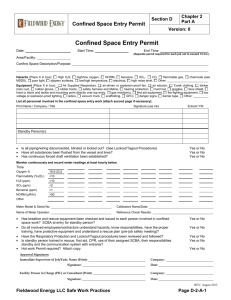

Subcivision J, General Environmental Controls

advertisement