MATERIEL SOLUTION ANALYSIS

advertisement

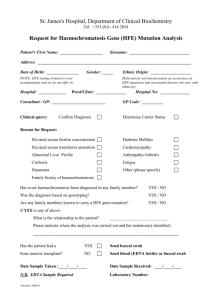

Human Factors Engineering Conduct Functional Analyses Strategic Guidance JCIDS Integrated Acquisition System MATERIEL SOLUTION ANALYSIS Joint Operations Concepts, Concept of Operations, Operations Plans Capabilities Based Assessment Functional Needs Analysis (FNA) Functional Solution Analysis (FSA) Functional Area Analysis (FAA) A MDD Draft ICD AoA Guidance Provide HSI Inputs to Acquisition Documentation Identify HFE high drivers and lessons learned from legacy systems Identify user needs and environmental constraints on human performance Contribute to assessment and development of system concepts/ materiel solutions ME ASR Assist in development of the cost estimate based on anticipated HFE activities/ contributions for proposed materiel solutions. Conduct Mission Task Analysis AoA Assessment Define HFE Concept/ Capability and Human Performance Requirements Perform an analysis of alternatives for Manpower optimization (OPNAV 1500.76A) Derive initial Manpower requirements Develop Mission Scenarios Develop Design Reference Scenarios Conduct Mission Level Functional Analysis Conduct Mission Level Task Analysis Establish manpower thresholds and objectives (DoDI 5000.02) Contribute to Assessment and Development of system concepts/ materiel solutions Assist in development of the cost estimate based on anticipated Manpower activities/contributions for proposed materiel solutions. Establish level and duration criterion for high sustained workload Identify initial manpower requirements that affect end strength (DoDI 5000.02) Identify manpower goals and parameters (DoD1100.4) Personnel Consider personnel alternatives based on FSA (CJCSM 3170.01C) Determine impacts on cost estimates Participate in Mission Task Analysis Conduct initial TDRA Identify expected problems and positive aspects of Manpower Initial Workload Analysis Compute time-on-task for readiness conditions and mission scenarios Incorporate findings from Mission Task Analysis into initial TDRA Assist in development of the cost estimate based on anticipated Personnel activities/contributions for proposed materiel solutions. Define the human performance characteristics of the user population. (DoDI 5000.02) Use findings from the mission task analysis and other personnel assessments to identify KSAs Identify Personnel shortfalls (DoDI 5000.02) Based on mission and system requirements Based on target occupational specialties Based on recruitment and retention trends Identify training deficiencies and root causes Provide recommendations to correct training deficiencies Assess human performance and effectiveness of training transfer Participate in Mission Task Analysis Input mission scenarios to the training assessments JTA NMETL Reviews Contribute to assessment and development of system concepts/ materiel solutions Identify safety issues, lessons learned and drivers from legacy systems Develop Preliminary Hazard List for each system concept/ materiel solution MEs Quantify workload reductions for each specific alternative (AoA) Identify constraints and limitations Perform an analysis of alternatives for Personnel optimization (OPNAVINST 1500.76A) Derive initial Personnel requirements Assist in development of cost estimates based on anticipate safety activities/ contributions for proposed concepts/solutions Participate in Mission Task Analysis Assess personnel readiness, personnel tempo, and funding issues that may impact the ability to fill Personnel requirements Required KSAs Current and needed MOS/NECs Hard to fill occupations (OPNAVINST 1100.16) Conduct assessments to determine KSAs, learning objectives, and training requirements for the proposed materiel solution (OPNAVINST 1500.76) Learning Performance and Solution Analysis Justify the training system Complete preliminary system safety analyses Identify capability gaps in Manpower reduction Produce data to support manpower determination from the allocated functions and tasks Address total force manpower requirements Assist in development of the cost estimate based on anticipated Training activities/contributions for proposed materiel solutions. Perform a training effectiveness evaluation on legacy systems (OPNAVINST1500.76A) Training ICD TES TDS CDD SEP HSIP NTSP TRPPM ITR Determine appropriate personnel approaches Safety & Occupational Health Initial CARD AoA Provide HSI Support to Program Reviews Identify manning needs, manpower lessons learned, and high drivers from legacy systems Manpower AoA Study Plan Training Requirements Analysis Perform an analysis of alternatives for Training optimization (OPNAVINST 1500.76A) Skills and Training Analysis Complete total training requirements Perform a media selection analysis Derive initial SOH requirements New occupational specialties (unique skill sets) Highly qualified personnel Hard to fill occupations Determine how requirements will be met New learning technologies Cost trade-off analyses for training options Assist in development, implementation, and evaluation of the training program planning Collaborate with the NPDC learning center Provide descriptions, methods, and technology requirements for the training concept Consider tasks, conditions, and standards from the Functional Area Analysis (CJCSM 3170.01C) Develop preliminary hazard list Contribute to TDRA, identifying SOH drivers and requirements HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 Human Factors Engineering Integrated Acquisition System TECHNOLOGY DEVELOPMENT A Provide HSI Inputs to Acquisition Documentation Establish a HSI IPT to support the usercentered design process Manpower Personnel Refine user needs, characteristics, and environmental constraints Users SMEs Engineers Other HSI domain experts Contractor/ government HSI representatives Perform analyses to support development of the ME Participate in HSI IPT CDD Acquisition RFP/ TEMP AoA SEP ME NTSP TRPPM PESHE HSIP Strategy SOW SRR Support prototyping and capability based technology downselection Perform technology assessments (with representative users) and evaluate HFE based technology/system requirements, user characteristics, and human performance COTS/GOTS Technologies Demonstrations Human Performance Evaluations and Risk Analysis Cognitive Walkthroughs HMI/HCI Evaluations Refine and finalize TDRA Participate in technology assessments to evaluate adequacy of manpower estimates and operational impacts of proposed manning solutions. Conduct trade studies to assess tradeoffs between technologies. Refine/update workload for specific technology operations and support activities Identify HFE technical risks and mitigation strategies. Develop a manpower reduction strategy Provide technology downselection recommendations Assess manpower tradeoffs between technologies Operations Maintenance Staff/Support Participate in HSI IPT Training CARD Provide HSI Support to Program Reviews Participate in HSI IPT Safety & Occupational Health B OPTEVFOR EOA Participate in technology assessments to evaluate personnel requirements and the adequacy of personnelrelated content in the NTSP. Participate in technology assessments to evaluate adequacy of the NTSP and operational impacts of proposed training solutions. Type of training curricula Ensure sufficient funding to support training needs Training devices/equipment Assist in final technology selections HMI HCI Workspaces Human Performance & Safety Communication KPP and KSA in CDD Addreses HFE requirements Satisfies concept and mission objectives Addresses user needs and goals Incorporates HFE design standards Refine/update Manpower requirements Assist in final technology selections KPP and KSA in CDD Addresses Manpower requirements Participate in the T&E IPT Perform analyses to ensure appropriate HFE considerations are included in system technology development Assist in development of the system functional baseline Task Analyses Operational Workflow Analysis Functional Allocation Analyses Participate in the T&E IPT Provide recommendations based on Manpower analyses Participate in the T&E IPT Provide recommendations based on Personnel analyses Participate in the T&E IPT Provide recommendations based on Training analyses Develop the HFE T&E/ V&V program plans PDR Review and provide inputs to preliminary designs/allocated baseline Methods Metrics Analyses Tools Provide Manpower inputs to functional allocation Ensure MEs can be met appropriately Assess personnel tradeoffs between technologies Identify and document formal training courses and training resource requirements Refine/update HFE requirements SFR Assess training trade-offs between technologies Refine/update Personnel requirements Assist in final technology selections KPP and KSA in CDD Addresses Personnel requirements Ensure Personnel needs can be met appropriately Refine/update Training requirements Assist in final technology selections KPP and KSA in CDD Addresses Training requirements Ensure Training needs can be met appropriately Participate in the T&E IPT Determine scope of SOH testing/evaluation Support development of T&E plans/supporting materials Assess gaps between personnel capabilities and system needs Provide Personnel inputs to functional allocation Perform system safety analyses Complete initial PESHE Derive and finalize safety requirements and Criteria for Analysis, develop preliminary hazard list Initiate preliminary hazard analysis and threat hazard assessment HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 Safety & Occupational Health Training Personnel Manpower Human Factors Engineering Integrated Acquisition System ENGINEERING & MANUFACTURING DEVELOPMENT: Integrated System Design B OPTEVFOR OA Provide HSI Inputs to Acquisition Documentation PDR CARD Provide HSI Support to Program Reviews Develop a usercentered test plan to evaluate initial detailed system designs Include operational use cases and operationally relevant tasks Post CDRA SEP TEMP NTSP HSIP MER PESHE CDR Finalize HFE requirements Determine assessment methods Identify metrics Support development of detailed design specifications Iteratively develop and review prototypes, mockups, screenshots, drawings and simulations HMI HCI Workstations/workspaces Facilities Heuristic evaluations Cognitive walkthroughs Usability testing Workspace evaluations Incorporate the HSI IPT Evaluate initial system designs and specifications having an impact on human performance and safety Verify detailed system designs Provide recommendations to resolve detailed system design deficiencies impacting users and system performance Validation approaches for HFE requirements Human performance metrics Identify scope of test demonstrations and develop procedures, materials, and instruments Identify high risk areas for testing Operationally relevant use cases and tasks Satisfy user needs and goals Support concept/mission goals/objectives Address HFE requirements Incorporate HFE design standards Mitigate known human performance risks Assess detailed system designs to ensure they meet Manpower requirements Participate in detailed system design demonstrations Identify potential personnel gaps based on detailed system designs Participate in detailed system design demonstrations Develop a user-centered test plan to evaluate the system during component and integration testing Provide recommendations for redesign/modification and/or develop mitigation strategies for Manpower estimates as required Provide recommendations for redesign/modification and/or develop mitigation strategies for Personnel qualifications as required Update personnel requirements Identify potential gaps in training based on detailed system designs Update media analysis of training tasks Update KSAs Update training requirements Review selections to determine if still appropriate based on current system design Assess detailed system design to ensure they meet SOH requirements Participate in detailed system design demonstrations Design training solutions Develop and prototype training solutions Develop an assessment plan for training solutions ILT ICW Embedded training (ACAT 1) Performance aids Develop JQR/PQS Participate in detailed system design demonstrations Provide recommendations for redesign/modification and/or develop mitigation strategies for SOH as required Refine/update system safety analyses Finalize hazard analyses Provide inputs to NEPA Compliance Schedule as required HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 Post CDRA OPTEVFOR DT Assist DT (Component) Provide HSI Inputs to Acquisition Documentation Acquisition RFP/SOW TEMP HSIP ME NTSP TRPPM Strategy CARD Provide HSI Support to Program Reviews TRR Provide inputs to developmental test plans to ensure they include appropriate human performance assessments for integrated system testing Evaluate system components having an impact on human performance and safety Identify human performance risks Provide HFE mitigation strategies AoA CPD SVR/PRR Collect human performance data during system test events HFE Requirements Compliance Assessments HFE System Performance Assessments Verify system compliance with HFE requirements Perform analysis and reporting on Manpower related test events, data collected, and findings Participate in system test events Support the review and development of job aids Design Recommendations Risk Analysis Impact Assessment Human Performance Mitigation Strategies Document HFE-related system performance issues (i.e., PTRs) User interaction with HW/SW interfaces, COTS integration, and operational workflows Report significance of findings based on user impact and system performance risk Analyze results from HFE testing Usability Testing Multiple user roles HFE high risk areas HFE requirements Quick Reference Guides User Manuals Training Course Material Updates Participate in ECP development Generate HFE related ECPs Review ECPs for human performance impacts Provide recommendations based on findings to support needed system manning Revise the ME to reflect system design Perform analysis and reporting on Personnel related test events, data collected, and findings Personnel Training Safety & Occupational Health C DT (Integrated) Manpower Human Factors Engineering Integrated Acquisition System ENGINEERING & MANUFACTURING DEVELOPMENT: System Capability and Manufacturing Process Demonstration Assess training solutions during initial system component demonstrations Refine training solutions based on findings from initial system component demonstrations Provide inputs to developmental test plans to ensure they include appropriate assessments of training solutions for integrated system testing Arrange for and teach a pilot course to train users Modify NKO and ILE Trainer installations Equipment, facility, and TTE plan Assess results from training pilot course Revise training solutions based on findings from integrated system demonstrations and pilot course Deliver final training solution for use in production and deployment phase Compare to learning objectives Participate in system test events Perform analyses and reporting on SOH related test events, data collected, and findings Revise the System Safety Analyses and Hazard analyses to reflect demonstrated system design Provide recommendations based on findings to support system design changes HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 PRODUCTION & DEPLOYMENT Human Factors Engineering Integrated Acquisition System LRIP FRP&D FRP DR C OPTEVFOR IOT&E (OPEVAL) Provide HSI Inputs to Acquisition Documentation OTRR Review/verify and develop HFE Installation Criteria Perform analysis of LRIP deficiencies Consider human performance, workload, and safety Identify human performance risks Identify gaps or potential installation problems Provide HFE mitigation strategies Provide recommendations for improvement Manpower Verify ME NAVMAC Survey Verify system installations meet Manpower requirements Develop a user-centered assessment plan to support IOT&E System Capabilities Performance Quality Compatibility Interoperability Participate in IOT&E Report significance of findings based on user impact and system performance risk Review OPTEVFOR reports and discuss HSI tradeoffs Validate HFE-based system changes Verify and validate final HFE-related production items Collect and analyze user feedback and service use data from the postdeployed system Analyze known system performance issues/program trouble reports Collect user feedback and human performance data Identify HFE lessons learned and life cycle improvements Develop a usercentered assessment plan to support FOT&E Provide ECP recommendations System Capabilities Performance Quality Compatibility Interoperability Provide mitigation strategies for outstanding HFE issues and risks Participate in FOT&E Analyze results from FOT&E to assess and redesign aspects of the system Develop an operations and support plan to monitor and assess the system and collect feedback from users Allocation of Functions Human-Machine Interfaces Human-Computer Interfaces Workstations/Workspaces Job Aids Procedures Review OPTEVFOR reports and discuss HSI tradeoffs Assess effects of equipment installations on workload Personnel Review OPTEVFOR reports and discuss HSI tradeoffs Review OPTEVFOR reports and discuss HSI tradeoffs Training Train system users (as needed) Safety & Occupational Health OPTEVFOR FOT&E Acquisition AoA TEMP RFP HSIP ME Strategy MAIS only CARD Provide HSI Support to Program Reviews OPTEVFOR VCD Verify system installations meet SOH requirements Review OPTEVFOR reports and discuss HSI tradeoffs Finalize the SOH footprint and attributes HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 IOC FOC OPTEVFOR FOT&E (Validation) Provide HSI Inputs to Acquisition Documentation Provide HSI Support to Program Reviews ISR Identify/document HFE lessons learned and lifecycle improvements from fielded system and feed forward Human Factors Engineering Integrated Acquisition System OPERATIONS & SUPPORT Collect feedback from operational fleet users across multiple platforms and commands Perform a system assessment to identify capability gaps Document system areas that have been significantly impacted by HFE Analyze and prototype post-product improvements for the next incremental build Provide HFE based recommendations for system modernization and increment upgrades Affordability Performance Risk Mitigation Safety & Health Quality of Life Human-Machine Interfaces Human-Computer Interfaces Workstations/workspaces Facilities Identify advanced technologies that will have a significant positive impact on human performance Identify and assess design/ engineering tradeoffs for modernization Manpower Identify/document manpower lessons learned and feed forward Collect feedback from users Identify and document areas where Manpower has had a significant impact Provide modernization recommendations that would optimize manpower Personnel Identify/document personnel lessons learned and feed forward Safety & Occupational Health Training Conduct a training effectiveness evaluation Redesign training procedures and decision aids Identify/document training lessons learned and feed forward Identify training deficiencies and root causes Provide recommendations to correct training deficiencies Incorporate representative mission scenarios Assess human performance and effectiveness of training transfer Identify/document safety and occupational health lessons learned and feed forward Complete a System (fielded) Safety Analysis; include sustaining hazard analysis for the fielded system and input for next increment HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 DOCUMENTATION STANDARDS MIL-STD-1472F MIL-HDBK-46855A MIL-HDBK-759C SECNAV M-5000.2 [Encl 7 Pg. 25 Section 7.2.3] NAVPERS 18068F Vol II DoDI 5000.02 [Pg. 60] DoDD 1100.4 SECNAVINST 5000.2D [Encl 7 Pg. 12-13 Section 7.2.2] OPNAVINST 1000.16K OPNAVINST 1500.76A OPNAVINST 5310.23 (draft) CJCSI 3500.1D CJCSM 3170.1C DoDD 1104.4 DoDD 4630.5 DoDD 5000.1 DoDI 1100.22 DoDI 4630.8 DoDI 8510.1 DoDM 5000.4M Interim Policy and Procedures for Strategic Manpower Planning and Development of Manpower Estimates DoDI 5000.02 [Pg. 60] DoDD 1100.4 SECNAVINST 5000.2D [Encl 7 Pg. 12-13 Section 7.2.2] OPNAVINST 1000.16K OPNAVINST 1500.76A OPNAVINST 5310.23 (draft) CJCSI 3500.1D CJCSM 3170.1C DoDD 4630.5 DoDD 5000.1 DoDI 1100.22 DoDI 4630.8 DoDI 8510.1 DoDM 5000.4M OPNAV P-751-1-9-97 OPNAV P-751-2-9-97 OPNAV P-751-3-9-97 DoDI 5000.02 [pg. 61] CJCSI 3500.01E DoDD 1322.18 DoDI 1322.20 DoDI 1322.26 SECNAVINST 5000.2D [Encl 7 Pg. 12-13 Section 7.2.2] OPNAVINST 11102.2 OPNAVINST 1500.76A OPNAVINST 5310.23 (draft) CJCSI 3500.1D CJCSM 3170.1C DoDD 4151.18 DoDD 4630.5 DoDD 5000.1 DoDI 4151.22 DoDI 4630.8 Survivability DoDI 5000.02 Pg.61 Habitability ESOH Training Manpower DoDI 5000.02 [Pg. 29 Section 8.c.(1)(c)2.a. & Pg.60 Section 2.a.] SECNAVINST 5000.2D [Encl 7 Pg. 12-13 Section 7.2.3; Pg. 26; Pg. 9] OPNAVINST 5310.23 (draft) [Pg. 2-7 Section 4.f.(5)(a); Pg. 2-9 Section 4.g.(3); Pg. 2-3: Section 2.c.(2)(a); Pg. 3; Pg. 5 (HFE risk)] DoDD 4715.1E DoDD 4151.18 [Pg. 3 Section 3.1.9] DoDI 5000.02 Pg. 61 DoDI 4715.15 OPNAVINST 5310.23 (draft) DoDI 5000.02 Pg.60 GUIDANCE SECNAV M-5000.2 JCIDS Manual [G-A-7] SPAWARINST 5400.3 (Policy within SPAWAR Enterprise) NAVSEAINST 3900.8A (Policy within NAVSEA Enterprise) DAU Guidebook [Ch 6] DoDD 5000.01 DoDI 5000.02 SECNAVINST 5000.2D OPNAVINST 5310.23 (draft) Personnel Human Factors Human Systems Engineering Integration POLICY OPNAV P-751-1-9-97 OPNAV P-751-2-9-97 OPNAV P-751-3-9-97 DoDI 8510.1 DoDM 5000.4M NAVSO P-1000 OPNAVINST 3500.34F NNWCINST 12271.1 SPAWARINST 4160.3B OPNAV P-751-1-9-97 OPNAV P-751-2-9-97 OPNAV P-751-3-9-97 DI-MGMT-81650 DI-SESS-81519B DI-SESS-81520B DI-SESS-81523B DI-SESS-81524B DI-SESS-81526B MIL-STD-882D MIL-STD-1474D MPT&ECIOSWIT-ILE-GUID-1B MPT&ECIOSWIT-ILE-GUID-2B MPT&ECIOSWIT-ILE-GUID-3B MPT&ECIOSWIT-ILE-GUID-4A MPT&ECIOSWIT-ILE-GUID-5A MPT&ECIOSWIT-ILE-HDBK-1B MPT&ECIOSWIT-ILE-INTR-1B MPT&ECIOSWIT-ILE-SPEC-1B MPT&ECIOSWIT-ILE-SPEC-2B MPT&ECIOSWIT-ILE-SPEC-3B MPT&ECIOSWIT-ILE-SPEC-4D MPT&ECIOSWIT-ILE-STD-1B DI-ILSS-81070 DI-SESS-81517B DI-SESS-81518B DI-SESS-81521B DI-SESS-81522B DI-SESS-81525B DI-SESS-81527B MIL-HDBK-29612-1A MIL-HDBK-29612-2A MIL-HDBK-29612-3A MIL-HDBK-29612-4A MIL-HDBK-29612-5 MIL-PRF-29612 SECNAV M-5000.2 [Encl 7 Pg. 27 Section 7.3] JCIDS Manual [G-A-7] JCIDS Manual HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 POLICY DOCUMENTS Materiel Solution Analysis – Human Factors Engineering Document/Product Reference Diagram (SAMPLE) OPNAVINST 5310.23 (draft) PRODUCTS MSA – HFE ACTIVITIES STANDARD/GUIDANCE DOCUMENTS DoDI 5000.02 SECNAVINST 5000.2D MIL-HDBK46855A Identify HFE high drivers and lessons learned from legacy systems Conduct Functional Analyses (in support of JCIDS as needed) Identify user needs and environmental constraints on human performance Contribute to assessment and development of system concepts/ materiel solutions Assist in development of the cost estimate based on anticipated HFE activities/contributions for proposed materiel solutions. Define HFE Concept/ Capability and Human Performance Requirements Alternative System Capabilities Assessment Conduct Mission Task Analysis Develop Mission Scenarios Develop Design Reference Scenarios Conduct Mission Level Functional Analysis Conduct Mission Level Task Analysis Functional area HSI considerations in support of HFE optimal recommendations for nonmateriel, materiel and nonmateriel, and materiel solutions Science, Technology, Research, and Development HSI Considerations and Implications in support of Materiel Solutions HFE High Drivers and Lessons Learned in support of the HSIP Requirements Traceability Matrix Concept HFE Drivers Anticipated HFE Activities/Contributions for materiel Solution in support of CARD Constraints, Trade Space, and Risk Assessment in support of Analysis of Alternatives (AOA) Mission/Task Analysis Report CDRL DI-SESS81635A Representative Mission Profiles in support of the CONOPS Preliminary System Specification Provide inputs to AoA Representative Mission Profiles in support of the JTA HFE Considerations derived from the Alternative System Capabilities Assessment Statement of Human Performance Objectives in support of the ICD HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4 ACRONYM LIST ACAT AoA ASR CARD CDD CDR CDRA COTS CPD DT ECP EOA FAA FOC FOT&E FRP&D FRP DR FNA FSA GOTS HCI HFE HMI HSI HSIP ICD ICW ILE ILT IOC IOT&E IPT ISD ISP ISR ITR JCIDS JQR JTA KPP KSA LRIP MAIS MDD ME MER MOS NAVMAC NEC NEPA NKO NMETL NPDC NTSP OA OPEVAL OPTEVFOR OTRR PDR PESHE PQS PRR RFP SCMPD SEP SFR SME SOH SOW SRR SVR TDRA TDS T&E TEMP TES TRR TTE VCD V&V Acquisition Category Analysis of Alternatives Alternative Systems Review Cost Analysis Requirements Description Capability Development Document Critical Design Review Critical Design Review Assessment Commercial Off The Shelf Capability Production Document Developmental Testing Engineering Change Proposal Early Operational Assessment Functional Area Analysis Full Operational Capability Follow-on Operational Test and Evaluation Full-Rate Production and Deployment Full-Rate Production Decision Review Functional Needs Analysis Functional Solution Analysis Government Off The Shelf Human-Computer Interface Human Factors Engineering Human-Machine Interface Human Systems Integration Human Systems Integration Plan Initial Capabilities Document Interactive Course Ware Interactive Learning Environment Instructor Led Training Initial Operational Capability Initial Operational Test and Evaluation Integrated Product Team Integrated System Design Information Support Plan In-Service Review Initial Technical Review Joint Capabilities Integration and Development System Job Qualifications Requirements Job Task Analysis Key Performance Parameter Knowledge Skills and Abilities Low-Rate Initial Production Major Automated Information System Materiel Development Decision Manpower Estimate Manpower Estimate Report Military Occupational Specialty Navy Manpower Analysis Center Navy Enlisted Classification National Environmental Policy Act Navy Knowledge On-line Navy Mission Essential Task List Naval Personnel Development Command Navy Training Systems Plan Operational Assessment Operational Evaluation Operational Test and Evaluation Force Operational Test Readiness Review Preliminary Design Review Programmatic Environmental Safety and Health Evaluation Personnel Qualification Standards Production Readiness Review Request For Proposal System Capability and Manufacturing Process Demonstration System Engineering Plan System Functional Review Subject Matter Expert Safety and Occupational Health Statement Of Work System Requirements Review System Verification Review Top Down Requirements Analysis Technology Development Strategy Test and Evaluation Test and Evaluation Master Plan Test and Evaluation Strategy Technology Readiness Review Technical Training Environment Verification of Correction of Deficiencies Verification and Validation HSI Integrated Framework Version 1.3 DRAFT (9/30/09) - Contact: Pacific Science and Engineering Group/SPAWAR 5.1.4