13 34 53 ADA 22 3.00 M22 x 2.5 49 69 26 20 ADA 24 4.00 M24 x 3.0 49 71 26 ADA 27 5.00 M27 x 3.0 49 65 ADA 30 6.30 M30 x 3.5 49 ADA 33 7.00 M33 x 3.5 BF Weight t Kg 2.0 0.43 13 3.5 0.43 22 5.0 0.46 12 35 6.5 0.46 23 10 55 8.0 0.47 27 28 10 80 10.0 0.47 68 30 32 10 110 12.5 0.47 53 70 105 33 33 14 150 15.0 1.85 20 53 70 105 36 33 14 190 20.0 1.87 26 20 53 70 105 40 36 14 280 25.0 1.93 65 26 20 53 70 105 40 45 14 380 31.5 2.00 65 83 35 29 72 100 146 55 50 19 520 35.0 4.90 ADA 36 10.00 M36 x 4.0 65 83 35 29 72 100 146 55 54 19 600 50.0 5.20 ADA 39 10.00 M39 x 4.0 65 83 35 29 72 100 146 55 54 19 870 50.0 5.30 ADA 42 12.50 M42 x 4.5 65 83 35 29 72 100 146 55 63 19 1000 62.5 5.50 6 6.5 Safety factor 5. Special thread and length on request. OL* ■ Small lifting eye These small lifting eyes are designed for assembly with all EXCEL clevis components. These combinations result in articulated lifting eyes, capable of lifting angles. Fitting the lifting eyes is made easier with their 6 sided bases. Code WLL OL 8 0.50 M8 OL 10 0.90 M10 OL 12 1.25 M12 OL 14 1.50 M14 OL 16 1.90 M16 OL 18 2.25 M18 OL 20 3.12 M20 OL 22 3.80 M22 OL 24 5.00 M24 OL 27 6.25 M27 OL 30 8.00 M30 OL 33 9.00 M33 OL 36 10.00 M36 OL 39 12.50 M39 OL 42 15.00 M42 t Above model is OL + CO. Ø ISO mm Dimensions in mm A 6 8 10 12 14 19 B 8 10 13 16 20 24 C 13 17 20 29 35 40 D 30 45 55 67 90 105 E 26 29 37 49 54 69 Assembly With XLC0 CO5/6 CSC5/6 XLC1 CO7/8 MP7/8 CSC7/8 XLC2 CO10 MP10 CSC10 XLC3 CO13 MP13 CSC13 XLC4 CO16 MP16 CSC16 XLC5 CO18/20 CSC18/20 MP18/20 BF Weight t Kg 2.0 0.05 3.6 0.06 5.0 0.07 6.0 0.13 7.6 0.15 9.0 0.17 12.5 0.28 15.2 0.31 20.0 0.59 25.0 0.65 32.0 1.07 36.0 1.17 40.0 1.29 50.0 2.00 60.0 2.16 * The OL corresponds to the lifting eye alone. The other clevis accessory must be ordered seperately. Possibility to supply a Nylstop screw. 22 OL+CO OL+CSC OL+XLC OL+MP Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 AAN ■ Hoist ring These metric hoist rings can rotate 360° and pivot 180° without the need to derate the WLL. Easily fitted, by simply screwing the ring onto the part to be lifted. Use instructions are supplied with each delivery. Code WLL t Thread BF Weight A B C D E F G H t Kg AA0.4N 0.40 M8 x 1.25 11 32 18 10 13 68 47 25 2.0 0.17 AA0.5N 0.50 M10 x 1.50 11 30 18 10 18 68 47 25 2.5 0.17 AA1N 1.05 M12 x 1.75 22 60 30 19 19 121 89 51 5.2 1.08 AA1LN 1.05 M12 x 1.75 22 110 30 19 19 171 89 51 5.2 1.08 AA1.9N 1.90 M16 x 2.00 22 56 30 19 29 121 89 51 9.5 1.12 AA1.9LN 1.90 M16 x 2.00 22 106 30 19 29 171 89 51 9.5 1.12 AA2.1N 2.15 M20 x 2.50 22 52 30 19 34 121 89 51 10.7 1.19 AA2.1LN 2.15 M20 x 2.50 22 102 30 19 34 171 89 51 10.7 1.19 AA3N 3.00 M20 x 2.50 36 78 43 25 32 166 131 76 15.0 3.03 AA3LN 3.00 M20 x 2.50 36 118 43 25 32 206 131 76 15.0 3.03 AA4.2N 4.20 M24 x 3.00 36 74 43 25 37 166 131 76 21.0 3.10 AA4.2LN 4.20 M24 x 3.00 36 114 43 25 37 206 131 76 21.0 3.10 AA7N 7.00 M30 x 3.50 45 106 54 32 42 222 165 95 35.0 6.30 AA11N 11.00 M36 x 4.00 57 166 71 44 64 317 217 124 55.0 15.50 AA12.5N 12.50 M42 x 4.50 57 160 71 44 82 317 217 124 62.5 16.00 AA13.5N 13.50 M48 x 5.00 57 154 71 44 82 317 217 124 67.5 16.80 AA22.3N 22.30 M64 x 6.00 76 204 103 57 101 428 296 165 111.5 39.00 AA31.5N 31.50 M72 x 6.00 95 220 133 70 132 495 359 206 157.5 74.00 AA51N 44.60 M90 x 6.00 102 235 153 83 177 561 404 218 255.0 118.00 On request. Safety factor 5. mm Dimensions in mm Nut not supplied 23 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 CPE ■ Fishing single hook This swivel hook is waterproof and supplied with ball bearings. of Waterpro Code WLL Chain Ø t mm CPE 5/6 1.12 CPE 7/8 2.00 CPE 10 3.15 10 CPE 13 5.30 CPE 16 8.00 Dimensions in mm BF Weight A B C D P t Kg 5/6 131 30 11 29 28 4.5 0.50 7/8 159 32 12 31 29 8.0 0.95 184 37 14 36 31 12.6 1.65 13 230 48 16 46 40 21.2 2.90 16 268 57 21 54 47 32.0 4.50 XLP ■ Fishing self locking hook This swivel hook with ball bearings is waterproof and can rotate under load. of Waterpro 24 Code WLL Chain Ø t mm XLP 5/6 1.12 XLP 7/8 2.00 XLP 10 3.15 10 XLP 13 5.30 XLP 16 8.00 Dimensions in mm BF Weight A B C D P t Kg 5/6 121 30 11 29 32 4.5 0.60 7/8 147 32 12 31 44 8.0 1.20 177 37 14 36 49 12.6 2.24 13 211 48 16 46 64 21.2 4.20 16 254 57 21 54 78 32.0 7.80 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 XLB ■ Swivel clevis self locking hook The clevis enables a direct connection to grade 8 chains (code C) and the ball bearing swivel enables easy rotation under load. of Waterpro Code WLL Chain Ø t mm XLB 0 1.12 XLB 1 2.00 XLB 2 3.15 10 XLB 3 5.30 XLB 4 8.00 Dimensions in mm BF Weight A B C D P t Kg 5/6* 130 16 24 34 32 4.5 0.67 7/8 191 23 29 40 44 8.0 1.30 231 30 34 47 49 12.6 2.45 13 285 35 43 60 64 21.2 4.40 16 339 39 57 72 78 32.0 8.00 * For 5 mm chain, special pin with flat. ELD ■ Ball bearing swivel Eye/Eye This swivel has two needle roller thrust bearings in the swivel as a standard. This feature enables smooth, easy rotation under load. Code WLL Dimensions in mm BF Weight t A B ØC t Kg ELD 0 1.12 118 30 11 4.5 0.29 ELD 1 2.00 126 32 12 8.0 0.56 ELD 2 3.15 155 37 14 12.6 0.92 ELD 3 5.30 195 48 16 21.2 1.67 ELD 4 8.00 229 58 21 32.0 2.73 ELD 5 12.50 266 73 24 50.0 4.59 ELD 6 15.00 330 82 25 60.0 7.65 EBC ■ Ball bearing swivel Eye/Clevis This swivel is supplied with ball bearings. Code of Waterpro WLL Chain Ø Dimensions in mm BF Weight t mm A B C t Kg EBC 6 1.12 6 74 30 11 4.5 0.29 EBC 7/8 2.00 7/8 84 32 12 8.0 0.55 EBC 10 3.15 10 104 37 14 12.6 0.90 EBC 13 5.30 13 129 48 16 21.2 2.30 EBC 16 8.00 16 150 57 21 32.0 3.98 25 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 EC ■ Ball bearing swivel Clevis/Clevis Can be easily used on chain slings. Supplied with ball bearings. Code of Waterpro WLL Chain Ø Dimensions in mm BF Weight t mm A B C t Kg EC 6 1.12 6 52 34 7 4.5 0.27 EC 8 2.00 8 81 40 9 8.0 0.62 EC 10 3.15 10 90 49 11 12.6 1.10 EC 13 5.30 13 129 60 14 21.2 2.30 EC 16 8.00 16 141 80 19 32.0 4.30 OLEC ■ Ball bearing swivel small Eye/Clevis Assembly with an omega link (code CO), pear shape link (code MP) or clevis hooks (XLC-GKC-CSC). of Waterpro Code WLL Chain Ø Dimensions in mm BF t mm A B C D t Kg OLEC 6 1.12 6 56 34 8 6 4.5 0.24 OLEC 8 2.00 8 68 40 9 10 8.0 0.50 OLEC 10 3.15 10 79 49 13 12 12.6 0.90 OLEC 13 5.30 13 109 60 16 13 21.2 1.80 OLEC 16 8.00 16 129 80 20 15 32.0 3.60 ALEC Weight ■ Ball bearing swivel Eye/Clevis This swivel is supplied with ball bearings. of Waterpro 26 Code WLL Chain Ø Dimensions in mm t mm A B C ALEC 6 1.12 6 93 30 13 AL14 ALEC 8 2.00 8 120 36 14 ALEC 10 3.15 10 148 45 18 ALEC 13 5.30 13 197 57 ALEC 16 8.00 16 215 68 AL Code BF Weight t Kg 4.5 0.24 AL18 8.0 0.48 AL22 12.6 0.84 25 AL30 21.2 2.84 25 AL36 32.0 3.60 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 GH ■ Excavator hook These hooks are welded directly to the booms of bucket or crane loaders. (Welding instructions are supplied with each hook). Note: Lifting with the teeth of an excavator is forbidden. Latches are fitted as standard, to prevent accidental unhooking. Code WLL Dimensions BF Weight t A B P t Kg GH 0.75 0.75 56 70 22 3.0 0.23 GH 1 1.00 71 78 25 4.0 0.48 GH 2 2.00 91 81 36 8.0 0.72 GH 3 3.00 104 104 39 12.0 1.07 GH 4 4.00 120 129 42 16.0 1.59 GH 5 5.00 136 146 47 20.0 2.32 GH 8 8.00 145 146 52 32.0 3.27 GH 10 10.00 178 193 77 40.0 6.07 GH 15 15.00 185 225 76 60.0 9.00 Respect welding instructions. CFO ■ Eye foundry hook The throats are designed to accommodate standard trunions, whereas the tips enable easy insertion into the holes of castings. These hooks must be used for specific applications as they do not have safety latches. Code WLL Chain Ø t Dimensions in mm BF Weight mm A B C D P t Kg CFO 6 1.12 6 93 17 21 19 48 4.5 0.33 CFO 7/8 2.00 7/8 124 22 28 25 63 8.0 0.76 CFO 10 3.15 10 157 28 36 34 80 12.6 1.47 CFO 13 5.30 13 190 36 46 44 96 21.2 3.00 CFO 16* 8.00 16 205 45 48 32 102 32.0 5.60 CFO 18/20* 12.50 18/20 235 51 54 40 114 50.0 10.40 CFO 22* 15.00 22 265 65 70 47 127 60.0 13.60 CFO 26* 21.20 26 305 72 80 52 136 84.8 20.00 CFO 32* 31.50 32 327 83 93 60 152 126.0 25.00 * Different from Excel design. 27 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 8 CST ■ Web sling hook These hooks are designed to be sewn into webbing slings. Fitted with forged latches for greater safety Code WLL Dimensions in mm BF Weight t A B C D P t Kg CST 75 3.00 132 79 40 75 36 12.0 2.63 XLS ■ Webbing self locking hook This self locking hook is adapted to flat webbings and enables an easy assembly with its removable pin. Code XLS 50 WLL Dimensions in mm BF Weight t A B C D E P t Kg 3.15 160 32 37 52 18 49 12.6 1.70 COS ■ Web sling connector This web link is suitable with an omega link (code CO) for connecting round or flat webbing slings to master links (code MS or MTS). Direct connection to clevis hooks is also possible. Code WLL t A B C D E F G t Kg COS 60 2.00 14 35 15 9 34 58 24 AS 60 8.0 0.17 COS 90 3.15 18 47 20 13 45 75 31 AS 90 12.6 0.37 COS 150 5.30 22 56 25 16 57 94 43 AS 150 21.2 0.70 COS 240 8.00 27 68 31 20 71 117 56 AS 240 32.0 1.30 Sold disassembled. 28 Dimensions in mm BF Spare kit’s code Weight Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Types of connection with a COS With a shortening clutch (GC/GCV). With a clevis sling hook (CSC). With an omega link (CO). With a clevis self locking hook (XLC/GKC). MJS ■ Webbing connecting link This webbing connecting link is suitable for connecting flat webbing slings to master links (code MS or MTS). Code WLL Chain Ø t mm MJS 7/8 2.00 MJS 10 3.15 MJS 13 5.30 Dimensions in mm BF Weight A B C D E t Kg 72 14 41 66 20 8.0 0.31 10 89 15 46 75 25 12.6 0.54 13 113 19 52 87 30 21.2 1.09 7/8 29 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 6 Shackles are available in two types: anchor (bow type) and chain (dee type). Both are available with either screw pins or safety nut & bolt type pins. Shackle bodies and pins are heat treated and tempered for added strength and to maintain the ductility standards required by Federal specifications RR-C-271d. Shackles should never be pulled at angles, as the capacity can be dramatically reduced. Safety type shackles have a threaded bolt a nut and a locking split pin. The split pin eliminates the possibility of the nut working loose. You must not replace the originally bolt & nut with a commercial nut & bolt, as the load lifting capacity may be jeopardised. Never use a safety shackle without the split pin. Safety shackles are mainly used for more permanent applications. MDV Screw pin dee chain shackle Code WLL Dimensions in mm t A F mm B C t Kg MDV 0.33 0.33 27 3/16” 5 6 9.5 2.0 0.01 MDV 0.5 0.50 22 1/4” 6 8 12 3.0 0.05 MDV 0.75 0.75 26 5/16” 8 10 13.5 4.5 0.08 MDV 1 1.00 32 3/8” 10 11 17 6.0 0.13 MDV 1.5 1.50 37 7/16” 11 13 19 9.0 0.20 MDV 2 2.00 41 1/2” 13 16 20 12.0 0.27 MDV 3.25 3.25 51 5/8” 16 19 27 19.0 0.57 MDV 4.75 4.75 60 3/4” 19 22 32 28.5 1.19 MDV 6.5 6.50 71 7/8” 22 25 36 39.0 1.43 MDV 8.5 8.50 81 1” 25 28 43 51.0 2.16 MDV 9.5 9.50 90 1”1/8 28 32 46 57.0 3.06 MDV 12 12.00 100 1”1/4 32 35 51 72.0 4.11 MDV 13.5 13.50 111 1”3/8 35 38 57 81.0 5.28 MDV 17 17.00 122 1”1/2 38 42 60 102.0 7.24 MDV 25 25.00 146 1”3/4 45 50 73 150.0 12.14 F inch BF Weight MLV Screw type anchor shackle Screw pin bow type anchor shackles feature an open throat design that permits free line movement without undue wear. The wide bow allows ample clearance for thimbles and turnbuckles. 30 Code WLL Dimensions in mm t A F mm B C D t Kg MLV 0.33 0.33 22 3/16” 5 6 9.5 15 2.0 0.03 MLV 0.5 0.50 29 1/4” 6 8 12 20 3.0 0.05 MLV 0.75 0.75 31 5/16” 8 10 13.5 21 4.5 0.09 MLV 1 1.00 37 3/8” 10 11 17 26 6.0 0.14 MLV 1.5 1.50 43 7/16” 11 13 19 29 9.0 0.17 MLV 2 2.00 48 1/2” 13 16 20 33 12.0 0.33 MLV 3.25 3.25 60 5/8” 16 19 27 43 19.0 0.62 MLV 4.75 4.75 71 3/4” 19 22 32 50 28.5 1.07 MLV 6.5 6.50 84 7/8” 22 25 36 58 39.0 1.64 MLV 8.5 8.50 95 1” 25 28 43 68 51.0 2.28 MLV 9.5 9.50 108 1”1/8 28 32 46 74 57.0 3.36 MLV 12 12.00 119 1”1/4 32 35 51 82 72.0 4.31 MLV 13.5 13.50 133 1”3/8 35 38 57 92 81.0 6.14 MLV 17 17.00 146 1”1/2 38 42 60 98 102.0 7.81 MLV 25 25.00 177 1”3/4 45 50 73 127 150.0 12.61 F inch BF Weight Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr Grade 6 MDB Safety nut & bolt dee shackle Safety dee type chain shackles are mainly used in one leg slings. Code WLL Dimensions in mm F inch BF Weight t A F mm B C t Kg MDB 1 1.00 32 3/8” 10 12 17 6.0 0.15 MDB 1.5 1.50 37 7/16” 11 14 18 9.0 0.20 MDB 2 2.00 41 1/2” 13 16 20 12.0 0.34 MDB 3.25 3.25 51 5/8” 16 19 27 19.0 0.67 MDB 4.75 4.75 60 3/4” 19 22 32 28.5 1.14 MDB 6.5 6.50 71 7/8” 22 25 36 39.0 1.75 MDB 8.5 8.50 81 1” 25 28 43 51.0 2.52 MDB 9.5 9.50 90 1”1/8 28 32 46 57.0 3.45 MDB 12 12.00 100 1”1/4 32 35 51 72.0 4.91 MDB 13.5 13.50 111 1”3/8 35 38 57 81.0 6.24 MDB 17 17.00 122 1”1/2 38 42 60 102.0 8.40 MDB 25 25.00 146 1”3/4 45 50 73 150.0 14.26 MLB Safety bow anchor shackle Safety bow type anchor shackles feature an open throat design that permits free line movement without undue wear. The wide bow allows ample clearance for thimbles and turnbuckles. Safety bow shackles are mainly used for multi leg slings. Code WLL Dimensions in mm F inch BF Weight t A F mm B C D t Kg MLB 2 2.00 48 1/2” 13 16 20 33 12.0 0.36 MLB 3.25 3.25 60 5/8” 16 19 27 43 19.0 0.76 MLB 4.75 4.75 71 3/4” 19 22 32 50 28.5 1.23 MLB 6.5 6.50 84 7/8” 22 25 36 58 39.5 1.79 MLB 8.5 8.50 95 1” 25 28 43 68 51.0 2.57 MLB 9.5 9.50 108 1”1/8 28 32 46 74 57.0 3.75 MLB 12 12.00 119 1”1/4 32 35 51 82 72.0 5.32 MLB 13.5 13.50 133 1”3/8 35 38 57 92 81.0 7.19 MLB 17 17.00 146 1”1/2 38 42 60 98 102.0 9.44 MLB 25 25.00 177 1”3/4 45 50 73 127 150.0 15.40 31 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr TAG ■ ■ Identification tag Grade 8/10 These aluminium tags have the advantage that they can be fixed on most types of machinery & slings. We can pre-stamp them according to your needs and norms, to identify chain, wire rope & webbing slings. Code Dimensions in mm TAG Weight A B C* Kg 51 76 220 0.07 * Length of wire rope out of tag. VR Replacement kit for self locking hooks VR kits are packed in individual plastic bags that contain one release lever, one spring and one pin. These kits can be used for the XL and GK ranges according to following table. A small plastic tube has to be used as a «leader pin» to help locate the kit, before pressing in the main roll pin. Code For fitting Weight GKO - XLO GKC - XLC GKE - XLE GKT - XLT XLB Kg VR 1 GKO1 - XLO0 GKC1 - XLC0 GKE1 - XLE0 GKT1 - XLT0 XLB0 0.02 VR 2 GKO2 - XLO1 GKC2 - XLC1 GKE2 - XLE1 GKT2 - XLT1 XLB1 0.03 VR 3 GKO3- XLO2 GKC3 - XLC2 GKE3 - XLE2 GKT3 - XLT2 XLB2 0.05 VR 4 GKO4 - XLO3 GKC4 - XLC3 GKE4 - XLE3 GKT4 - XLT3 XLB3 0.10 GKT5 - XLT4 XLB4 0.18 VR 5 GKO5 - GKO6 GKC5 - GKC6 XLO4 - XLO5 XLC4 - XLC5 GKE5 XLE4 - XLE5 RCOS Replacement kit for webbing connector Code 32 For fittings Weight COS Kg RCOS 7/8 COS 60 0.03 RCOS 10 COS 90 0.08 RCOS 13 COS 150 0.15 RCOS 16 COS 240 0.25 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr AC Spare kit for clevis fittings AC kits are packed in individual plastic bags that contain one load pin and 2 retaining pins. These kits can be fitted to all Excel clevis components, excepted for the COS. Code For fittings MP CO Weight GKC XLC/XLB CRC Kg AC 5/6 - CO 5/6 - XL 0 CSC 5/6 GC 6 CRC 5/6 0.01 AC 7/8 MP 7/8 CO 7/8 GKC 1 XL 1 CSC 7/8 GC 7/8 CRC 7/8 0.02 AC 10 MP 10 CO 10 GKC 2 XL 2 CSC 10 GC 10 CRC 10 0.04 AC 13 MP 13 CO 13 GKC 3 XL 3 CSC 13 GC 13 CRC 13 0.08 AC 16 MP 16 CO 16 GKC 4 XL 4 CSC 16 GC 16 CRC 16 0.16 AC 18/20 MP 18/20 CO 18/20 GKC 5 XL 5 CSC 18/20 GC 18/20 GKC 6 AC 22 CSC GC - 0.28 CSC 22 0.40 RMJ Spare kit for MJ/MJS RMJ kits are packed in individual plastic bags that contain one spring and one load pin. Code For fitting Weight MJ 6 0.01 RMJ 7/8 MJ 7/8 - MJS 7/8 0.01 RMJ 10 MJ 10 - MJS 10 0.02 RMJ 13 MJ 13 - MJS 13 0.05 RMJ 16 MJ 16 0.10 MJ 18/20 0.15 RMJ 22 MJ 22 0.38 RMJ 26 MJ 26 0.63 RMJ 32 MJ 32 1.00 RMJ 6 RMJ 18/20 LF ■ ■ Forged latch LF kits are packed in individual plastic bags that contain one forged latch, one spring and one retaining pin. These latches are a standard, and can be fitted to all Excel products utilising safety latches. Code For fittings Weight CSO CSC CSE (C) CST Kg LF 0 CSO 5/6 CSC 5/6 CSE (C) 5/6 GH 0.75 - 0.04 LF 1 CSO 7/8 CSC 7/8 CSE (C) 7/8 GH 1-2-3 CST 75 0.05 LF 2 CSO 10 CSC 10 CSE (C) 10 GH 4 - 0.10 LF 3 CSO 13 CSC 13 CSE (C) 13 GH 5-8 - 0.20 LF 4 CSO 16 CSC 16 CSE (C) 16 - - 0.30 LF 5 CSO 18/20 CSC 18/20 CSE 18/20 GH 10 - 0.40 LF 6 CSO 22 CSC 22 - GH 15 - 0.60 GH 33 Tel. +33(0)4 73 51 89 51 Tel. +33(0)4 73 51 56 13 Tel. +33(0)4 73 51 56 14 Fax. +33(0)4 73 51 56 15 e-mail: contact@excellifting.fr VCR Spare kit for shortener hook XLR Code For fitting Chain Ø Weight Kg VCR 7/8 XLR 7/8 7/8 0.03 VCR 10 XLR 10 10 0.04 VCR 13 XLR 13 13 0.05 REG Load indicator This load indicator made in plastic (recto- Grade 8 and verso Grade 10 ) assists with sling concepts and calculations and can be used on the building sites. Dimensions: 80 mm x 150 mm. 34